|

// Marquetry Layers |

|

// Ed Nisley KE4ZNU |

|

// 2022-08-21 layered paper test piece |

|

|

|

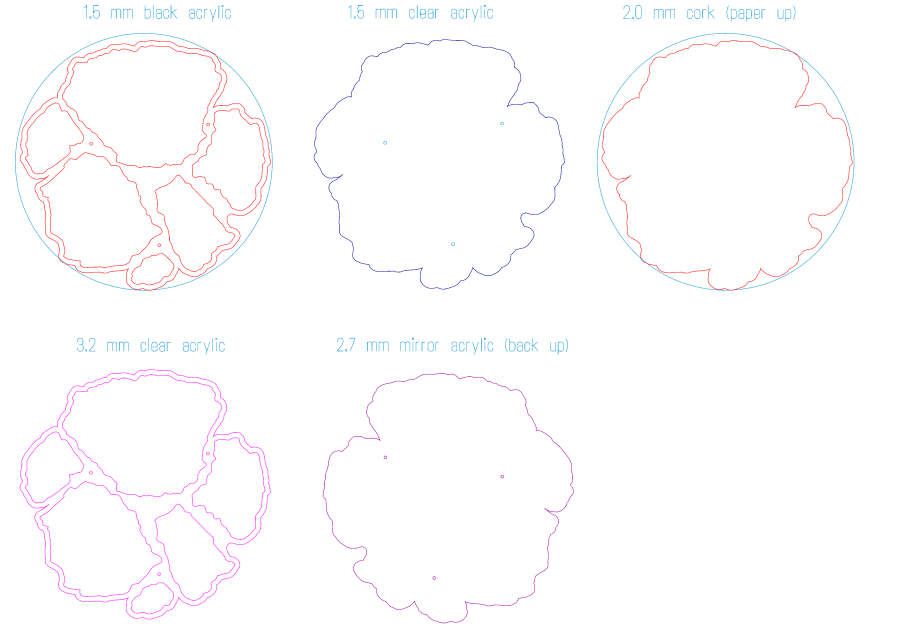

layerstack("Frame","Leaves","Rim","Base","Center","Tool1"); // SVG layers map to LightBurn colors |

