The cheese slicer frame looked much better after sandblasting with 220 aluminum oxide grit:

The flower bed outside the Basement Laboratory door seems a bit dusty, though.

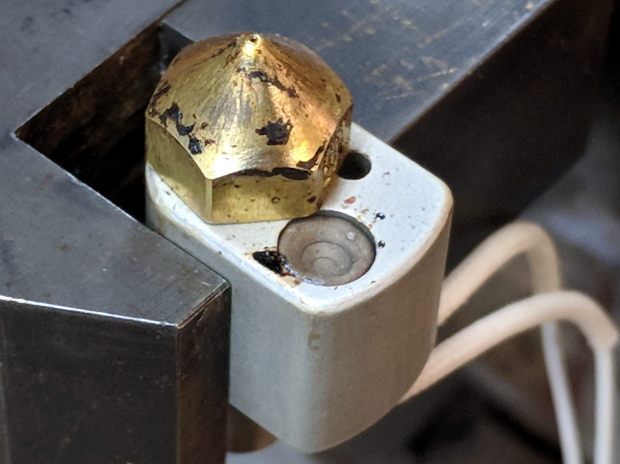

Slathering it with JB Weld steel-filled epoxy went reasonably well:

JB Weld is much much more viscous than the clear XTC-3D I used last year and the final coating, while smoother than what you see here, has too many sags and dents to say “good job”. I didn’t bother coating the upper tips, because the epoxy will wear off from my morning KP.

The aluminum roller turned on those bare stainless steel screws in the tray, with the threads chewing into the roller bore. While the epoxy was curing, I drilled out the roller to remove most of the ridges:

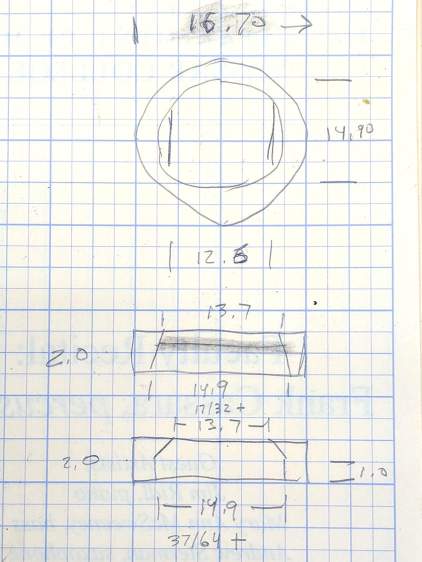

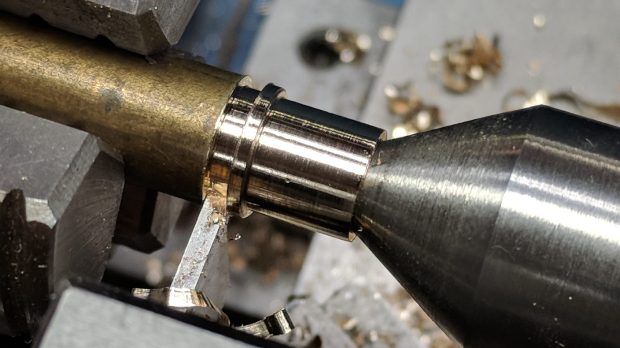

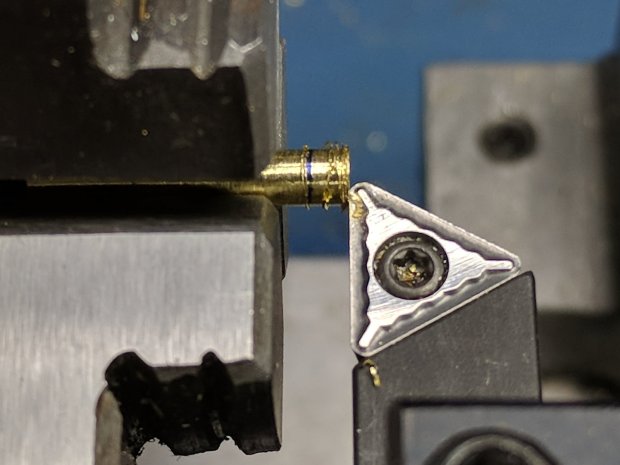

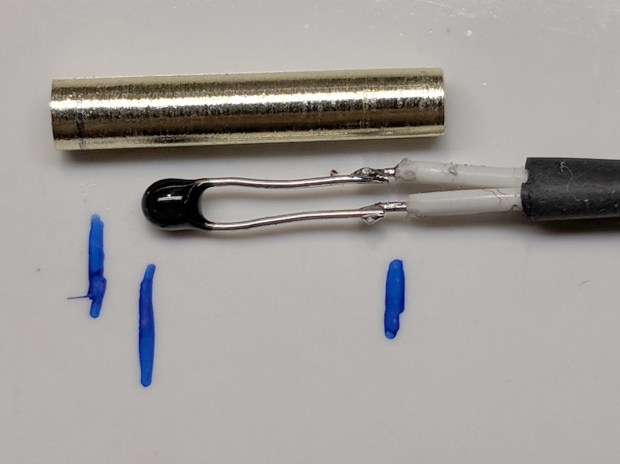

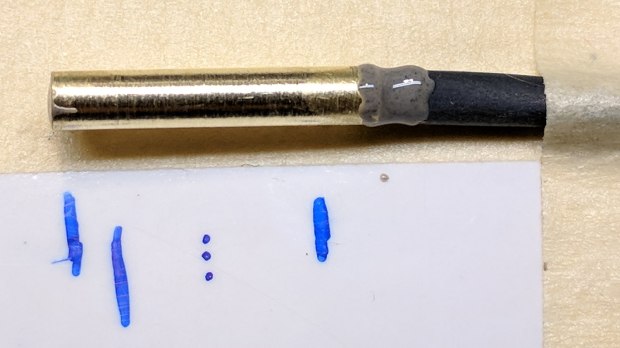

Cut a pair of stainless screws slightly longer than the old screws, then turn the threads off to make a shaft:

The lathe spindle runs in reverse, so the cutting force tends to tighten the screw in the nuts. The big old South Bend lathe had a screw-on chuck and didn’t really like turning backwards.

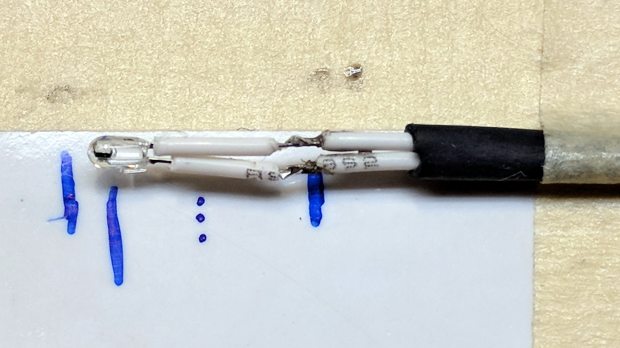

The new screws won’t win any beauty prizes, but they get the job done:

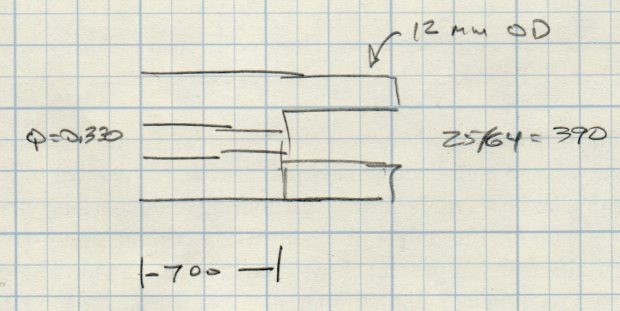

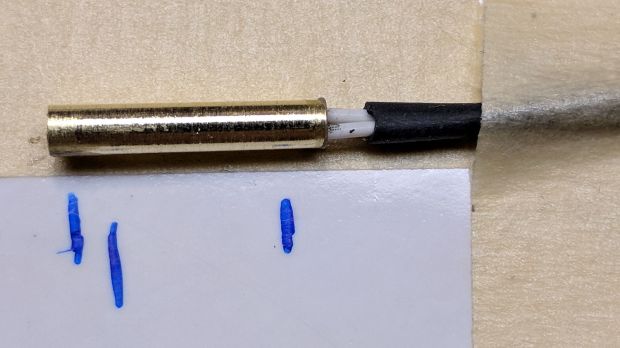

Turn a Delrin rod to a press fit in the drilled-out roller:

Part it off, repeat, ram them into the roller, then drill to a loose fit around the smooth-ish screw shafts:

Reassemble in reverse order:

Looks downright industrial, it does.

Stipulated: this makes no economic sense, absent the simple fact we appreciate utensils that just work.