The CNC 3018-Pro normally holds a small DC motor with a nicely cylindrical housing,so this was an easy adaptation of the MPCNC’s diamond drag bit holder:

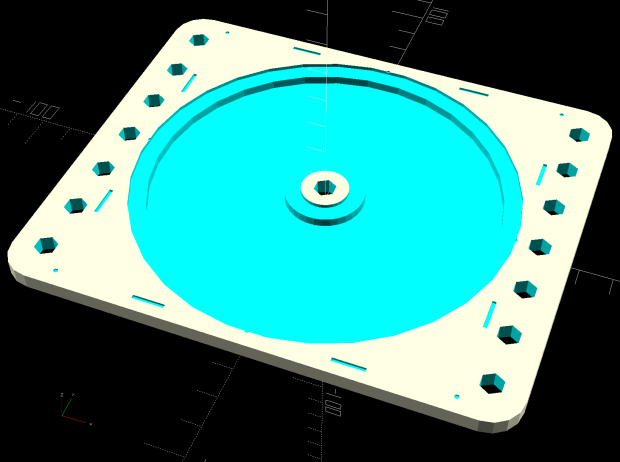

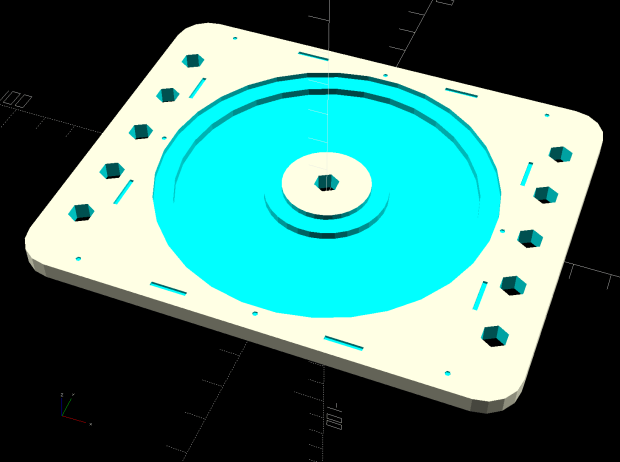

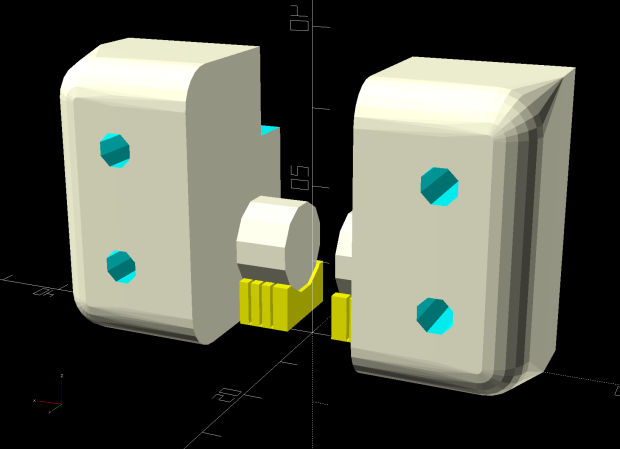

The lip around the bottom part rests atop the tool clamp, with the spring reaction plate sized to clear the notch in the Z-axis stage.

