|

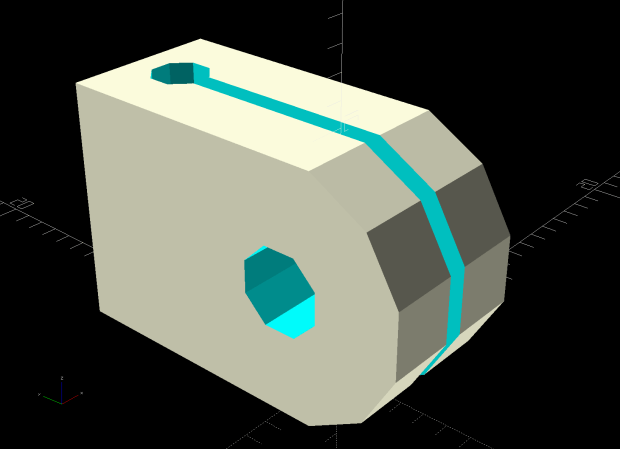

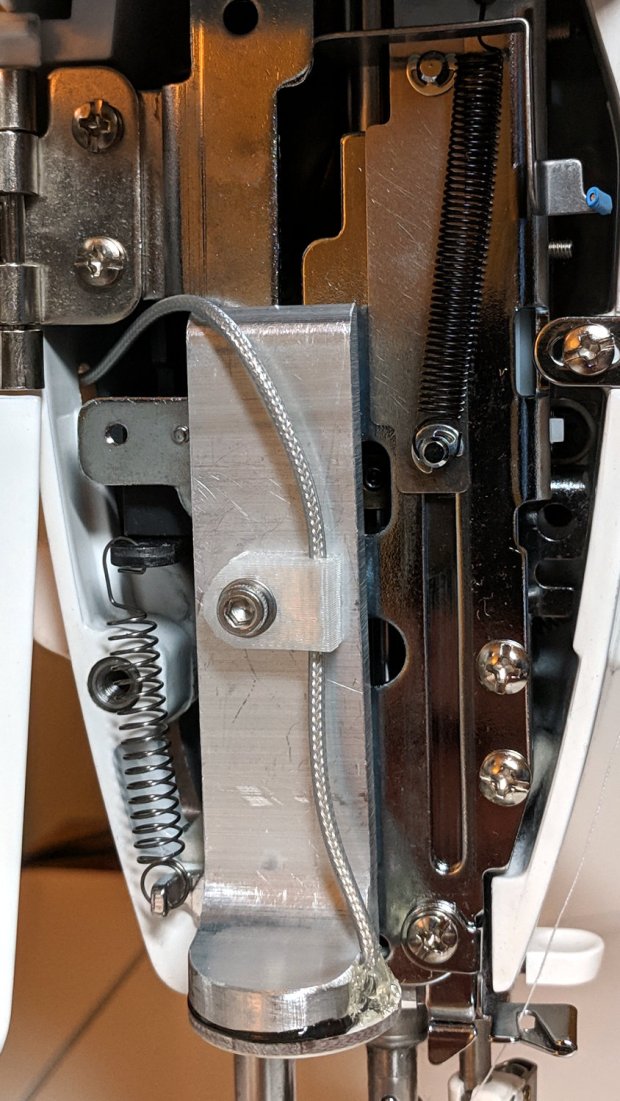

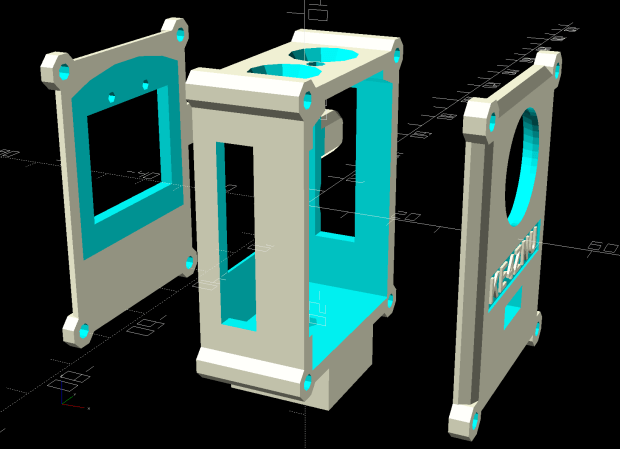

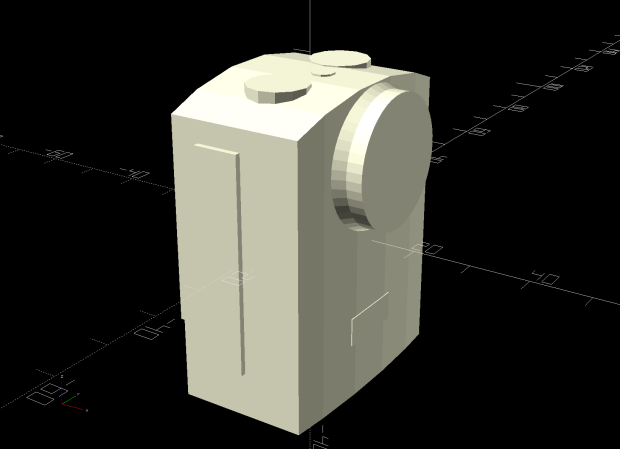

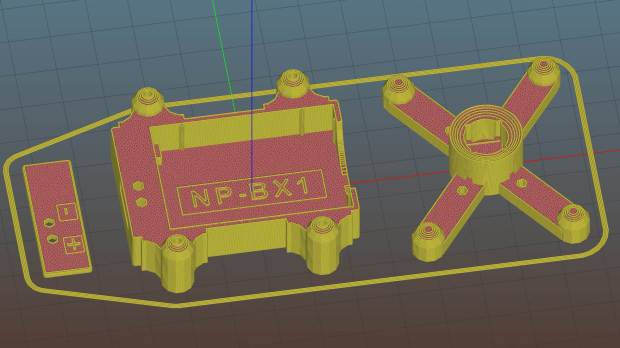

// SJCAM M20 Camera Mount for Tour Easy seat back rail |

|

// Ed Nisley – KE4ZNU |

|

// 2019-02 |

|

|

|

/* [Layout Options] */ |

|

|

|

Layout = "Fit"; // [Show,Fit,Build] |

|

|

|

Part = "Shell"; // [Cradle,Shell,Clamp,ShellSections,M20,Interposer,Battery,Buttons] |

|

|

|

LookAngle = [0,5,-25]; // camera angle, looking backwards |

|

|

|

|

|

/* [Extrusion Parameters] */ |

|

|

|

ThreadWidth = 0.40; |

|

ThreadThick = 0.25; |

|

|

|

HoleWindage = 0.2; |

|

|

|

Protrusion = 0.1; |

|

|

|

//—– |

|

// Dimensions |

|

|

|

/* [Hidden] */ |

|

|

|

ID = 0; |

|

OD = 1; |

|

LENGTH = 2; |

|

|

|

ClampScrew = [5.0,10.0,50.0]; // ID=thread OD=washer LENGTH=total |

|

ClampInsert = [5.0,7.5,10.5]; // brass insert |

|

|

|

MountScrew = [3.0,7.0,23]; // ID=thread OD=washer LENGTH=tune to fit clamp arch |

|

MountInsert = [3.0,4.95,8.0]; // ID=screw OD, OD=knurl dia |

|

|

|

EmbossDepth = 2*ThreadThick + Protrusion; // recess depth + Protrusion beyond surface |

