Now, having seen what we’ve been living through, you might ask yourself

Wouldn’t It Be Nice If there was some way to be absolutely sure that mumble does not happen to me?

There isn’t, but you can stack the odds in your favor by disinsecting everything that enters your house. In particular, when you return from a trip, you must treat your luggage with the same casual regard as you apply to any lump of highly radioactive waste.

Because all bed bug stages die when exposed to temperatures over 45°C (113°F, which I round to 120°F), the simplest way to ensure that you’re not bringing any passengers home is to heat your luggage / packages / clothing / whatever to an internal temperature around 120°F, then let it soak for maybe an hour to ensure all the occupants get the message.

What you need is a box that gets hot on the inside, but not hot enough to set your luggage on fire. As with all things sold for bed bug problems, the commercial solution seems grossly overpriced for what looks like an uninsulated ripstop nylon bag containing a rack, a heater, and a fan.

It should come as no surprise that I built something that’s bigger, uglier, and harder to use… but it produces data and you can do science. And, with liberal use of my parts heap, the overall price is maybe 10 dB down from the commercial version…

I figured that this widget is going to be a major part of our lives from now on, so a foldable / storable heater wasn’t particularly useful. In point of fact, we’ve been using it heavily and I don’t expect that to stop any time soon.

It’s a rigid box made of Dow Tuff-R rigid polyisocyanurate foam insulating board, held together with 4-inch wide aluminum HVAC tape. The rim around the top is sealed with opposing strips of felt weatherstripping, held on with double-stick tape.

Inside, I used lengths of wire shelving to support the thing-to-be-baked. After we’ve used it a bit more, I’ll conjure up permanent supports for the second level shelving (stacked on the right of the exterior picture); right now, they’re supported on wood blocks as needed.

The interior dimensions work out to 34x22x24 inches: it’s made from a single 4×8 foot sheet of insulating board. Here’s my working sketch showing how the parts lay out and fit together. (clicky the pic for more dots).

The only waste is the 1-inch strip along the right edge; the slab I bought came with a molding imperfection, so discarding that edge was OK.

I cut the sheet into four 2×4 foot strips, cut a 13-inch strip off each plank, then trimmed the 1 inch waste. That seemed less prone to catastrophic blundering than (trying to) make a pair of 8-foot cuts and whack each resulting strip in quarters. An ordinary razor utility knife worked fine, although I found that making two passes along each cut produced cleaner results than trying to do it all in one.

I assembled it with the heavy / shiny aluminum foil side inward, although I doubt it makes any difference. Cover all the edges with tape, tape all the joints both inside and outside, and it becomes a nice rigid box when you’re done. Pay attention to getting the sides at right angles; I used a framing square.

The board allegedly has an insulating mojo of:

R = 6.5 ft2 • h • °F/Btu

Figuring a surface area of 32 ft2 and a temperature differential of 120 – 60 = 60°F, the box should require 295 BTU/hr = 87 W to maintain that temperature.

Which, as it turns out, is pretty close to how it worked out:

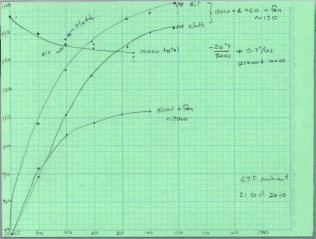

The lower curve shows a 60 W bulb with a 10 W 120 VAC fan heats the interior to a bit over 100°F in 100 minutes, where it looks to be stabilizing. That was the first test and showed that I was on the right track.

The second test, with a pair of 60 W bulbs and the fan produced the two upper curves: one for air, the other inside some cloth jammed inside a plastic bucket to simulate a (tiny) suitcase. The combined 130 W heats the box over 150°F in two hours, with the somewhat insulated bucket trailing neatly behind as you’d expect.

Without opening the box, I connected the bulbs and fan to a Variac plugged into my Kill-A-Watt meter and dialed it for 100 W total dissipation. The temperature fell to slightly over 130°F in 80 minutes and looks like it would stabilize near there.

Ambient temperature was 67°F, so

R = 32 ft2 • 67°F / (341 BTU/hr) = 6.3

Close enough, I’d say. Given those few data points, it looks like the temperature sensitivity around 130°F is 0.7°F / W. [Update: typo in the equation. Doesn’t change the answer much at all.]

