|

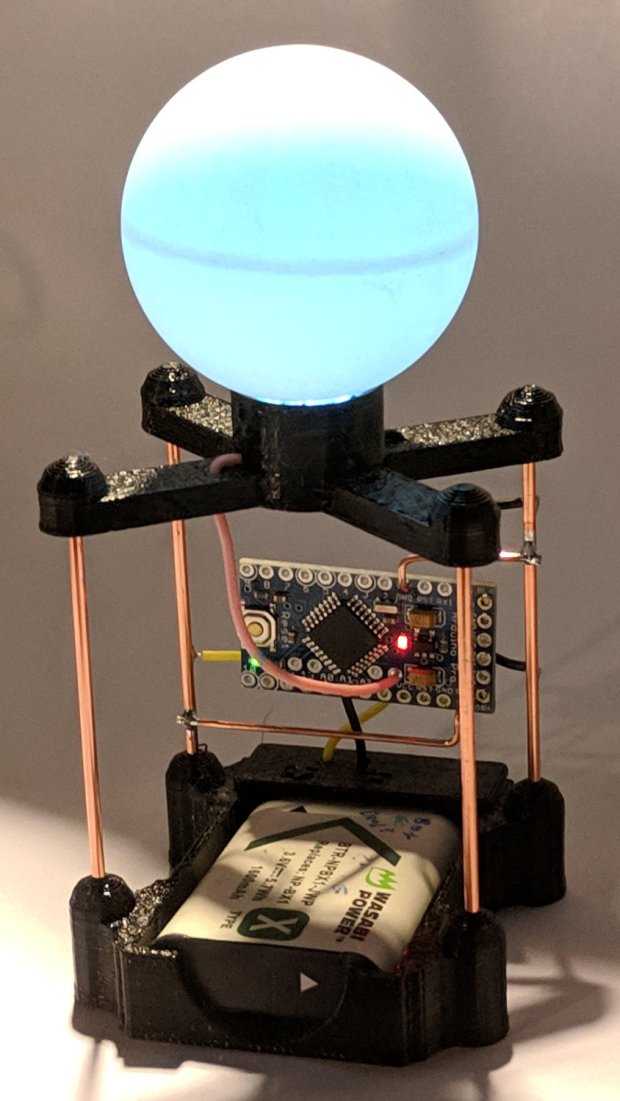

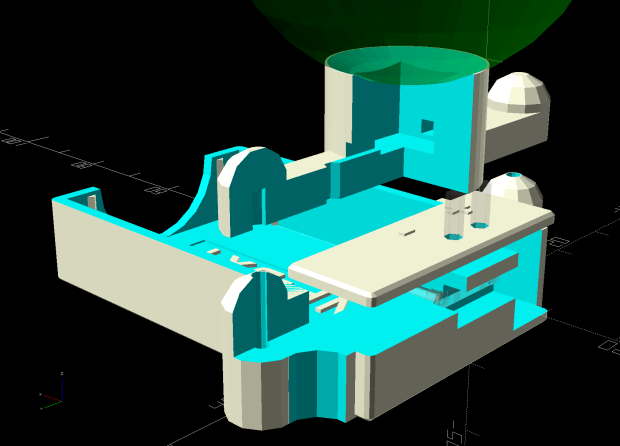

// Holder for Li-Ion battery packs |

|

// Ed Nisley KE4ZNU January 2013 |

|

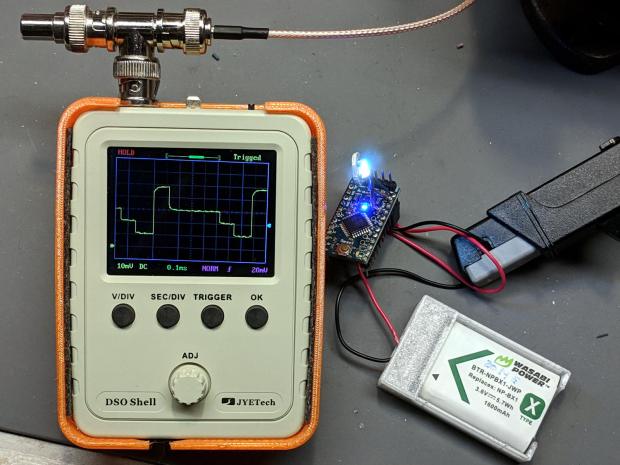

// 2018-11-15 Adapted for 1.5 mm pogo pins, battery data table |

|

// 2018-12 RGB LED spider, general cleanups |

|

|

|

/* [Layout options] */ |

|

|

|

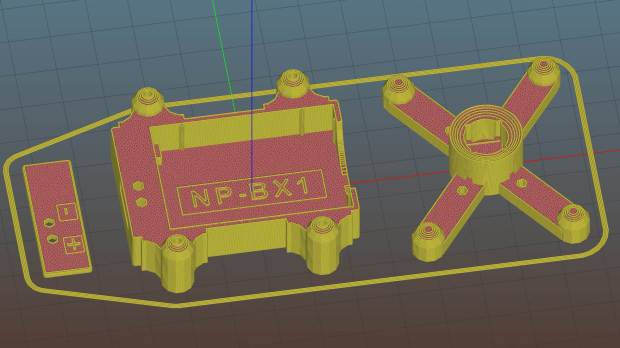

BatteryName = "NP-BX1"; // [NP-BX1,NB-5L,NB-6L] |

|

|

|

RGBCircuit = false; // false = 1 strut pair, true = 2 pairs |

|

|

|

Layout = "Spider"; // [Build,Show,Fit,Case,Lid,Pins,RGBSpider,Spider] |

|

|

|

/* [Extrusion parameters] – must match reality! */ |

|

// Print with +2 shells and 3 solid layers |

|

|

|

ThreadThick = 0.25; |

|

ThreadWidth = 0.40; |

|

|

|

HoleWindage = 0.2; |

|

|

|

function IntegerMultiple(Size,Unit) = Unit * ceil(Size / Unit); |

|

function IntegerLessMultiple(Size,Unit) = Unit * floor(Size / Unit); |

|

|

|

Protrusion = 0.1; // make holes end cleanly |

|

|

|

/* [Hidden] */ |

|

|

|

inch = 25.4; |

|

|

|

BuildOffset = 3.0; // clearance for build layout |

|

|

|

Gap = 2.0; // separation for Fit parts |

|

|

|

//- Basic dimensions |

|

|

|

WallThick = 4*ThreadWidth; // holder sidewalls |

|

|

|

BaseThick = 6*ThreadThick; // bottom of holder to bottom of battery |

|

