Although compact fluorescent lamps have fallen out of favor, I’m burning through a box of the things donated by a friend who upgraded to LEDs and figured I could put them to good use. In general, complex electronic doodads (like CFL or even LED lamps) used in hostile situations (like an ordinary downlight fixture) seem to fail too quickly to justify the power savings; searching for “cfl fail” will produce some evidence from around here.

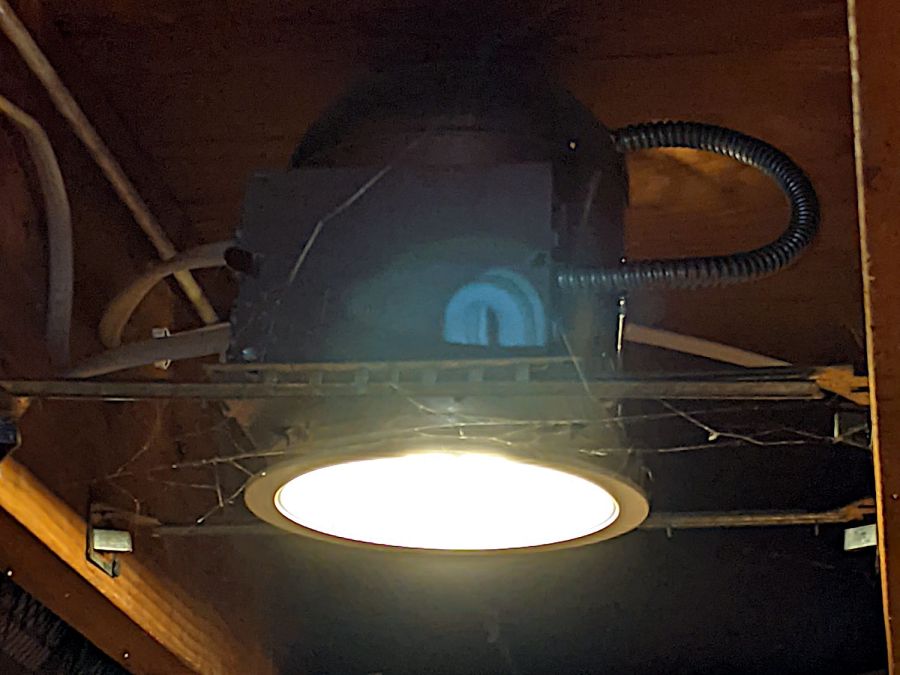

One of the downlights in the Basement Office just killed this specimen:

Much to my surprise, however, it survived for more than five years:

The previous CFL bulb in that fixture lasted only two years, so their average lifetime is entirely too short.

A taller bulb does a better job of lighting up that corner, although it started with enough power-on hours to suggest it won’t survive for another five years:

The ghostly humps above the overexposed glare are the long CFL tubes reflected inside the Pixel’s camera optics.

I didn’t see much point in nailing a ceiling to too-low floor joists.

I tried using a CFL as a work light for the mill-drill. After a minute’s worth of life, I realized that vibration and CFLs are not compatible. I moved the work light to an old swinging-monitor platform and dug out an incandescent flood light. That works fairly well.

After redoing the roof on the house, I had to replace a few of the ceiling lights in the bedrooms. There was a pretty solid connection from the roof to the ceiling. Oops.

The CFLs removed from the house spent their declining years in the shop/barn until I redid its lighting. I now have a work room where I have to turn off a couple of lights to use the computer.

The LED bulb in the garage door opener is still going strong after six years!

I tucked an incandescent floodlight inside the drill press a while ago and hope it keeps working forever, because screwing it into the wobbly socket was a death match inside a cast-iron cage.

I have discovered the joys of the 4 foot florescent fixture with LEDs in them – instant-on regardless of how cold they get in the barn. I have eight foot florescents in the center aisle and even the “cold weather” rated ones don’t always start on the first try. They also only seem to last about three years of light use*. I’m sort of close to Raleigh so you know how gentle the winters are here. Rarely does it get below 20F. Anyway, the long tubes cast rather gentle shadows, and at full tilt I have a killowatt of 8 foot tubes lighting 1600 ft^2 in the center. I finally have enough light to do fine-pitch work again! Strongly recommended, especially with solid state ballasts. Keep an eye on your favorite recycled building materials reseller and you can open the Basement Laboratory Daylight Therapy Wing.

See what I did there?

Good idea: my Next Shop™ should have longer fixtures. Back in the day, filling the floor joists with four foot fluorescent shop lights worked pretty well; LED tubes seem more directional.

I hope warm white LED tubes become cheap and readily available, though, because cool white LED tubes definitely makes me look dead.

I did two strings of shop lights in the shop/barn for task lighting. (Overhead lights were a half dozen 23W CFLs; not enough light.) After too many tube and ballast failures, I changed some of these to LED tubes (non-ballast type). This was successful and I did the rest. (The two batches have different wiring, so I had to note the oddballs.)

The trusses now sport several (8?) shop lights for the main room, while the white-painted workroom has 4 more shop lights. There’s also some bare-bulb fixtures, but the two over the monitor have to be off.

We have had some failures in the LED bulbs in the house, though these seem to be from the first round of cheapenifying.