|

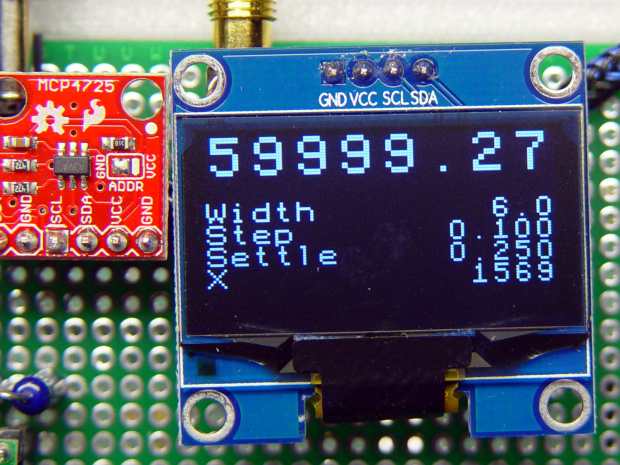

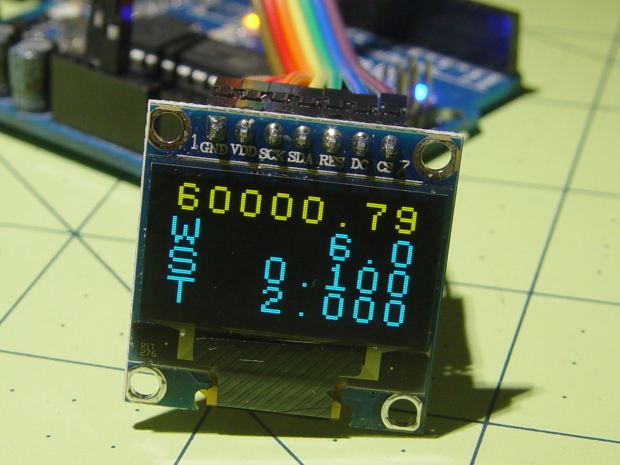

// OLED display test for 60 kHz crystal tester |

|

|

|

#include <avr/pgmspace.h> |

|

//#include <SPI.h> |

|

#include <U8g2lib.h> |

|

#include <U8x8lib.h> |

|

|

|

// Turn off DDS SPI for display checkout |

|

|

|

#define DOSPI 0 |

|

|

|

//——————— |

|

// Pin locations |

|

// SPI uses hardware support: those pins are predetermined |

|

|

|

#define PIN_HEARTBEAT 9 |

|

|

|

#define PIN_DDS_RESET 7 |

|

#define PIN_DDS_LATCH 8 |

|

|

|

#define PIN_DISP_SEL 4 |

|

#define PIN_DISP_DC 5 |

|

#define PIN_DISP_RST 6 |

|

|

|

#define PIN_SCK 13 |

|

#define PIN_MISO 12 |

|

#define PIN_MOSI 11 |

|

#define PIN_SS 10 |

|

|

|

char Buffer[10+1+10+1]; // string buffer for long long conversions |

|

|

|

#define GIGA 1000000000LL |

|

#define MEGA 1000000LL |

|

#define KILO 1000LL |

|

|

|

struct ll_fx { |

|

uint32_t low; // fractional part |

|

uint32_t high; // integer part |

|

}; |

|

|

|

union ll_u { |

|

uint64_t fx_64; |

|

struct ll_fx fx_32; |

|

}; |

|

|

|

union ll_u CtPerHz; // will be 2^32 / 125 MHz |

|

union ll_u HzPerCt; // will be 125 MHz / 2^32 |

|

|

|

union ll_u One; // 1.0 as fixed point |

|

union ll_u Tenth; // 0.1 as fixed point |

|

|

|