TopThick = 6*ThreadThick; // top of battery to top of holder |

|

|

|

//- Battery dimensions – rationalized from several samples |

|

// Coordinate origin at battery corner with contacts, key openings downward |

|

|

|

T_NAME = 0; // Name must fit recess, so don't get loquacious |

|

T_SIZE = 1; |

|

T_CONTACTS = 2; |

|

T_KEYS = 3; |

|

|

|

BatteryData = [ |

|

["NP-BX1",[43.0,30.0,9.5],[[-0.75,6.0,6.2,"+"],[-0.75,16.0,6.2,"-"]],[[1.70,3.70,2.90],[1.70,3.60,2.90]]], |

|

["NB-5L", [45.0,32.0,8.0],[[-0.82,4.5,3.5,"-"],[-0.82,11.0,3.5,"+"]],[[2.2,0.75,2.0],[2.2,2.8,2.0]]], |

|

["NB-6L",[42.5,35.5,7.0],[[-0.85,5.50,3.05,"-"],[-0.85,11.90,3.05,"+"]],[[2.0,0.70,2.8],[2.0,2.00,2.8]]], |

|

]; |

|

|

|

echo(str("Battery: ",BatteryName)); |

|

|

|

BatteryIndex = search([BatteryName],BatteryData,1,0)[0]; |

|

echo(str(" Index: ",BatteryIndex)); |

|

|

|

BatterySize = BatteryData[BatteryIndex][T_SIZE]; // X = length, Y = width, Z = thickness |

|

echo(str(" Size: ",BatterySize)); |

|

|

|

Contacts = BatteryData[BatteryIndex][T_CONTACTS]; // relative to battery edge, front, and bottom |

|

echo(str(" Contacts: ",Contacts)); |

|

|

|

ContactOC = Contacts[1].y – Contacts[0].y; // + and – terminals for pogo pin contacts |

|

ContactCenter = Contacts[0].y + ContactOC/2; |

|

|

|

KeyBlocks = BatteryData[BatteryIndex][T_KEYS]; // recesses in battery face set X position |