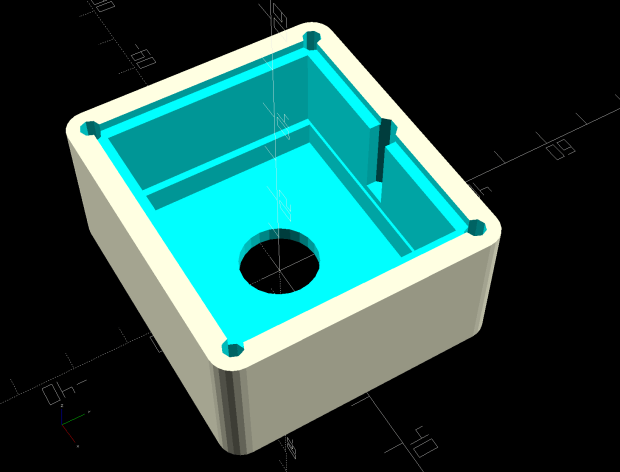

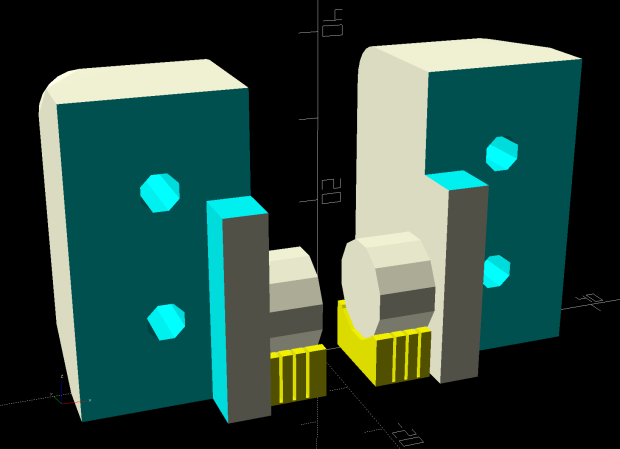

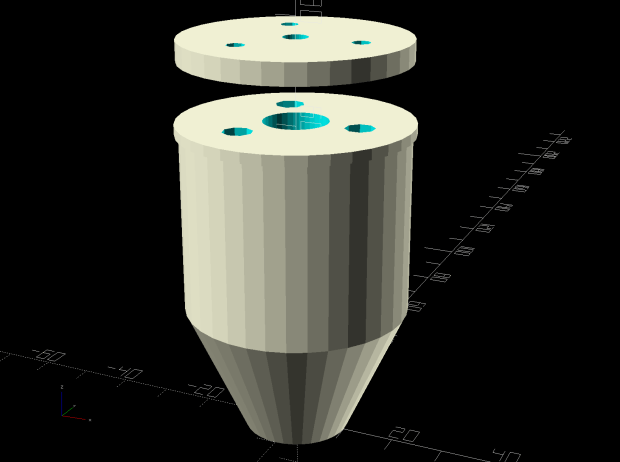

The solid model looks about like you’d expect:

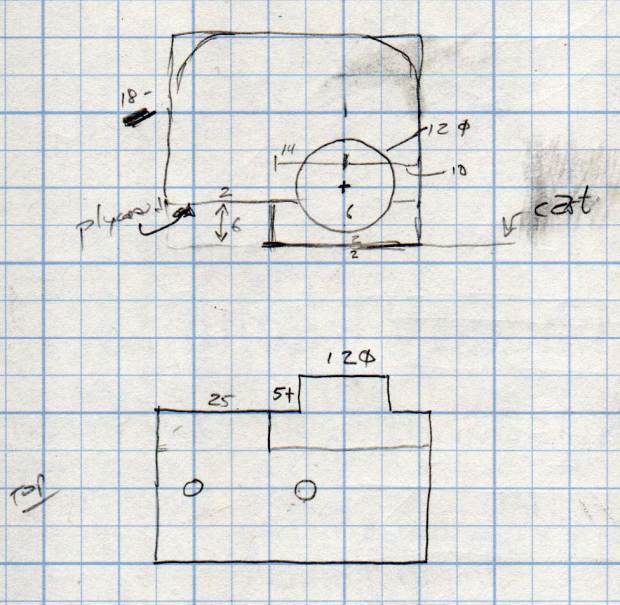

The New Thing compared to the MPCNC holder is wrapping LM6UU bearings around an actual 6 mm shaft, instead of using LM3UU bearings for the crappy diamond bit shank:

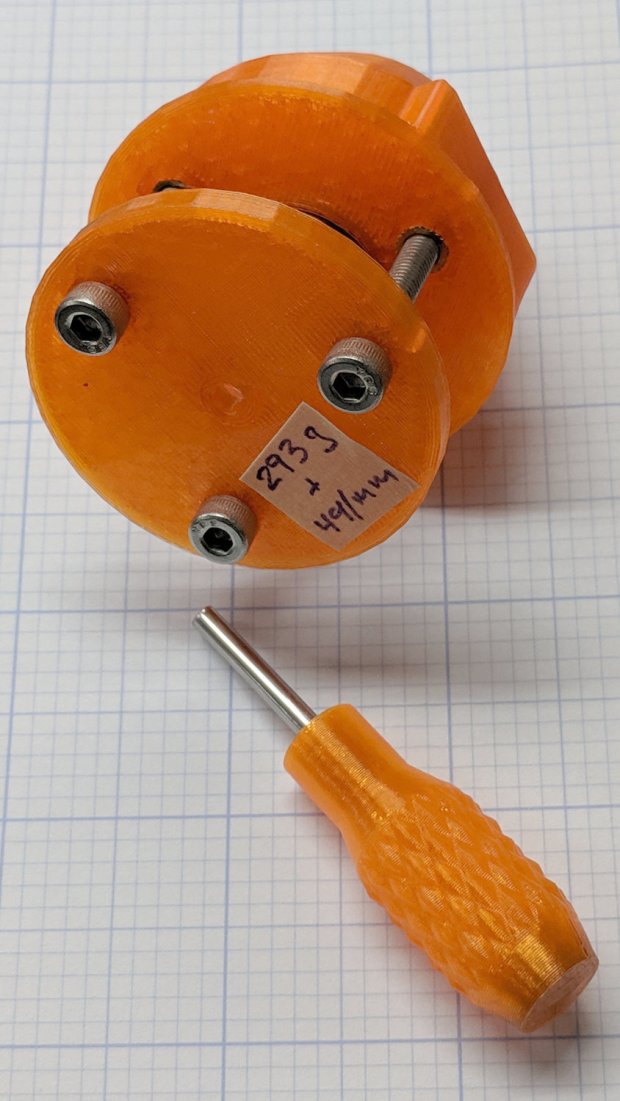

I cut the shank in two pieces, epoxied them into 3 mm holes drilled into the 6 mm shaft, then epoxied the knurled stop ring on the end. The ring is curing in the bench block to stay perpendicular to the 6 mm shaft.

