One of those LED spotlights may have barely outlasted its worthless warranty, but not by much, and has been languishing on the back of the bench with “Flickers hot” scrawled on its side.

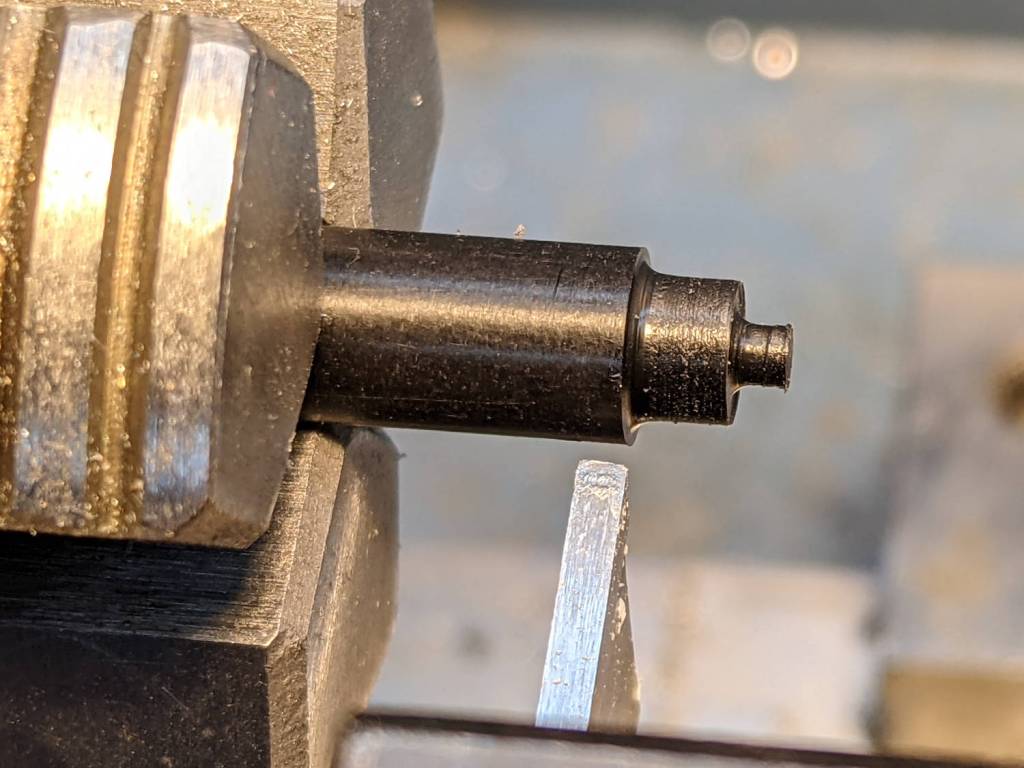

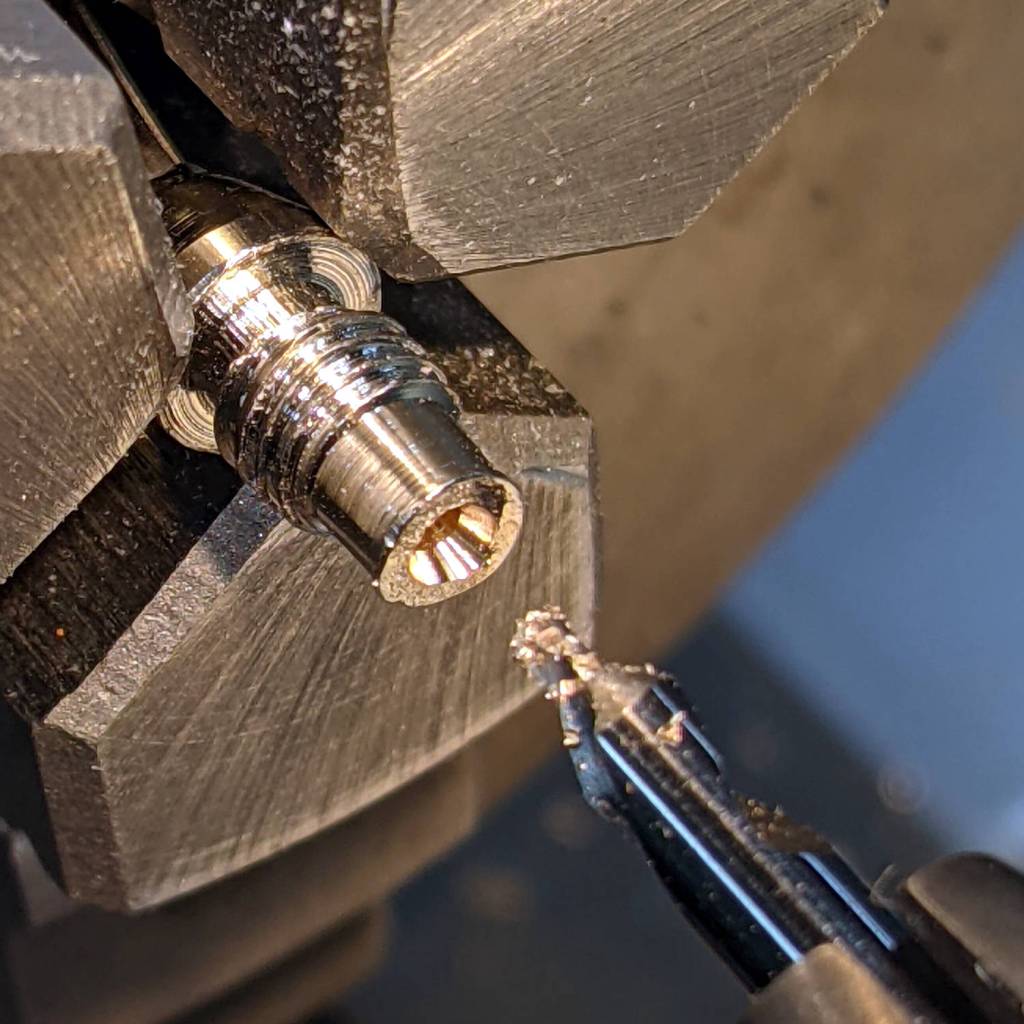

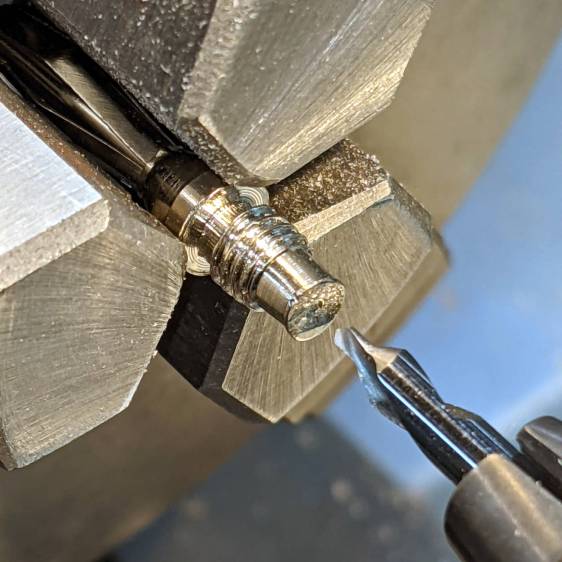

The metal base didn’t respond to twisting, so I slit the threads with a cutoff wheel:

Applying the screwdriver removed the base to reveal a silicone rubber casting:

The small wire emerging near the edge of the plastic case seems to be the neutral contact to the shell, with a poor enough joint to suggest it might have been why the lamp flickered when it got hot.

