|

// Pride wheelchair brake lever mods |

|

// Ed Nisley KE4ZNU 2020-11 |

|

|

|

/* [Layout options] */ |

|

|

|

Layout = "Build"; // [Build, Show, Fit, TabCap, Handle, Knob, Support] |

|

|

|

// Hold up the knob's inside |

|

Support = true; |

|

|

|

/* [Extrusion parameters] */ |

|

|

|

/* [Hidden] */ |

|

|

|

ThreadThick = 0.25; |

|

ThreadWidth = 0.40; |

|

|

|

HoleWindage = 0.2; |

|

|

|

function IntegerMultiple(Size,Unit) = Unit * ceil(Size / Unit); |

|

function IntegerLessMultiple(Size,Unit) = Unit * floor(Size / Unit); |

|

|

|

Protrusion = 0.1; // make holes end cleanly |

|

|

|

inch = 25.4; |

|

|

|

ID = 0; |

|

OD = 1; |

|

LENGTH = 2; |

|

|

|

//———————- |

|

// Useful routines |

|

|

|

module PolyCyl(Dia,Height,ForceSides=0) { // based on nophead's polyholes |

|

|

|

Sides = (ForceSides != 0) ? ForceSides : (ceil(Dia) + 2); |

|

|

|

FixDia = Dia / cos(180/Sides); |

|

|

|

cylinder(r=(FixDia + HoleWindage)/2,h=Height,$fn=Sides); |

|

} |

|

|

|

|

|

|

|

//* [Basic dimensions] */ |

|

|

|

WallThick = 4.0; // min wall thickness |

|

|

|

Screw = [3.0,5.5,20.0]; // thread, head, length under head |

|

Insert = [3.0,4.1,8.0]; // thread, knurl, length |

|

|

|

//———————- |

|

// Brake tab cap |

|

|

|

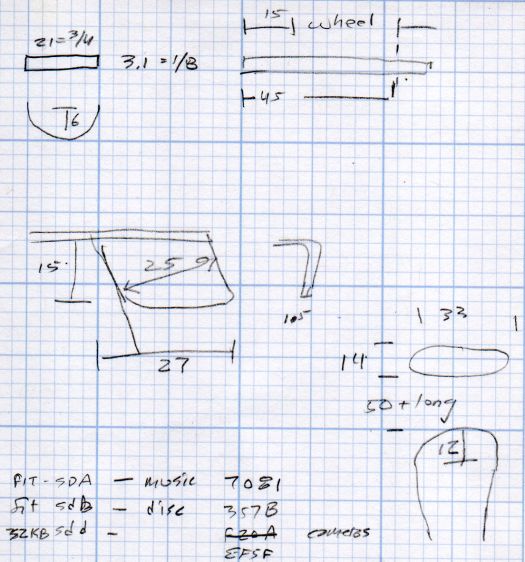

BrakeTab = [15,21,3.1]; // length to wheel, width, thickness |

|

BrakeTabSagitta = 8.0; // height of curved endcap |

|

|

|

CapOAL = [BrakeTab.y + 2*WallThick,BrakeTab.y + 2*WallThick,BrakeTab.z + 2*WallThick]; |

|

|

|

module TabCap() { |

|

|

|

difference() { |

|

rotate(180/8) |

|

cylinder(d=CapOAL.y,h=CapOAL.z,center=true,$fn=8); |

|

translate([BrakeTab.x/2,0,0]) |

|

cube(BrakeTab,center=true); |

|

rotate(180/8) |

|

cylinder(d=BrakeTab.y/cos(180/8),h=BrakeTab.z,center=true,$fn=8); |

|

} |

|

} |

|

|

|

//———————- |

|

// Brake lever handle |

|

// Soft covering with rounded sides that we square off for simplicity |

|

|

|

HandleRibs = [15,34,14]; // ignoring slight taper from end |

|

HandleCore = [50.0,24.0,12.0]; // straight section of lever to top of ribs |

|

HandleTipWidth = 30.0; // ignoring actual sector height |

|

|

|

module Handle() { |

|

|

|

union() { |

|

hull() { |

|

rotate(180/8) |

|

cylinder(d=HandleTipWidth/cos(180/8),h=HandleCore.z,center=true,$fn=8); |

|

translate([-HandleCore.x/2,0,0]) |

|

cube(HandleCore,center=true); |

|

} |

|

translate([-(3*HandleCore.x/2 – Protrusion),0,0]) // extend base for ball trimming |

