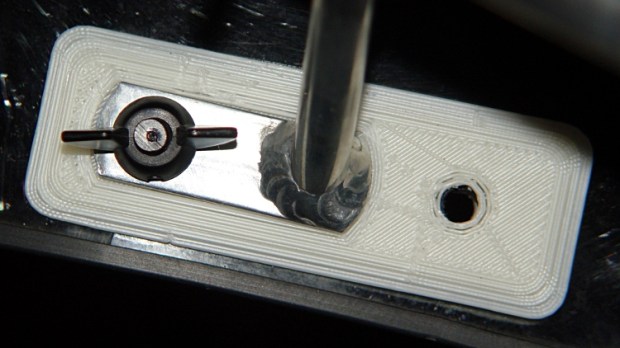

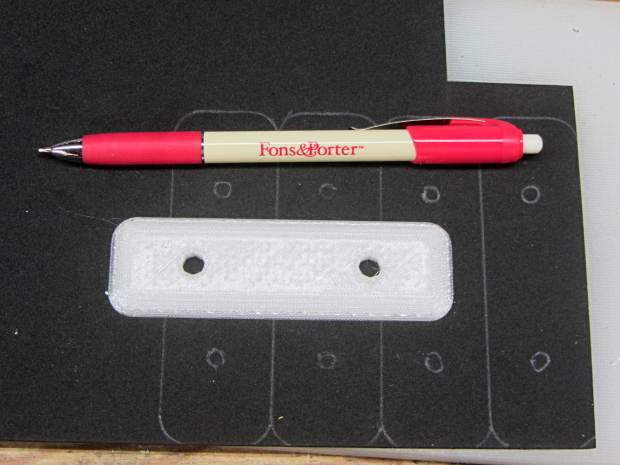

Pending more test rides, the flashlight fairing mount works well:

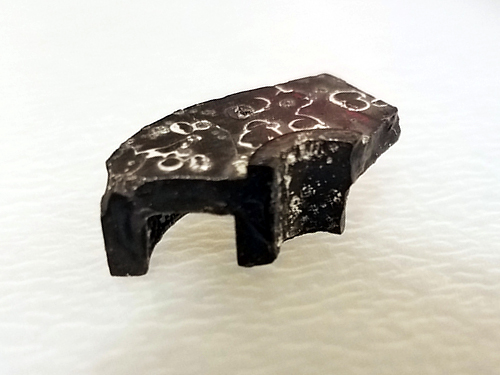

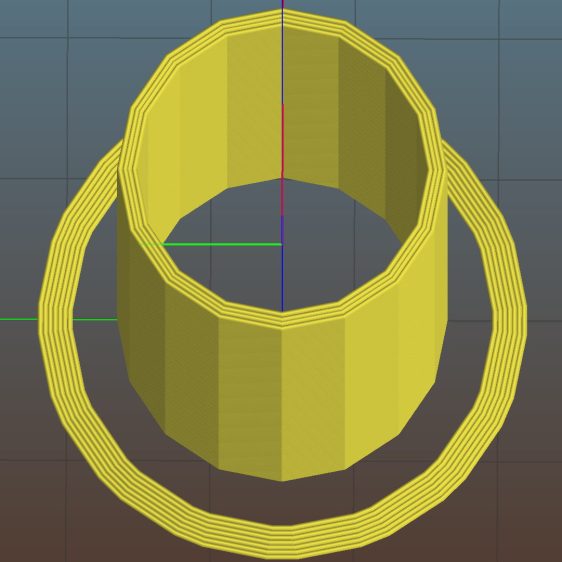

Despite all my fussing with three rotational angles, simply tilting the mount upward by 20° with respect to the fairing clamp aims the flashlight straight ahead, with the ball nearly centered in the clamp:

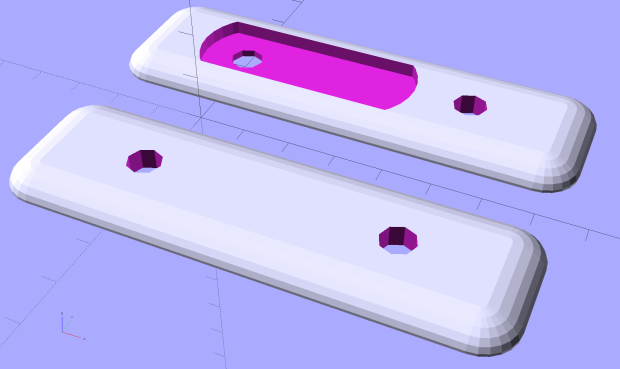

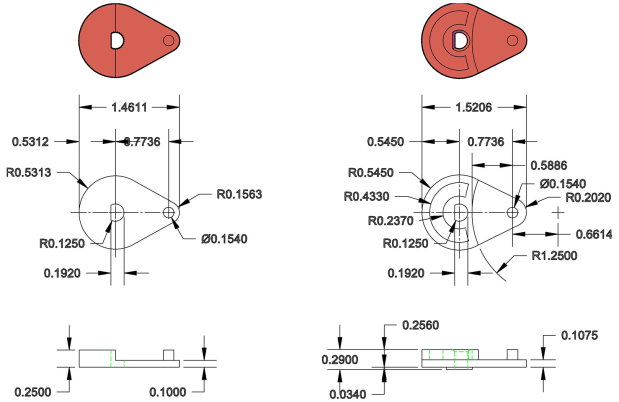

That obviously depends on the handlebar angle and the fairing length (which affects the strut rotation), but it’s close enough to make me think a simpler mount will suffice: clamp the flashlight into a cylinder with a slight offset angle, maybe 2°, then mount the cylinder into a much thinner ring clamp at the 20° tilt. Rotating the cylinder would give you some aim-ability, minus the bulk of a ball mount.

