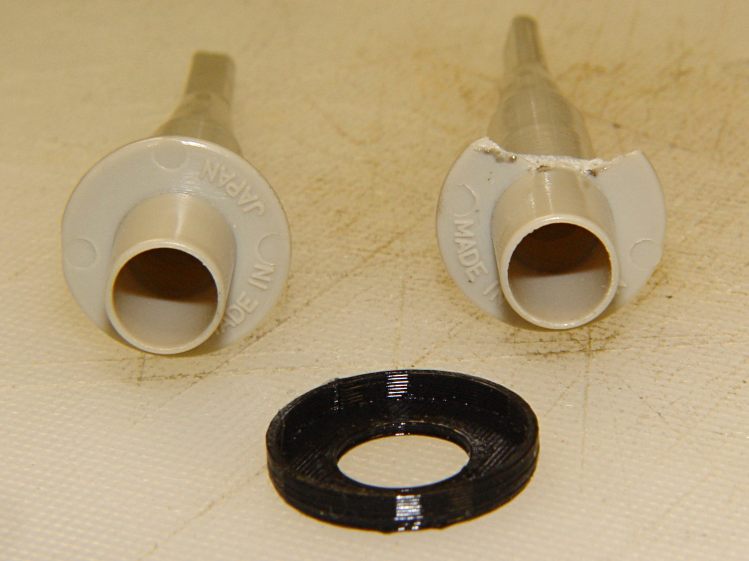

Quite some time ago I manage to break the finger flange on one of my scope probes and, what with it being made of an un-glueable engineering plastic, a simple repair job failed quickly. It’s entirely round and a perfect lathe project, but … this is easier:

You can see remnants of that failed repair just below the fracture:

Some epoxy around the rim of the flange, plus filling the missing sector, looks about as grubby as you’d expect:

That’s a tiny zit at about 1 o’clock which came off with fingernail pressure.

From the business end, it actually looks pretty snappy:

I’m mildly tempted to preemptively reinforce the other probes…

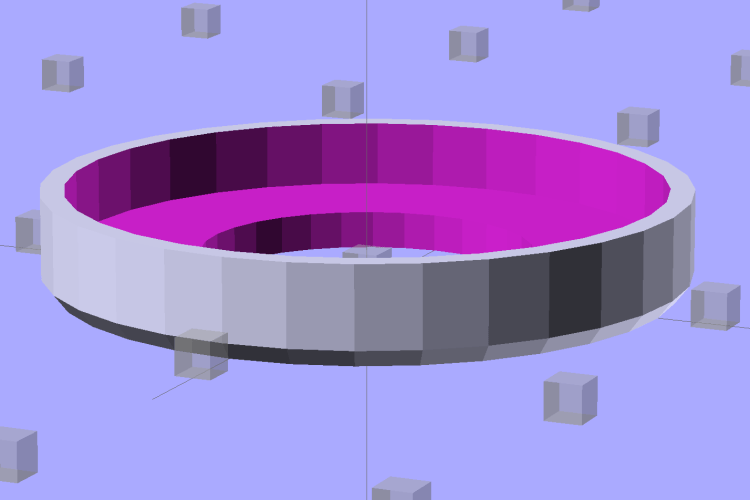

The OpenSCAD source code joins two parts with coincident faces, but it worked out OK for once:

// Tek Scope Probe Flange

// Ed Nisley KE4ZNU November 2013

//- Extrusion parameters must match reality!

// Print with 2 shells and 3 solid layers

ThreadThick = 0.25;

ThreadWidth = 0.40;

HoleWindage = 0.2;

Protrusion = 0.1; // make holes end cleanly

function IntegerMultiple(Size,Unit) = Unit * ceil(Size / Unit);

//----------------------

// Dimensions

FlangeOD = 16.0;

FlangeID = 8.75;

FlangeThick = IntegerMultiple(1.25,ThreadThick);

DiskOD = FlangeOD + 4*ThreadWidth;

DiskThick = FlangeThick + 4*ThreadThick;

NumSides = 8*4;

//----------------------

// Useful routines

module PolyCyl(Dia,Height,ForceSides=0) { // based on nophead's polyholes

Sides = (ForceSides != 0) ? ForceSides : (ceil(Dia) + 2);

FixDia = Dia / cos(180/Sides);

cylinder(r=(FixDia + HoleWindage)/2,

h=Height,

$fn=Sides);

}

module ShowPegGrid(Space = 10.0,Size = 1.0) {

Range = floor(50 / Space);

for (x=[-Range:Range])

for (y=[-Range:Range])

translate([x*Space,y*Space,Size/2])

%cube(Size,center=true);

}

//----------------------

// Build it

ShowPegGrid();

difference() {

union() {

translate([0,0,2*ThreadThick])

cylinder(r=DiskOD/2,h=DiskThick,$fn=NumSides); // main repair part

cylinder(r1=(DiskOD - 2*ThreadWidth)/2,r2=DiskOD/2,h=2*ThreadThick,$fn=NumSides);

}

translate([0,0,(DiskThick - FlangeThick)]) // flange clearance

PolyCyl(FlangeOD,2*FlangeThick,NumSides);

translate([0,0,-DiskThick/2])

PolyCyl(FlangeID,2*DiskThick,NumSides);

}