|

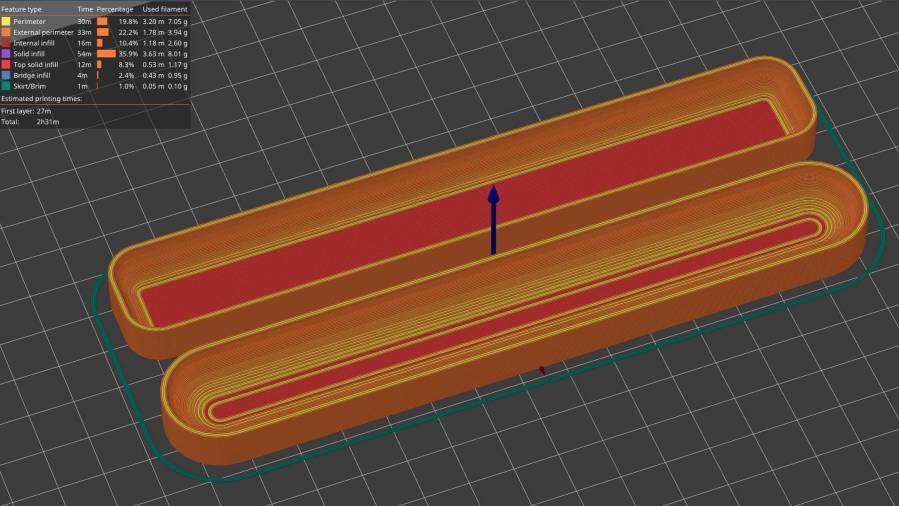

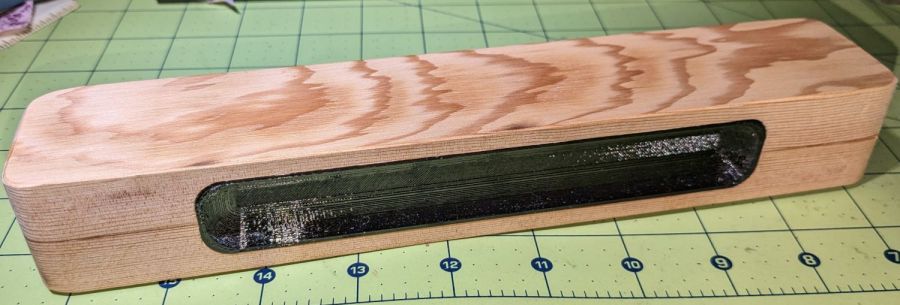

// Ironing weight pocketing |

|

// Ed Nisley KE4ZNU – 2023-01 |

|

|

|

//—– |

|

// Library routines |

|

|

|

include("/opt/gcmc/example/cc_hole.inc.gcmc"); |

|

include("varcs.inc.gcmc"); |

|

include("tracepath_comp.inc.gcmc"); |

|

include("trochoidal.inc.gcmc"); |

|

|

|

/* |

|

include("tracepath.inc.gcmc"); |

|

include("engrave.inc.gcmc"); |

|

*/ |

|

|

|

//—– |

|

// Useful constants |

|

|

|

SafeZ = 10.0mm; // above all obstructions |

|

TravelZ = 2.0mm; // within engraving / milling area |

|

|

|

BlockHome = [0.0mm,0.0mm,TravelZ]; // Origin on surface at center of pocket |

|

|

|

FALSE = 0; |

|

TRUE = !FALSE; |

|

|

|

//—– |

|

// Overall values |

|

|

|

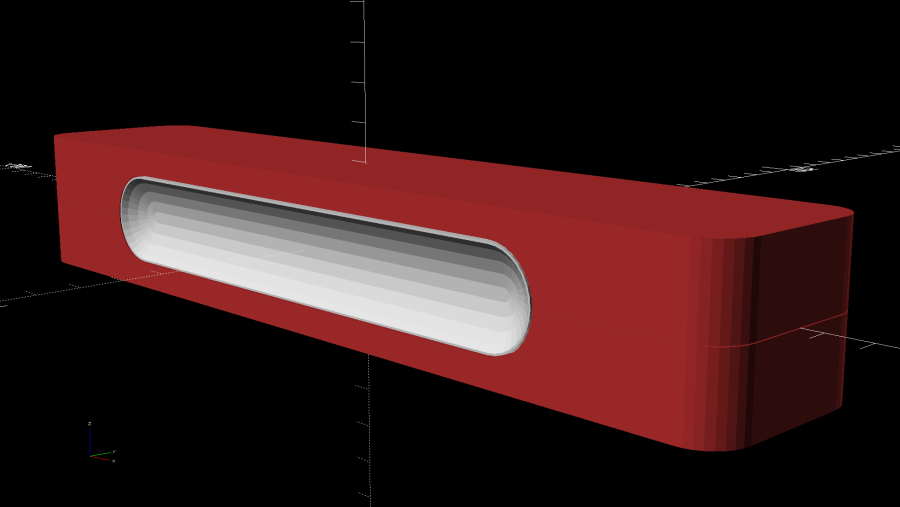

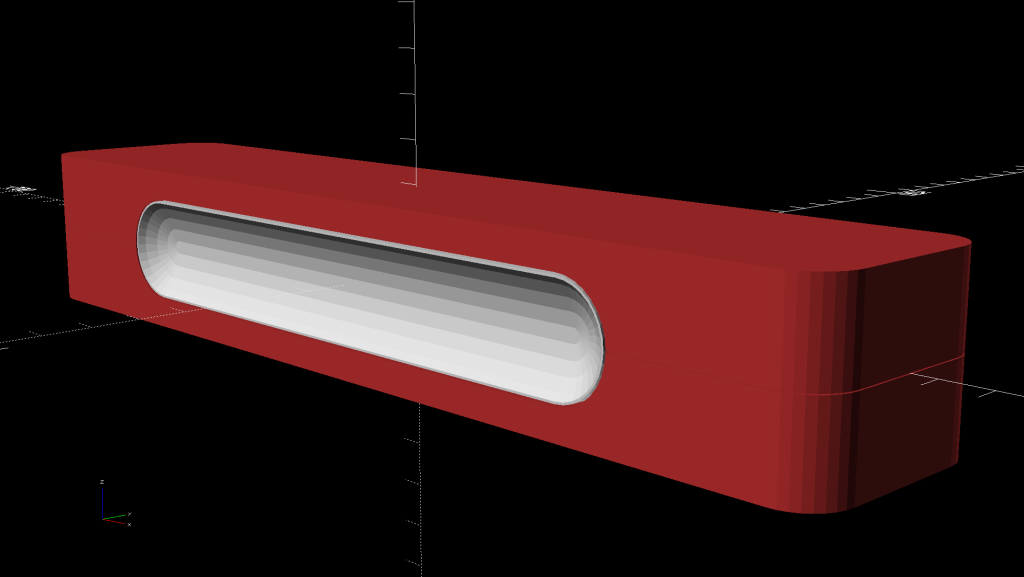

Socket = [160.0mm,25.0mm,7.0mm]; // raw grip recess into block |

|

|

|