|

|

|

//—– |

|

// Library routines |

|

|

|

include("tracepath.inc.gcmc"); |

|

include("varcs.inc.gcmc"); |

|

|

|

FALSE = 0; |

|

TRUE = !FALSE; |

|

|

|

//—– |

|

// Command line parameters |

|

|

|

// -D various useful tidbits |

|

// add unit to speeds and depths: 2000mm / -3.00mm / etc |

|

|

|

if (!isdefined("OuterDia")) { |

|

OuterDia = 120.0mm; |

|

} |

|

|

|

if (!isdefined("CenterDia")) { |

|

CenterDia = 20.0mm; |

|

} |

|

|

|

if (!isdefined("NumLeaves")) { |

|

NumLeaves = 8; |

|

} |

|

|

|

if (!isdefined("Sash")) { |

|

Sash = 4.0mm; |

|

} |

|

|

|

if (!isdefined("LeafAspect")) { |

|

LeafAspect = 0.50; |

|

} |

|

|

|

// Leaf values |

|

|

|

LeafStemAngle = 360.0deg/NumLeaves; // subtended by inner sides |

|

LeafStemHA = LeafStemAngle/2; |

|

|

|

LeafOAL = OuterDia/2 – Sash – (Sash/2)/sin(LeafStemHA); |

|

|

|

LeafWidth = LeafAspect*LeafOAL; |

|

L1 = (LeafWidth/2)/tan(LeafStemHA); |

|

L2 = LeafOAL – L1; |

|

// message("Len: ",LeafOAL," L1: ",L1," L2: ",L2); |

|

|

|

LeafTipHA = to_deg(atan(LeafWidth/2,L2)); // subtended by outer sides |

|

LeafTipAngle = 2*LeafTipHA; |

|

|

|

// message("Width: ",LeafWidth); |

|

// message("Tip HA: ",LeafTipHA); |

|

|

|

LeafID = CenterDia + 2*Sash; |

|

LeafOD = LeafID + LeafOAL; |

|

|

|

// message("ID: ",LeafID," OD: ",LeafOD); |

|

|

|

// Find leaf and rim vertices |

|

|

|

P0 = [(Sash/2) / sin(LeafStemHA),0.0mm]; |

|

|

|

m = tan(LeafStemHA); |

|

y0 = -(Sash/2) / cos(LeafStemHA); |

|

|

|

if (CenterDia) { // one sash width around center spot |

|

a = 1 + pow(m,2); |

|

b = 2 * m * y0; |

|

c = pow(y0,2) – pow(LeafID/2,2); |

|

xp = (-b + sqrt(pow(b,2) – 4*a*c))/(2*a); |

|

xn = (-b – sqrt(pow(b,2) – 4*a*c))/(2*a); |

|

y = xp*tan(LeafStemHA) – (Sash/2) / cos(LeafStemHA); |

|

P1 = [xp,y]; |

|

if (FALSE) { |

|

message("a: ",a); |

|

message("b: ",b); |

|

message("c: ",c); |

|

message("p: ",xp," n: ",xn," y: ",y); |

|

} |

|

} |

|

else { // force sharp point without center spot |

|

P1 = P0; |

|

} |

|

|

|

P2 = P0 + [L1,LeafWidth/2]; |

|

P3 = P0 + [LeafOAL,0mm]; |

|

|

|

P4 = P3 + [Sash/sin(LeafTipHA),0.0mm]; |

|

P5r = P4.x * sin(LeafTipHA) / sin(180deg – LeafStemHA – LeafTipHA); |

|

P5 = rotate_xy([P5r,0.0mm],LeafStemHA); |

|

P6 = rotate_xy(P4,LeafStemAngle); |

|

|

|

t2 = pow(tan(-LeafTipHA),2); |

|

a = 1 + t2; |

|

b = -2 * t2 * P4.x; |

|

c = t2 * pow(P4.x,2) – pow(P3.x,2); |

|

|

|

xp = (-b + sqrt(pow(b,2) – 4*a*c))/(2*a); |

|

xn = (-b – sqrt(pow(b,2) – 4*a*c))/(2*a); |

|

y = (xp – P4.x)*tan(-LeafTipHA); |

|

// message("p: ",xp," n: ",xn," y: ",y); |

|

|

|

P4a = [xp,y]; |

|

P6a = rotate_xy(P4a,LeafStemAngle – 2*atan(P4a.y,P4a.x)); |

|

|

|

if (FALSE) { |

|

message("P0: ",P0); |

|

message("P1: ",P1); |

|

message("P2: ",P2); |

|

message("P3: ",P3); |

|

message("P4: ",P4); |

|

message("P4a: ",P4a); |

|

message("P5: ",P5); |

|

message("P6: ",P6); |

|

message("P6a: ",P6a); |

|

} |

|

|

|

// Construct paths |

|

|

|

LeafPoints = {P1,P2,P3,[P2.x,-P2.y],[P1.x,-P1.y]}; |

|

|

|

if (P0 != P1) { |

|

StemArc = varc_ccw(P1 – [P1.x,-P1.y],LeafID/2); |

|

StemArc += [P1.x,-P1.y]; |

|

LeafPoints += StemArc; |

|

} |

|

|

|

RimChord = length(P4a – P6a); |

|

RimThick = OuterDia/2 – Sash – length(P5); |

|

|

|

RimPoints = {P4a,P5,P6a}; |

|

RimArc = varc_cw(P4a – P6a,P4a.x); |

|

RimArc += P6a; |

|

RimPoints += RimArc; |

|

|

|

//— Lay out the frame |

|

|

|

linecolor(0xff0000); |

|

|

|

layer("Frame"); |

|

|

|

if (CenterDia) { |

|

goto([CenterDia/2,0mm]); |

|

circle_cw([0mm,0mm]); |

|

} |

|

|

|

repeat(NumLeaves;i) { |

|

a = (i-1)*LeafStemAngle; |

|

tracepath(rotate_xy(LeafPoints,a)); |

|

} |

|

|

|

repeat(NumLeaves;i) { |

|

a = (i-1)*LeafStemAngle; |

|

tracepath(rotate_xy(RimPoints,a)); |

|

} |

|

|

|

linecolor(0xff0000); |

|

|

|

goto([OuterDia/2,0]); |

|

circle_cw([0mm,0mm]); |

|

|