Today I Learned that maple seed spinners are properly called samaras:

The Norway Maple near the road produced a bumper crop of triples this year, along with the first quad spinner samara I’ve ever seen.

Looks like the odds are ever in my favor …

The Smell of Molten Projects in the Morning

Ed Nisley's Blog: Shop notes, electronics, firmware, machinery, 3D printing, laser cuttery, and curiosities. Contents: 100% human thinking, 0% AI slop.

Who’d’a thunk it?

Today I Learned that maple seed spinners are properly called samaras:

The Norway Maple near the road produced a bumper crop of triples this year, along with the first quad spinner samara I’ve ever seen.

Looks like the odds are ever in my favor …

The robin nestlings fledged fourteen days after we spotted the first eggshell on the driveway below the nest. The first one may have flown away the previous evening, leaving three increasingly restless siblings behind:

They’re recognizably robins now, covered in young-bird speckle camouflage.

Feeding continued apace:

After feeding, robin nestlings produce fecal sacs, which the parents either eat or carry away:

Robins aren’t big on facial expressions, but, speaking from personal experience, anything to do with diapers isn’t the high point of a parent’s day.

And then there were none:

The gazillion black dots on the soffit are pinpoint-sized insects / mites / ticks infesting the nest and, presumably, the birds. The earlier pictures don’t show them, so perhaps these missed the last bird off the nest and are now regretting their life choices.

Go, birds, … gone!

Despite knowing the wire colors inside USB cables need not follow any particular convention, this still came as a surprise:

Yes, that’s a negative indicator on the meter: it reads -5.020 V.

No, I didn’t swap the test probe banana plugs on the other end.

A bit of continuity testing shows the green and white data wires are also reversed, so whoever assembled the cable simply soldered the proper wire color sequence backwards onto both connectors. As long as you don’t cut the cable to reuse the connectors, it’s all good.

Memo to Self: Stop trusting, always verify!

NYS DOT cleared the Japanese Knotweed from the shoulder along Rt 376 north of Maloney last year:

The last image in that gallery is from the end of April; you can see the weeds just starting to grow under the guide rail.

Japanese Knotweed, being basically a weed on crystal meth, becomes a lush hedge from a standing start in five weeks:

Knowing how NYS DOT’s Region 8 Dutchess South Residency’s brush trimming has(n’t) worked in previous years, this took us by surprise:

Because chopping Japanese Knotweed to the ground doesn’t actually discourage it, we hope they’re scheduled to return every couple of months …

The robin nesting atop the garage door spotlights keeps a careful watch over her surroundings:

Based on past experience, we though a blue jay had discovered the nest when we found this in front of the garage door:

A day later, a quick peek when she was off the nest told a different story:

As with humans, only parents can love things like that …

Another pair of robins built a more conventional nest in a small front-yard tree, although they seemed content to start brooding atop only two eggs.

We wish both families well, along with the wrens nesting in the front bird box.

Go, birds, go!

The strip mall down the road recently sprouted ersatz stone pillars around the steel posts holding up the roof:

Six days later, more slabs have fallen off the first pillar in the row:

And the second pillar:

Those fancy(-ish) bases consist of a wood frame covered with a mortar layer holding tiles of imitation stonework. From what little I know of stonework, mortar works only in compression, so you can’t glue tiles onto the side of a concrete lump using mortar.

Epoxy, maybe. Silicone snot, probably. Mortar, nope.

This happened barely weeks after the project’s completion, so I foresee poor ROI for the mall owner and plenty of warranty work for the contractor.

I’ve been putting this type of support structure inside screw holes & suchlike for years:

It’s basically a group of small rectangles rotated around the hole’s axis and about one thread thickness shorter than the overhanging interior.

I’ve found that incorporating exactly the right support structure eliminates Slic3r’s weird growths, eases removal, and generally works better all around.