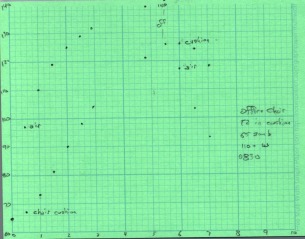

I swapped in a 100 W bulb, removed the Variac, and heated the cushions from my office chair.

One thermocouple is hanging in mid-air, the other is wedged inside one of the cushions. After nearly 5 hours the cushion is up to killing temperature and I turned the heater off. The air temperature drops rapidly, but the cushion stays over 120°F for another two hours.

The light bulb is just a proof of concept, because it’s entirely too hot: if the fan fails, your luggage ignites. I plan to build a rather subdued heater with a surface temperature around 140°F and a controller that monitors several sensors to ensure the contents reach killing temperatures and stay there long enough.

But that’s a project for another day…

[Update: If you’re arriving from a link, start at the overview to get The Whole Story.]

Have you thought of using a heat source like an electric heat pad? You could control the temperature with it’s control (possibly hacking it) and setting it to a maximum temperature rather than a wattage. Of course the other option is to set up a controller, like an Arduino to monitor the temperature and shut off the bulb when it hits a certain temperature and turns it back on when it cycles below a bottom temperature, effectively controlling the temp like a cooking oven.

A heating pad isn’t quite the right hammer for the job: you need a heater that does a really good job of transferring energy to the air. That light bulb wasn’t the right hammer, either, because it’s too hot, but putting it over the fan did a great job of heating up the air.

Basically, I’m going to build a set of hulking heatsinks with power resistors and fans, plus a controller with temperature probes. The heatsink surface temperature won’t get over about 150 F (thus, no ignition risk) and the fans will ensure a very low temperature differential (thus, good heat transfer).

The luggage / whatever in the box will heat at whatever rate it can support when surrounded by constantly hot air, but the exterior won’t go over 150 F and controller will back off the external heat when the interior hits 120 F. Soak the interior for an hour, let it cool, and stick a fork in it!

That’s the plan, anyway…

In the same vein, how about heating entire rooms at a time to 50C for extermination (rather than decontamination of returning luggage)?

With the exception of some delicate items, I imagine most belongings would be fine.

Move furniture away from the walls and windows, set a (hacked?) space heater to 50C, leave it for a day!

A circulation fan might be a good idea.

As long as your insulation is good (think draught arrestors…), I don’t imagine it would be too expensive!

Assuming 5KW, for 10hours, US$0.10/KWh, that’s 5$ (power required is a wild guestimate)

A DIY solar heater (600W/sq.m is a rough value for 80% efficiency) could help a lot.

Thoughts?

Unfortunately, room heating doesn’t work.

Because they’re in the cracks and crevices around the edges of the room, they’re tucked into the coolest and hardest to heat locations. Worse, they move away from increasing heat, so they just scuttle out of the room ahead of the inferno: you can’t heat their hiding spots fast enough to kill them before they move across the hall or through the wall.

The same thing happens with hot air from, say, a heat gun: you just force the survivors out of the room. Ditto for extreme cold. Neither have residual killing power: if you miss a couple of bugs or eggs, They’ll Be Baaack.

What does work is to bag up the entire house and roast the contents using an extremely high-power external hot-air source. They do this on a huge scale to entire hotels, but it’s certainly not a DIY project!

The real secret is to kill them all before they get into your house. Right now, that hot box is in our basement, but I’ll put it in the garage so we can cook incoming objects without carrying them into the house.

I see, sneaky little……

> What does work is to bag up the entire house and roast the contents using an extremely high-power external hot-air source. They do this on a huge scale to entire hotels, but it’s certainly not a DIY project!

Unless you own a hot-air balloon? :D

> I’ll put it in the garage so we can cook incoming objects without carrying them into the house.

Sounds like a plan :)

Could that be a good excuse to build a sauna? :P

Best of luck, I hope you manage to keep them away.

Well, but you can still put sticky worlds and powder around the corners of the room and before cracks, then heat the room, and catch all bugs that try to run away; then, put more tape and power facing the opposite side, so any bug that was hiding inside cracks would get caught as soon as he tries to move back to the bed.

By the way, thank you very much for your informative writeup – I now have bedbug-phobia.

catch all bugs that try to run away

That works for the bugs in the furniture, but (if you’ve got a nontrivial infestation) the ones in the walls will simply move into the adjacent room… which is a Bad Thing in an apartment. Worse, they will disperse vertically as well as horizontally, so you can turn a single-room problem into a whole-house problem in a few hours.