|

|

|

DebossHeight = EmbossDepth; // text height + Protrusion into part |

|

|

|

Projection = 10; // stick-out to punch through shell sides & suchlike |

|

|

|

SupportColor = "Yellow"; |

|

FadeColor = "Green"; |

|

FadeAlpha = 0.25; |

|

|

|

//—– |

|

// Useful routines |

|

|

|

function IntegerMultiple(Size,Unit) = Unit * ceil(Size / Unit); |

|

|

|

module PolyCyl(Dia,Height,ForceSides=0) { // based on nophead's polyholes |

|

|

|

Sides = (ForceSides != 0) ? ForceSides : (ceil(Dia) + 2); |

|

|

|

FixDia = Dia / cos(180/Sides); |

|

|

|

cylinder(r=(FixDia + HoleWindage)/2, |

|

h=Height, |

|

$fn=Sides); |

|

} |

|

|

|

//—– |

|

// M20 Camera |

|

// Looks backwards from seat = usual right-hand coordinates work fine |

|

// X parallel to bike frame, Y parallel to seat strut, Z true vertical |

|

|

|

M20 = [24.5,40.5,54.0]; |

|

|

|

M20tm = 4.0; // chord height at top of case |

|

M20tr = (pow(M20tm,2) + pow(M20.y,2)/4) / (2*M20tm); // … radius |

|

echo(str("Top radius: ",M20tr)); |

|

|

|

M20TopSides = 3*3*4; |

|

echo(str(" … sides: ",M20TopSides)); |

|

|

|

M20fm = 1.0; // chord height at front of case |

|

M20fr = (pow(M20fm,2) + pow(M20.y,2)/4) / (2*M20fm); // … radius |

|

echo(str("Front radius: ",M20fr)); |

|

|

|

M20FrontSides = ceil(M20fr / M20tr * M20TopSides); // make arc sides match up |

|

echo(str(" … sides: ",M20FrontSides)); |

|

|

|

Lens = [19.0,22.5,5.5]; // ID=optical element, OD=tube |

|

LensBezel = [23.0,24.5,2.5]; // ID=lens tube, OD=bezel |

|

LensOffset = [-M20fm,0,41.5]; // bottom of case to lens centerline |

|

|

|

LensCap = [Lens[OD],24.5,4.5]; // silicone lens cap |

|

|

|

Spkr = [0.75,M20.y,14.3]; // speaker recess below LCD |

|

|

|

Switch = [8.0,1.0,38.0]; // selection switches |

|

SwitchOffset = [9.0,0,0]; // from rear to center of switches |

|

|

|

Jack = [10.0,0.1,36.0]; // jack and MicroSD card access, slightly enlarged |

|

JackOffset = [10.0,0,30.0]; // rear, bottom to center of jack block |

|

|

|

USB = [JackOffset.x – Jack.x/2,20.0,10.0]; // strut under USB plug |

|

USBOffset = [0,0,33.5]; // bottom to center of jack |

|

|

|

SDCard = [2.0,0.1,12.0]; // SD Card slot |

|

SDOffset = [9.0,0,20.0]; // bottom, rear to center of slot |

|

|

|

Button = [8.5,10.5,M20tm]; // ID = button, OD = bezel |

|

ButtonOC = 18.0; // on-center Y separation, assume X centered |

|

|

|

Screen = [0.1,31,24]; // LCD on rear face |

|

ScreenOffset = [0,0,33]; |

|

|

|

BarLEDs = [0.1 + M20fm,12.0,5.0]; // Bar LEDs on front face |

|

BarLEDsOffset = [-M20fm,0,12.5]; |

|

|

|

PwrLED = [3.5,3.5,0.1 + M20tm]; // power LED on top |

