|

// Quilting – Hexagon Templates |

|

// Ed Nisley KE4ZNU – July 2020 |

|

// Reverse-engineered to repair a not-quite-standard hexagon quilt |

|

// Useful geometry: |

|

// https://en.wikipedia.org/wiki/Hexagon |

|

|

|

/* [Layout Options] */ |

|

|

|

Layout = "Build"; // [Build, HexBuild, HexPlate, TriBuild, TriPlate, EndBuild, EndPlate] |

|

|

|

//——- |

|

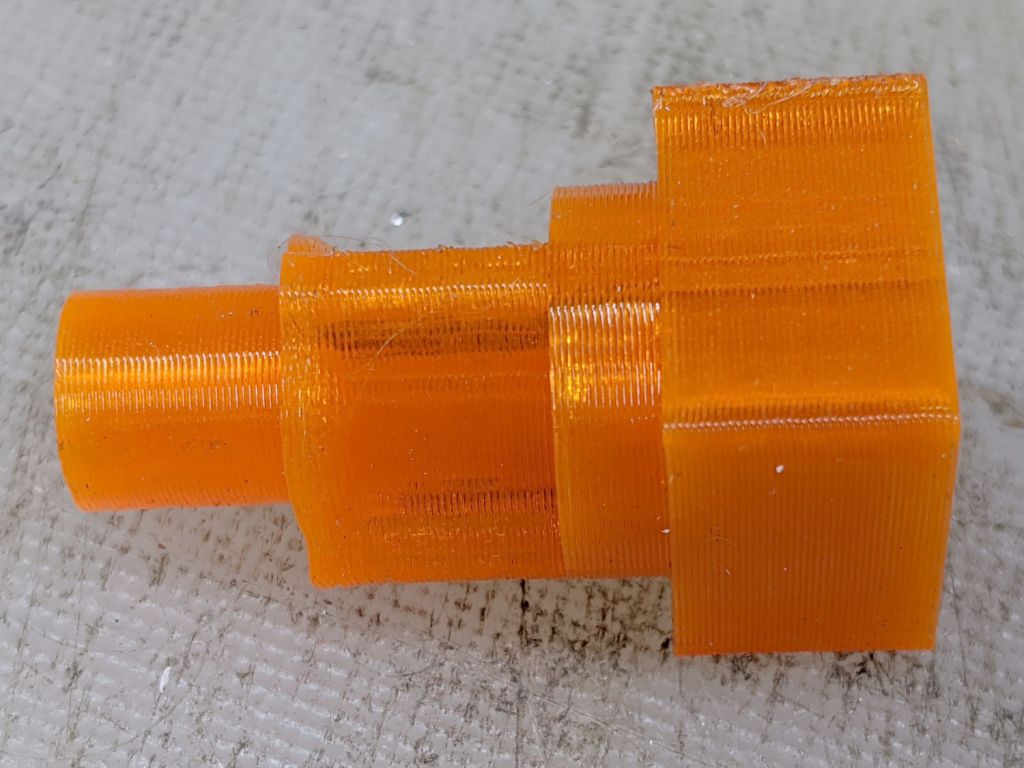

//- Extrusion parameters must match reality! |

|

// Print with 2 shells |

|

|

|

/* [Hidden] */ |

|

|

|

ThreadThick = 0.25; |

|

ThreadWidth = 0.40; |

|

|

|

HoleFinagle = 0.2; |

|

HoleFudge = 1.00; |

|

|

|

function HoleAdjust(Diameter) = HoleFudge*Diameter + HoleFinagle; |

|

|

|

Protrusion = 0.1; // make holes end cleanly |

|

|

|

function IntegerMultiple(Size,Unit) = Unit * ceil(Size / Unit); |

|

|

|

inch = 25.4; |

|

|

|

//——- |

|

// Dimensions |

|

|

|

/* [Layout Options] */ |

|

|

|

FinishedWidthInch = 2.75; |

|

FinishedWidth = FinishedWidthInch * inch; |

|

|

|

SeamAllowanceInch = 0.25; |

|

SeamAllowance = SeamAllowanceInch * inch; |

|

|

|

TemplateThick = 3.0; |

|

|

|

TriKnob = true; |

|

EndKnob = false; |

|

|

|

/* [Hidden] */ |

|

|

|

FinishedSideInch = FinishedWidthInch/sqrt(3); |

|

FinishedSide = FinishedSideInch * inch; |

|

|

|

echo(str("Finished side: ",FinishedSideInch," inch")); |

|

|

|

CutWidth = FinishedWidth + 2*SeamAllowance; |

|

|

|

CutSide = CutWidth/sqrt(3); |

|

echo(str("Cut side: ",CutSide / inch," inch")); |

|

|

|

// Make polygon-circles circumscribe the target widths |

|

|

|

TemplateID = FinishedWidth / cos(180/6); |

|

TemplateOD = CutWidth / cos(180/6); |

|

|

|

/* [Hidden] */ |

|

|

|

TriRadius = FinishedSide/sqrt(3); |

|

|

|

TriPoints = [[TriRadius,0], |

|

[TriRadius*cos(120),TriRadius*sin(120)], |

|

[TriRadius*cos(240),TriRadius*sin(240)] |

|

]; |

|

echo(str("TriPoints: ",TriPoints)); |

|

|

|

EndPoints = [[TriRadius,0], |

|

[TriRadius*cos(120),TriRadius*sin(120)], |

|

[TriRadius*cos(120),0] |

|

]; |

|

echo(str("EndPoints: ",EndPoints)); |

|

|

|

TipCutRadius = 2*(TriRadius + SeamAllowance); // circumscribing radius of tip cutter |