|

echo(str(" Keys: ",KeyBlocks)); |

|

|

|

//- Pin dimensions |

|

|

|

ID = 0; |

|

OD = 1; |

|

LENGTH = 2; |

|

|

|

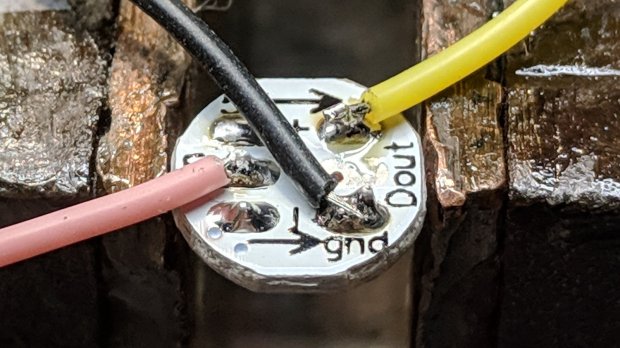

PinShank = [1.5,2.0,6.5]; // shank, flange, compressed length |

|

PinFlange = [1.5,2.0,0.5]; // flange, length included in PinShank |

|

PinTip = [0.9,0.9,2.5]; // extended spring-loaded tip |

|

|

|

WireOD = 1.7; // wiring from pins to circuitry |

|

|

|

PinChannel = WireOD; // cut behind flange for solder overflow |

|

PinRecess = 3.0; // recess behind pin flange end for epoxy fill |

|

|

|

echo(str("Contact tip dia: ",PinTip[OD])); |

|

echo(str(" .. shank dia: ",PinShank[ID])); |

|

|

|

OverTravel = 0.5; // space beyond battery face at X origin |

|

|

|

//- Holder dimensions |

|

|

|

GuideRadius = ThreadWidth; // friction fit ridges |

|

GuideOffset = 7; // from compartment corners |

|

|

|

LidOverhang = 2.0; // atop of battery for retention |

|

LidClearance = LidOverhang * (BatterySize.z/BatterySize.x); // … clearance above battery for tilting |

|

echo(str("Lid clearance: ",LidClearance)); |

|

|

|

CaseSize = [BatterySize.x + PinShank[LENGTH] + OverTravel + PinRecess + GuideRadius + WallThick, |

|

BatterySize.y + 2*WallThick + 2*GuideRadius, |

|

BatterySize.z + BaseThick + TopThick + LidClearance]; |

|

echo(str("Case size: ",CaseSize)); |

|

|

|

CaseOffset = [-(PinShank[LENGTH] + OverTravel + PinRecess),-(WallThick + GuideRadius),0]; // position around battery |

|

|

|

ThumbRadius = 10.0; // thumb opening at end of battery |

|

|

|

CornerRadius = 3*ThreadThick; // nice corner rounding |

|

|

|

LidSize = [-CaseOffset.x + LidOverhang,CaseSize.y,TopThick]; |

|

|

|

LidOffset = [0.0,CaseOffset.y,0]; |

|

|

|

//- Wire struts |

|

|

|

StrutDia = 1.6; // AWG 14 = 1.6 mm |

|

StrutSides = 3*4; |

|

|

|

StrutBase = [StrutDia,StrutDia + 4*WallThick,CaseSize.z – TopThick]; // ID = wire, OD = buildable |

|

|

|

//StrutOC = [IntegerLessMultiple(BatterySize.x – StrutBase[OD],5.0), // set easy OC wire spacing |

|

// IntegerMultiple(CaseSize.y + StrutBase[OD],5.0)]; |

|

StrutOC = [IntegerLessMultiple(CaseSize.x – 2*CornerRadius -2*StrutBase[OD],5.0), |

|

IntegerMultiple(CaseSize.y + StrutBase[OD],5.0)]; |

|

|

|

StrutOffset = [CaseSize.x/2 + CaseOffset.x,BatterySize.y/2]; // from case centerlines |

