-

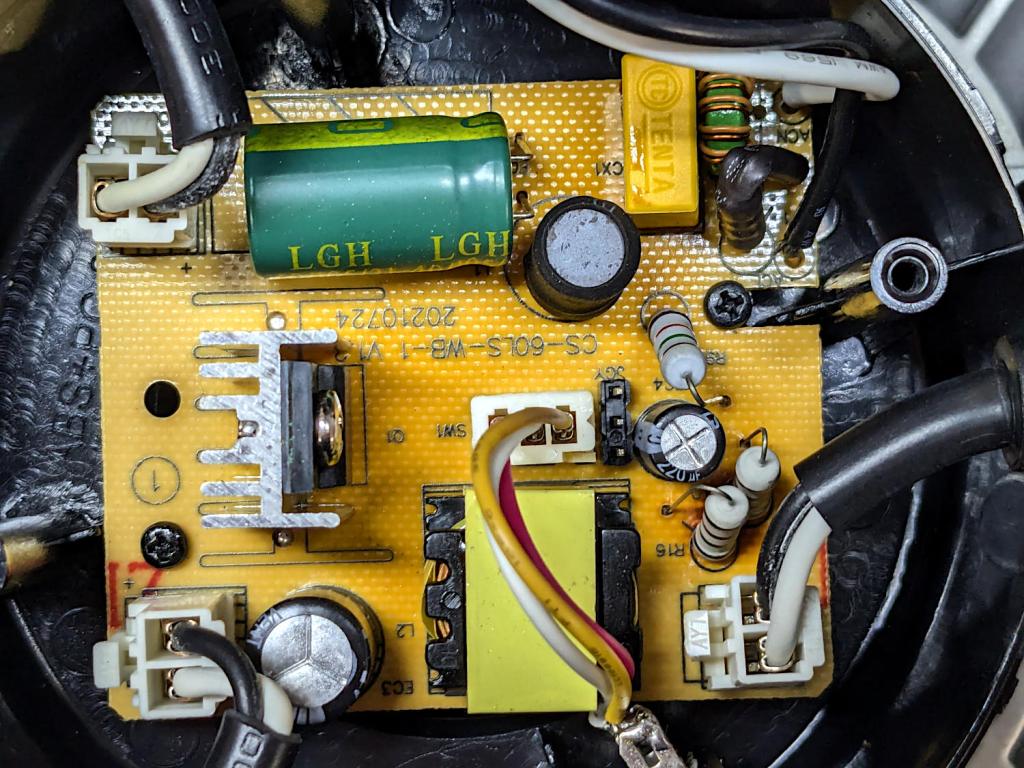

Over the course of a few days that panel went dark

-

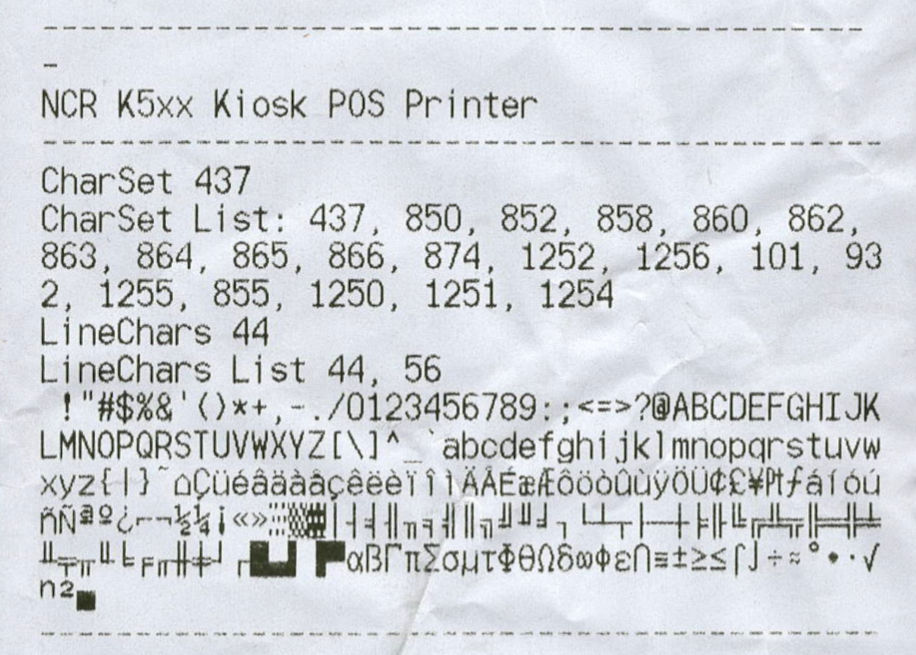

It wasn’t just beginner’s luck, because I did it again

-

A present emerged before our receipt

-

Apparently the other colors don’t generate much smoke

-

Subscribe

Subscribed

Already have a WordPress.com account? Log in now.