|

PwrLEDOffset = [2.5,0,0]; |

|

|

|

RearLEDs = [1.0,2.0,0.1]; // charge and power LED openings above LCD |

|

RearLEDsOffset = [0,13.0/2,M20tm + 3.0]; // .. from top center of case |

|

|

|

module Buttons(KO) { |

|

for (j = [-1,1]) |

|

translate([0,j*ButtonOC/2,0]) { |

|

cylinder(d=Button[OD],h=Button[LENGTH],$fn=12); |

|

if (KO) |

|

translate([0,0,M20tm]) |

|

cylinder(d1=Button[OD],d2=1.5*Button[OD],h=Button.z,$fn=12); |

|

} |

|

} |

|

|

|

module M20Shape(Knockout = false) { |

|

|

|

difference() { |

|

intersection() { |

|

translate([0,0,M20.z/2 – M20tr]) // top curve |

|

rotate([0,90,0]) rotate(180/M20TopSides) |

|

cylinder(r=M20tr,h=2*(M20.x + Protrusion),$fn=M20TopSides,center=true); |

|

translate([M20.x/2 – M20fr,0,0]) |

|

rotate(180/M20FrontSides) |

|

cylinder(r=M20fr,h=2*M20.z,$fn=M20FrontSides,center=true); |

|

cube(M20,center=true); |

|

} |

|

translate([Spkr.x/2 – M20.x/2 – Protrusion,0,Spkr.z/2 – Protrusion/2 – M20.z/2]) |

|

cube(Spkr + [Protrusion,2*Protrusion,Protrusion],center=true); |

|

} |

|

|

|

translate([M20.x/2,0,-M20.z/2] + LensOffset) |

|

rotate([0,90,0]) |

|

cylinder(d=Lens[OD] + HoleWindage,h=(Knockout ? Projection : Lens[LENGTH]),$fn=4*4*3,center=false); |

|

|

|

translate([M20.x/2 + M20fm/2,0,-M20.z/2] + LensOffset) // lens bezel |

|

rotate([0,90,0]) |

|

cylinder(d1=LensBezel[OD],d2=Lens[OD],h=LensBezel[LENGTH],$fn=4*4*3,center=false); |

|

|

|

translate([-M20.x/2 + SwitchOffset.x, // side switches |

|

-(Switch.y + M20.y – Protrusion)/2, |

|

0]) |

|

cube(Switch + [0,Protrusion,0] + (Knockout ? [0,Projection,0] : [0,0,0]),center=true); |

|

|

|

if (Knockout) |

|

translate([(M20.x/2 – M20fm)/2,-M20.y/2,0]) // side switch slide-in clearance |

|

cube([M20.x/2 – M20fm,2*Switch.y,Switch.z],center=true); |

|

|

|

translate([-M20.x/2 + JackOffset.x, |

|

(Jack.y + M20.y – Protrusion)/2, |

|

JackOffset.z – M20.z/2]) |

|

cube(Jack + [0,Protrusion,0] + (Knockout ? [0,Projection,0] : [0,0,0]),center=true); |

|

|

|

translate([0,0,M20.z/2 – M20tm]) // top control buttons |

|

Buttons(Knockout); |

|

|

|

if (Knockout) |

|

translate([(M20.x – M20fm)/4,0,M20.z/2 – M20tm + Button[LENGTH]/2]) // slide-in button clearance |

|

cube([(M20.x – M20fm)/2,ButtonOC + Button[OD],Button[LENGTH]],center=true); |

|

|

|

translate([-(M20.x + Screen.x – Protrusion)/2,0,-M20.z/2] + ScreenOffset) |

|

cube(Screen + [Protrusion,0,0] + (Knockout ? [Projection,0,0] : [0,0,0]),center=true); |

|

|

|

for (j = [-1,1]) |

|

translate([-M20.x/2 + Protrusion,j*RearLEDsOffset.y,M20.z/2 – RearLEDsOffset.z]) |

