After replacing the nozzle and the filament drive body on the M2, I figured I might as well throw all the balls in the air and switch to PrusaSlicer for all my slicing needs. It’s built from the Slic3r project, gaining features used by Prusa’s printers / filaments and a considerably improved UI, with a full-time paid staff working on it:

Of course, I immediately turned on Expert mode.

CAUTION: My heavily customized start_gcode will crash your M2, because you haven’t relocated the Z-axis switch, haven’t calibrated Z=0 at the platform surface, and don’t put the XY=0 origin in the center of the platform.

You have been warned: consider this as a serving suggestion, not a finished product.

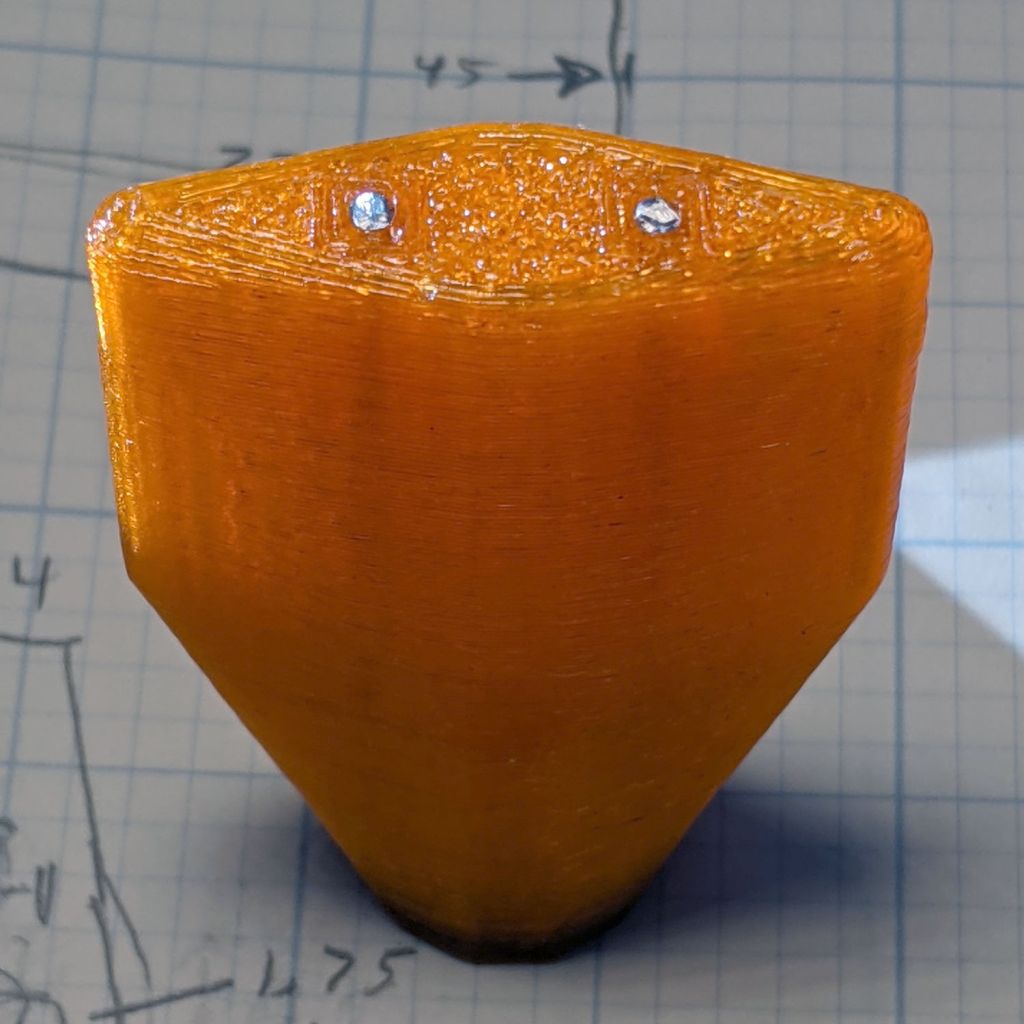

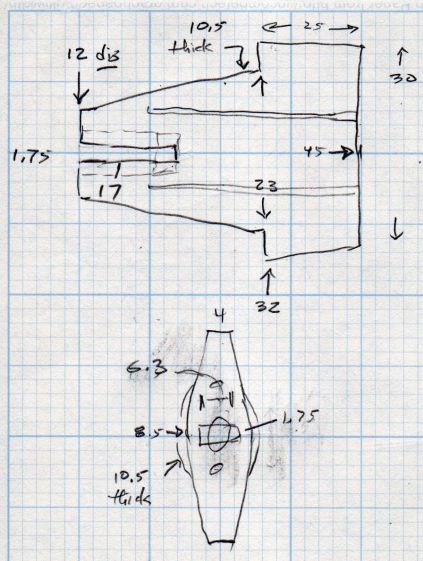

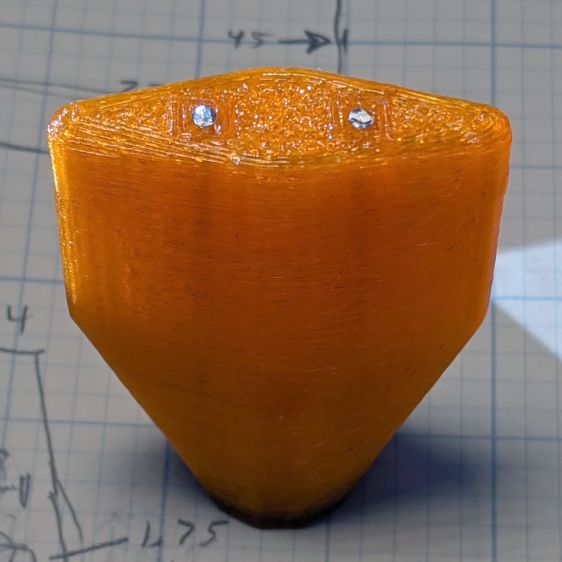

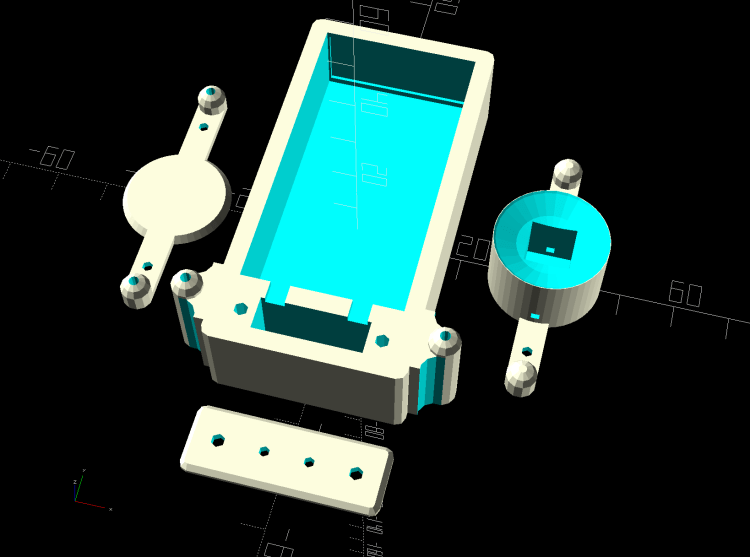

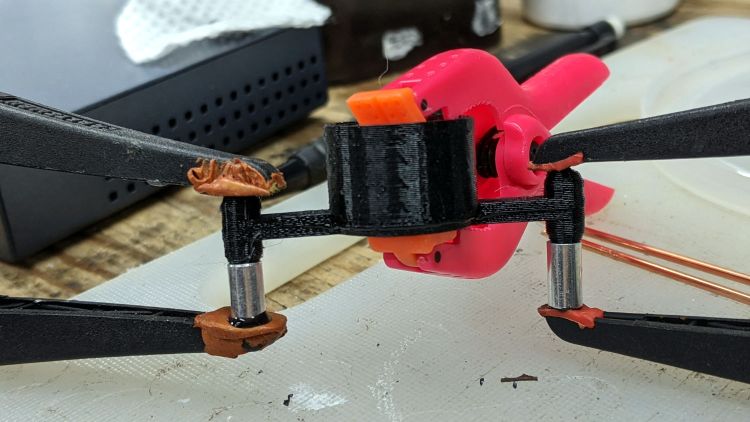

Because everything I design looks more-or-less like a bracket, I absolutely don’t care about surface finish, and I’m content to use only a few colors of PETG from a single supplier, a single Slic3r configuration has sufficed for nearly everything I print. A few manual tweaks for specific models, perhaps to change the number of perimeters or the infill percentage, handle the remaining cases.