union ll_u TenthHzCt; // 0.1 Hz in counts |

|

|

|

// All nominal values are integers for simplicity |

|

|

|

#define OSC_NOMINAL (125 * MEGA) |

|

#define OSC_OFFSET_NOMINAL (-344LL) |

|

|

|

union ll_u OscillatorNominal; // nominal oscillator frequency |

|

union ll_u OscOffset; // … and offset, which will be signed 64-bit value |

|

union ll_u Oscillator; // true oscillator frequency with offset |

|

|

|

union ll_u CenterFreq; // center of scan width |

|

|

|

#define SCAN_WIDTH 6 |

|

#define SCAN_SETTLE 2000 |

|

|

|

union ll_u ScanFrom, ScanTo, ScanFreq, ScanStep; // frequency scan settings |

|

uint8_t ScanStepCounter; |

|

|

|

union ll_u TestFreq,TestCount; // useful variables |

|

|

|

//U8X8_SH1106_128X64_NONAME_4W_HW_SPI u8x8(PIN_DISP_SEL, PIN_DISP_DC , PIN_DISP_RST); |

|

U8X8_SH1106_128X64_NONAME_4W_SW_SPI u8x8(PIN_SCK, PIN_MOSI, PIN_DISP_SEL, PIN_DISP_DC , PIN_DISP_RST); |

|

//U8X8_SH1106_128X64_NONAME_HW_I2C u8x8(U8X8_PIN_NONE); |

|

|

|

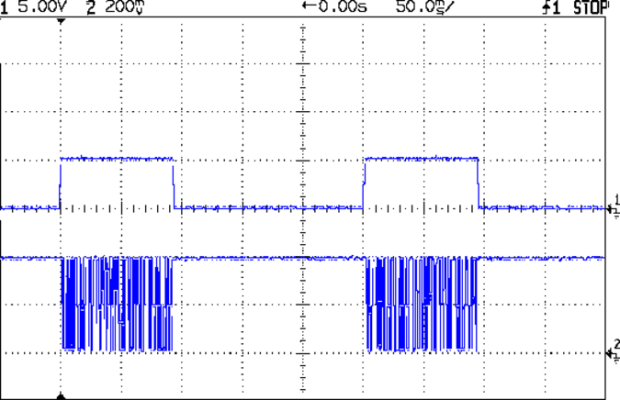

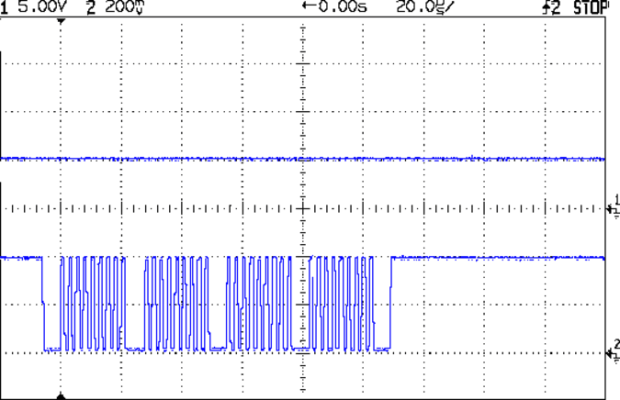

#define HEARTBEAT_MS 3000 |

|

|

|

unsigned long MillisNow,MillisThen; |

|

|

|

//———– |

|

// Useful functions |

|

|

|

// Pin twiddling |

|

|

|

void TogglePin(char bitpin) { |

|

digitalWrite(bitpin,!digitalRead(bitpin)); // toggle the bit based on previous output |