|

|

|

StrutAngle = atan(StrutOC.y/StrutOC.x); |

|

|

|

echo(str("Strut OC: ",StrutOC)); |

|

|

|

//- RGB / Pirhana / Neopixel-ish LEDs |

|

|

|

RGBBody = [8.0,8.0,5.0]; // Z = body height |

|

|

|

PixelPCB = [4.0,10.0,3.0]; // Neopixel-ish PCBs, ID = chip window |

|

|

|

RGBPin = 5.0; // pin length |

|

RGBPinsOC = [5.0,5.0]; // pin layout |

|

|

|

RGBRecess = RGBBody.z + RGBPin/2; // maximum LED recess depth |

|

|

|

BallOD = 40.0; // radome sphere |

|

BallSides = 4*StrutSides; // nice number of sides |

|

|

|

BallPillar = [norm([RGBBody.x,RGBBody.y]), |

|

norm([RGBBody.x,RGBBody.y]) + 4*WallThick, |

|

StrutBase[OD] + RGBBody.z]; |

|

BallChordM = BallOD/2 – sqrt(pow(BallOD/2,2) – (pow(BallPillar[OD],2))/4); |

|

echo(str("Ball chord depth: ",BallChordM)); |

|

|

|

//———————- |

|

// Useful routines |

|

|

|

module PolyCyl(Dia,Height,ForceSides=0) { // based on nophead's polyholes |

|

|

|

Sides = (ForceSides != 0) ? ForceSides : (ceil(Dia) + 2); |

|

|

|

FixDia = Dia / cos(180/Sides); |

|

|

|

cylinder(r=(FixDia + HoleWindage)/2,h=Height,$fn=Sides); |

|

} |

|

|

|

//——————- |

|

//– Guides for tighter friction fit |

|

|

|

module Guides() { |

|

translate([GuideOffset,-GuideRadius,0]) |

|

PolyCyl(2*GuideRadius,(BatterySize.z – Protrusion),4); |

|

translate([GuideOffset,(BatterySize.y + GuideRadius),0]) |

|

PolyCyl(2*GuideRadius,(BatterySize.z – Protrusion),4); |

|

translate([(BatterySize.x – GuideOffset),-GuideRadius,0]) |

|

PolyCyl(2*GuideRadius,(BatterySize.z – Protrusion),4); |

|

translate([(BatterySize.x – GuideOffset),(BatterySize.y + GuideRadius),0]) |

|

PolyCyl(2*GuideRadius,(BatterySize.z – Protrusion),4); |

|

translate([(BatterySize.x + GuideRadius),GuideOffset/2,0]) |

|

PolyCyl(2*GuideRadius,(BatterySize.z – Protrusion),4); |

|

translate([(BatterySize.x + GuideRadius),(BatterySize.y – GuideOffset/2),0]) |

|

PolyCyl(2*GuideRadius,(BatterySize.z – Protrusion),4); |

|

|

|

} |

|

|

|

//– Contact pins |

|

// Rotated to put them in their natural oriention |

|

// Aligned to put tip base / end of shank at Overtravel limit |

|

|

|

module PinShape() { |

|

|

|

translate([-(PinShank[LENGTH] + OverTravel),0,0]) |

|

rotate([0,90,0]) |

|

rotate(180/6) |

|

union() { |

|

PolyCyl(PinTip[OD],PinShank[LENGTH] + PinTip[LENGTH],6); |

|

PolyCyl(PinShank[ID],PinShank[LENGTH] + Protrusion,6); // slight extension for clean cuts |

