|

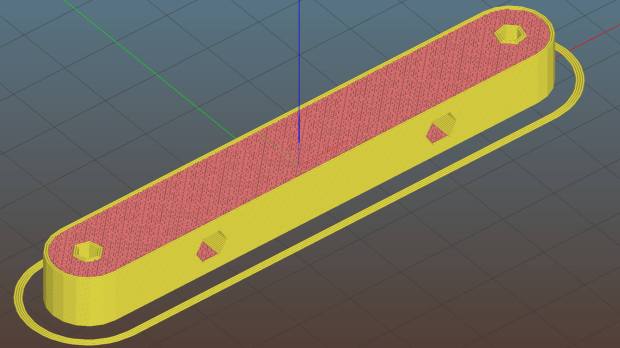

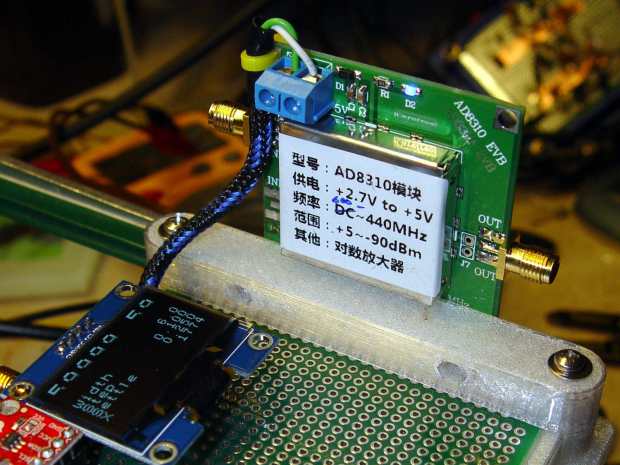

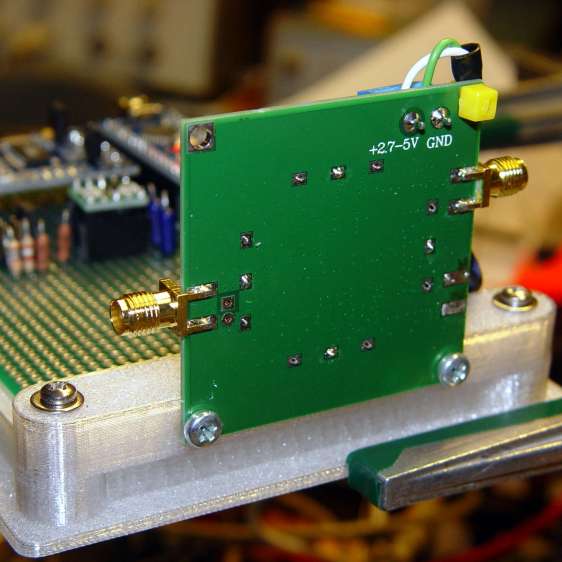

// Test support frame for proto boards |

|

// Ed Nisley KE4ZNU – Jan 2017 |

|

// June 2017 – Add side-mount bracket |

|

|

|

Layout = "Bracket"; |

|

|

|

ClampFlange = true; |

|

|

|

Channel = false; |

|

|

|

//- Extrusion parameters – must match reality! |

|

|

|

ThreadThick = 0.25; |

|

ThreadWidth = 0.40; |

|

|

|

function IntegerMultiple(Size,Unit) = Unit * ceil(Size / Unit); |

|

|

|

Protrusion = 0.1; |

|

|

|

HoleWindage = 0.2; |

|

|

|

//- Screw sizes |

|

|

|

inch = 25.4; |

|

|

|

Tap4_40 = 0.089 * inch; |

|

Clear4_40 = 0.110 * inch; |

|

Head4_40 = 0.211 * inch; |

|

Head4_40Thick = 0.065 * inch; |

|

Nut4_40Dia = 0.228 * inch; |

|

Nut4_40Thick = 0.086 * inch; |

|

Washer4_40OD = 0.270 * inch; |

|

Washer4_40ID = 0.123 * inch; |

|

|

|

ID = 0; |

|

OD = 1; |

|

LENGTH = 2; |

|

|

|

Insert = [3.9,4.6,5.8]; |

|

|

|

//- PCB sizes |

|

|

|

PCBSize = [80.0,120.0,1.6]; |

|

PCBShelf = 1.5; |

|

|

|

Clearance = 2*[ThreadWidth,ThreadWidth,0]; |

|

|

|

WallThick = 4.0; |

|

FrameHeight = 8.0; |

|

|

|

ScrewOffset = 0.0 + Clear4_40/2; |

|

|

|

ScrewSites = [[-1,1],[-1,1]]; // -1/0/+1 = left/mid/right and bottom/mid/top |

|

|

|

OAHeight = FrameHeight + Clearance[2] + PCBSize[2]; |

|

echo(str("OAH: ",OAHeight)); |

|

|

|

FlangeExtension = 3.0; |

|

FlangeThick = IntegerMultiple(2.0,ThreadThick); |

|

Flange = PCBSize |

|

+ 2*[ScrewOffset,ScrewOffset,0] |

|

+ 2*[Washer4_40OD,Washer4_40OD,0] |

|

+ [2*FlangeExtension,2*FlangeExtension,(FlangeThick – PCBSize[2])] |

|

; |

|

|

|

echo(str("Flange: ",Flange)); |

|

NumSides = 4*5; |

|

|

|

WireChannel = [Flange[0],15.0,3.0 + PCBSize[2]]; |

|

WireChannelOffset = [Flange[0]/2,25.0,(FrameHeight + PCBSize[2] – WireChannel[2]/2)]; |