|

rotate([0,-90,0]) rotate(180/6) |

|

PolyCyl(RearLEDs[OD],Knockout ? Projection : RearLEDs[LENGTH],6); |

|

|

|

translate([M20.x/2 + BarLEDs.x/2,0,-M20.z/2] + BarLEDsOffset) |

|

cube(BarLEDs + (Knockout ? [Projection,0,0] : [0,0,0]),center=true); |

|

|

|

translate([0,0,M20.z/2 – M20tm] + PwrLEDOffset) |

|

rotate(180/8) |

|

PolyCyl(PwrLED[OD],(Knockout ? Projection : PwrLED[LENGTH]),8); |

|

|

|

if (Knockout) { |

|

translate([0,0,-M20.z/2]) |

|

rotate([180,0,0]) { // mounting screw |

|

PolyCyl(MountScrew[ID],MountScrew[LENGTH],6); |

|

translate([0,0,MountScrew[LENGTH] – Protrusion]) |

|

PolyCyl(MountScrew[OD],MountScrew[ID] + 4*ThreadThick,6); // SHCS head is about 1 ID long |

|

} |

|

|

|

translate([0,0,-(M20.z/2 + MountInsert[LENGTH] + 4*ThreadWidth – Protrusion)]) |

|

PolyCyl(MountInsert[OD],MountInsert[LENGTH] + 4*ThreadWidth,6); // insert inside Interposer |

|

} |

|

|

|

} |

|

|

|

//—– |

|

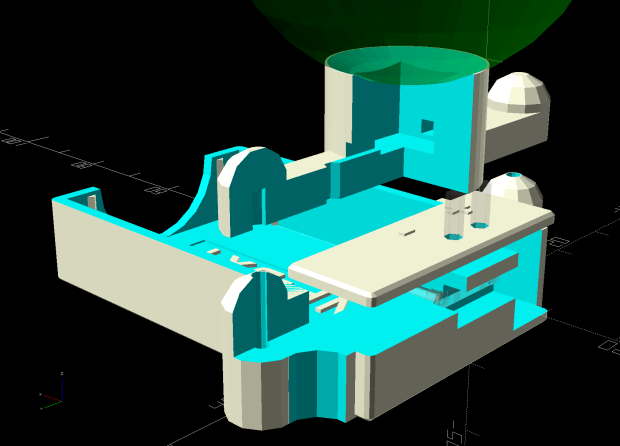

// Shell |

|

// Wraps around camera |

|

|

|

NomWall = 3.0; |

|

|

|

ShellWall = [IntegerMultiple(NomWall,ThreadThick), |

|

IntegerMultiple(NomWall,ThreadWidth), |

|

IntegerMultiple(NomWall,ThreadWidth)]; |

|

ShellRadius = ShellWall.x; |

|

ShellSides = 8; |

|

|

|

ShellOA = M20 + 2*ShellWall; |

|

echo(str("Shell OA: ",ShellOA)); |

|

|

|

Interposer = [M20.x – M20fm,M20.x – M20fm,10.0]; // if you can't be smart, be square |

|

|

|

module Shell() { |

|

|

|

Screw = [3.0,6.75,30]; // ID=thread OD=washer LENGTH |

|

ScrewClear = 1.0; // additional washer clearance |

|

ScrewSides = 8; |

|

|

|

ScrewOC = M20 + [0,Screw[ID]/cos(180/ScrewSides),Screw[ID]/cos(180/ScrewSides)]; // use PolyCyl hole dia, ignore .x value |

|

|

|

difference() { |

|

union() { |

|

hull() |

|

for (i=[-1,1], j=[-1,1], k=[-1,1]) |

|

translate([i*(ShellOA.x – 2*ShellRadius)/2, |

|

j*(ShellOA.y – 2*ShellRadius)/2, |

|

k*(ShellOA.z – 2*ShellRadius)/2]) |

|

sphere(r=ShellRadius/cos(180/ShellSides),$fn=ShellSides); // fix low-poly approx radius |

|

|

|

for (j=[-1,1], k=[-1,1]) // screw bosses, full length |

|

translate([0,j*ScrewOC.y/2,k*ScrewOC.z/2]) |

|

rotate([0,90,0]) rotate(180/ScrewSides) |

|

cylinder(d=Screw[OD] + ScrewClear,h=ShellOA.x,center=true,$fn=ScrewSides); |

|

|

|

translate([-(ShellOA.x – USB.x – ShellWall.x)/2, // USB plug support strut |

|

(M20.y + USB.y)/2 – ShellRadius, |

|

-M20.z/2] + USBOffset) |

|

hull() |

|

for (i=[-1,1], j=[-1,1], k=[-1,1]) |

|

translate([i*(USB.x + ShellWall.x – 2*ShellRadius)/2, |

|

j*(USB.y – 2*ShellRadius)/2, |

|

k*(USB.z – 2*ShellRadius)/2]) |

|

rotate(0*180/ShellSides) rotate([90,0,90]) |

|

sphere(r=ShellRadius/cos(180/ShellSides),$fn=ShellSides); |

|

|

|

translate([-M20fm/2,0,-ShellOA.z/2 – Interposer.z + Protrusion/2]) |

|

InterposerShape(Embiggen = false); |

|

} |

|

|

|

render(convexity=4) // remove camera shape from interior |

|

M20Shape(Knockout = true); |

|

|

|

for (j=[-1,1], k=[-1,1]) // screw bores |

|

translate([-ShellOA.x,j*ScrewOC.y/2,k*ScrewOC.z/2]) |

|

rotate([0,90,0]) rotate(180/ScrewSides) |

|

PolyCyl(Screw[ID],2*ShellOA.x,ScrewSides); |

|

|

|

translate([ShellOA.x/2 – ThreadThick + Protrusion/2,0,-5]) // recess for legend |