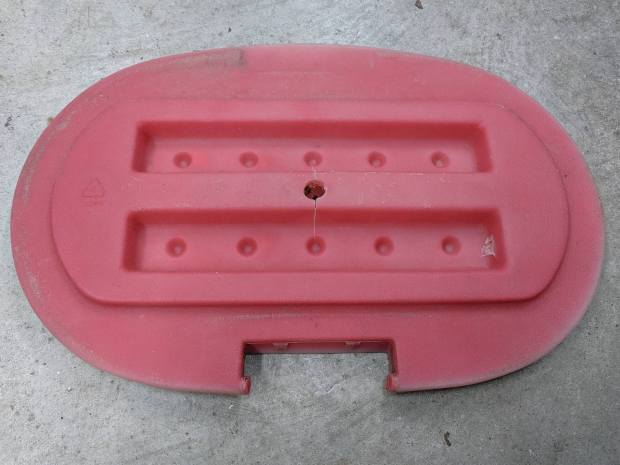

The spring constant is 55 g/mm and it’s now set for 125 g preload:

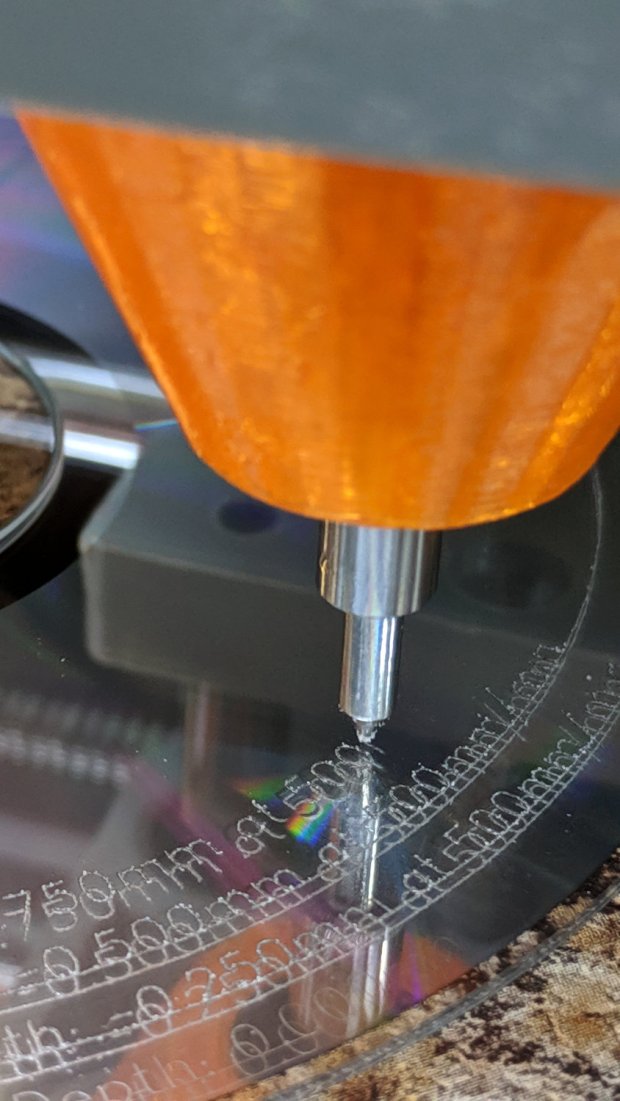

A quick test says all the parts have begun flying in formation:

It’s definitely more rigid than the MPCNC!