I now have bedbug-phobia

It will be a very, very long time before we stop feeling bugs crawling on us, even though you cannot feel a bed bug crawling on your body… and there’s never anything when we look.

this is a good idea, but i would not mind your feed back on few ideas, what about using a heat gun like this a dewalt D26950

Heat Gun that has a base heat output of 120F

the other thing that i think would work good is if you made a separate heater chamber and used a slightly modified 110v house heater, i am sure most would get that hot any how with out tripping there over heat but i am not sure, what there safety limits have to be set at but CSA or your us counterparts. i do think it is a good idea,

and a person could also use some the the controllers i have seen in a few DIY’s for controlling crock-pots they would be another good way to control the device

using a heat gun

Nope, terrible idea: the wind blows the bugs all over the place.

Read the Australian CoP (in the References) for a good summary of what doesn’t work… nearly everything, alas.

a separate heater chamber

You want a container with as few harborages as possible: clean walls, no crevices, and no escape. The fewer gadgets on the inside, the better!

I don’t like the commercial unit because it has uninsulated walls: if the contents rest against the wall, then that part simply doesn’t get heated. With foam insulation all around, there’s very little heat flow outward from any point of contact and the interior still reaches a decent temperature.

I think Mike is suggesting to use the heat gun inside your dis-insector…

The trouble with heat guns is the concentrated blast of hot air coming out the business end: not good for whatever you’re heating. Remember, those things are basically a fan wrapped around some incandescent heating wires, which is exactly what I want to avoid.

I actually know several people who were successful at heating their bedrooms to exterminate them. However, you have to seal up your room very carefully with caulk first, lay down a perimeter of fresh poison (like around the bedroom door), hang several thermometers around the room and heat to the extreme! They employed a few other steps, probably like pulling things away from the wall a bit and treating clothes in the dryer and etc. but that was the jist of it.

As long as they’re not already in the walls, that could work… but driving them through the outlets into the walls really, really complicates things.

Until you’ve seen a first instar, you think you can seal up the cracks. Even if you do a good job, your house still looks like a giant collection of hiding places!

Fortunately, in our case they never got into the walls…

Great project, smart thinking. How about adding some styrofoam to the outside to insulate it even more?

I have a dustmite allergy, I think this might be a effect method to lower their numbers, in my bed & surroundings.

Isn’t there an better solution then a lightbulb? Like a dedicated heatsource, combined with an attanuator to lower voltage and therefore power, making it possible to tune it to a certain degrees Celsius/ Fahrenheit? Something like a hairdryer and a wallsocket attenuator?

adding some styrofoam to the outside

The thing is exactly as large as you can get from a single 4×8-foot sheet of 1-inch foam board. The next step would be to shrink the interior two inches in all dimensions and use 2-inch foam board. You get a nice aluminum box that way, without those white crumbs all over the basement.

Isn’t there an better solution then a lightbulb?

Absolutely!

As I pointed out, those lightbulbs were an expedient way to dump a known amount of power into the box so I could draw that graph and verify that I ran the numbers correctly.

What you don’t want is a high-temperature heater: the outlet will melt your luggage or ignite your undies. You also need a bit of logic to servo the air temperature in the box based on the temperature inside the object-to-be-killed, so a simple thermostat won’t quite work. And then you want an overall timer to cut it off an hour after the interior reaches the kill zone, a failsafe timer ensuring it doesn’t stay on forever, and a failsafe overtemperature lockout.

I’m still doodling…

Could clear caulking prevent them from going under the trim and into the walls?

Yes, but remember all the switches, outlets, window moulding, and suchlike. If you have an opening into the attic or basement, that’s a fine highway.

In practical terms, I think if you already have a serious bed bug infestation, it’s too late to seal the cracks. They can survive for a year without feeding, so they have plenty of time to find the one pinhole you missed. It can’t hurt, but …

These battery-powered USB temperature loggers may help you: http://pcsensor.com/index.php?_a=viewProd&productId=41

I have not tried them myself but seem appropriated for your temperature range.

Years ago, in a rented place in Berkeley, CA, we suffered that problem and I know how bad it is.

Would that they had a Linux-based interface program!