|

cube([EmbossDepth,ShellOA.y – 12,7],center=true); |

|

|

|

translate([0,(M20.y + 1.5*SDCard.z)/2 + ThreadWidth,-M20.z/2 + SDOffset.z]) |

|

resize([M20.x,0,0]) |

|

sphere(d=1.5*SDCard.z,$fn=24); |

|

|

|

} |

|

|

|

translate([ShellOA.x/2 – DebossHeight,0,-5]) |

|

rotate([90,0,90]) |

|

linear_extrude(height=DebossHeight,convexity=20) |

|

text(text="KE4ZNU",size=5,spacing=1.20,font="Arial:style:Bold",halign="center",valign="center"); |

|

|

|

|

|

// Totally ad-hoc support structures |

|

|

|

if (false) |

|

color(SupportColor) { |

|

for (j=[-1,1], k=[0,1]) |

|

translate([-ShellOA.x/2 + Screw[LENGTH],j*ShellOA.y/2,k*ShellOA.z]) |

|

rotate([0,90,0]) |

|

SupportScrew(Dia=Screw[OD] + ScrewClear,Length=ShellOA.x – Screw[LENGTH],Num=ScrewSides); |

|

} |

|

} |

|

|

|

// Generate support structure for screw boss |

|

|

|

module SupportScrew(Dia,Length,Num = 6) { |

|

for (a=[0 : 360/Num : 360/2]) |

|

rotate(a) |

|

translate([0,0,(Length + ThreadThick)/2]) |

|

cube([Dia – 2*ThreadWidth,2*ThreadWidth,Length – ThreadThick],center=true); |

|

} |

|

|

|

// Generate interposer block |

|

// Origin at center bottom surface for E-Z rotation |

|

|

|

module InterposerShape(Embiggen = false) { |

|

|

|

translate([0,0,Interposer.z/2]) |

|

if (Embiggen) { |

|

minkowski() { |

|

cube(Interposer,center=true); |

|

cube(HoleWindage,center=true); |

|

} |

|

} |

|

else |

|

cube(Interposer + [-Protrusion,0,Protrusion],center=true); // avoid slivers, merge with shell |

|

} |

|

|

|

// Cut shell sections for printing |

|

// "Front" = lens end, toward +X direction |

|

// origin centered on M20.xyz and ShellOA.xyz |

|

|

|

module ShellSection(Section="Front") { |

|

|

|

if (Section == "Front") // include front curve |

|

intersection() { |

|

Shell(); |

|

translate([ShellOA.x – (M20fm + ShellWall.x),0,0]) |

|

cube([ShellOA.x,2*ShellOA.y,2*ShellOA.z],center=true); |

|

} |

|

else if (Section == "Center") // exclude front curve for E-Z printing |

|

intersection() { |

|

Shell(); |

|

translate([-M20fm/2,0,0]) |

|

cube([M20.x – M20fm,2*ShellOA.y,2*ShellOA.z],center=true); |

|

} |

|

else if (Section == "Back") // flush with LCD on rear face |

|

intersection() { |

|

Shell(); |

|

translate([-ShellOA.x + (ShellWall.x),0,0]) |

|

cube([ShellOA.x,2*ShellOA.y,2*ShellOA.z],center=true); |

|

} |

|

|

|

} |

|

|

|

//—– |

|

// Clamp |

|

// Grips seat frame rail |

|

// Uses shell rounding values for tidiness |

|

// Adjust MountScrew[LENGTH] to put head more-or-less flush with clamp arch |

|

|

|

RailOD = 20.0; // slightly elliptical in bent section |

|

RailSides = 2*3*4; |

|

|

|

ClampOA = [60.0,40.0,ClampScrew[LENGTH]]; // set clamp size to avoid weird screw spacing |

|

echo(str("Clamp OA: ",ClampOA)); |

|

|

|

ClampOffset = 0.0; // raise clamp to allow more room for mount |

|

|

|

ClampTop = ClampOA.z/2 + ClampOffset; |

|

InsertCap = 6*ThreadThick; // fill layers atop inserts |

|

|

|

Kerf = 2.0; |

|

|

|

module Clamp(Support = false) { |

|

|

|

RibThick = 2*ThreadWidth; |

|

NumRibs = IntegerMultiple(ceil(ClampOA.y / 4.0),2); // space ribs roughly 4 mm apart |

|

RibSpace = ClampOA.y / NumRibs; |

|

echo(str("Ribs: ",NumRibs," spaced: ",RibSpace)); |

|

|

|

ClampScrewOC = IntegerMultiple(ClampOA.x – ClampScrew[OD] – 10*ThreadWidth,1.0); |