|

cube(HandleCore,center=true); |

|

translate([-HandleRibs.x/2,0,0]) |

|

cube(HandleRibs,center=true); |

|

} |

|

|

|

} |

|

|

|

//———————- |

|

// Support structure for handle cavity inside knob |

|

// Totally ad-hoc tweakage |

|

// Remember it's lying on its side to match the handle |

|

|

|

NumRibs = 2 + 1; // must be odd |

|

RibSpace = floor(HandleCore.z/(NumRibs + 1)); |

|

|

|

module KnobSupport() { |

|

|

|

color("Yellow") { // support overlaps in the middle |

|

render(convexity=3) |

|

intersection() { |

|

for (k=[-1,1]) |

|

translate([0,k*ThreadThick,0]) // shrink inward to break adhesion |

|

Handle(); |

|

|

|

translate([(HandleCore.x – HandleRibs.x)/2 – HandleCore.x – Protrusion,0,0]) |

|

cube([HandleCore.x – HandleRibs.x,HandleRibs.y,HandleCore.z],center=true); |

|

|

|

union() |

|

for (k=[-floor(NumRibs/2):floor(NumRibs/2)]) |

|

translate([0,0,k* RibSpace]) |

|

cube([2*HandleCore.x,HandleRibs.y,2*ThreadWidth],center=true); |

|

} |

|

|

|

translate([(HandleCore.x – HandleRibs.x)/2 – HandleCore.x,0,0]) |

|

cube([HandleCore.x – HandleRibs.x,4*ThreadWidth,NumRibs*RibSpace],center=true); |

|

} |

|

} |

|

|

|

//———————- |

|

// Brake handle knob |

|

// Largely built with magic numbers |

|

// Includes support because it's not really optional |

|

|

|

KnobOD = 55.0; |

|

KnobOffset = HandleRibs.x/1; |

|

|

|

KnobSides = 2*4*3; |

|

|

|

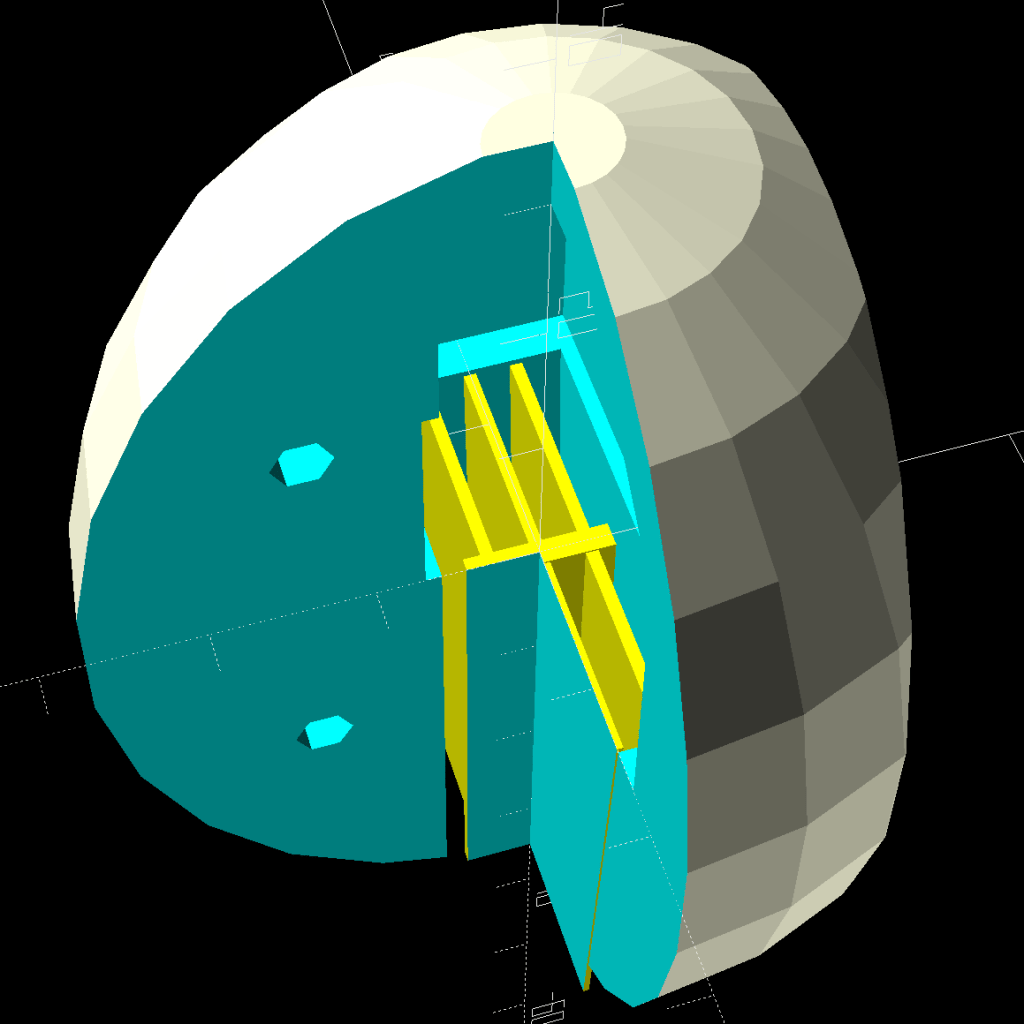

module Knob() { |

|

|

|

difference() { |

|

hull() { |

|

resize([0,HandleRibs.y + 4*WallThick,HandleCore.x + HandleTipWidth/2 + WallThick]) |