Right now, I have a waterproof Hobo data logger in the freezer tracking its ups and downs; I want to see how the duty cycle varies with the tonnage of stuff in there. Fortunately, we’re done freezing keyboards and suchlike.

Don’t really Ed. There is no mention of Linux and just a not so good looking piece of software for Windows on the website. Perhaps if they use a file to log the data, it acts as a USB regular pendrive, but I have no clue.

But as it is mostly an offline device, we all keep a windows box hidden somewhere :-D

There are similar devices on eBays, some even log humidity rate too (which you may want to measure in your freezer).

I just thought you could get a detailed temperature monitoring (no wires) by sticking it inside your test bag.

How about a simple electronic mechanism? Timer and a mechanism for automatic on/off as to control the temperature?

Set to Tmax = 50 *C and timer in minutes? That would seem like the most logic solution….

BTW Toasting my undies, doens’t seem like a good plan indeed :P

Set to Tmax = 50 *C and timer in minutes?

That gets you most of the way to the goal, but you want the timer to start when the interior temperature (as measured with a probe tucked into your undies or whatever) reaches the kill zone. I have a stack of hand-drawn plots for various things we’ve heat-treated and the time-to-start ranges from an hour to six hours.

As with any project, the first half-dozen things you come up with… don’t work!

Which is why I had to build that box and use those awful lamps: that gave me some numbers to kick around.

Could always do immersion heater in water. Steam transfers heat might quick especially if stirred by a fan.

And if you REALLY wanted to get it over with quickly, pressure seal the box and add a release valve and you’ve got a gigantic pressure cooker. That’ll shoot the temp up over minutes, not hours.

Steaming luggage just seems like a Bad Idea: unless the steam penetrates to (and the water soaks) everything in the middle, it’s not much better than hot air.

And, c’mon, at 15 psi gauge, the lid would require 6.5 tons of clamping force! Now you’re talking boiler design, not cobbling something up from the basement stockpile! [grin]

More to the steaming idea, how about a small radiator type device inside the box. something like what would be on a motorcycle, these are fairly common and inexpensive from junk yards. where you have a closed loop water pump to circulate externally heated water supply, perhaps liberating a tea kettle as the water heating source. but surely it would be possible to control the internal temperature by adjusting the water heating source.

I’m not seeing the point of replacing a straightforward electric heater with a pressurized boiling water heat transfer plumbing project, all to heat the air in a box…

Have you thought of trying a bathroom heat lamp and fan for heat sourse? Good sourse of heat, fan for air movement, & thermal protection. It might be the perfect fit for this project?

The trouble with all lamps is that they operate at too high a temperature, despite the fan. What I really want is a low-temperature heater that can’t possibly ignite / melt / distort whatever’s in the box, but with enough wattage to bring the box temperature up to killing levels in fairly short order.

The other catch is that the controller must monitor both the box air temperature (not above 150 F) and the internal object temperature (above 120 F, but not much over 140 F), then start a timer when the interior reaches killing temperature. That requires more than a simple thermostat, although I think having an overall dumb temperature cutout will be a good thing.

I’m doodling with some power resistors on a big heatsink, although running at an ambient of maybe 150 F requires grossly over-rated resistors. More doodling is in order!

what about just steaming the luggage? it’s manual and slow, but i don’t see why it would fail. and you don’t have to build anything (ok, i can see how that’s a down point)

that’s what i did. sadly i only knew about them after they where in my house. i did steamed the bed and clothes too.

seems to have solved it.

it’s manual and slow

And it requires opening your luggage, fiddling around with it, and maybe not killing a bug or two.

You just dump a suitcase in the heater, stick the temperature probe inside, turn on the heat, and come back a few hours later knowing that there’s no sign of life inside.

you don’t have to build anything (ok, i can see how that’s a down point)

Now you’re getting into the spirit of the thing… [grin]

Ed,

I stumbled across this post while searching for a diy heat box. I found the heat treatment device for sale and thought is was pretty much overpriced for the quality. I would love to build one myself. Would you be so kind as to email me directions on how to build one. You post talks about your tests and unless I’m missing it never says what you finally ended up with. Thank you for your help!

Cheers,

Lisa

The box pretty much assembles itself from a single sheet of foam insulation and a roll of aluminum (or stainless steel) tape.

The shelves inside are random lengths of wire shelving I had lying around; if you had to buy a real wire shelf, get the widest one that will fit, a bag of end caps, and chop it up. I used a bolt cutter, but a hacksaw will suffice.