|

echo(str("ClampScrew OC: ",ClampScrewOC)); |

|

|

|

difference() { |

|

hull() |

|

for (i=[-1,1], j=[-1,1], k=[-1,1]) |

|

translate([i*(ClampOA.x – 2*ShellRadius)/2, |

|

j*(ClampOA.y – 2*ShellRadius)/2, |

|

k*(ClampOA.z – 2*ShellRadius)/2 + ClampOffset]) |

|

sphere(r=ShellRadius/cos(180/ShellSides),$fn=ShellSides); |

|

|

|

cube([2*ClampOA.x,2*ClampOA.y,Kerf],center=true); // split across middle |

|

|

|

rotate([90,0,0]) // seat rail |

|

cylinder(d=RailOD,h=2*ClampOA.y,$fn=RailSides,center=true); |

|

|

|

for (i=[-1,1]) // clamp inserts |

|

translate([i*ClampScrewOC/2,0,0]) |

|

rotate(180/6) |

|

PolyCyl(ClampInsert[OD],ClampTop – InsertCap,6); |

|

|

|

for (i=[-1,1]) // clamp screw clearance |

|

translate([i*ClampScrewOC/2,0,-(ClampOA.z/2 – ClampOffset) – InsertCap]) |

|

rotate(180/6) |

|

PolyCyl(ClampScrew[ID],ClampOA.z,6); |

|

|

|

translate([0,0,ClampTop + 0.7*Interposer.z]) // mounting bolt hole |

|

rotate(LookAngle) |

|

translate([0,0,ShellOA.z/2]) { |

|

M20Shape(Knockout = true); |

|

translate([0,0,-ShellOA.z/2 – Interposer.z]) |

|

InterposerShape(Embiggen = true); |

|

} |

|

|

|

translate([ClampOA.x/2 – (EmbossDepth – Protrusion)/2, // recess for LookAngle.z |

|

0, |

|

ClampOA.z/4 + ClampOffset]) |

|

cube([EmbossDepth,17,8],center=true); |

|

|

|

translate([0.3*ClampOA.x, // recess for LookAngle.z |

|

-(ClampOA.y/2 – (EmbossDepth – Protrusion)/2), |

|

ClampOA.z/4 + ClampOffset]) |

|

cube([10,EmbossDepth,8],center=true); |

|

|

|

translate([0,0,-ClampOA.z/2 + (EmbossDepth – Protrusion)/2]) // recess bottom legend |

|

cube([35,10,EmbossDepth],center=true); |

|

} |

|

|

|

translate([ClampOA.x/2 – DebossHeight,0,ClampOA.z/4 + ClampOffset]) // LookAngle.z legend |

|

rotate([90,0,90]) |

|

linear_extrude(height=DebossHeight,convexity=20) |

|

text(text=str(LookAngle.z),size=6,spacing=1.20, |

|

font="Arial:style:Bold",halign="center",valign="center"); |

|

|

|

translate([0.3*ClampOA.x,-ClampOA.y/2 + DebossHeight + Protrusion/2,ClampOA.z/4 + ClampOffset]) // LookAngle.y legend |

|

rotate([90,0,00]) |

|

linear_extrude(height=DebossHeight,convexity=20) |

|

text(text=str(LookAngle.y),size=6,spacing=1.20, |

|

font="Arial:style:Bold",halign="center",valign="center"); |

|

|

|

translate([0,0,-ClampOA.z/2]) |

|

linear_extrude(height=DebossHeight,convexity=20) |

|

mirror([0,1,0]) |

|

text(text="KE4ZNU",size=5,spacing=1.20, |

|

font="Arial:style:Bold",halign="center",valign="center"); |

|

|

|

|

|

if (Support) { |

|

difference() { |

|

color(SupportColor) |

|

union() { |

|

for (j=[-NumRibs/2:NumRibs/2]) |

|

translate([0,j*RibSpace,0]) |

|

rotate([90,0,0]) |

|

cylinder(d=RailOD – 2*ThreadThick,h=RibThick,$fn=2*3*4,center=true); |

|

cube([RailOD – 4*ThreadWidth,NumRibs*RibSpace,Kerf + 2*ThreadThick],center=true); |