RoundEnds = TRUE; // TRUE for smooth rounded endcaps |

|

|

|

SocketRadius = RoundEnds ? Socket.y/2 : 10.0mm; |

|

comment("SocketRadius: ",SocketRadius); |

|

|

|

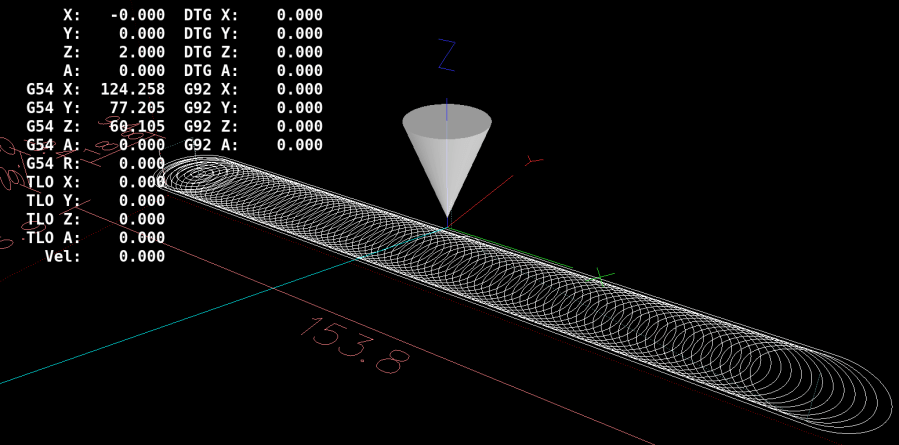

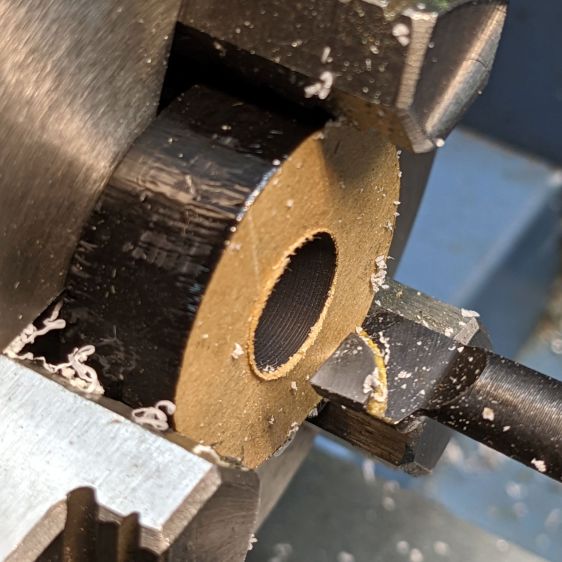

CutterDia = 6.32mm – 0.15; // actual cutter diameter – windage |

|

MillStep = 0.25 * CutterDia; // stepover in XY plane |

|

comment("CutterDia: ",CutterDia," MillStep: ",MillStep); |

|

MillClean = MillStep/2; |

|

|

|

PlungeSpeed = 150.0mm; // cutter Z plunge into work |

|

MillSpeed = 600.0mm; // XY speed |

|

|

|

if (CutterDia > SocketRadius) { |

|

error("Cutter too large for corner radius"); |

|

} |

|

|

|

CornerOC = head(Socket,2) – 2*[SocketRadius,SocketRadius]; |

|

comment("CornerOC: ",CornerOC); |

|

|

|

Corners = RoundEnds ? // rear left CCW around slot |

|

{-CornerOC/2, CornerOC/2} : |

|

{[-CornerOC.x,CornerOC.y]/2, [-CornerOC.x,-CornerOC.y]/2, [CornerOC.x,-CornerOC.y]/2, CornerOC/2}; |

