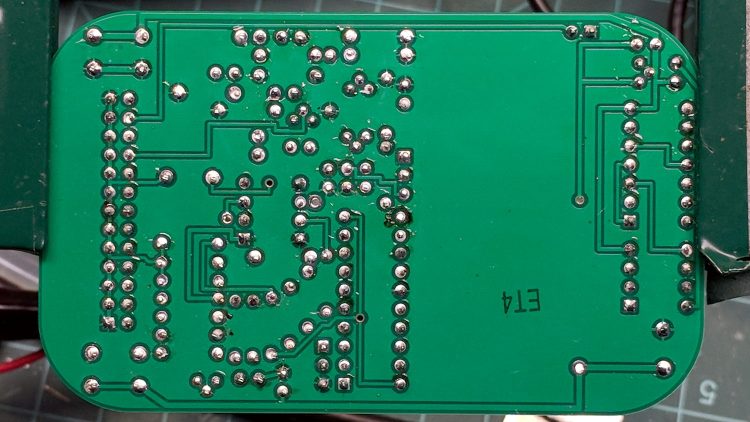

The first white LED fixture built to illuminate one of Mary’s Kenmore 158 sewing machines has been in regular use for the last four years:

We never found a good time to rip-and-replace the “prototype” with brighter SMD LEDs and one of the LEDs finally gave up.

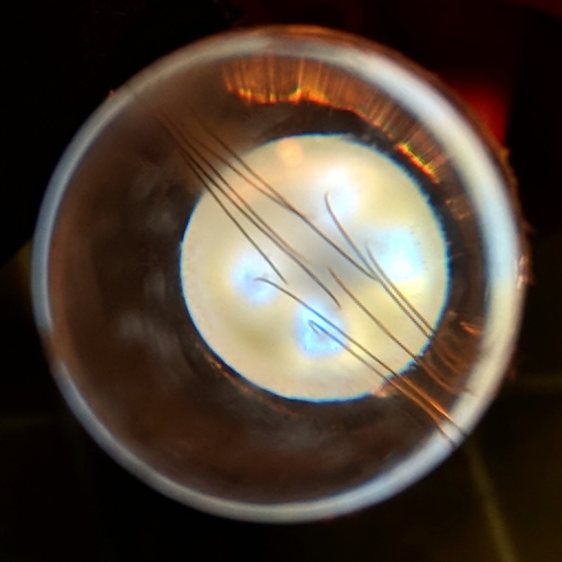

They’re 10 mm white LEDs with five chips wired in parallel, which is obvious when you look into the remaining LED running at 1 mA:

The center chip is just dimmer than the others, which means their QC doesn’t tightly control the forward voltage spec.

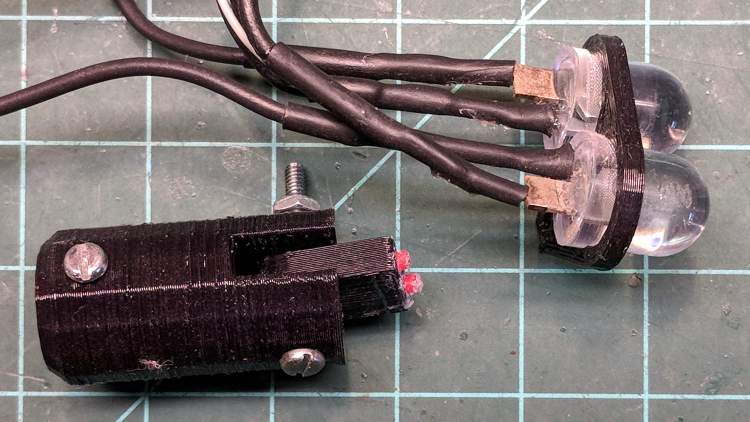

The wire bonds on the anode terminal of the failed LED look a bit sketchy:

Fortunately, I hadn’t removed the 120 VAC wiring for the original bulb and I have two OEM bulbs from other machines, so I just removed my LED gimcrackery, installed a good old incandescent bulb, and she’s back to sewing with a pleasantly warm machine.

The fixture holding the LEDs broke apart as I extracted it, but it’ll never be used again:

The LEDs are rated at 3.5 V and 200 mA (!), but were reasonably bright in series from a 6 V unregulated supply. Perhaps a power glitch killed the poor thing? We’ll never know.

LEDs are reputed to have lifetimes in the multiple tens of thousands of hours, but I’ve seen plenty of failed automotive LEDs and fancy new LED streetlights out there, not to mention many dead and dying traffic signals. Seeing as how they’re in (presumably) well-engineered fixtures with good power supplies and are at most only a few years old, there shouldn’t be any failures yet.