At this point, I’m still using the crude light-bulb-and-fan arrangement you see there, while doodling up a temperature controller that only an engineer could love. That’s certainly not going to be a DIY gadget, if only because I’m using a bunch of random parts I have lying around here; if it were a commercial venture, it’d be far too expensive.

You must put a temperature probe inside the luggage (or stack of books, or whatever) so you know when the interior gets killing hot. An ordinary weather thermometer with an outdoor probe would work for that.

The worst part is that you must keep an eye on the thing while it’s heating, then time it by hand. I used that time to plot the temperature against the time to produce those graphs… but I’m just that way.

It’d make sense to plug the heater into a timer so that it can’t stay on overnight by accident. When the luggage reaches killing temperature, set the timer for an hour and then you could ignore it.

Hope that helps; I don’t have anything more in the way of directions…

I

Thanks!

I managed to do something horrible to my neck last week and spent a lot of time lying on the couch using my cheap, crappy chinese heating pad. Which lead me to wonder if a flotilla thereof would be a suitable heat source here; I haven’t measured but I imagine they’re only ~10W each but they seem to maintain a low surface temperature and you ought to to be able to find them for a few bucks on the intertubes…

spent a lot of time lying on the couch

With your neck at an awkward angle so you could see the screen while typing, right? [grin]

I’m in the midst of some tedious power-vs-temperature-vs-airflow measurements on some honkin’ big aluminum heatsinks…

Frankly, I’m afraid of anything line-powered inside that nice aluminum hot box. Whatever I come up with, it’ll be low voltage and high current; a PC power supply seems to be a cheap source of nicely controlled and well-isolated voltages.

More data is in order…

A reader commented by email, but I’ve moved the discussion here so everybody can get some useful information…

The reason I didn’t go with commercial heaters is that I really want tight control over the heat source temperature. A higher-powered source intended to heat a room will produce a much hotter air stream than I want and can raise the box temperature to unsafe levels that are perfectly normal for a room heater.

Plus, of course, I’m a DIY kind of guy…

I hadn’t found the Paktite design discussion, but they’re certainly driven by different motivations and have different criteria than I do. [grin]

Thanks for the good words… glad to be of some use, even if as a Bad Example!

I agree a light bulb is too hot and heating elements are even worse. But there’s a simple answer: Wire them in series! Cutting the voltage in half will cut the energy output per bulb to a quarter. For example two 100W light bulbs in series produce 25 Watt each. Wire two strings of 2 100 W bulbs in parallel and you have 100W again, but with a bigger and cooler surface and a red glow that’s mostly IR.

If the surface still feels too hot, do 3 or more in series till it feels right and add more parallel strings to achieve the wattage you want. (You could even switch strings on and off to change wattage.)

Of course half a dozen old electric irons, heating coils, or even elements from broken toasters would also work.

The only downside is running 120 VAC inside a metal-lined box, but if you’re really careful and double-insulate everything inside a grounded case, that’d work fine. I like it!

Awesome. It produces DATA and you can do SCIENCE (somewhere near the beginning of your post). I’m sucked in generally. I’m all about DIYing one of these, both because the commercial one is too small and the non-insulated aspect bothers me too. Of course, once could make a larger one using a second sheet of Tuff-R.

Regarding ignition being bad, we can use the lightbulbs in series approach to prevent ignition and maybe use some kind of thermostat set to 140. So, power cycles on and off as needed. Acceptable? Provided I have enough power to work in a range of ambient temps (I’m looking at 30-80 in my garage), for which I still need to do the math on my lightbulbs, should work. It’ll take longer to heat up in the winter, but I can live with that. Ideally then we need a timer that starts ticking when kill temp is reached on the luggage probe, and counts down for a couple of hours and then shuts the whole thing off.

What can go wrong.

Thermostat can fail. Could put in a second t-stat circut as a failsafe that shuts it OFF if it goes above 160.

Timer could fail and either undercook or over cook your stuff. Overcooking (duration) is acceptable. Undercooking is a problem. I suppose that’s where making a time/temp record would be nice. So, I need a thermometer that keeps a history and can trigger a timer. Where do I get one of those? I suppose the thermometer could be a t-stat instead, which sends power to an electro-mechanical timer, then in case the probe temp drops below the desired value it shuts off and the electro-timer does too. This only gets us the correct total cooking duration but doesn’t ensure it was sequential… automation is definitely a tricky issue. More noodling required.