|

|

|

//- Adjust hole diameter to make the size come out right |

|

|

|

module PolyCyl(Dia,Height,ForceSides=0) { // based on nophead's polyholes |

|

|

|

Sides = (ForceSides != 0) ? ForceSides : (ceil(Dia) + 2); |

|

|

|

FixDia = Dia / cos(180/Sides); |

|

|

|

cylinder(r=(FixDia + HoleWindage)/2,h=Height,$fn=Sides); |

|

} |

|

|

|

//- Build things |

|

|

|

if (Layout == "Frame") |

|

difference() { |

|

union() { // body block |

|

translate([0,0,OAHeight/2]) |

|

cube(PCBSize + Clearance + [2*WallThick,2*WallThick,FrameHeight],center=true); |

|

|

|

for (x=[-1,1], y=[-1,1]) { // screw bosses |

|

translate([x*(PCBSize[0]/2 + ScrewOffset), |

|

y*(PCBSize[1]/2 + ScrewOffset), |

|

0]) |

|

cylinder(r=Washer4_40OD,h=OAHeight,$fn=NumSides); |

|

} |

|

|

|

if (ClampFlange) // flange for work holder |

|

linear_extrude(height=Flange[2]) |

|

hull() |

|

for (i=[-1,1], j=[-1,1]) { |

|

translate([i*(Flange[0]/2 – Washer4_40OD/2),j*(Flange[1]/2 – Washer4_40OD/2)]) |

|

circle(d=Washer4_40OD,$fn=NumSides); |

|

} |

|

} |

|

|

|

for (x=[-1,1], y=[-1,1]) { // screw position indexes |

|

|

|

translate([x*(PCBSize[0]/2 + ScrewOffset), |

|

y*(PCBSize[1]/2 + ScrewOffset), |

|

-Protrusion]) |

|

rotate(x*y*180/(2*6)) |

|

PolyCyl(Clear4_40,(OAHeight + 2*Protrusion),6); // screw clearance holes |

|

|

|

translate([x*(PCBSize[0]/2 + ScrewOffset), |

|

y*(PCBSize[1]/2 + ScrewOffset), |

|

OAHeight – PCBSize[2] – Insert[LENGTH]]) |

|

rotate(x*y*180/(2*6)) |

|

PolyCyl(Insert[OD],Insert[LENGTH] + Protrusion,6); // inserts |

|

|

|

translate([x*(PCBSize[0]/2 + ScrewOffset), |

|

y*(PCBSize[1]/2 + ScrewOffset), |

|

OAHeight – PCBSize[2]]) |

|

PolyCyl(1.2*Washer4_40OD,(PCBSize[2] + Protrusion),NumSides); // washers |

|

} |

|

|

|

translate([0,0,OAHeight/2]) // through hole below PCB |

|

cube(PCBSize – 2*[PCBShelf,PCBShelf,0] + [0,0,2*OAHeight],center=true); |

|

|

|

translate([0,0,(OAHeight – (PCBSize[2] + Clearance[2])/2 + Protrusion/2)]) // PCB pocket on top |

|

cube(PCBSize + Clearance + [0,0,Protrusion],center=true); |

|

|

|

if (Channel) |

|

translate(WireChannelOffset) // opening for wires from bottom side |

|

cube(WireChannel + [0,0,Protrusion],center=true); |

|

} |

|

|

|

// Add-on bracket to hold smaller PCB upright at edge |

|

|

|

PCB2Insert = [3.0,4.9,4.1]; |

|

PCB2OC = 45.0; |

|

|

|

if (Layout == "Bracket") |

|

difference() { |

|

hull() // frame body block |

|

for (x=[-1,1]) // bosses around screws |

|

translate([x*(PCBSize[0]/2 + ScrewOffset),0,0]) |

|

cylinder(r=Washer4_40OD,h=OAHeight,$fn=NumSides); |

|

|

|

for (x=[-1,1]) // frame screw holes |

|

translate([x*(PCBSize[0]/2 + ScrewOffset),0,-Protrusion]) |

|

rotate(x*180/(2*6)) |

|

PolyCyl(Clear4_40,(OAHeight + 2*Protrusion),6); |

|

|

|

for (x=[-1,1]) // PCB insert holes |

|

translate([x*PCB2OC/2,(Washer4_40OD + Protrusion),OAHeight/2]) |

|

rotate([90,0,0]) |

|

cylinder(d=PCB2Insert[OD],h=2*(Washer4_40OD + Protrusion),$fn=6); |

|

|

|

} |

|

|