|

TipPoints = [[TipCutRadius,0], |

|

[TipCutRadius*cos(120),TipCutRadius*sin(120)], |

|

[TipCutRadius*cos(240),TipCutRadius*sin(240)] |

|

]; |

|

|

|

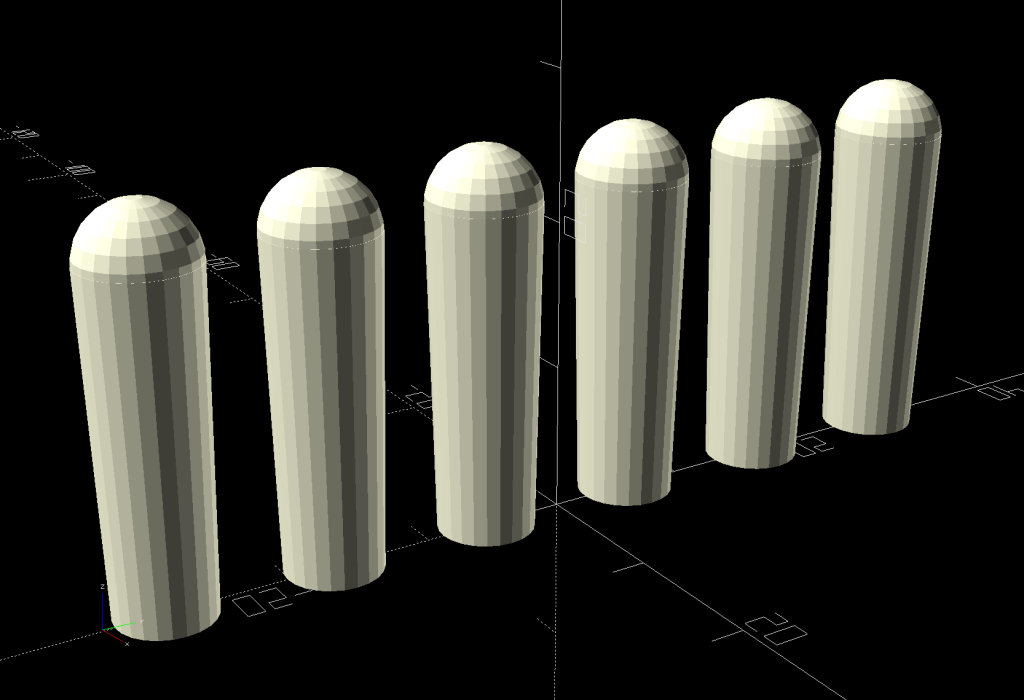

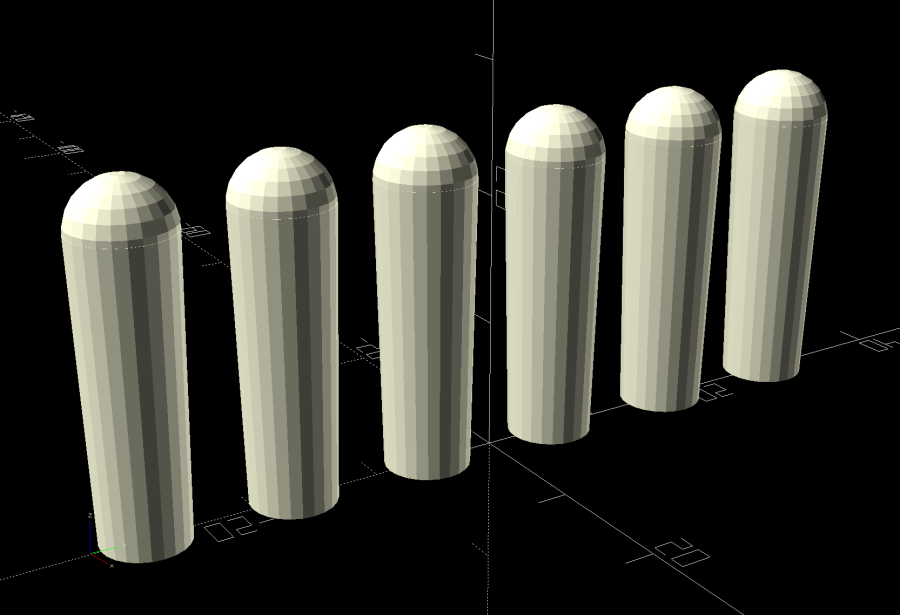

HandleHeight = 1 * inch; |

|

HandleLength = (TemplateID + TemplateOD)/2; |

|

HandleThick = IntegerMultiple(3.0,ThreadWidth); |

|

HandleSides = 12*4; |

|

|

|

StringDia = 4.0; |

|

StringHeight = 0.6*HandleHeight; |

|

|

|

DentDepth = HandleThick/4; |

|

DentDia = 15 * DentDepth; |

|

DentSphereRadius = (pow(DentDepth,2) + pow(DentDia,2)/4)/(2*DentDepth); |

|

|

|

KnobOD = 15.0; // Triangle handle |

|

KnobHeight = 20.0; |

|

|

|

//——- |

|

|

|

module PolyCyl(Dia,Height,ForceSides=0) { // based on nophead's polyholes |

|

Sides = (ForceSides != 0) ? ForceSides : (ceil(Dia) + 2); |

|

FixDia = Dia / cos(180/Sides); |

|

cylinder(r=HoleAdjust(FixDia)/2,h=Height,$fn=Sides); |

|

} |

|

|

|

|

|

//——- |

|

// Hex template |

|

|

|

module HexPlate() { |

|

|

|

difference() { |

|

cylinder(r=TemplateOD/2,h=TemplateThick,$fn=6); |

|

translate([0,0,-Protrusion]) |

|

cylinder(r=TemplateID/2,h=(TemplateThick + 2*Protrusion),$fn=6); |

|

} |

|

|

|

for (i=[1:6/2]) |

|

rotate(i*60) |

|