In any case, I suppose with the right t-stats for safety and accepting power cycling as a viable way to address my range of ambient temperatures, I could live with manual timing in my DISINSECTOR for now. Now I just need to find t-stats that operate in the right ranges. Ideas?

I’ve been distracted with other projects and haven’t gotten around to building a controller, but we’ve been cooking most of the stuff that comes into the house. It turns out that 100 W heats the thing to a stable 140 F, which is a bit hotter than needed, and having it in the basement keeps it at a fairly stable ambient temperature year-round… so I think one could limit the top temperature by total power and the overall cook time with a probe in the best-insulated part of the contents (the interior temperature of larger objects continues to rise after the power goes off).

Even that could turn into an Arduino project easily enough… [grin]

I was reading through this all again this evening, starting my disinsector design. As I mentioned, I have that whole ambient temperature changing issue with keeping this in the garage, and I thought…why doesn’t Ed have that issue? Oh, because you keep it in the basement. Just FYI, the basement is part of…the house. So of course is my garage, though somehow it seems less so, possibly because my basement is finished?

Anyway, my largest piece of luggage doesn’t fit in your max volume box. I may need two sheets, but I haven’t sorted that part out – optimization of that part of the plan is pending. What I have sorted out are the volume needs, the consequent surface area and the likely power needs (how many 60W light bulbs in parallel and series strings I’ll need and which ones will go on a switch to deal with different ambient temps, etc.) That part is all good. I’m planning to go with a timer, set it for 12 or 24 hours or whatever when I start, and then when I get to the right target temp inside the luggage I’ll just reset it to an hour. It’ll do since I need the box ASAP and can refine it’s autonomous operation later

.

A couple of questions I’d be interested in your input.

First, instead of a giant bulb array, I wonder if something like this would work:

http://www.farnam-custom.com/air_heaters/axialfanheater.php

My concern would be that the air still comes out too hot and the temp cut out (I’d probably go with about 185F for the t-stat, I think my luggage and clothes can take 185 degrees, and that would only be in the summer anyway, in the winter it wouldn’t break 150F according to my power calcs) would simply trip immediately and/or often. I’ve sent them a note to see how this would work in a small space. They claim the use is for warming, so…we’ll see. I can’t have 400F air blasting out and starting to melt stuff. Maybe it wouldn’t. Maybe luggage is more robust than that.

Anyway, my second Q is, if I did do a bulb array, have you found anything online that makes that easy? So far I have not. I’m not really excited about screwing 27 sockets onto a plank and wiring them all up

Third and final Q is, how to hinge and lock/secure the box when closed. What did you do for that?

I’d be tempted to go with thicker sheets the next time around: better mechanical stability and lower heat loss. If you must use two sheets anyway, see if you can optimize the dimensions around 1.5 or 2 inch slabs.

That was my overriding concern; typical plastic won’t survive much over 200 F for very long. The heating element in those fan heaters is obviously a coiled nichrome (or whatever) wire and the thermostat looks to be mounted on the terminating plate, so the temperature control mostly monitors incoming ambient air.

I’ve tested a set of hulking aluminum heatsinks with power resistors and fans, which eliminates the high exhaust temperature problem, but I’ll admit I haven’t yet built the whole thing…

I don’t have any good answers, which is one of the reasons I didn’t go that way. The classic board-mounted porcelain socket with exposed screw terminals makes my skin crawl.

Matching lines of weatherstripping felt along the top edge of the box and the perimeter of the lid makes it airtight, particularly if you put a broad, flat weight atop the lid. That does not make it bug-tight, but I figured that the intent was to kill ’em off; getting off the luggage and then climbing two feet of hot aluminum sheet ought to be reasonably difficult.

If you’re willing to wrap the whole thing with 1/4 inch plywood, then a piano hinge along the back and over-center snap latches on three sides would work better and reduce the overall craziness by turning it into a wood box. Plywood strips glued along the edges might anchor the hardware just as well, though.

That was my overriding concern; typical plastic won’t survive much over 200 F for very long. The heating element in those fan heaters is obviously a coiled nichrome (or whatever) wire and the thermostat looks to be mounted on the terminating plate, so the temperature control mostly monitors incoming ambient air.

