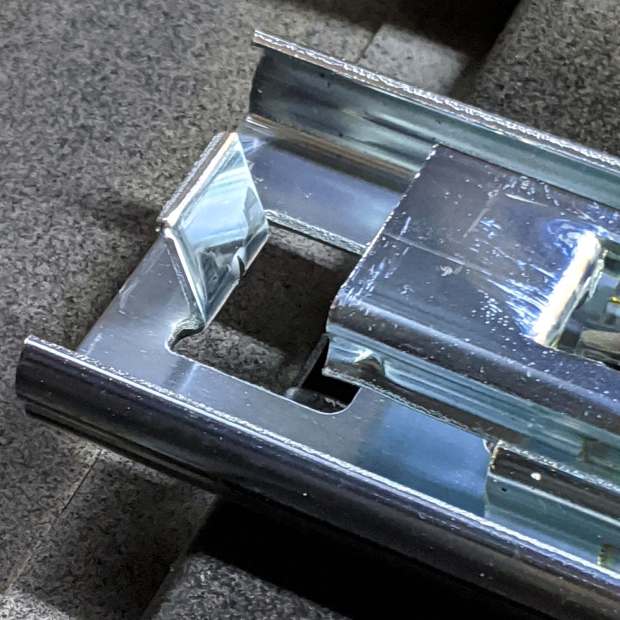

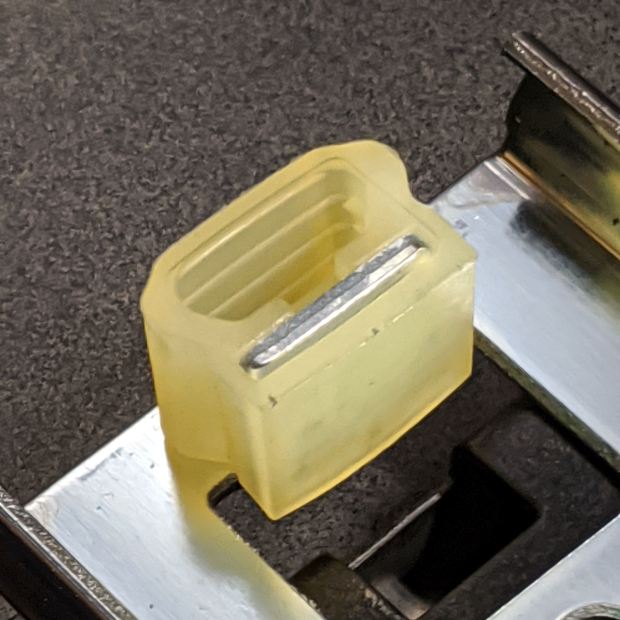

One of two new round rubber soaker hoses arrived with a slight crimp, enough to suggest it would crumble at an inopportune moment. Rather than return the hose for something that’s not an obvious failure, I clamped the crimp:

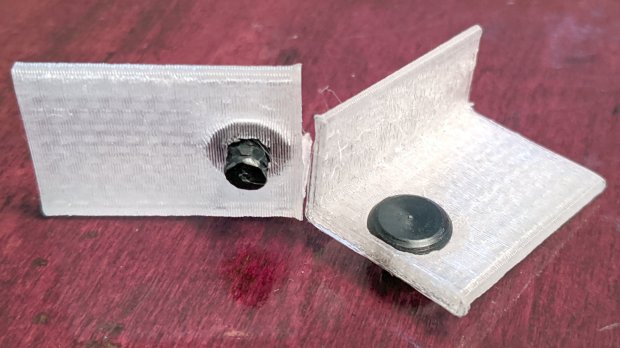

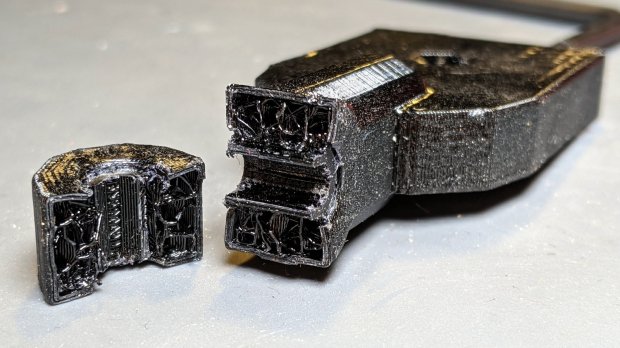

Unlike the clamps for the punctured flat soaker hoses, this one doesn’t need to withstand much pressure and hold back a major leak, so I made the pieces a bit thicker and dispensed with the aluminum backing plates:

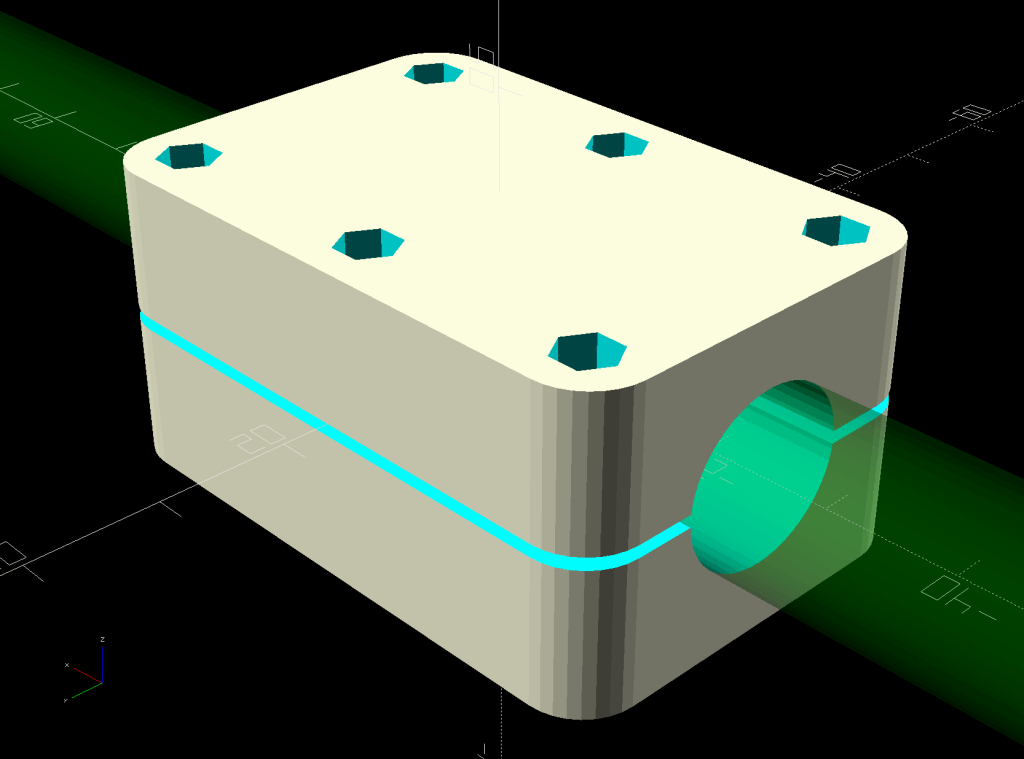

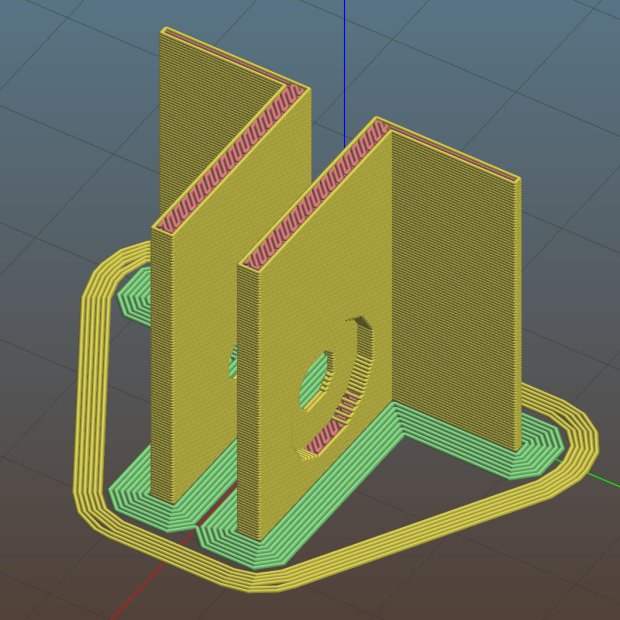

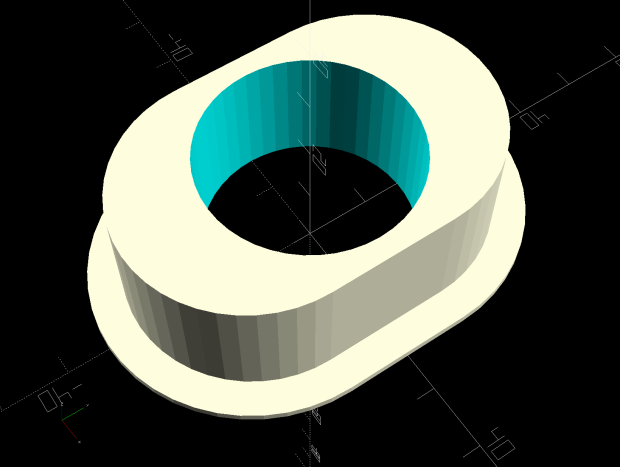

The solid model is basically the same as for the flat hoses, with a slightly oval cylinder replacing the three channels:

The OpenSCAD source code as a GitHub Gist:

| // Rubber Soaker Hose Splice | |

| // Ed Nisley KE4ZNU 2020-03 | |

| Layout = "Build"; // [Hose,Block,Show,Build] | |

| TestFit = false; // true to build test fit slice from center | |

| //- Extrusion parameters must match reality! | |

| /* [Hidden] */ | |

| ThreadThick = 0.25; | |

| ThreadWidth = 0.40; | |

| HoleWindage = 0.2; | |

| Protrusion = 0.1; // make holes end cleanly | |

| inch = 25.4; | |

| function IntegerMultiple(Size,Unit) = Unit * ceil(Size / Unit); | |

| ID = 0; | |

| OD = 1; | |

| LENGTH = 2; | |

| //———- | |

| // Dimensions | |

| // Hose lies along X axis | |

| Hose = [200,14.5,13.6]; // X = longer than anything else | |

| // 8-32 stainless screws | |

| Screw = [4.1,8.0,3.0]; // OD = head LENGTH = head thickness | |

| Washer = [4.4,9.5,1.0]; | |

| Nut = [4.1,9.7,6.0]; | |

| Block = [50.0,Hose.y + 2*Washer[OD],4.0 + 1.5*Hose.z]; // overall splice block size | |

| echo(str("Block: ",Block)); | |

| Kerf = 1.0; // cut through middle to apply compression | |

| CornerRadius = Washer[OD]/2; | |

| NumScrews = 3; // screws along each side of cable | |

| ScrewOC = [(Block.x – 2*CornerRadius) / (NumScrews – 1), | |

| Block.y – 2*CornerRadius, | |

| 2*Block.z // ensure complete holes | |

| ]; | |

| echo(str("Screw OC: x=",ScrewOC.x," y=",ScrewOC.y)); | |

| //———————- | |

| // Useful routines | |

| module PolyCyl(Dia,Height,ForceSides=0) { // based on nophead's polyholes | |

| Sides = (ForceSides != 0) ? ForceSides : (ceil(Dia) + 2); | |

| FixDia = Dia / cos(180/Sides); | |

| cylinder(d=(FixDia + HoleWindage),h=Height,$fn=Sides); | |

| } | |

| // Hose shape | |

| // This includes magic numbers measured from reality | |

| module HoseProfile() { | |

| NumSides = 12*4; | |

| rotate([0,-90,0]) | |

| translate([0,0,-Hose.x/2]) | |

| resize([Hose.z,Hose.y,0]) | |

| cylinder(d=Hose.z,h=Hose.x,$fn=NumSides); | |

| } | |

| // Outside shape of splice Block | |

| // Z centered on hose rim circles, not overall thickness through center ridge | |

| module SpliceBlock() { | |

| difference() { | |

| hull() | |

| for (i=[-1,1], j=[-1,1]) // rounded block | |

| translate([i*(Block.x/2 – CornerRadius),j*(Block.y/2 – CornerRadius),-Block.z/2]) | |

| cylinder(r=CornerRadius,h=Block.z,$fn=4*8); | |

| for (i = [0:NumScrews – 1], j=[-1,1]) // screw holes | |

| translate([-(Block.x/2 – CornerRadius) + i*ScrewOC.x, | |

| j*ScrewOC.y/2, | |

| -(Block.z/2 + Protrusion)]) | |

| PolyCyl(Screw[ID],Block.z + 2*Protrusion,6); | |

| cube([2*Block.x,2*Block.y,Kerf],center=true); // slice through center | |

| } | |

| } | |

| // Splice block less hose | |

| module ShapedBlock() { | |

| difference() { | |

| SpliceBlock(); | |

| HoseProfile(); | |

| } | |

| } | |

| //———- | |

| // Build them | |

| if (Layout == "Hose") | |

| HoseProfile(); | |

| if (Layout == "Block") | |

| SpliceBlock(); | |

| if (Layout == "Show") { | |

| difference() { | |

| SpliceBlock(); | |

| HoseProfile(); | |

| } | |

| color("Green",0.25) | |

| HoseProfile(); | |

| } | |

| if (Layout == "Build") { | |

| SliceOffset = TestFit && !NumScrews%2 ? ScrewOC.x/2 : 0; | |

| intersection() { | |

| translate([SliceOffset,0,Block.z/4]) | |

| if (TestFit) | |

| cube([ScrewOC.x/2,4*Block.y,Block.z/2],center=true); | |

| else | |

| cube([4*Block.x,4*Block.y,Block.z/2],center=true); | |

| union() { | |

| translate([0,0.6*Block.y,Block.z/2]) | |

| ShapedBlock(); | |

| translate([0,-0.6*Block.y,Block.z/2]) | |

| rotate([0,180,0]) | |

| ShapedBlock(); | |

| } | |

| } | |

| } |