|

sphere(d=KnobOD,$fn=KnobSides); |

|

} |

|

|

|

translate([0,0,KnobOffset]) |

|

rotate([0,-90,0]) |

|

Handle(); |

|

|

|

for (i=[-1,1],k=[-1,1]) |

|

translate([i*KnobOD/4,0,k*KnobOD/4]) { |

|

rotate([90,0,0]) |

|

PolyCyl(Insert[OD],1.5*Insert[LENGTH],6); |

|

translate([0,-Screw[LENGTH]/2,0]) |

|

rotate([-90,0,0]) |

|

PolyCyl(Screw[ID],KnobOD,6); |

|

translate([0,Screw[LENGTH] – Insert[LENGTH],0]) |

|

rotate([-90,0,0]) |

|

PolyCyl(Screw[OD],KnobOD,6); |

|

} |

|

} |

|

|

|

if (Support) |

|

translate([0,0,KnobOffset]) |

|

rotate([0,-90,0]) |

|

KnobSupport(); |

|

|

|

} |

|

|

|

//———————- |

|

// Lash it together |

|

|

|

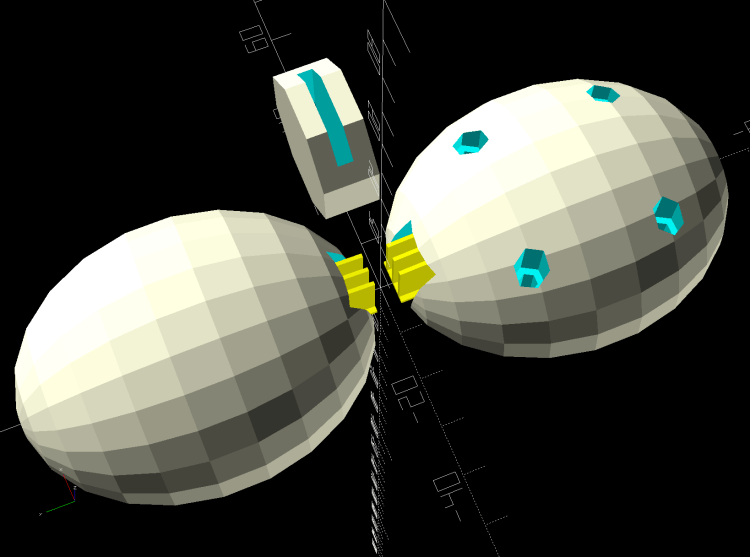

if (Layout == "TabCap") { |

|

TabCap(); |

|

} |

|

|

|

if (Layout == "Handle") { |

|

Handle(); |

|

} |

|

|

|

if (Layout == "Support") { |

|

KnobSupport(); |

|

} |

|

|

|

if (Layout == "Knob") { |

|

Knob(); |

|

} |

|

|

|

if (Layout == "Show") { |

|

translate([60,0,0]) |

|

TabCap(); |

|

Knob(); |

|

} |

|

|

|

if (Layout == "Fit") { |

|

translate([60,0,0]) |

|

difference() { |

|

TabCap(); |

|

translate([0,0,CapOAL.z/2]) |

|

cube(CapOAL,center=true); |

|

} |

|

difference() { |

|

Knob(); |

|

translate([KnobOD + KnobOD/4,0*KnobOD,0]) |

|

cube(2*KnobOD,center=true); |

|

translate([-KnobOD,-KnobOD,0]) |

|

cube(2*KnobOD,center=true); |

|

} |

|

} |

|

|

|

if (Layout == "Build") { |

|

translate([KnobOD/2,0,(CapOAL.y*cos(180/8))/2]) |

|

rotate([0,-90,90]) |

|

TabCap(); |

|

|

|

for (j=[-1,1]) |

|

translate([0,-j*0.75*HandleCore.x,0]) |

|

difference() { |

|

rotate([j*90,0,0]) |

|

Knob(); |

|

translate([0,0,-KnobOD]) |

|

cube(2*KnobOD,center=true); |

|

} |

|

|

|

} |