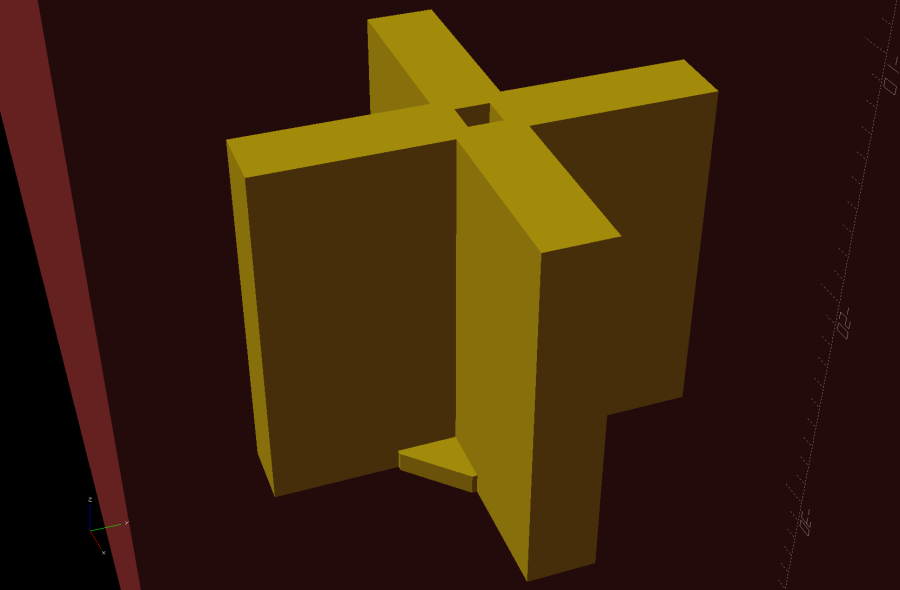

So doing this for the baseplate of the Glass Tile frame came naturally:

This OpenSCAD snippet plunks one of those asterisks in each of four screw holes:

if (Support)

color("Yellow")

for (i=[-1,1], j=[-1,1])

translate([i*InsertOC.x/2,j*InsertOC.y/2,0])

for (a=[0:45:135])

rotate(a)

translate([0,0,(Screw[LENGTH] - ThreadThick)/2])

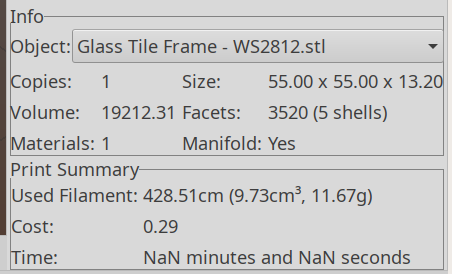

cube([Screw[OD] - 2*ThreadWidth,2*ThreadWidth,Screw[LENGTH] - ThreadThick],center=true);The “cubes” overlap in the middle, with no completely coincident faces or common edges, so it’s 2-manifold. Slic3r, however, produces a weird time estimate whenever the model includes those structures:

NaN stands for Not A Number and means something horrible has happened in the G-Code generation. Fortunately, the G-Code worked perfectly and produced the desired result, but I’m always uneasy when Something Seems Wrong.

Messing around with the code produced a slightly different support structure:

The one thread thick square on the bottom helps glue the structure to the platform and four ribs work just as well as eight in the octagonal hole:

Fin = [Screw[OD]/2 - 1.5*ThreadWidth,2*ThreadWidth,ScrewRecess - ThreadThick];

if (Inserts && SupportInserts)

color("Yellow")

for (i=[-1,1], j=[-1,1])

translate([i*InsertOC.x/2,j*InsertOC.y/2,0]) {

rotate(180/8)

cylinder(d=6*ThreadWidth,h=ThreadThick,$fn=8);

for (a=[0:90:360])

rotate(a)

translate([Fin.x/2 + ThreadWidth/2,0,(ScrewRecess - ThreadThick)/2])

cube(Fin,center=true);

}Which changed the NaN time estimates into actual numbers.

One key difference may be the small hole in the middle. The four ribs (not two!) now overlap by one thread width around the hole, so they’re not quite coincident and Slic3r produces a tidy model:

The hole eliminates a smear of infill from the center, which may have something to do with the improvement.

In any event, I have an improved copypasta recipe for the next screw holes in need of support, even if I don’t understand why it’s better.