With all that in mind, here’s the current result of File → Export → Export Config as a GitHub Gist:

| # generated by PrusaSlicer 2.2.0+linux-x64 on 2021-01-01 at 13:33:03 UTC | |

| avoid_crossing_perimeters = 0 | |

| bed_custom_model = | |

| bed_custom_texture = | |

| bed_shape = -100x-125,100x-125,100×125,-100×125 | |

| bed_temperature = 90 | |

| before_layer_gcode = | |

| between_objects_gcode = | |

| bottom_fill_pattern = hilbertcurve | |

| bottom_solid_layers = 3 | |

| bottom_solid_min_thickness = 0 | |

| bridge_acceleration = 0 | |

| bridge_angle = 0 | |

| bridge_fan_speed = 100 | |

| bridge_flow_ratio = 1 | |

| bridge_speed = 50 | |

| brim_width = 0 | |

| clip_multipart_objects = 1 | |

| colorprint_heights = | |

| complete_objects = 0 | |

| cooling = 1 | |

| cooling_tube_length = 5 | |

| cooling_tube_retraction = 91.5 | |

| default_acceleration = 0 | |

| default_filament_profile = "" | |

| default_print_profile = | |

| deretract_speed = 0 | |

| disable_fan_first_layers = 6 | |

| dont_support_bridges = 1 | |

| draft_shield = 0 | |

| duplicate_distance = 6 | |

| elefant_foot_compensation = 0 | |

| end_filament_gcode = "; Filament-specific end gcode \n;END gcode for filament\n" | |

| end_gcode = ;– PrusaSlicer End G-Code for M2 starts –\n; Ed Nisley KE4NZU – 15 November 2013\nG1 Z160 F2000 ; lower bed\nG1 X135 Y100 F30000 ; nozzle to right, bed front\nM104 S0 ; drop extruder temperature\nM140 S0 ; drop bed temperature\nM106 S0 ; bed fan off\nM84 ; disable motors\n;– PrusaSlicer End G-Code ends –\n\n | |

| ensure_vertical_shell_thickness = 1 | |

| external_perimeter_extrusion_width = 0 | |

| external_perimeter_speed = 50% | |

| external_perimeters_first = 0 | |

| extra_loading_move = -2 | |

| extra_perimeters = 1 | |

| extruder_clearance_height = 20 | |

| extruder_clearance_radius = 20 | |

| extruder_colour = "" | |

| extruder_offset = 0x0 | |

| extrusion_axis = E | |

| extrusion_multiplier = 0.95 | |

| extrusion_width = 0.4 | |

| fan_always_on = 0 | |

| fan_below_layer_time = 15 | |

| filament_colour = #29B2B2 | |

| filament_cooling_final_speed = 3.4 | |

| filament_cooling_initial_speed = 2.2 | |

| filament_cooling_moves = 4 | |

| filament_cost = 25 | |

| filament_density = 0.95 | |

| filament_deretract_speed = nil | |

| filament_diameter = 1.72 | |

| filament_load_time = 0 | |

| filament_loading_speed = 28 | |

| filament_loading_speed_start = 3 | |

| filament_max_volumetric_speed = 0 | |

| filament_minimal_purge_on_wipe_tower = 15 | |

| filament_notes = "" | |

| filament_ramming_parameters = "120 100 6.6 6.8 7.2 7.6 7.9 8.2 8.7 9.4 9.9 10.0| 0.05 6.6 0.45 6.8 0.95 7.8 1.45 8.3 1.95 9.7 2.45 10 2.95 7.6 3.45 7.6 3.95 7.6 4.45 7.6 4.95 7.6" | |

