Mounting the Z-axis platform switch on the X gantry to sense the actual platform position worked perfectly with the original MakerGear V3 hot end, at least after I relocated the switch a bit further from the balance point. It does require moving the nozzle off the platform before homing the Z axis, for the obvious reason:

The smaller MakerGear V4 hot end uses a completely different mount that puts the nozzle higher than the switch lever:

The clearances were close enough to rule out plastic, so I bandsawed some 33 mil (1/32 inch) brass shim stock and drilled holes in the appropriate spots:

After discovering the blindingly obvious fact that you can’t heat brass sheets clamped to a steel vise enough to melt silver solder, I padded the brass with cardboard insulation and tried again:

The cardboard charred and burned and stank up the shop, but held everything in alignment long enough:

A bit of file & sandpaper work shined it up just fine, then I slotted the lower mounting holes enough to accommodate 2-56 nuts between the gantry and the bracket:

Yeah, I could tap 2-56 holes into the brass sheet, but let’s be reasonable: two turns does not a secure fitting make.

Here’s why a plastic bracket wouldn’t work:

That’s with the V4 hot end aligned per instructions, although I may rotate it 1/4 turn clockwise at some point. Note that there’s no filament going in the top, as I did all this before firing that devil up for the first time.

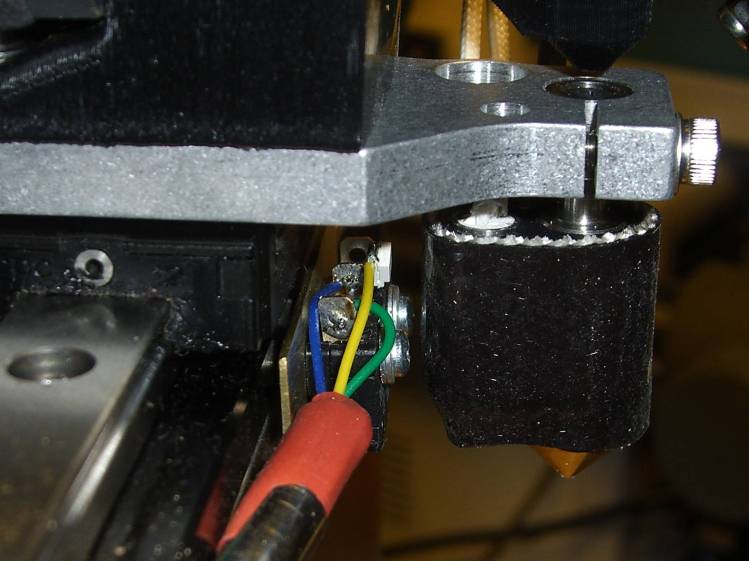

The switch lever had enough free travel that the platform would hit the bottom of the X axis linear slide screws before activating the switch, but lowering the switch would put the lever below the nozzle. I added a 15 mil brass shim to the lever and it’s all good:

Admittedly, the lever rests a bit less than 1.000 mm above the nozzle, but we’ll see how much trouble that causes.

The switch trips 2.0 mm above the nozzle, so the new startup G-Code looks like this:

;-- Slic3r Start G-Code for M2 starts -- ; Ed Nisley KE4NZU - 2015-03-01 ; Makergear V4 hot end ; Z-min switch at platform, must move nozzle to X=135 to clear M140 S[first_layer_bed_temperature] ; start bed heating G90 ; absolute coordinates G21 ; millimeters M83 ; relative extrusion distance G92 Z0 ; set Z to zero, wherever it might be now G1 Z10 F1000 ; move platform downward to clear nozzle; may crash at bottom G28 Y0 ; home Y to clear plate, origin in middle G92 Y-127 G28 X0 ; home X, origin in middle G92 X-100 G1 X130 Y0 F30000 ; move off platform to right side, center Y G28 Z0 ; home Z to platform switch, with measured offset G92 Z-2.00 G0 Z2.0 ; get air under switch G0 Y-127 F10000 ; set up for priming, zig around corner G0 X0 ; center X G0 Y-125.0 ; just over platform edge G0 Z0 F500 ; exactly at platform M109 S[first_layer_temperature] ; set extruder temperature and wait M190 S[first_layer_bed_temperature] ; wait for bed to finish heating G1 E20 F300 ; prime to get pressure, generate blob on edge G0 Y-123 ; shear off blob G1 X15 F20000 ; jerk away from blob, move over surface G4 P500 ; pause to attach G1 X45 F500 ; slowly smear snot to clear nozzle G1 Z1.0 F2000 ; clear bed for travel ;-- Slic3r Start G-Code ends --

The prime-and-wipe section accommodates gooey PETG, although that will require more attention.

One thought on “MakerGear M2: V4 Nozzle vs. Re-Relocated Z-axis Switch”

Comments are closed.