|

comment("Corners: ", Corners); |

|

|

|

if (RoundEnds) { |

|

SlotPerimeter = {[0.0mm,Socket.y/2,-Socket.z]}; // entry point at center rear |

|

SlotPerimeter += {Corners[0] + [0.0mm,SocketRadius]}; |

|

SlotPerimeter += varc_ccw([-SocketRadius,-SocketRadius],SocketRadius) + SlotPerimeter[-1]; |

|

SlotPerimeter += varc_ccw([+SocketRadius,-SocketRadius],SocketRadius) + (Corners[0] + [-SocketRadius,0.0mm]); |

|

SlotPerimeter += {Corners[1] + [0.0mm,-SocketRadius]}; // across front |

|

SlotPerimeter += varc_ccw([+SocketRadius,+SocketRadius],SocketRadius) + SlotPerimeter[-1]; |

|

SlotPerimeter += varc_ccw([-SocketRadius,+SocketRadius],SocketRadius) + (Corners[1] + [+SocketRadius,0.0mm]); |

|

} |

|

else { |

|

SlotPerimeter = {[0.0mm,Socket.y/2,-Socket.z]}; // entry point at center rear |

|

SlotPerimeter += {Corners[0] + [0.0mm,SocketRadius]}; |

|

SlotPerimeter += varc_ccw([-SocketRadius,-SocketRadius],SocketRadius) + SlotPerimeter[-1]; |

|

SlotPerimeter += {Corners[1] + [-SocketRadius,0.0mm]}; |

|

SlotPerimeter += varc_ccw([+SocketRadius,-SocketRadius],SocketRadius) + SlotPerimeter[-1]; |

|

SlotPerimeter += {Corners[2] + [0.0mm,-SocketRadius]}; // across front |

|

SlotPerimeter += varc_ccw([SocketRadius,SocketRadius],SocketRadius) + SlotPerimeter[-1]; |

|

SlotPerimeter += {Corners[3] + [SocketRadius,0.0mm]}; |

|

SlotPerimeter += varc_ccw([-SocketRadius,SocketRadius],SocketRadius) + SlotPerimeter[-1]; |

|

} |

|

|

|

|

|

//— Begin cutting |

|

|

|

goto([-,-,TravelZ]); |

|

goto(BlockHome); |

|

|

|

if (!RoundEnds) { // clear corners outward of main pocket |

|

foreach(Corners; xy) { |

|

comment("Plunge corner at: ",xy); |

|

feedrate(PlungeSpeed); |

|

goto(xy); |

|

move([-,-,-Socket.z]); |

|

comment(" pocket"); |

|

feedrate(MillSpeed); |

|

cc_hole(xy,(SocketRadius – MillClean),CutterDia/2,MillStep,-Socket.z); |

|

goto([-,-,TravelZ]); |

|

comment(" done!"); |

|

} |

|

} |

|

|

|

comment("Open slot"); |

|

|

|

TrochRadius = (Socket.y – CutterDia)/2 – MillClean; |

|

TrochPath = {[-(Socket.x/2 – TrochRadius – CutterDia/2 – MillStep),TrochRadius], |

|

[ (Socket.x/2 – TrochRadius – CutterDia/2 – MillStep),TrochRadius]}; |

|

|

|

comment(" clear landing zone"); |

|

xy = [TrochPath[0].x,0.0mm]; |

|

feedrate(PlungeSpeed); |

|

goto(xy); |

|

move([-,-,-Socket.z]); |

|

feedrate(MillSpeed); |

|

cc_hole(xy,Socket.y/2 – MillClean,CutterDia/2,MillStep,-Socket.z); |

|

goto([-,-,TravelZ]); |

|

|

|

comment(" trochoid pocket milling"); |

|

|

|

feedrate(MillSpeed); |

|

trochoid_move(TrochPath[0],TrochPath[1], |

|

-Socket.z, TrochRadius, MillStep); |

|

goto([-,-,TravelZ]); |

|

|

|

comment("Clean slot perimeter"); |

|

feedrate(MillSpeed); |

|

goto([-,-,-Socket.z]); |

|

tracepath_comp(SlotPerimeter,CutterDia/2,TPC_CLOSED + TPC_LEFT + TPC_ARCIN + TPC_ARCOUT); |

|

|

|

goto([-,-,TravelZ]); |

|

goto(BlockHome); |