|

} |

|

cube([2*ClampOA.x,2*ClampOA.y,Kerf],center=true); // split across middle |

|

} |

|

} |

|

|

|

} |

|

|

|

|

|

//—– |

|

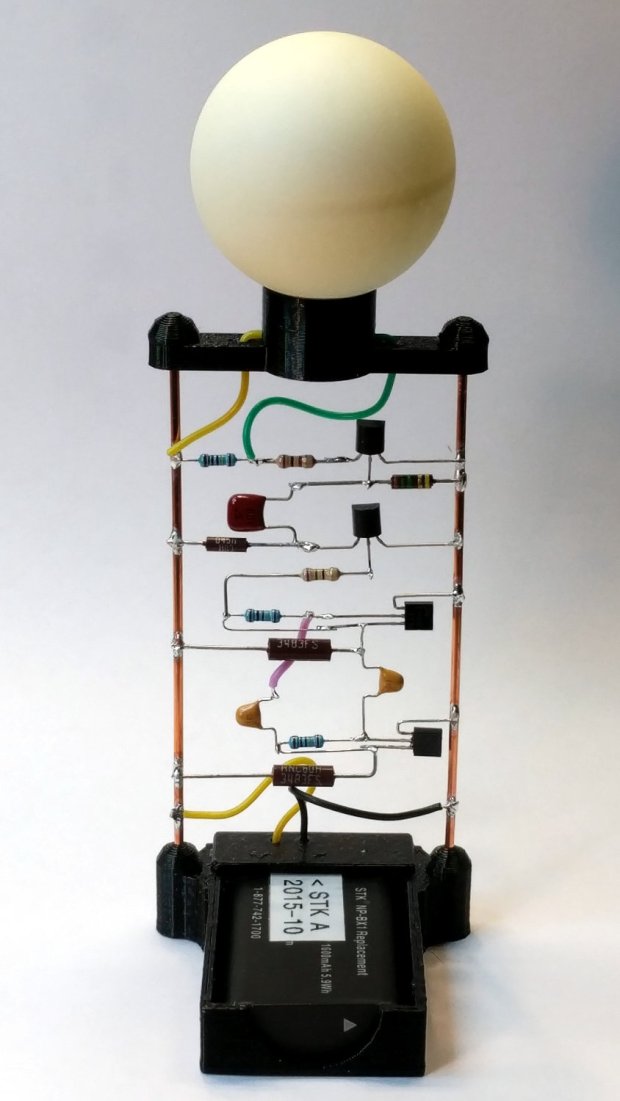

// Battery |

|

// Based on Anker PowerCore, simplified shapes |

|

// Includes port & button punchouts |

|

|

|

Battery = [97.5,80.0,22.5]; // X=length, Y includes rounded edges, Z = Y dia |

|

|

|

module BatteryShape() { |

|

|

|

USB = [Projection,38,10]; // clearance around USB output ports |

|

USBOffset = [0,25.5,0]; // from -Y edge to center of USB block |

|

|

|

ChargeBtn = [11.0 + 5.0,10,5.0 + 5.0]; // charge level check button, enlarged |

|

Btnc = ChargeBtn.z; // figure button recess into battery curve |

|

Btnr = Battery.z/2; |

|

Btnm = Btnr – sqrt(pow(Btnr,2) – pow(Btnc,2)/4); |

|

ChargeBtnOffset = [17.0,0,0]; // from +X edge to center, centered on Z |

|

|

|

BatterySides = 2*3*4; |

|

|

|

hull() |

|

for (j=[-1,1]) |

|

translate([0,j*(Battery.y – Battery.z)/2,0]) |

|

rotate([0,90,0]) |

|

cylinder(d=Battery.z,h=Battery.x,$fn=BatterySides,center=true); |

|

translate([(Battery.x + USB.x)/2 – Protrusion,-Battery.y/2 + USBOffset.y,0]) |

|

cube(USB,center=true); |

|

translate([Battery.x/2 – ChargeBtnOffset.x,Battery.y/2 + ChargeBtn.y/2 – 2*Btnm,0]) |

|

cube(ChargeBtn,center=true); |

|

} |

|

|

|

//—– |

|

// Battery cradle |

|

|

|

RackWidth = 89.0; // flat width between rack rails |

|

|

|

CradleWall = [4.0,4.0,3.0]; // wall thickness |

|

CradleRadius = 2.0; // corner rounding |

|

|

|

CradlePad = 0.5; // cushion around battery |

|

BatteryBase = CradleWall.z + CradlePad; // actual bottom surface of battery |

|

|

|

CradleOA = [Battery.x + 2*CradleWall.x, |

|

min((Battery.y + 2*CradleWall.y),RackWidth), |

|

BatteryBase + Battery.z/3]; |

|

echo(str("Cradle OA: ",CradleOA)); |

|

|

|

module Cradle() { |

|

|

|

difference() { |

|

hull() |

|

for (i=[-1,1], j=[-1,1]) { // box with tidy rounded corners |

|

translate([i*(CradleOA.x/2 – CradleRadius), |

|

j*(CradleOA.y/2 – CradleRadius), |

|

1*(CradleOA.z – CradleRadius)]) |

|

sphere(r=CradleRadius,$fn=6); |

|

translate([i*(CradleOA.x/2 – CradleRadius), |

|

j*(CradleOA.y/2 – CradleRadius), |

|

0*(CradleOA.z/2 – CradleRadius)]) |

|

cylinder(r=CradleRadius,h=CradleOA.z/2,$fn=6); |

|

} |

|

|

|

translate([0,0,Battery.z/2 + BatteryBase]) // minus the battery |

|

minkowski(convexity=3) { // … slightly embiggened |

|

BatteryShape(); |

|

cube(2*CradlePad,center=true); |

|

} |

|

|

|

if (false) // reveal insets for debug |

|

translate([0,0,-Protrusion]) |

|

cube(CradleOA + [0,0,CradleOA.z],center=false); |

|

|

|

translate([0,0,CradleWall.z – ThreadThick + Protrusion/2]) // recess top legend |

