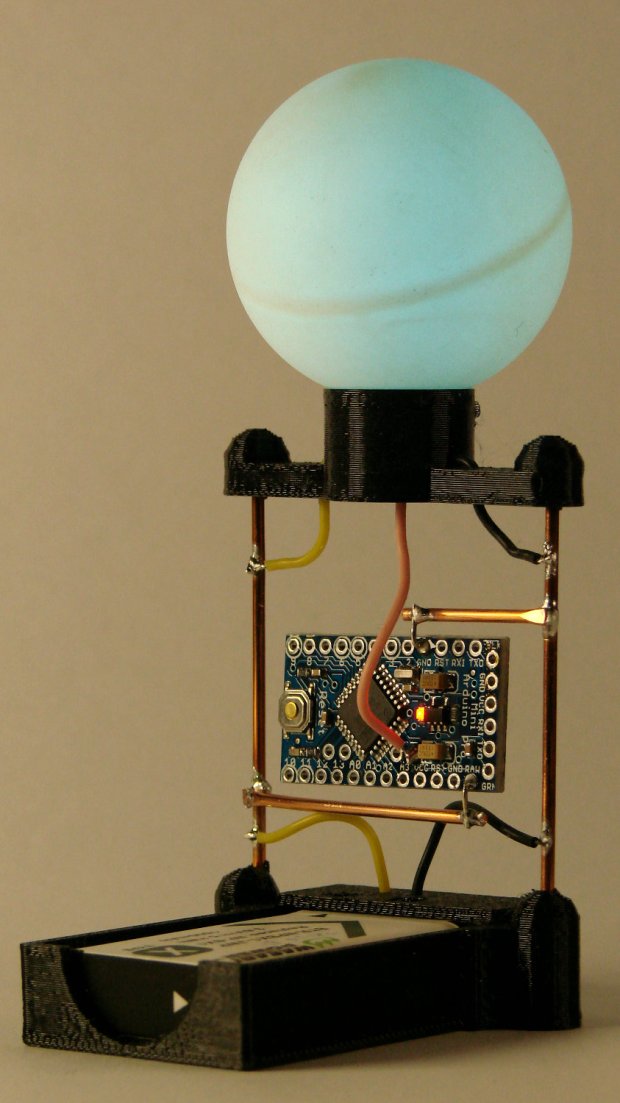

The wires to my earlier LED lights on Mary’s Kenmore 158 produced one absolute requirement: the Juki TL-2010Q lights must not have any external wiring. Some experimentation showed putting the COB LED module across the rear of the arm, just over the opening, would spill enough light to the front:

Juki’s teeny OEM SMD LED in the endcap, just above the far side of the needle, casts a dim glow over her left hand. Although they deem it sufficient, I’ll fix that in the near future.

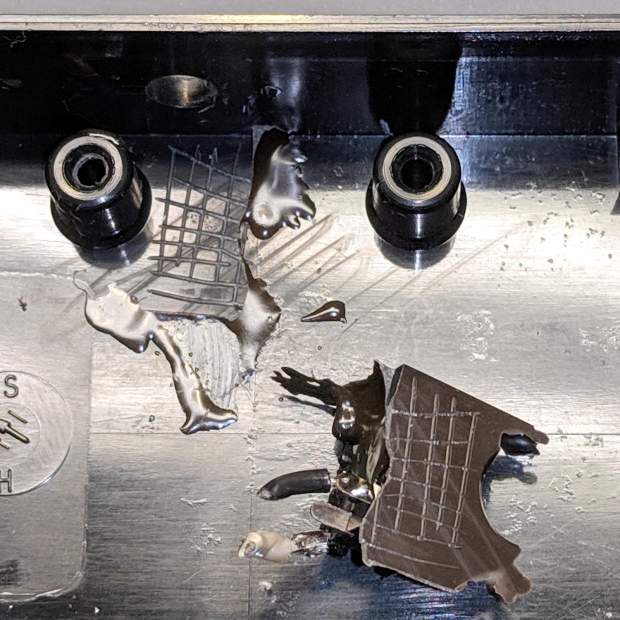

The machine’s power supply and drive motor live inside a plastic cover on the rear of the machine, just to the left of where the LED lights will attach to the arm:

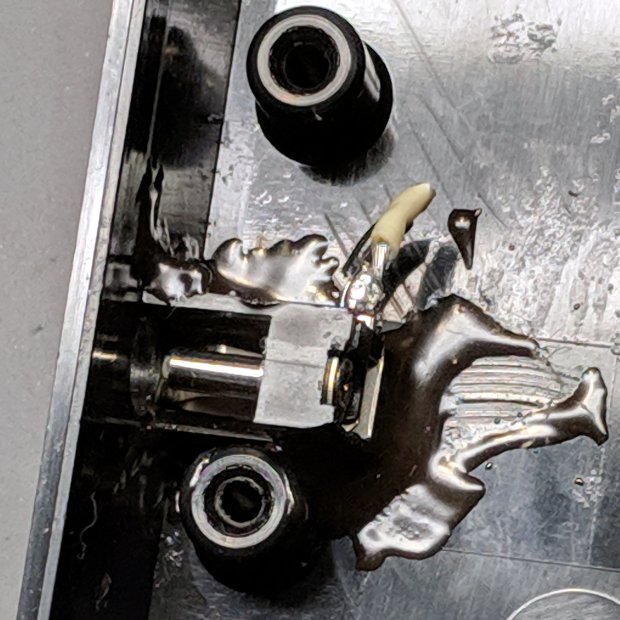

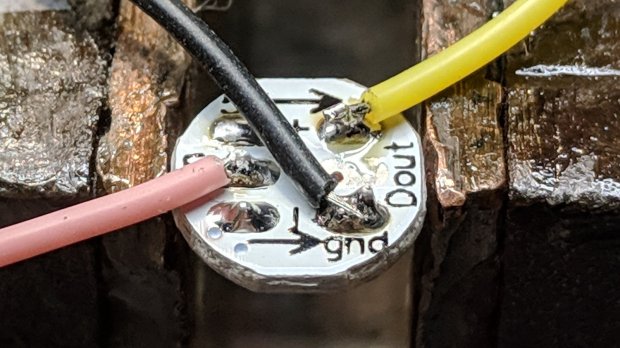

For future reference, a detailed look at the PCB:

The yellow-and-blue pair come from the AC power line switch. The brown-and-blue pair carry +120 VDC from the bridge rectifier (left of their connector) to the motor driver. The white-and-blue pair carry filtered 120 VAC from the PCB to the bulky transformer below the motor.

I snipped the white-and-blue pair, added Y connections, and threaded the wires through the vent slots to the 12 VDC power supply:

If I had to do it again, I’d cut the white-and-blue pair an inch further away from the transformer, so as to move the butt splice connectors around the corner of the frame, rather than across the back of the transformer frame. The flanged screw boss pretty well fills the space left of the transformer and made it difficult to arrange the new connectors.

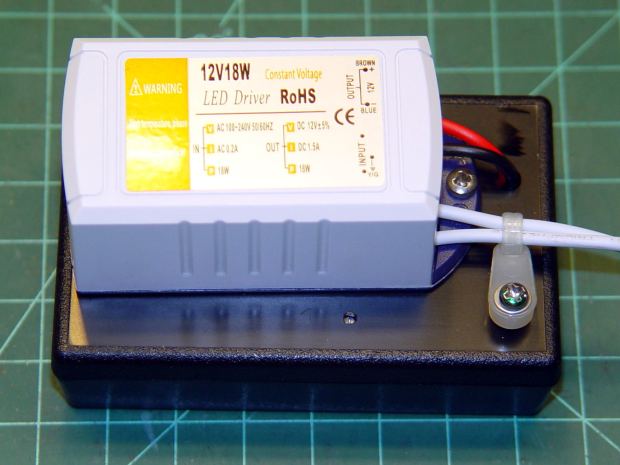

The 12 VDC 18 W LED supply attaches to the 120 VAC lines with 1/4 inch quick-disconnects, making it possible, if not easy, to completely remove the cover and LED power supply. You’d install dummy plugs in the vacant QD sockets to keep the AC out of harm’s way.

There’s just enough space to the right of the PCB enclosure to route the LED wires around-and-down to meet the wire nuts. They’re not the most elegant connectors you’ve ever seen, but wire nuts are impossible to confuse with the QD connectors on the AC line.

With that in hand, the power supply almost looks like it grew under the spool flange:

In an ideal world, the label would be right-side-up, but ya can’t have everything. The wires had to be where they are, primarily to avoid snagging on fabric passing through the machine.

The green-and-black PET braid covers the AC wires to make them a little less exposed, but it’s surely unnecessary. I gently singed the braid ends to prevent unraveling.

The COB LED supply wires emerge through a slot filed in the cover:

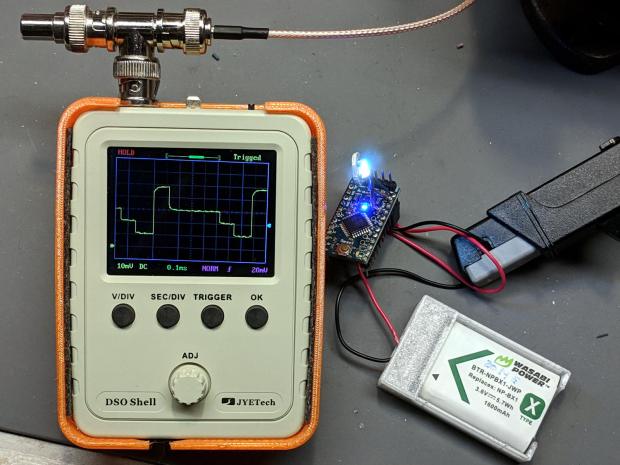

Next step: LED brightness tweakage.