Some brute force snapped the silicone off at the bottom of the plastic case and broke the two wires bringing AC to the PCB:

Digging around inside produced a debris field of silicone crumbs, broken resistors, torn caps, and various other components, with zero progress toward removing the shell:

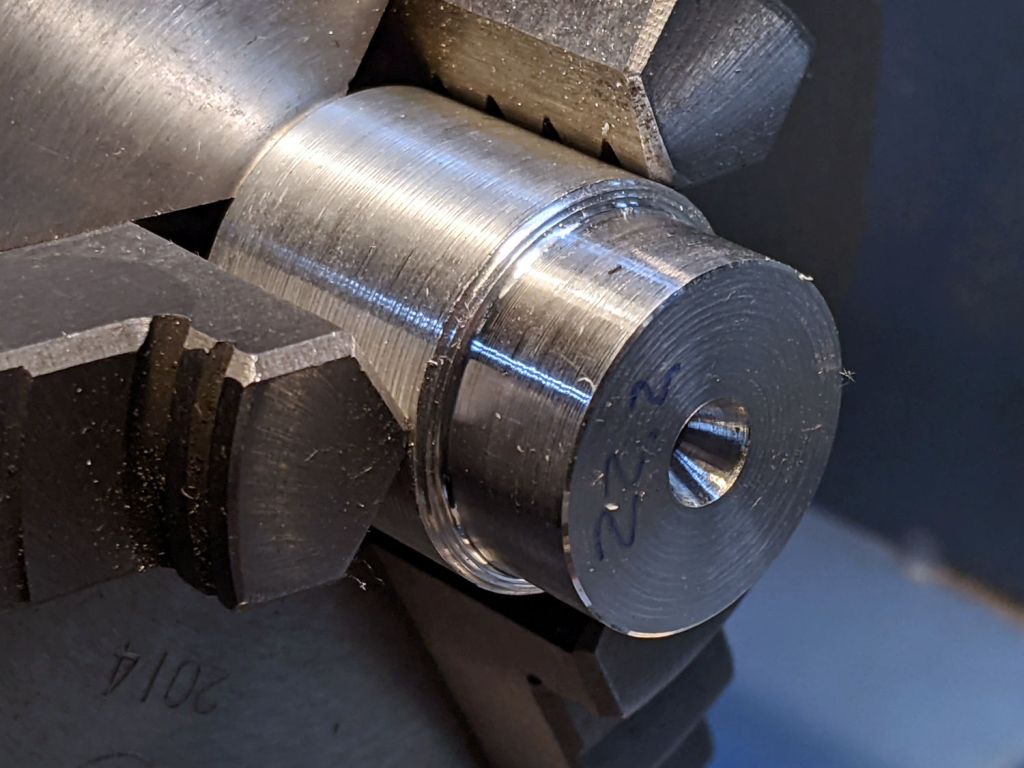

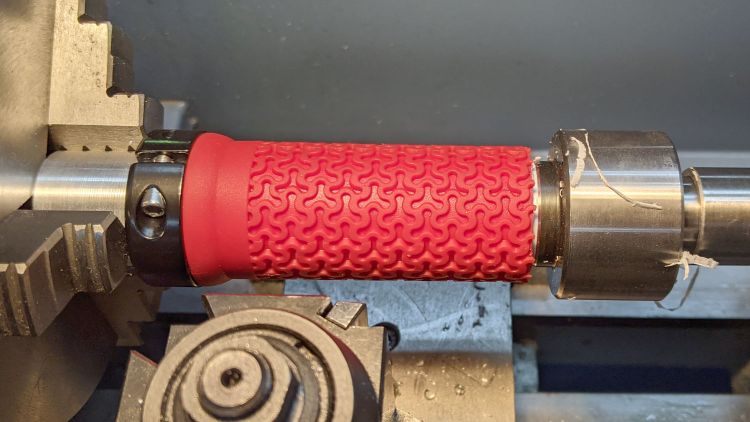

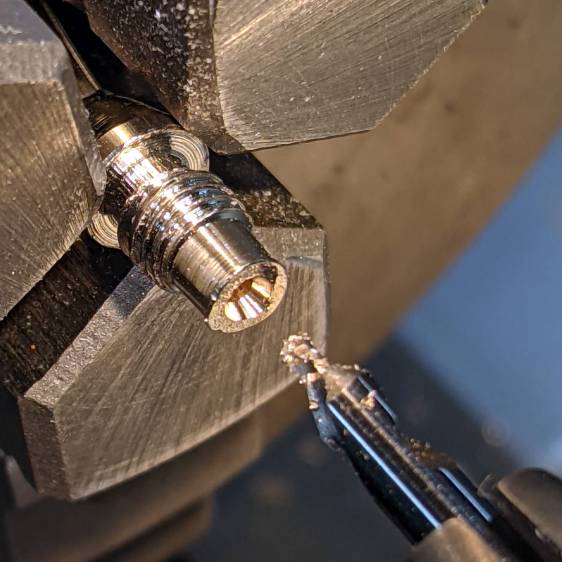

A little lathe work converted a chunk of PVC pipe into a crude mandrel supporting the mangled case:

A few millimeters of sissy cuts released a silicone O-ring sealing the shell against the reflector:

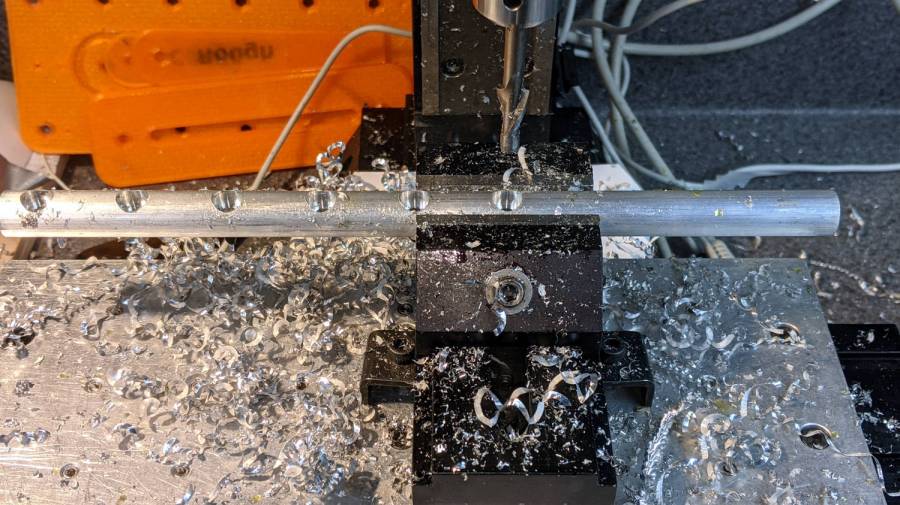

Continuing the cuts eventually revealed the three screws holding the shell to the reflector and the two wires powering the LED:

Chopping off the screws with a diagonal cutter freed the shell and revealed the top of the PCB:

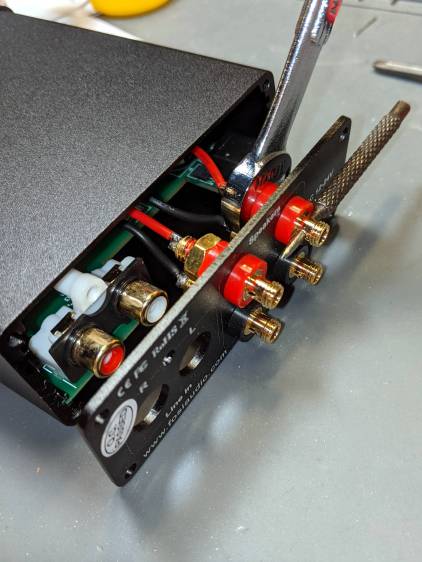

It really does have a surprising number of components!

Those three screws connected the LED panel / heatsink to the shell through the back of the double-walled reflector. More brute force peeled the outer shell away and released the panel:

Each of the 5050 packages contains a pair of white LEDs with 5.2 V forward drop for the pair, at the very low test current. They’re all in series, so you’re looking at well over 60 V total forward drop:

Note that the wiring, which nobody will ever see, follows the electrical color code of white = common and gray = hot.

Perhaps I should turn the lens into an interesting art object …