translate([0,0,TemplateThick/2]) |

|

cube([HandleLength,HandleThick,TemplateThick],center=true); |

|

} |

|

|

|

module HexHandle() { |

|

|

|

difference() { |

|

rotate([90,0,0]) |

|

scale([1,HandleHeight/(TemplateOD/2),1]) |

|

rotate(180/HandleSides) |

|

cylinder(d=HandleLength,h=HandleThick,center=true,$fn=HandleSides); |

|

translate([0,0,-HandleHeight]) |

|

cube([2*TemplateOD,2*TemplateOD,2*HandleHeight],center=true); |

|

translate([0,HandleThick,StringHeight]) |

|

rotate([90,090,0]) |

|

rotate(180/8) |

|

PolyCyl(StringDia,2*HandleThick,8); |

|

for (j=[-1,1]) { |

|

translate([0,j*(DentSphereRadius + HandleThick/2 – DentDepth),StringHeight]) |

|

rotate(180/48) |

|

sphere(r=DentSphereRadius,$fn=48); |

|

} |

|

} |

|

|

|

} |

|

|

|

module HexTemplate() { |

|

HexPlate(); |

|

HexHandle(); |

|

} |

|

|

|

//——- |

|

// Triangle template |

|

|

|

module TriPlate() { |

|

|

|

linear_extrude(height=TemplateThick) |

|

intersection() { |

|

offset(delta=SeamAllowance) // basic cutting outline |

|

polygon(points=TriPoints); |

|

rotate(180) |

|

polygon(points=TipPoints); |

|

} |

|

} |

|

|

|

|

|

module TriTemplate() { |

|

|

|

union() { |

|

if (TriKnob) |

|

cylinder(d=KnobOD,h=KnobHeight,$fn=HandleSides); |