| filament_retract_before_travel = nil | |

| filament_retract_before_wipe = nil | |

| filament_retract_layer_change = nil | |

| filament_retract_length = nil | |

| filament_retract_lift = nil | |

| filament_retract_lift_above = nil | |

| filament_retract_lift_below = nil | |

| filament_retract_restart_extra = nil | |

| filament_retract_speed = nil | |

| filament_settings_id = "M2 Esun PETG" | |

| filament_soluble = 0 | |

| filament_toolchange_delay = 0 | |

| filament_type = PET | |

| filament_unload_time = 0 | |

| filament_unloading_speed = 90 | |

| filament_unloading_speed_start = 100 | |

| filament_vendor = (Unknown) | |

| filament_wipe = nil | |

| fill_angle = 45 | |

| fill_density = 25% | |

| fill_pattern = 3dhoneycomb | |

| first_layer_acceleration = 0 | |

| first_layer_bed_temperature = 90 | |

| first_layer_extrusion_width = 0 | |

| first_layer_height = 0.25 | |

| first_layer_speed = 15 | |

| first_layer_temperature = 250 | |

| gap_fill_speed = 25 | |

| gcode_comments = 0 | |

| gcode_flavor = marlin | |

| gcode_label_objects = 0 | |

| high_current_on_filament_swap = 0 | |

| host_type = octoprint | |

| infill_acceleration = 0 | |

| infill_every_layers = 1 | |

| infill_extruder = 1 | |

| infill_extrusion_width = 0 | |

| infill_first = 1 | |

| infill_only_where_needed = 0 | |

| infill_overlap = 15% | |

| infill_speed = 60 | |

| interface_shells = 0 | |

| layer_gcode = | |

| layer_height = 0.25 | |

| machine_max_acceleration_e = 10000,5000 | |

| machine_max_acceleration_extruding = 10000,1250 | |

| machine_max_acceleration_retracting = 10000,1250 | |

| machine_max_acceleration_x = 2500,1000 | |

| machine_max_acceleration_y = 2500,1000 | |

| machine_max_acceleration_z = 2500,200 | |

| machine_max_feedrate_e = 10000,5000 | |

| machine_max_feedrate_x = 450,200 | |

| machine_max_feedrate_y = 450,200 | |

| machine_max_feedrate_z = 100,30 | |

| machine_max_jerk_e = 100,50 | |

| machine_max_jerk_x = 25,10 | |

| machine_max_jerk_y = 25,10 | |

| machine_max_jerk_z = 10,5 | |

| machine_min_extruding_rate = 0,0 | |

| machine_min_travel_rate = 0,0 | |

| max_fan_speed = 100 | |

| max_layer_height = 0 | |

| max_print_height = 200 | |

| max_print_speed = 80 | |

| max_volumetric_speed = 0 | |

| min_fan_speed = 100 | |

| min_layer_height = 0.1 | |

| min_print_speed = 10 | |

| min_skirt_length = 25 | |

| notes = | |

| nozzle_diameter = 0.35 | |

| only_retract_when_crossing_perimeters = 1 | |

| ooze_prevention = 0 | |

| output_filename_format = [input_filename_base].gcode | |

| overhangs = 1 | |

| parking_pos_retraction = 92 | |

| perimeter_acceleration = 0 | |

| perimeter_extruder = 1 | |

| perimeter_extrusion_width = 0 | |

| perimeter_speed = 50 | |

| perimeters = 3 | |

| post_process = | |

| print_host = | |

| print_settings_id = M2 Default | |

| printer_model = | |

| printer_notes = | |

| printer_settings_id = M2 Default | |

| printer_technology = FFF | |

| printer_variant = | |

| printer_vendor = | |

| printhost_apikey = | |

| printhost_cafile = | |

| raft_layers = 0 | |

| remaining_times = 0 | |

| resolution = 0.01 | |

| retract_before_travel = 3 | |

| retract_before_wipe = 0% | |

| retract_layer_change = 0 | |

| retract_length = 1 | |

| retract_length_toolchange = 10 | |

| retract_lift = 0 | |

| retract_lift_above = 0 | |

| retract_lift_below = 0 | |

| retract_restart_extra = 0 | |

| retract_restart_extra_toolchange = 0 | |

| retract_speed = 60 | |

| seam_position = nearest | |

| serial_port = | |

| serial_speed = 250000 | |

| silent_mode = 1 | |

| single_extruder_multi_material = 0 | |

| single_extruder_multi_material_priming = 1 | |