|

} |

|

|

|

void PulsePin(char bitpin) { |

|

TogglePin(bitpin); |

|

TogglePin(bitpin); |

|

} |

|

|

|

// SPI I/O |

|

|

|

void EnableSPI(void) { |

|

digitalWrite(PIN_SS,HIGH); // set SPI into Master mode |

|

SPCR |= 1 << SPE; |

|

} |

|

|

|

void DisableSPI(void) { |

|

SPCR &= ~(1 << SPE); |

|

} |

|

|

|

void WaitSPIF(void) { |

|

while (! (SPSR & (1 << SPIF))) { |

|

TogglePin(PIN_HEARTBEAT); |

|

TogglePin(PIN_HEARTBEAT); |

|

continue; |

|

} |

|

} |

|

|

|

byte SendRecSPI(byte Dbyte) { // send one byte, get another in exchange |

|

SPDR = Dbyte; |

|

WaitSPIF(); |

|

return SPDR; // SPIF will be cleared |

|

} |

|

|

|

// DDS module |

|

|

|

void EnableDDS(void) { |

|

|

|

digitalWrite(PIN_DDS_LATCH,LOW); // ensure proper startup |

|

|

|

digitalWrite(PIN_DDS_RESET,HIGH); // minimum reset pulse 40 ns, not a problem |

|

digitalWrite(PIN_DDS_RESET,LOW); |

|

delayMicroseconds(1); // max latency 100 ns, not a problem |

|

|

|

DisableSPI(); // allow manual control of outputs |

|

digitalWrite(PIN_SCK,LOW); // ensure clean SCK pulse |

|

PulsePin(PIN_SCK); // … to latch hardwired config bits |

|

PulsePin(PIN_DDS_LATCH); // load hardwired config bits = begin serial mode |

|

|

|

EnableSPI(); // turn on hardware SPI controls |

|

SendRecSPI(0x00); // shift in serial config bits |

|

PulsePin(PIN_DDS_LATCH); // load serial config bits |

|

|

|

} |

|

|

|

// Write delta phase count to DDS |

|

// This comes from the integer part of a 64-bit scaled value |

|

|

|

void WriteDDS(uint32_t DeltaPhase) { |

|

|

|

SendRecSPI((byte)DeltaPhase); // low-order byte first |

|

SendRecSPI((byte)(DeltaPhase >> 8)); |

|

SendRecSPI((byte)(DeltaPhase >> 16)); |

|

SendRecSPI((byte)(DeltaPhase >> 24)); |

|

|

|

SendRecSPI(0x00); // 5 MSBs = phase = 0, 3 LSBs must be zero |

|

|

|

PulsePin(PIN_DDS_LATCH); // write data to DDS |

|

} |

|

|

|

//———– |

|

// Round scaled fixed point to specific number of decimal places: 0 through 8 |

|

// You should display the value with only Decimals characters beyond the point |

|

// Must calculate rounding value as separate variable to avoid mystery error |

|

|

|

uint64_t RoundFixedPt(union ll_u TheNumber,unsigned Decimals) { |

|

union ll_u Rnd; |

|

|

|

Rnd.fx_64 = (One.fx_64 / 2) / (pow(10LL,Decimals)); |

|

TheNumber.fx_64 = TheNumber.fx_64 + Rnd.fx_64; |

|

|

|

return TheNumber.fx_64; |

|

} |

|

|

|

|

|

//———– |

|

// Multiply two unsigned scaled fixed point numbers without overflowing a 64 bit value |

|

// The product of the two integer parts mut be < 2^32 |

|

|

|

uint64_t MultiplyFixedPt(union ll_u Mcand, union ll_u Mplier) { |

|

union ll_u Result; |

|

|

|

Result.fx_64 = ((uint64_t)Mcand.fx_32.high * (uint64_t)Mplier.fx_32.high) << 32; // integer parts (clear fract) |

|

Result.fx_64 += ((uint64_t)Mcand.fx_32.low * (uint64_t)Mplier.fx_32.low) >> 32; // fraction parts (always < 1) |

|

Result.fx_64 += (uint64_t)Mcand.fx_32.high * (uint64_t)Mplier.fx_32.low; // cross products |