The OpenSCAD source code as a GitHub Gist:

| // Diamond Scribe in linear bearings for CNC3018 | |

| // Ed Nisley KE4ZNU – 2019-08-9 | |

| Layout = "Build"; // [Build, Show, Base, Mount, Plate] | |

| /* [Hidden] */ | |

| ThreadThick = 0.25; // [0.20, 0.25] | |

| ThreadWidth = 0.40; // [0.40, 0.40] | |

| /* [Hidden] */ | |

| Protrusion = 0.1; // [0.01, 0.1] | |

| HoleWindage = 0.2; | |

| inch = 25.4; | |

| function IntegerMultiple(Size,Unit) = Unit * ceil(Size / Unit); | |

| ID = 0; | |

| OD = 1; | |

| LENGTH = 2; | |

| //- Adjust hole diameter to make the size come out right | |

| module PolyCyl(Dia,Height,ForceSides=0) { // based on nophead's polyholes | |

| Sides = (ForceSides != 0) ? ForceSides : (ceil(Dia) + 2); | |

| FixDia = Dia / cos(180/Sides); | |

| cylinder(r=(FixDia + HoleWindage)/2,h=Height,$fn=Sides); | |

| } | |

| //- Dimensions | |

| // Knife holder & suchlike | |

| ScribeOD = 3.0; // diamond scribe shaft | |

| Bearing = [6.0,12.0,19.0]; // linear bearing body, ID = shaft diameter | |

| Spring = [4.5,5.5,3*ThreadThick]; // compression spring around shaft, LENGTH = socket depth | |

| //Spring = [9.5,10.0,3*ThreadThick]; // compression spring around shaft, LENGTH = socket depth | |

| WallThick = 4.0; // minimum thickness / width | |

| Screw = [3.0,6.75,25.0]; // holding it all together, OD = washer | |

| Insert = [3.0,5.0,8.0]; // brass insert | |

| //Insert = [4.0,6.0,10.0]; | |

| Clamp = [43.2,44.0,34.0]; // tool clamp ring, OD = clearance around top | |

| LipHeight = IntegerMultiple(2.0,ThreadThick); // above clamp for retaining | |

| BottomExtension = 25.0; // below clamp to reach workpiece | |

| MountOAL = LipHeight + Clamp[LENGTH] + BottomExtension; // total mount length | |

| echo(str("Mount OAL: ",MountOAL)); | |

| Plate = [1.5*ScribeOD,Clamp[ID] – 0*2*WallThick,WallThick]; // spring reaction plate | |

| NumScrews = 3; | |

| ScrewBCD = Bearing[OD] + Insert[OD] + 2*WallThick; | |

| echo(str("Retainer max OD: ",ScrewBCD – Screw[OD])); | |

| NumSides = 9*4; // cylinder facets (multiple of 3 for lathe trimming) | |

| // Basic mount shape | |

| module CNC3018Base() { | |

| translate([0,0,MountOAL – LipHeight]) | |

| cylinder(d=Clamp[OD],h=LipHeight,$fn=NumSides); | |

| translate([0,0,MountOAL – LipHeight – Clamp[LENGTH] – Protrusion]) | |

| cylinder(d=Clamp[ID],h=(Clamp[LENGTH] + 2*Protrusion),$fn=NumSides); | |

| cylinder(d1=Bearing[OD] + 2*WallThick,d2=Clamp[ID],h=BottomExtension + Protrusion,$fn=NumSides); | |

| } | |

| // Mount with holes & c | |

| module Mount() { | |

| difference() { | |

| CNC3018Base(); | |

| translate([0,0,-Protrusion]) // bearing | |

| PolyCyl(Bearing[OD],2*MountOAL,NumSides); | |

| for (i=[0:NumScrews – 1]) // clamp screws | |

| rotate(i*360/NumScrews) | |

| translate([ScrewBCD/2,0,MountOAL – Clamp[LENGTH]]) | |

| rotate(180/8) | |

| PolyCyl(Insert[OD],Clamp[LENGTH] + Protrusion,8); | |

| } | |

| } | |

| module SpringPlate() { | |

| difference() { | |

| cylinder(d=Plate[OD],h=Plate[LENGTH],$fn=NumSides); | |

| translate([0,0,-Protrusion]) | |

| PolyCyl(Plate[ID],2*MountOAL,NumSides); | |

| translate([0,0,Plate[LENGTH] – Spring[LENGTH]]) // spring retainer | |

| PolyCyl(Spring[OD],Spring[LENGTH] + Protrusion,NumSides); | |

| for (i=[0:NumScrews – 1]) // clamp screws | |

| rotate(i*360/NumScrews) | |

| translate([ScrewBCD/2,0,-Protrusion]) | |

| rotate(180/8) | |

| PolyCyl(Screw[ID],2*MountOAL,8); | |

| } | |

| } | |

| //—– | |

| // Build it | |

| if (Layout == "Base") | |

| CNC3018Base(); | |

| if (Layout == "Mount") | |

| Mount(); | |

| if (Layout == "Plate") | |

| SpringPlate(); | |

| if (Layout == "Show") { | |

| Mount(); | |

| translate([0,0,1.25*MountOAL]) | |

| rotate([180,0,0]) | |

| SpringPlate(); | |

| } | |

| if (Layout == "Build") { | |

| translate([0,-0.75*Clamp[OD],MountOAL]) | |

| rotate([180,0,0]) | |

| Mount(); | |

| translate([0,0.75*Plate[OD],0]) | |

| SpringPlate(); | |

| } |