|

PolyCyl(PinFlange[OD],PinFlange[LENGTH],6); |

|

} |

|

} |

|

|

|

// Position pins to put end of shank at battery face |

|

// Does not include recess access into case |

|

|

|

module PinAssembly() { |

|

|

|

union() { |

|

for (p = Contacts) |

|

translate([0,p.y,p.z]) |

|

PinShape(); |

|

|

|

translate([-(PinShank[LENGTH] + OverTravel) + PinChannel/2, // solder space |

|

ContactCenter, |

|

Contacts[0].z]) |

|

cube([PinChannel, |

|

(Contacts[1].y – Contacts[0].y + PinFlange[OD]), |

|

PinFlange[OD]],center=true); |

|

|

|

for (j=[-1,1]) // wire channels |

|

translate([-(PinShank[LENGTH] + OverTravel – PinChannel/2), |

|

j*ContactOC/4 + ContactCenter, |

|

Contacts[0].z – PinFlange[OD]/2]) |

|

rotate(180/6) |

|

PolyCyl(WireOD,CaseSize.z,6); |

|

} |

|

} |

|

|

|

//– Case with origin at battery corner |

|

|

|

module Case() { |

|

|

|

difference() { |

|

|

|

union() { |

|

|

|

difference() { |

|

union() { |

|

translate([(CaseSize.x/2 + CaseOffset.x), // basic case shape |

|

(CaseSize.y/2 + CaseOffset.y), |

|

(CaseSize.z/2 – BaseThick)]) |

|

hull() |

|

for (i=[-1,1], j=[-1,1], k=[-1,1]) |

|

translate([i*(CaseSize.x/2 – CornerRadius), |

|

j*(CaseSize.y/2 – CornerRadius), |

|

k*(CaseSize.z/2 – CornerRadius)]) |

|

sphere(r=CornerRadius/cos(180/8),$fn=8); // cos() fixes undersize spheres! |

|

|

|

for (i= RGBCircuit ? [-1,1] : -1) { // strut bases |

|

hull() |

|

for (j=[-1,1]) |

|

translate([i*StrutOC.x/2 + StrutOffset.x,j*StrutOC.y/2 + StrutOffset.y,-BaseThick]) |

|

rotate(180/StrutSides) |

|

cylinder(d=StrutBase[OD],h=StrutBase[LENGTH],$fn=StrutSides); |

|

|

|

translate([i*StrutOC.x/2 + StrutOffset.x,StrutOffset.y,StrutBase[LENGTH]/2 – BaseThick]) |

|

cube([2*StrutBase[OD],StrutOC.y,StrutBase[LENGTH]],center=true); // blocks for fairing |

|

|

|

for (j=[-1,1]) // hemisphere caps |

|

translate([i*StrutOC.x/2 + StrutOffset.x, |

|

j*StrutOC.y/2 + StrutOffset.y, |

|

StrutBase[LENGTH] – BaseThick]) |

|

rotate(180/StrutSides) |

|

sphere(d=StrutBase[OD]/cos(180/StrutSides),$fn=StrutSides); |

|

|

|

} |

|

} |

|

|

|

translate([-OverTravel,-GuideRadius,0]) |

|

cube([(BatterySize.x + GuideRadius + OverTravel), |

|

(BatterySize.y + 2*GuideRadius), |

|

(BatterySize.z + LidClearance + Protrusion)]); // battery space |

|

|

|

translate([BatterySize.x/2,BatterySize.y/2,0]) // recess around battery name |

|

cube([0.8*BatterySize.x,8,2*ThreadThick],center=true); |

|

|

|

translate([CaseOffset.x + CaseSize.x/2,BatterySize.y/2,-BaseThick + ThreadThick – Protrusion]) // recess around battery name |

|

cube([0.75*CaseSize.x,8,2*ThreadThick],center=true); |

|

} |

|

|

|

Guides(); // improve friction fit |

|

|

|

translate([-OverTravel,-GuideRadius,0]) // battery keying blocks |

|

cube(KeyBlocks[0] + [OverTravel,GuideRadius,0],center=false); |

|

translate([-OverTravel,(BatterySize.y – KeyBlocks[1].y),0]) |

|

cube(KeyBlocks[1] + [OverTravel,GuideRadius,0],center=false); |

|

|

|

translate([BatterySize.x/2,BatterySize.y/2,-ThreadThick]) |

|

linear_extrude(height=2*ThreadThick,convexity=10) |

|

text(text=BatteryName,size=5,spacing=1.20,font="Arial:style:Bold",halign="center",valign="center"); |

|

|

|

translate([CaseOffset.x + CaseSize.x/2,BatterySize.y/2,-BaseThick]) |

|

linear_extrude(height=2*ThreadThick + Protrusion,convexity=10) |

|

mirror([0,1,0]) |

|

text(text="KE4ZNU",size=6,spacing=1.20,font="Arial:style:Bold",halign="center",valign="center"); |