|

Result.fx_64 += (uint64_t)Mcand.fx_32.low * (uint64_t)Mplier.fx_32.high; |

|

|

|

return Result.fx_64; |

|

} |

|

|

|

|

|

//———– |

|

// Long long print-to-buffer helpers |

|

// Assumes little-Endian layout |

|

|

|

void PrintHexLL(char *pBuffer,union ll_u FixedPt) { |

|

sprintf(pBuffer,"%08lx %08lx",FixedPt.fx_32.high,FixedPt.fx_32.low); |

|

} |

|

|

|

// converts all 9 decimal digits of fraction, which should suffice |

|

|

|

void PrintFractionLL(char *pBuffer,union ll_u FixedPt) { |

|

union ll_u Fraction; |

|

|

|

Fraction.fx_64 = FixedPt.fx_32.low; // copy 32 fraction bits, high order = 0 |

|

Fraction.fx_64 *= GIGA; // times 10^9 for conversion |

|

Fraction.fx_64 >>= 32; // align integer part in low long |

|

sprintf(pBuffer,"%09lu",Fraction.fx_32.low); // convert low long to decimal |

|

} |

|

|

|

void PrintIntegerLL(char *pBuffer,union ll_u FixedPt) { |

|

sprintf(pBuffer,"%lu",FixedPt.fx_32.high); |

|

} |

|

|

|

void PrintFixedPt(char *pBuffer,union ll_u FixedPt) { |

|

PrintIntegerLL(pBuffer,FixedPt); // do the integer part |

|

pBuffer += strlen(pBuffer); // aim pointer beyond integer |

|

*pBuffer++ = '.'; // drop in the decimal point, tick pointer |

|

PrintFractionLL(pBuffer,FixedPt); |

|

} |

|

|

|

void PrintFixedPtRounded(char *pBuffer,union ll_u FixedPt,unsigned Decimals) { |

|

char *pDecPt; |

|

|

|

FixedPt.fx_64 = RoundFixedPt(FixedPt,Decimals); |

|

|

|

PrintIntegerLL(pBuffer,FixedPt); // do the integer part |

|

pBuffer += strlen(pBuffer); // aim pointer beyond integer |

|

|

|

pDecPt = pBuffer; // save the point location |

|

*pBuffer++ = '.'; // drop in the decimal point, tick pointer |

|

|

|

PrintFractionLL(pBuffer,FixedPt); // do the fraction |

|

|

|

if (Decimals == 0) |

|

*pDecPt = 0; // 0 places means discard the decimal point |

|

else |

|

*(pDecPt + Decimals + 1) = 0; // truncate string to leave . and Decimals chars |

|

|

|

} |

|

|

|

//———– |

|

// Calculate useful "constants" from oscillator info |

|

// Args are integer constants in Hz |

|

|

|

void CalcOscillator(uint32_t Base,uint32_t Offset) { |

|

|

|

union ll_u Temp; |

|

|

|

Oscillator.fx_32.high = Base + Offset; // get true osc frequency from integers |

|

Oscillator.fx_32.low = 0; |

|

|

|

HzPerCt.fx_32.low = Oscillator.fx_32.high; // divide oscillator by 2^32 with simple shifting |

|

HzPerCt.fx_32.high = 0; |

|

|

|

CtPerHz.fx_64 = -1; // Compute (2^32 – 1) / oscillator |

|

CtPerHz.fx_64 /= (uint64_t)Oscillator.fx_32.high; // remove 2^32 scale factor from divisor |

|

|

|

TenthHzCt.fx_64 = MultiplyFixedPt(Tenth,CtPerHz); // 0.1 Hz as delta-phase count |