| skirt_distance = 3 | |

| skirt_height = 1 | |

| skirts = 3 | |

| slice_closing_radius = 0.049 | |

| slowdown_below_layer_time = 5 | |

| small_perimeter_speed = 25% | |

| solid_infill_below_area = 70 | |

| solid_infill_every_layers = 0 | |

| solid_infill_extruder = 1 | |

| solid_infill_extrusion_width = 0 | |

| solid_infill_speed = 75% | |

| spiral_vase = 0 | |

| standby_temperature_delta = -5 | |

| start_filament_gcode = "; Filament gcode\n" | |

| start_gcode = ;– PrusaSlicer Start G-Code for M2 starts –\n; Ed Nisley KE4NZU\n; Makergear V4 hot end\n; Origin at platform center, set by MANUAL_X_HOME_POS compiled constants\n; Z-min switch at platform, must move nozzle to X=135 to clear\nG90 ; absolute coordinates\nG21 ; millimeters\nM83 ; relative extrusion distance\nM104 S[first_layer_temperature] ; start extruder heating\nM140 S[first_layer_bed_temperature] ; start bed heating\nM17 ; enable steppers\nG4 P500 ; … wait for power up\nG92 Z0 ; set Z to zero, wherever it might be now\nG0 Z10 F1000 ; move platform downward to clear nozzle; may crash at bottom\nG28 Y ; home Y to clear plate, offset from compiled constant\nG28 X ; home X, offset from M206 X, offset from compiled constant\nG0 X135 Y0 F15000 ; move off platform to right side, center Y\nG28 Z ; home Z to platform switch, offset from M206 Z measured\nG0 Z2.0 F1000 ; get air under switch\nG0 Y-126 F10000 ; set up for priming, zig around corner\nG0 X0 ; center X\nG0 Y-124.5 ; just over platform edge\nG0 Z0 F500 ; exactly at platform\nM190 S[first_layer_bed_temperature] ; wait for bed to finish heating\nM109 S[first_layer_temperature] ; set extruder temperature and wait\nG1 E20 F300 ; prime to get pressure, generate blob on edge\nG0 Y-123 F5000 ; shear off blob\nG0 X15 F15000 ; jerk away from blob, move over surface\nG4 P500 ; pause to attach\nG1 X45 F500 ; slowly smear snot to clear nozzle\nG1 Z1.0 F2000 ; clear bed for travel\n;– PrusaSlicer Start G-Code ends –\n | |

| support_material = 0 | |

| support_material_angle = 0 | |

| support_material_auto = 1 | |

| support_material_buildplate_only = 0 | |

| support_material_contact_distance = 0.2 | |

| support_material_enforce_layers = 0 | |

| support_material_extruder = 1 | |

| support_material_extrusion_width = 0.31 | |

| support_material_interface_contact_loops = 0 | |

| support_material_interface_extruder = 1 | |

| support_material_interface_layers = 3 | |

| support_material_interface_spacing = 0 | |

| support_material_interface_speed = 100% | |

| support_material_pattern = rectilinear | |

| support_material_spacing = 2.5 | |

| support_material_speed = 60 | |

| support_material_synchronize_layers = 0 | |

| support_material_threshold = 0 | |

| support_material_with_sheath = 1 | |

| support_material_xy_spacing = 50% | |

| temperature = 250 | |

| thin_walls = 1 | |

| threads = 4 | |

| thumbnails = | |

| toolchange_gcode = | |

| top_fill_pattern = hilbertcurve | |

| top_infill_extrusion_width = 0 | |

| top_solid_infill_speed = 50% | |

| top_solid_layers = 3 | |

| top_solid_min_thickness = 0 | |

| travel_speed = 300 | |

| use_firmware_retraction = 0 | |

| use_relative_e_distances = 0 | |

| use_volumetric_e = 0 | |

| variable_layer_height = 1 | |

| wipe = 0 | |

| wipe_into_infill = 0 | |

| wipe_into_objects = 0 | |

| wipe_tower = 0 | |

| wipe_tower_bridging = 10 | |

| wipe_tower_no_sparse_layers = 0 | |

| wipe_tower_rotation_angle = 0 | |

| wipe_tower_width = 60 | |

| wipe_tower_x = 180 | |

| wipe_tower_y = 140 | |

| wiping_volumes_extruders = 70,70 | |

| wiping_volumes_matrix = 0 | |

| xy_size_compensation = 0 | |

| z_offset = 0 |