As part of converting the halogen desk lamp to LEDs, I replaced the hulking iron transformer with a flatter counterweight:

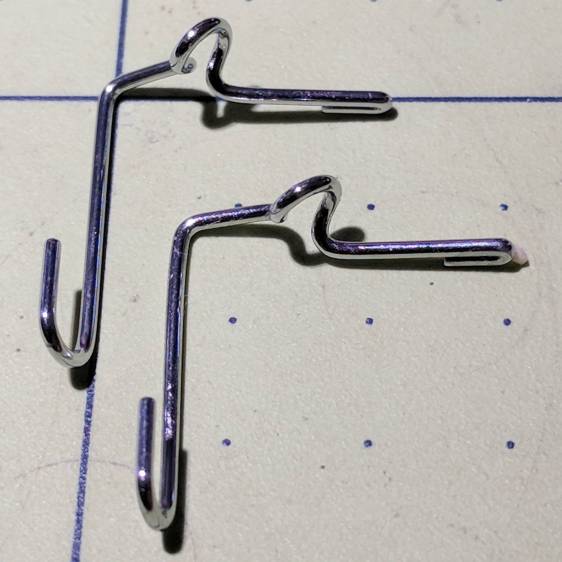

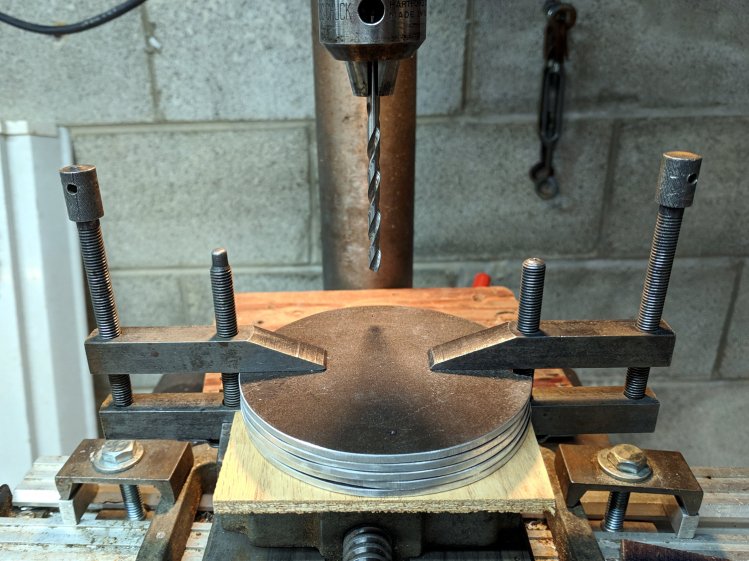

Under normal circumstances, you’d use something like steel or lead sheets, but Tiny Bandsaw™ can’t cut any appreciable thickness of steel and I gave away my entire lead stockpile, so I sawed disks from a pile of non-stick pancake griddles and drilled suitable mounting holes:

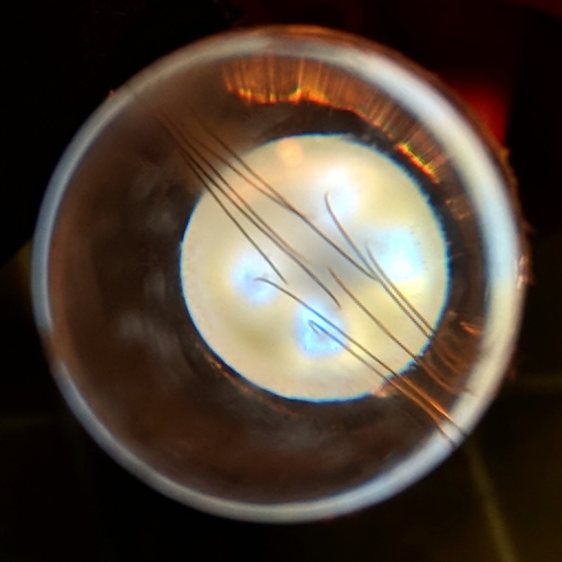

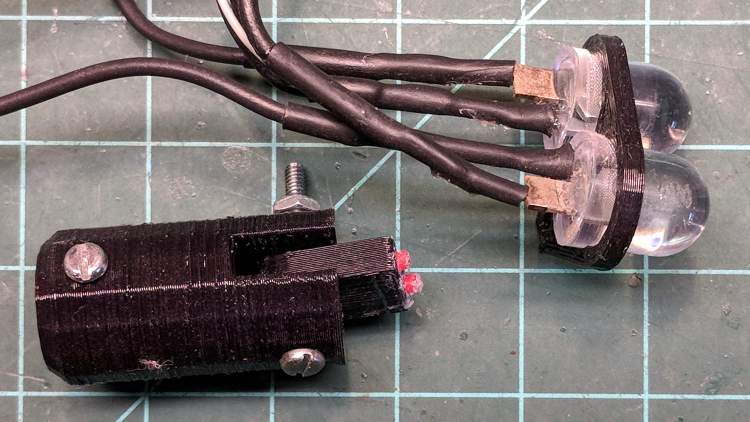

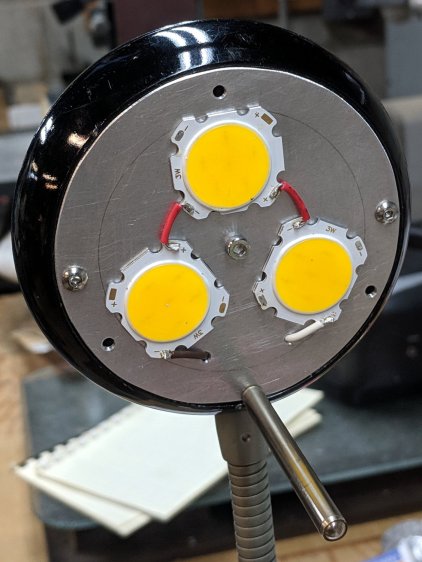

Another disk (from a formal aluminum sheet!) goes into the lamp head, with a trio of 3W COB LEDs epoxied in place:

The other side of the disk sports a heatsink harvested from a PC, also epoxied in place:

Realizing the head required only a little filing to accommodate the heatsink sealed both their fates.

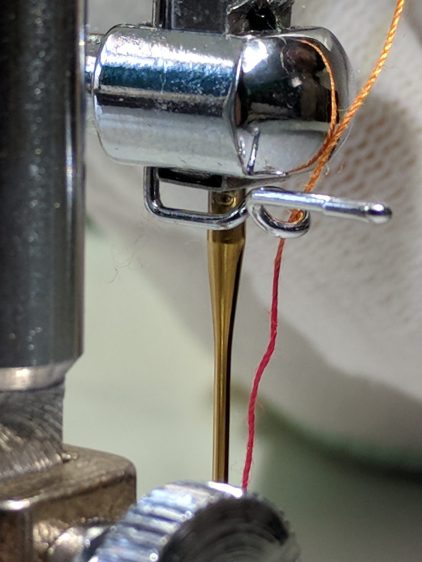

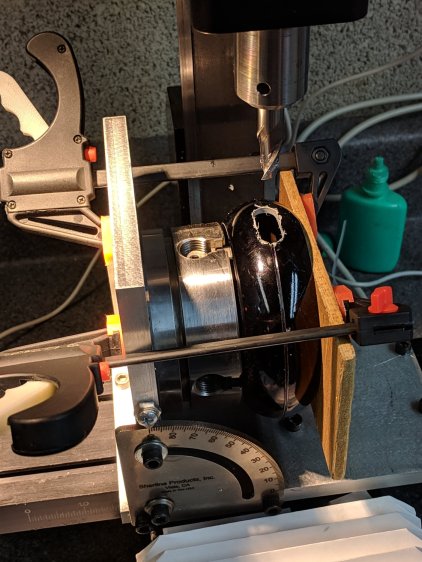

A test firing showed the heatsink needed more airflow, which didn’t come as much of a surprise, so I milled slots in the lamp head:

Deburring the holes, blackening the sides with a Sharpie, and tucking a bit of black window screen behind the opening made the vents look entirely professional.

The small dome in the base originally cleared the transformer and now holds the entire 10 W LED driver, along with all the wiring, atop the counterweight sheets:

A cork pad covers the base for a bit of non-skid action:

I couldn’t convince myself filling in those sectors would improve anything, so I didn’t.

And then It Just Worked:

All without a trace of solid modeling or G-Code …