|

} |

|

|

|

translate([2*CaseOffset.x, // battery top access |

|

(CaseOffset.y – Protrusion), |

|

BatterySize.z + LidClearance]) |

|

cube([2*CaseSize.x,(CaseSize.y + 2*Protrusion),2*TopThick]); |

|

|

|

for (i2 = RGBCircuit ? [-1,1] : -1) { // strut wire holes and fairing |

|

for (j=[-1,1]) |

|

translate([i2*StrutOC.x/2 + StrutOffset.x,j*StrutOC.y/2 + StrutOffset.y,0]) |

|

rotate(180/StrutSides) |

|

PolyCyl(StrutBase[ID],2*StrutBase[LENGTH],StrutSides); |

|

|

|

for (i=[-1,1], j=[-1,1]) |

|

translate([i*StrutBase[OD] + (i2*StrutOC.x/2 + StrutOffset.x), |

|

j*StrutOC.y/2 + StrutOffset.y, |

|

-(BaseThick + Protrusion)]) |

|

rotate(180/StrutSides) |

|

PolyCyl(StrutBase[OD],StrutBase[LENGTH] + 2*Protrusion,StrutSides); |

|

} |

|

|

|

translate([(BatterySize.x – Protrusion), // remove thumb notch |

|

(CaseSize.y/2 + CaseOffset.y), |

|

(ThumbRadius)]) |

|

rotate([90,0,0]) |

|

rotate([0,90,0]) |

|

cylinder(r=ThumbRadius, |

|

h=(WallThick + GuideRadius + 2*Protrusion), |

|

$fn=22); |

|

|

|

PinAssembly(); // pins and wiring |

|

|

|

translate([CaseOffset.x + PinRecess + Protrusion,(Contacts[1].y + Contacts[0].y)/2,Contacts[0].z]) |

|

translate([-PinRecess,0,0]) |

|

cube([2*PinRecess, |

|

(Contacts[1].y – Contacts[0].y + PinFlange[OD]/cos(180/6) + 2*HoleWindage), |

|

2*PinFlange[OD]],center=true); // pin insertion hole |

|

|

|

} |

|

|

|

} |

|

|

|

// Lid position offset to match case |

|

// The polarity indicator recesses are pure bodges |

|

|

|

module Lid() { |

|

|

|

union() { |

|

difference() { |

|

translate([-LidSize.x/2 + LidOffset.x + LidOverhang,LidSize.y/2 + LidOffset.y,0]) |

|

difference() { |

|

hull() |

|

for (i=[-1,1], j=[-1,1], k=[-1,1]) |

|

translate([i*(LidSize.x/2 – CornerRadius), |

|

j*(LidSize.y/2 – CornerRadius), |

|

k*(LidSize.z – CornerRadius)]) // double thickness for flat bottom |

|

sphere(r=CornerRadius,$fn=8); |

|

|

|

translate([0,0,-LidSize.z/2]) // remove bottom |

|

cube([(LidSize.x + 2*Protrusion),(LidSize.y + 2*Protrusion),LidSize.z],center=true); |

|

|

|

translate([LidSize.x/8,0,0]) |

|

cube([LidSize.x/4,0.75*LidSize.y,4*ThreadThick],center=true); // epoxy recess |

|

} |

|

|

|

translate([0,0,-(Contacts[0].z + PinFlange[OD])]) // punch wire holes |

|

PinAssembly(); |

|

|

|

for (n=[0,1]) // polarity recesses |

|

translate([-LidOverhang/2 – 0.40,Contacts[n].y,LidSize.z – ThreadThick/2]) |

|

cube([4,4.5,ThreadThick + Protrusion],center=true); |

|

|

|

} |

|

|

|

for (n=[0,1]) // polarity indicators |

|

translate([-LidOverhang/2,Contacts[n].y,LidSize.z – 1*ThreadThick]) // … proud of surface |

|

rotate(90) |

|

linear_extrude(height=2*ThreadThick,convexity=10) |

|

text(text=Contacts[n][3],size=5,font="Arial:style:Bold",halign="center",valign="center"); |