|

|

|

#if 0 |

|

printf("Inputs: %ld = %ld%+ld\n",Base+Offset,Base,Offset); |

|

|

|

PrintFixedPt(Buffer,Oscillator); |

|

printf("Osc freq: %s\n",Buffer); |

|

|

|

PrintFixedPt(Buffer,HzPerCt); |

|

printf("Hz/Ct: %s\n",Buffer); |

|

PrintFixedPt(Buffer,CtPerHz); |

|

printf("Ct/Hz: %s\n",Buffer); |

|

|

|

PrintFixedPt(Buffer,TenthHzCt); |

|

printf("0.1 Hz Ct: %s",Buffer); |

|

#endif |

|

|

|

} |

|

|

|

//– Helper routine for printf() |

|

|

|

int s_putc(char c, FILE *t) { |

|

Serial.write(c); |

|

} |

|

|

|

//———– |

|

|

|

void setup () |

|

{ |

|

pinMode(PIN_HEARTBEAT,OUTPUT); |

|

digitalWrite(PIN_HEARTBEAT,HIGH); // show we got here |

|

|

|

Serial.begin (115200); |

|

fdevopen(&s_putc,0); // set up serial output for printf() |

|

|

|

Serial.println (F("DDS OLED exercise")); |

|

Serial.println (F("Ed Nisley – KE4ZNU – May 2017\n")); |

|

|

|

// DDS module controls |

|

|

|

pinMode(PIN_DDS_LATCH,OUTPUT); |

|

digitalWrite(PIN_DDS_LATCH,LOW); |

|

pinMode(PIN_DDS_RESET,OUTPUT); |

|

digitalWrite(PIN_DDS_RESET,HIGH); |

|

|

|

// Light up the display |

|

|

|

Serial.println("Initialize OLED"); |

|

u8x8.begin(); |

|

u8x8.setPowerSave(0); |

|

|

|

u8x8.setFont(u8x8_font_pxplusibmcga_f); |

|

u8x8.draw2x2String(0,0,"OLEDTest"); |

|

u8x8.drawString(0,2,"Ed Nisley"); |

|

u8x8.drawString(0,3," KE4ZNU"); |

|

u8x8.drawString(0,4,"May 2017"); |

|

|

|

// configure SPI hardware |

|

|

|

#if DOSPI |

|

SPCR = B01110001; // Auto SPI: no int, enable, LSB first, master, + edge, leading, f/16 |