I’ve tested a set of hulking aluminum heatsinks with power resistors and fans, which eliminates the high exhaust temperature problem, but I’ll admit I haven’t yet built the whole thing…

How about hacking one apart and relocating the thermostat to the output?

If it reacts fast enough it should be OK

OK, let’s review my basic objectives here:

I think those are reasonable design criteria and, frankly, I’m not particularly interested in hacks that don’t behave that way.

So far, I haven’t heard of anything better than suitably sized low-voltage power resistors on an aluminum heatsink.

Now, of course, you can do anything you want… [grin]

This text column is starting to get narrow. I am not as concerned about line voltage in the box as you, I have lots of metal boxes with line voltage in them all over my house, but the other two things matter more, and the board full of sockets makes me like the line-voltage issue less than something clean and simple like a UL approved prefab fan.

I’m not even sure if the thermostat position matters, its enough fan and little enough space that I expect the inlet temp and the average ambient temp won’t be too different, but I am concerened about melting whatever is right in front of the exhuast and that, if I put the t-stat THERE that the average ambient temp will NEVER get high enough because the fan will just keep turning itself on and off constantly. Maybe the fan needs a highly conductive extended exhaust shrowd to direct outflowing air and cool it further before it blows directly on anything.

Or, I’m back to a board full of bulbs, which, by running cool, solves both the running cool and catastrophic failure issues. Unless you get your heatsink solution done soon enough and post a DIY. [grin]

Solving all three is hard, but I need a stop gap. If I’m not electrocuted, I could still convert to your heatsink solution later if it solves all three problems. I’ll be staying tuned and post if I figure something out.

I turned on threaded comments, which seemed like a good idea at the time. This is the most-commented post of all and the threaded model just doesn’t fit…

Another option I don’t like that would probably be OK: a 100 W (or so) length of the heating cable used to keep gutters de-iced in the winter. It’s probably not rated for continuous service at 120-150 F, but it produces nicely distributed, low density heat. Figure out how to affix it firmly to a large grounded metal plate and you’d be most of the way to the goal.

The box is assembled, at least the Tuff-R part is. I’m going to build a hardboard shell for it to prevent incidental damage. I need a couple of thermometers/temp probes and a heat source still. And ideally a controller, but I’m increasingly convinced that’s a different project.

Based on ambient temperatures variations, I figure I need between 120 and 180 watts to reach and stay at 150F, which I realize is a bit more than I need, but if the larger temperature differential will mean the interior of stuff is warmed that much more quickly.

I looked into the line level light bulb thing and I found that even three 60W in series were still very hot and they take up a lot of space (if I put 27 of them in there to deliver my 180W of power). Maybe if I added a cooling fan they’d be OK, but I’m now convinced on the heat sinks.

Doing a little math it occurs to me that to get my required power output there is a minimum useable voltage on a typical household 15A circuit, so I’m looking at a switched power supply with 24V output. Correct me if I’m wrong, but I think I can’t achieve this with a 5V or 12V supply, at least, not without putting in a different circuit.

My back-of-the-envelope calculation suggested using a power supply harvested from an obsolete PC. You get beefy +5 V and +12 V outputs that can produce entirely enough power: a 1 ohm resistor on the 5 V output produces 25 W, a 6 ohm resistor on the 12 V output produces 24 W. Put one of each on a beefy heatsink, wire up a crappy 4-pin Molex connector, plug it in, apply a fan, and you have a reasonably low-temperature heat source. Put three in the box and you have a 150 W heater that you can control in 25 W chunks.

Measurements there, with links to previous doodles & hardware. It’s been on my to-do list for far too long… let me know how it works out for you!

Has anyone looked into using a peltier?

In a past job I used large laboratory incubators for testing electronic equipment over temperature/humidity ranges. As I remember, the heater in the incubators utilized several coarse selections on a resistive heater coupled to a peltier. The thermostat selected a resistive heater (if necessary) to pair up with the peltier’s delta-t. The peltier was then used to perform the actual temperature adjustment. I believe that the peltier can achieve better then 100% heating efficiency in this configuration. Additionally all real hackers have these in their junk pile and they interface well to heat sinks. I may attempt to engineer/build a peltier version of your device next weekend if an actual incubator does not show up for cheap on ebay.