|

} |

|

|

|

} |

|

|

|

// Spider for RGB LED + radome atop vertical struts |

|

|

|

module RGBSpider() { |

|

|

|

difference() { |

|

union() { |

|

for (i=[-1,1], j=[-1,1]) { |

|

translate([i*StrutOC.x/2,j*StrutOC.y/2,StrutBase[OD]/2]) |

|

rotate(180/StrutSides) // doesn't quite match crosspieces; close enough |

|

sphere(d=StrutBase[OD]/cos(180/StrutSides),$fn=StrutSides); |

|

translate([i*StrutOC.x/2,j*StrutOC.y/2,0]) |

|

rotate(180/StrutSides) |

|

cylinder(d=StrutBase[OD],h=StrutBase[OD]/2,$fn=StrutSides); |

|

} |

|

|

|

for (m=[-1,1]) // connecting bars |

|

rotate(m*StrutAngle) |

|

translate([0,0,StrutBase[OD]/4]) |

|

cube([norm(StrutOC),StrutBase[OD],StrutBase[OD]/2],center=true); |

|

|

|

translate([0,0,0]) // pillar for RGB LED and ball |

|

cylinder(d=BallPillar[OD],h=BallPillar[LENGTH],$fn=BallSides); |

|

} |

|

|

|

for (i=[-1,1], j=[-1,1]) // strut wires |

|

translate([i*StrutOC.x/2,j*StrutOC.y/2,-Protrusion]) |

|

rotate(0) |

|

PolyCyl(StrutBase[ID],StrutBase[OD]/2,6); |

|

|

|

for (m=[-1,1], n=[0,1]) // RGBA wires through bars |

|

rotate(m*StrutAngle + n*180) |

|

translate([StrutOC.x/3,0,-Protrusion]) |

|

PolyCyl(StrutBase[ID],StrutBase[OD],6); |

|

|

|

translate([0,0,BallOD/2 + BallPillar[LENGTH] – BallChordM]) // ball inset |

|

sphere(d=BallOD); |

|

|

|

translate([0,0,2*RGBBody.z + (BallPillar[LENGTH] – BallChordM) – RGBRecess]) // LED inset |

|

cube(RGBBody + [HoleWindage,HoleWindage,3*RGBBody.z],center=true); // XY clearance + huge height for E-Z cut |

|

|

|

translate([0,0,StrutBase[OD]/2]) // Neopixel recess |

|

PolyCyl(PixelPCB[OD],3*RGBBody.z,BallSides/2); |

|

|

|

for (m=[-1,1]) // RGBA wires through pillar |

|

rotate(m*StrutAngle) |

|

translate([0,0,StrutBase[OD]/2 + WireOD/2 + 0*Protrusion]) |

|

cube([norm(StrutOC)/2,WireOD,WireOD],center=true); |

|

|

|

} |

|

} |

|

|

|

// Spider for single LED atop struts, with the ball |

|

// Aligned to struts at terminal end of battery on Y axis |

|

|

|

module Spider() { |

|

|

|

difference() { |

|

union() { |

|

for (j=[-1,1]) { |

|

translate([-StrutOC.x/2,j*StrutOC.y/2,StrutBase[OD]/2]) |

|

rotate(180/StrutSides) |

|

sphere(d=StrutBase[OD]/cos(180/StrutSides),$fn=StrutSides); |

|

translate([-StrutOC.x/2,j*StrutOC.y/2,0]) |

|

rotate(180/StrutSides) |

|

cylinder(d=StrutBase[OD],h=StrutBase[OD]/2,$fn=StrutSides); |

|

} |

|

|

|

translate([-StrutOC.x/2,0,StrutBase[OD]/4]) // connecting bars |

|

cube([StrutBase[OD]*cos(180/StrutSides),StrutOC.y,StrutBase[OD]/2],center=true); |

|

|

|

translate([-StrutOC.x/2,0,0]) // pillar for RGB LED and ball |

|

cylinder(d=BallPillar[OD],h=BallPillar[LENGTH],$fn=BallSides); |

|

} |

|

|

|

for (j=[-1,1]) // strut wires |

|

translate([-StrutOC.x/2,j*StrutOC.y/2,-Protrusion]) |

|

rotate(0) |

|

PolyCyl(StrutBase[ID],StrutBase[OD]/2,6); |

|

|

|

translate([-StrutOC.x/2,0,0]) // wires through bars |

|

for (n=[-1,1]) |

|

rotate(n*90) |

|

translate([StrutOC.x/3,0,-Protrusion]) |

|

PolyCyl(StrutBase[ID],StrutBase[OD],6); |

|

|

|

translate([-StrutOC.x/2,0,-Protrusion]) // center hole for Neopixel |

|

rotate(180/6) |

|

PolyCyl(StrutBase[ID],StrutBase[OD],6); |

|

|

|

translate([-StrutOC.x/2,0,BallOD/2 + BallPillar[LENGTH] – BallChordM]) // ball inset |

|

sphere(d=BallOD); |

|

|

|

translate([-StrutOC.x/2,0,2*RGBBody.z + (BallPillar[LENGTH] – BallChordM) – RGBRecess]) // LED inset |

|

cube(RGBBody + [HoleWindage,HoleWindage,3*RGBBody.z],center=true); // XY clearance + huge height for E-Z cut |

|

|

|

translate([-StrutOC.x/2,0,StrutBase[OD]/2]) // Neopixel recess |

|

PolyCyl(PixelPCB[OD],3*RGBBody.z,BallSides/2); |

|

|

|

translate([-StrutOC.x/2,0,StrutBase[OD]/2 + WireOD/2 + 0*Protrusion]) // wire channels |