|

SPSR = B00000000; // not double data rate |

|

|

|

pinMode(PIN_SS,OUTPUT); |

|

digitalWrite(PIN_SCK,HIGH); |

|

pinMode(PIN_SCK,OUTPUT); |

|

digitalWrite(PIN_SCK,LOW); |

|

pinMode(PIN_MOSI,OUTPUT); |

|

digitalWrite(PIN_MOSI,LOW); |

|

|

|

pinMode(PIN_MISO,INPUT_PULLUP); |

|

#endif |

|

|

|

TogglePin(PIN_HEARTBEAT); // show we got here |

|

|

|

// Calculate useful constants |

|

|

|

One.fx_64 = 1LL << 32; // Set up 1.0, a very useful constant |

|

Tenth.fx_64 = One.fx_64 / 10; // Likewise, 0.1 |

|

|

|

// Set oscillator "constants" |

|

|

|

CalcOscillator(OSC_NOMINAL,OSC_OFFSET_NOMINAL); |

|

|

|

TogglePin(PIN_HEARTBEAT); // show we got here |

|

|

|

// Set the crystal-under-test nominal frequency |

|

|

|

CenterFreq.fx_64 = One.fx_64 * (60 * KILO); |

|

|

|

#if 1 |

|

PrintFixedPtRounded(Buffer,CenterFreq,1); |

|

printf("Center: %s\n",Buffer); |

|

#endif |

|

|

|

// Set up scan limits based on center frequency |

|

|

|

ScanFrom.fx_64 = CenterFreq.fx_64 – SCAN_WIDTH * (One.fx_64 >> 1); |

|

ScanTo.fx_64 = CenterFreq.fx_64 + SCAN_WIDTH * (One.fx_64 >> 1); |

|

|

|

ScanFreq = ScanFrom; // start scan at lower limit |

|

|

|

// ScanStep.fx_64 = One.fx_64 / 4; // 0.25 Hz = 8 or 9 tuning register steps |

|

ScanStep.fx_64 = One.fx_64 / 10; // 0.1 Hz = 3 or 4 tuning register steps |

|

// ScanStep.fx_64 = One.fx_64 / 20; // 0.05 Hz = 2 or 3 tuning register steps |

|

// ScanStep = HzPerCt; // smallest possible frequency step |

|

|

|

#if 1 |

|

Serial.println("\nScan limits"); |

|

PrintFixedPtRounded(Buffer,ScanFrom,1); |

|

printf(" from: %11s\n",Buffer); |

|

PrintFixedPtRounded(Buffer,ScanFreq,1); |

|

printf(" at: %11s\n",Buffer); |

|

PrintFixedPtRounded(Buffer,ScanTo,1); |

|

printf(" to: %11s\n",Buffer); |

|

PrintFixedPtRounded(Buffer,ScanStep,3); |

|

printf(" step: %s\n",Buffer); |

|

#endif |

|

|

|

// Wake up and load the DDS |

|

|

|

#if DOSPI |

|

TestCount.fx_64 = MultiplyFixedPt(ScanFreq,CtPerHz); |

|

EnableDDS(); |

|

WriteDDS(TestCount.fx_32.high); |

|

#endif |

|

|

|

delay(2000); |

|

u8x8.clearDisplay(); |

|

u8x8.setFont(u8x8_font_artossans8_r); |

|

|

|

Serial.println("\nStartup done!"); |

|

|

|

MillisThen = millis(); |

|

} |

|

|

|

//———– |

|

|

|

void loop () { |

|

|

|

MillisNow = millis(); |

|

if ((MillisNow – MillisThen) >= SCAN_SETTLE) { |

|

TogglePin(PIN_HEARTBEAT); |

|

MillisThen = MillisNow; |

|

|

|

PrintFixedPtRounded(Buffer,ScanFreq,2); |

|

TestCount.fx_64 = MultiplyFixedPt(ScanFreq,CtPerHz); |

|

// printf("%12s -> %9ld\n",Buffer,TestCount.fx_32.high); |

|

|

|

#if DOSPI |

|

WriteDDS(TestCount.fx_32.high); |

|

#endif |

|

|

|

TestCount.fx_32.low = 0; // truncate to integer |

|

TestFreq.fx_64 = MultiplyFixedPt(TestCount,HzPerCt); // recompute frequency |

|

PrintFixedPtRounded(Buffer,TestFreq,2); |

|

|

|

int ln = 0; |

|

u8x8.draw2x2String(0,ln,Buffer); |

|

ln += 2; |

|

|

|

TestFreq.fx_64 = ScanTo.fx_64 – ScanFrom.fx_64; |

|

PrintFixedPtRounded(Buffer,TestFreq,1); |

|

u8x8.draw2x2String(0,ln,"W "); |

|

u8x8.draw2x2String(2*(8-strlen(Buffer)),ln,Buffer); |

|

ln += 2; |

|

|

|

PrintFixedPtRounded(Buffer,ScanStep,3); |

|

u8x8.draw2x2String(0,ln,"S "); |

|

u8x8.draw2x2String(2*(8-strlen(Buffer)),ln,Buffer); |

|

ln += 2; |

|

|

|

TestFreq.fx_32.high = SCAN_SETTLE; // milliseconds |

|

TestFreq.fx_32.low = 0; |

|

TestFreq.fx_64 /= KILO; // to seconds |

|

PrintFixedPtRounded(Buffer,TestFreq,3); |

|

u8x8.draw2x2String(0,ln,"T "); |

|

u8x8.draw2x2String(2*(8-strlen(Buffer)),ln,Buffer); |

|

ln += 2; |

|

|

|

ScanFreq.fx_64 += ScanStep.fx_64; |

|

|

|

if (ScanFreq.fx_64 > (ScanTo.fx_64 + ScanStep.fx_64 / 2)) { |

|

ScanFreq = ScanFrom; |

|

} |

|

|

|

|

|

} |

|

|

|

} |

|

|

|

|