There’s no reason to introduce a fiddly and expensive (yes, I have some on the heap, too!) heat pump that requires a port through the box insulation to an external heatsink and fan (which is wasted energy right there); all you need is raw power with a bang-bang temperature control loop. The thermal mass inside the box doesn’t change temperature very rapidly at all: fancy PWM and delicate control doesn’t buy you anything.

The ones I have are about 50 mm on a side and look like they’d suck maybe 10% more energy from the exterior than they’d burn from the supply. Given that ratio, I suspect the external fans and leakage around the port would blow any benefit.

I’ll grant you Peltier coolers whip resistors, hands down, for geekiness…

I work for a pest control company and I handle all the bedbug heat treatments we do. From what I see you came up with a pretty effective and simple solution. The only thing I would want to bring up is that even at 1 hour I’m not so sure you are going to get everything inside the suitcase up to temperature. If you could open the suitcase that would really help with that. I might suggest getting a remote temperature sensor and stashing it in the suitcase as close to the center as possible. For what it’s worth, the bedbugs are attracted to the heat and are going to be more likely to be drawn out in the process. On severe infestations we will see piles of dead bedbugs right at the base of the heaters.

Like I said, I think it’s a great idea and very well executed.

Although it’s not obvious from that post, I’m actually measuring the temperature using a thermocouple poked into the innermost part of the heaviest object in the heater, with the meter outside the box. When that interior point reaches 120 F, then it soaks for an hour; the rest of the stuff stays much hotter than that for much longer than an hour and the critters (if there are any) certainly get toasted.

I generally do a suitcase in two passes: most of the contents laid out on the wire racks, then the suitcase on the bottom rack with whatever’s left on the top rack. It takes most of an afternoon and evening to process one suitcase, but I can’t get heat into the contents at a much higher rate without melting something.

Thanks for the good words: I’m glad to hear your experiences support the idea!

“…very well executed.”

The heat treatments are really effective IE they kill even bigger animals equipped with low IQ.

http://en.wikipedia.org/wiki/World_Sauna_Championships#2010_accident

Bed bugs, fortunately, lack thumbs…

Have you looked at using a ceramic heater bulb? http://www.amazon.com/Zoo-Med-ReptiCare-Ceramic-Infrared/dp/B0002AQCPK

That looks interesting, because it certainly runs at a lower temperature than a tungsten filament.

I don’t know how to interpret the comments that suggest just a few months of run time. If the terrariums run at 100% duty cycle, then it’s just a few thousand hours and I’d expect much better than that. On the other hand, I’d be using the things at 100% for just a few hours at a time, so they should last basically forever as measured by the calendar.

A pair of 60 W heaters backed by fans should do the trick…

Hi,

Sorry to burst you bubble on this but the latest version here still has the potential for bedbugs to survive even an extended cycle in this device. The reason for this is two fold:

1/ The method of heating is conductive which bedbugs will generally try to escape from by searching out cool spots.

2/ The design has some obvious cool spots that bedbugs would be able to detect.

If you look at this research document you will see what I mean:

Click to access REP_12221%20Efficacy%20of%20Heat%20on%20Bed%20Bugs.pdf

I have tested all the commercial products on the market and to date only 2 of the 5 actually pass my rigorous QC.

I appreciate you mean well but you really should not put a project like this out there unless its 100% effective and will work reliably, otherwise you will have people thinking its working when you simply cant defy the laws of physics.

Good luck anyone who tries this for numerous reasons.

David Cain

Bed Bug Specialist

The wood support blocks for the wire shelves touch the insulated bottom panel; everything else has an air gap to the sides.

I put a thermocouple probe in the innermost part of the most dense object on the shelves, wait for that temperature to reach 120 F, then wait for an hour. By then, the temperature outside that object is far over 120 F, including all the supports and walls. So a bed bug fleeing the heat has a problem: everything is hotter than where it came from!

Metal tape seals all the interior joints and the lid has a wool gasket compressed by weights, so there aren’t any paths to the outside. The bug can crawl down the wood support to the aluminum panel, but … there’s nowhere to go and it’s getting hotter by the minute.

Please build one, test it according to your protocols, and report back; I’d like to know how it fares!

Aye, Scotty… [grin]

I’m thinking of plumbing a water heater thermostat into a extension cord and use that to turn the lights on and off. I’ll run the fan continuously. Shouldn’t take long to dial in the right temp setting with a couple thermostats.

And it doubles as a food dehydrator. Maybe not at the same time.

Oh, I don’t know, some folks do enjoy toasted insects…