|

TriPlate(); |

|

} |

|

|

|

} |

|

|

|

//——- |

|

// End piece template |

|

|

|

module EndPlate() { |

|

|

|

linear_extrude(height=TemplateThick) |

|

intersection() { |

|

offset(delta=SeamAllowance) // basic cutting outline |

|

polygon(points=EndPoints); |

|

rotate(180) |

|

polygon(points=TipPoints); |

|

} |

|

} |

|

|

|

module EndTemplate() { |

|

|

|

union() { |

|

if (EndKnob) |

|

translate([0,(TriRadius/2)*sin(30),0]) |

|

cylinder(d=KnobOD,h=KnobHeight,$fn=HandleSides); |

|

EndPlate(); |

|

} |

|

|

|

} |

|

|

|

|

|

|

|

//——- |

|

// Build it! |

|

|

|

if (Layout == "HexPlate") |

|

HexPlate(); |

|

|

|

if (Layout == "HexBuild") |

|

HexTemplate(); |

|

|

|

if (Layout == "TriPlate") |

|

TriPlate(); |

|

|

|

if (Layout == "TriBuild") |

|

TriTemplate(); |

|

|

|

if (Layout == "EndPlate") |

|

EndPlate(); |

|

|

|

if (Layout == "EndBuild") |

|

EndTemplate(); |

|

|

|

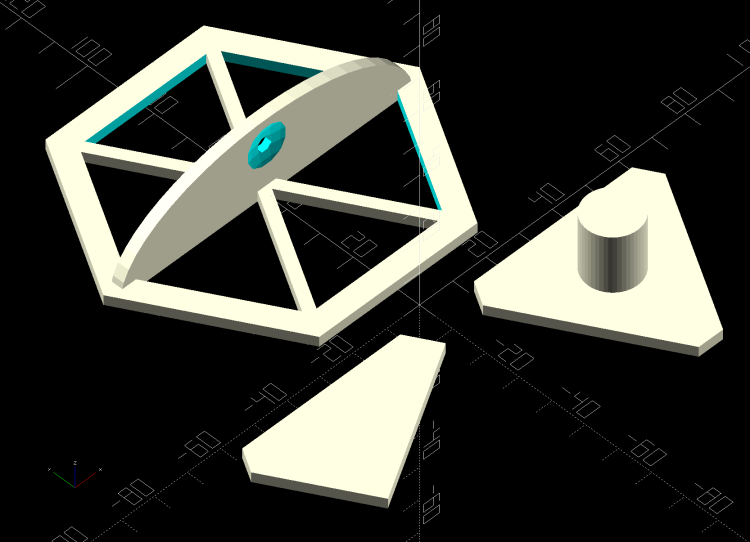

if (Layout == "Build") { |

|

translate([1.5*TriRadius,-TriRadius,0]) |

|

rotate(180/6) |

|

TriTemplate(); |

|

translate([-1.5*TriRadius,-TriRadius,0]) |

|

rotate(180/6) |

|

EndTemplate(); |

|

translate([0,TemplateOD/2,0]) |

|

HexTemplate(); |

|

} |