|

cube([55,20,EmbossDepth],center=true); |

|

translate([0,0,(EmbossDepth – Protrusion)/2]) // recess bottom legend |

|

cube([70,15,EmbossDepth],center=true); |

|

} |

|

|

|

translate([0,4.0,CradleWall.z – DebossHeight – Protrusion]) |

|

linear_extrude(height=DebossHeight,convexity=20) |

|

text(text="PowerCore",size=6,spacing=1.20, |

|

font="Arial:style:Bold",halign="center",valign="center"); |

|

|

|

translate([0,-4.0,CradleWall.z – DebossHeight – Protrusion]) |

|

linear_extrude(height=DebossHeight,convexity=20) |

|

text(text="13000",size=6,spacing=1.20, |

|

font="Arial:style:Bold",halign="center",valign="center"); |

|

|

|

linear_extrude(height=DebossHeight,convexity=20) |

|

mirror([0,1,0]) |

|

text(text="KE4ZNU",size=10,spacing=1.20, |

|

font="Arial:style:Bold",halign="center",valign="center"); |

|

|

|

|

|

} |

|

|

|

|

|

//—– |

|

// Build things |

|

|

|

// Layouts for design & tweaking |

|

|

|

if (Layout == "Show") |

|

|

|

if (Part == "Battery") |

|

BatteryShape(); |

|

|

|

else if (Part == "Buttons") |

|

Buttons(); |

|

|

|

else if (Part == "Interposer") |

|

InterposerShape(Embiggen = false); |

|

|

|

else if (Part == "Shell") |

|

Shell(); |

|

|

|

else if (Part == "M20") |

|

M20Shape(Knockout = false); |

|

|

|

else if (Part == "ShellSections") { |

|

translate([ShellOA.x,0,0]) |

|

ShellSection(Section="Front"); |

|

translate([0,0,0]) |

|

ShellSection(Section="Center"); |

|

translate([-ShellOA.x,0,0]) |

|

ShellSection(Section="Back"); |

|

} |

|

|

|

else if (Part == "Clamp") { |

|

Clamp(Support = false); |

|

color(FadeColor,FadeAlpha) |

|

rotate([90,0,0]) |

|

cylinder(d=RailOD,h=2*ClampOA.y,$fn=RailSides,center=true); |

|

} |

|

|

|

else if (Part == "Cradle") { |

|

Cradle(); |

|

translate([0,0,Battery.z/2 + CradleWall.z]) |

|

color(FadeColor,FadeAlpha) |

|

BatteryShape(); |

|

} |

|

|

|

// Build layouts for top-level parts |

|

|

|

if (Layout == "Build") |

|

|

|

if (Part == "Cradle") |

|

Cradle(); |

|

|

|

else if (Part == "Clamp") { |

|

translate([0,0.7*ClampOA.y,0]) |

|

difference() { |

|

translate([0,0,-Kerf/2]) |

|

Clamp(Support = true); |

|

translate([0,0,-ClampOA.z]) |

|

cube(2*ClampOA,center=true); |

|

} |

|

translate([0,-0.7*ClampOA.y,-0]) |

|

difference() { |

|

translate([0,0,-Kerf/2]) |

|

rotate([0,180,0]) |

|

Clamp(Support = true); |

|

translate([0,0,-ClampOA.z]) |

|

cube(2*ClampOA,center=true); |

|

} |

|

} |

|

|

|

else if (Part == "Shell") { |

|

translate([0,-1.2*ShellOA.y,ShellOA.x/2]) |

|

rotate([0,90,180]) |

|

ShellSection(Section="Front"); |

|

translate([0,0,M20.x/2]) |

|

rotate([0,-90,0]) |

|

ShellSection(Section="Center"); |

|

translate([0,1.4*ShellOA.y,ShellOA.x/2]) |

|

rotate([0,-90,180]) |

|

ShellSection(Section="Back"); |

|

} |

|

|

|

// Ad-hoc arrangement to see how it all goes together |

|

|

|

if (Layout == "Fit") { |

|

rotate(180) { |

|

Cradle(); |

|

translate([0,0,Battery.z/2 + CradleWall.z]) |

|

color(FadeColor,FadeAlpha) |

|

BatteryShape(); |

|

} |

|

translate([0,-100,0]) { |

|

Clamp(); |

|

color(FadeColor,FadeAlpha) |

|

rotate([90,0,0]) |

|

cylinder(d=RailOD,h=2*ClampOA.y,$fn=RailSides,center=true); |

|

} |

|

|

|

translate([0,-100,(ClampOA.z + ShellOA.z)/2 + Interposer.z]) |

|

translate([0,0,-ShellOA.z/2 + Interposer.z]) |

|

rotate(LookAngle) |

|

translate([0,0,ShellOA.z/2]) { |

|

Shell(); |

|

color(FadeColor,FadeAlpha) |

|

M20Shape(Knockout = false); |

|

} |

|

} |

|

|