|

cube([WireOD,StrutOC.y/2,WireOD],center=true); |

|

|

|

} |

|

} |

|

|

|

//——————- |

|

// Build it! |

|

|

|

if (Layout == "Case") |

|

Case(); |

|

|

|

if (Layout == "Lid") |

|

Lid(); |

|

|

|

if (Layout == "RGBSpider") { |

|

RGBSpider(); |

|

} |

|

|

|

if (Layout == "Spider") { |

|

Spider(); |

|

} |

|

|

|

if (Layout == "Pins") { |

|

color("Silver",0.5) |

|

PinShape(); |

|

PinAssembly(); |

|

} |

|

|

|

if (Layout == "Fit") { // reveal pin assembly |

|

difference() { |

|

Case(); |

|

|

|

translate([(CaseOffset.x – Protrusion), |

|

Contacts[1].y, |

|

Contacts[1].z]) |

|

cube([(-CaseOffset.x + Protrusion),CaseSize.y,CaseSize.z]); |

|

|

|

translate([(CaseOffset.x – Protrusion), |

|

(CaseOffset.y – Protrusion), |

|

0]) |

|

cube([(-CaseOffset.x + Protrusion), |

|

Contacts[0].y + Protrusion – CaseOffset.y, |

|

CaseSize.z]); |

|

} |

|

|

|

translate([0,0,BatterySize.z + Gap]) |

|

Lid(); |

|

|

|

color("Silver",0.15) |

|

PinAssembly(); |

|

|

|

if (RGBCircuit) { |

|

translate([StrutOC.x/2,BatterySize.y/2,2*BatterySize.z]) |

|

difference() { |

|

RGBSpider(); |

|

rotate(180-StrutAngle) |

|

translate([0,0,-Protrusion]) |

|

cube([norm(StrutOC),StrutBase[OD],2*BallPillar.z],center=false); |

|

} |

|

color("Green",0.35) |

|

translate([StrutOC.x/2,BatterySize.y/2,2*BatterySize.z + BallOD/2 + BallPillar[LENGTH] – BallChordM]) |

|

sphere(d=BallOD); |

|

} |

|

else { |

|

difference() { |

|

translate([StrutOC.x/2,BatterySize.y/2,2*BatterySize.z]) |

|

Spider(); |

|

translate([-BallPillar[OD],BatterySize.y/2,2*BatterySize.z – Protrusion]) |

|

cube([BallPillar[OD],StrutOC.y,2*BallPillar.z],center=false); |

|

} |

|

color("Green",0.35) |

|

translate([0,BatterySize.y/2,2*BatterySize.z + BallOD/2 + BallPillar[LENGTH] – BallChordM]) |

|

sphere(d=BallOD); |

|

} |

|

} |

|

|

|

if (Layout == "Build") { |

|

rotate(90) { |

|

translate([-BatterySize.x/2,-BatterySize.y/2,BaseThick]) |

|

Case(); |

|

translate([-CaseSize.x + LidSize.x,-(LidSize.y/2 + LidOffset.y),0]) |

|

Lid(); |

|

if (RGBCircuit) |

|

translate([StrutOC.x + BatterySize.x/2,0,0]) |

|

RGBSpider(); |

|

else |

|

translate([StrutOC.x + BatterySize.x/2,0,0]) |

|

Spider(); |

|

} |

|

} |

|

|

|

if (Layout == "Show") { |

|

Case(); |

|

translate([0,0,(BatterySize.z + Gap)]) |

|

Lid(); |

|

color("Silver",0.25) |

|

PinAssembly(); |

|

if (RGBCircuit) { |

|

translate([StrutOC.x/2,BatterySize.y/2,2*BatterySize.z]) |

|

RGBSpider(); |

|

color("Green",0.35) |

|

translate([StrutOC.x/2,BatterySize.y/2,2*BatterySize.z + BallOD/2 + BallPillar[LENGTH] – BallChordM]) |

|

sphere(d=BallOD); |

|

} |

|

else { |

|

translate([StrutOC.x/2,BatterySize.y/2,2*BatterySize.z]) |

|

Spider(); |

|

color("Green",0.35) |

|

translate([0,BatterySize.y/2,2*BatterySize.z + BallOD/2 + BallPillar[LENGTH] – BallChordM]) |

|

sphere(d=BallOD); |

|

} |

|

} |

|

|

|

|