The LightBurn forums have many despairing posts from folks with CO₂ lasers sprinkling random dots all over their engravings:

- Weird dots all over my engraving

- Dots appear all around engraving

- Random dots when engraving

- Just search for engraving dots to find many more

Well, as it turns out, engraving lots of small test patterns on scrap acrylic and peering at the results revealed the same problem:

The test patterns were engraved at various power levels, which was the whole point of the exercise: I was looking at the current waveforms, rather than the acrylic. Despite that, the result should be solid blocks with no speckles in between, which is not quite what happened.

For reference, the test pattern:

An early hint came from a trace captured while looking at an entire scan line across the pattern:

See that isolated spike left of center, where the L-ON signal (magenta trace) is high? That shouldn’t be possible.

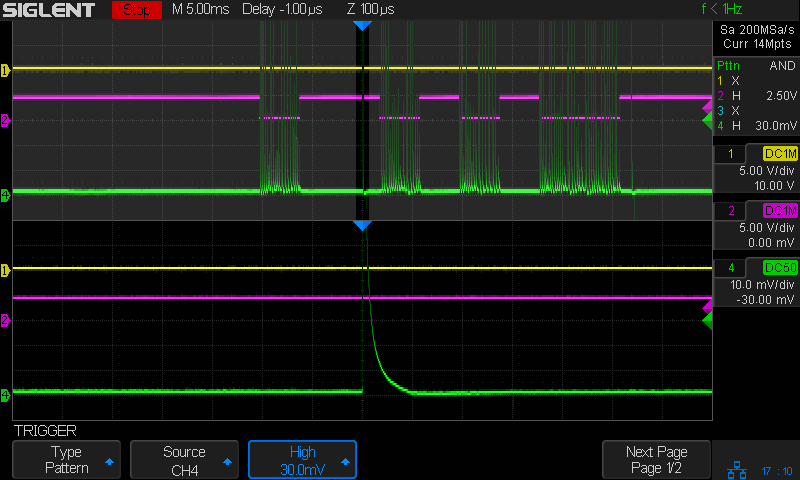

Setting the scope to trigger when the L-ON signal is high (= laser power supply disabled) and the tube current is more than a few milliamps (= laser beam active) captures those errant dots.

Sometimes a spurious pulse happens just after L-ON goes high to disable the HV output:

The X axis stepper DIR signal (yellow trace) shows the laser was scanning right-to-left, so the glitch will be just to the left of the 2 mm block in the pattern. In point of fact, it’s about ¾ of the way down the right-hand column:

A closer look shows a distinct circular pit at the end of the line:

The two left-to-right lines bracketing that line also show how the high-intensity pulses affect the laser beam startup intensity during a scan line.

Sometimes the glitches happen quite some time after the laser turns off:

Sometimes they’re in the middle of what should be a blank space:

The glitches are not always full-scale events. The two nearly invisible pulses just to the right of the block (bottom green trace) make the smaller dots you can see on the targets:

As far as I can tell, spurious dots happen most often with current levels around 20% PWM, less at 10% PWM, and rarely above 30% PWM. I think it has something to do with the chaotic spikes that the power supply produces at lower currents, instead of the relatively stable outputs for higher currents.

Although these measurements are for the replacement HV supply I got when the original supply failed, I saw similar chaotic waveforms with a Cloudray HV supply I bought as a backup. Given that other people have reported similar random dots with many other machines & power supplies, I think these scope traces show where the dots come from: all the power supplies behave the same way.

The only way to reduce the number of speckles is to use higher power, which will require higher scanning speeds to achieve similar results. Unfortunately, higher speeds give the power supply less settling time, so there may be no good answer.

I haven’t been able to find any “official” schematics for the HV laser power supplies shipped in typical lasers (there are many terminal wiring diagrams), so I have no idea how the L-ON signal controls the output current. Apparently the oscillating chaos inside the power supply occasionally punches through the output switch, which isn’t too surprising given the voltage and power levels in there.

If nothing else, the acrylic test pieces look pretty on the microscope positioner:

In the usual techie sort of way …

Might there be some way to “shed” some of the PS output while engraving, to allow a higher PWM duty cycle (avoiding the speckles) yet still maintain the slower scanning speed? I’m not familiar with how psychotic a load the laser is, so perhaps this is easier said than done…

IMO, describing the load as “psychotic” seems perfect.

You could probably run a beam combiner in reverse, with the (defocused) waste beam heating a block of black-anodized aluminum (or graphite or some such), which would dump half the power. The gotcha would be making enough space between the tube and the first mirror.

This is one of the cases where a lower-power tube (and power supply) would work better than throttling a higher-power tube, at least until you tried to cut the engraving out of the sheet.

Well, surely 100% of the power supplies are made in the same factory in China from the same bad design, so it makes sense they’d all be defective in the same way. I continue to think that the FDA would love to know about any case of coherent output with a control line off…

You’ve got a spare, why not crack it open and scan the PCBs? :)

Huh, this looks interesting:

https://donsthings.blogspot.com/2017/03/laser-response-charcteristics.html

And links to this schematic:

https://www.digikey.com/schemeit/project/k40-lps-2-EFKO7C8303M0/

As with the factory producing Tiny Lathes, different “brands” can buy whatever QC level they want: every power supply ever made sold at the right price, with the savings passed on to the AliExpress / eBay / Amazon customer! Unlike the lathes, all the power supplies have the same paint job, so you can’t tell them apart.

OK, I’ll take apart the dead (failed hot) supply and see what’s inside.

The “one more pulse, after a variable delay” behavior looks to me a lot like what a simple relaxation oscillator circuit does. It’s as if something was partially charged, and eventually discharges, producing an extra cycle after a delay depending on what the conditions were when it was switched off.

AFAICT, the laser is just a really long neon tube, the power supply has an output capacitor, and the output voltage must stay just under the firing level until the next time it’s enabled. If the oscillator continues ticking along to keep the voltage up, I can see where an occasional glitch pulse could leak out.

All of the schematics in the wild seem to be for older K40 lasers, although I have no idea what the differences might be from contemporary higher-power supplies. Most likely, they’re all the same.