Or dispense with the separate cylinder, build the entire mount at the (now known) aim angle, clamp the flashlight directly into the mount, then affix mount to fairing strut. Rapid prototyping FTW!

For now, it’s great riding weather …

The OpenSCAD source code as a GitHub Gist:

| // Tour Easy Fairing Flashlight Mount | |

| // Ed Nisley KE4ZNU – July 2017 | |

| /* [Build Options] */ | |

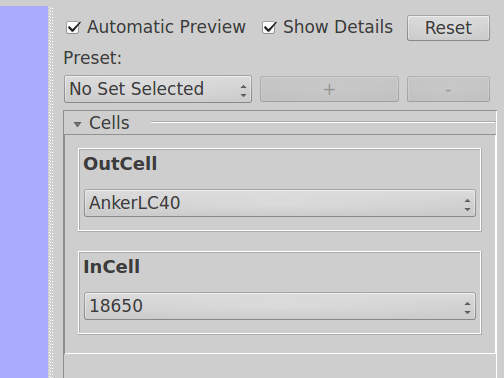

| FlashName = "AnkerLC40"; // [AnkerLC40,AnkerLC90,J5TactV2,InnovaX5] | |

| Component = "Mount"; // [Ball, BallClamp, Mount, Plates, Bracket] | |

| Layout = "Show"; // [Build, Show] | |

| Support = false; | |

| MountSupport = true; | |

| /* [Extrusion] */ | |

| ThreadThick = 0.25; // [0.20, 0.25] | |

| ThreadWidth = 0.40; // [0.40] | |

| function IntegerMultiple(Size,Unit) = Unit * ceil(Size / Unit); | |

| Protrusion = 0.01; // [0.01, 0.1] | |

| HoleWindage = 0.2; | |

| /* [Fairing Mount] */ | |

| ToeIn = 0; // inward from ahead | |

| Tilt = 20; // upward from forward | |

| Roll = 0; // outward from top | |

| Shift = -5; // realign to plate center | |

| //- Screws *c | |

| /* [Hidden] */ | |

| ID = 0; | |

| OD = 1; | |

| LENGTH = 2; | |

| /* [Screws and Inserts] */ | |

| BallInsert = [2.0,3.5,4.0]; | |

| BallScrew = [2.0,3.5,2.0]; | |

| ClampInsert = [3.0,4.2,8.0]; | |

| ClampScrew = [3.0,5.9,50.0]; // thread dia, head OD, screw length | |

| ClampScrewWasher = [3.0,6.75,0.5]; | |

| ClampScrewNut = [3.0,6.1,4.0]; // nyloc nut | |

| /* [Hidden] */ | |

| F_NAME = 0; | |

| F_GRIPOD = 1; | |

| F_GRIPLEN = 2; | |

| LightBodies = [ | |

| ["AnkerLC90",26.6,48.0], | |

| ["AnkerLC40",26.6,55.0], | |

| ["J5TactV2",25.0,30.0], | |

| ["InnovaX5",22.0,55.0] | |

| ]; | |

| NumSides = 8*4; | |

| echo(str("Flashlight: ",FlashName)); | |

| FlashIndex = search([FlashName],LightBodies,1,0)[F_NAME]; | |

| BallThick = IntegerMultiple(5.0,ThreadWidth); // thickness of ball wall | |

| echo(str("Ball wall: ",BallThick)); | |

| BallOD = max(45,IntegerMultiple(LightBodies[FlashIndex][F_GRIPOD] + 2*(BallThick + BallInsert[OD]),2.0)); | |

| echo(str(" OD: ",BallOD)); | |

| BallScrewOC = BallOD – BallThick – BallInsert[OD]; // from OD to allow different body diameters | |

| echo(str(" screw OC: ",BallScrewOC)); | |

| BallLength = min(sqrt(pow(BallOD,2) – pow(LightBodies[FlashIndex][F_GRIPOD],2)), | |

| LightBodies[FlashIndex][F_GRIPLEN]); | |

| echo(str(" hole len: ",BallLength)); | |

| ClampThick = 2*ClampInsert[OD]; | |

| echo(str("Clamp wall: ",ClampThick)); | |

| ClampOD = BallOD + 2*ClampThick; | |

| echo(str(" OD: ",ClampOD)); | |

| ClampScrewOC = BallOD + 2*ClampInsert[OD]; | |

| echo(str(" screw OC: ",ClampScrewOC)); | |

| ClampLength = 0.70 * BallLength; | |

| echo(str(" length: ",ClampLength)); | |

| //- Adjust hole diameter to make the size come out right | |

| module PolyCyl(Dia,Height,ForceSides=0) { // based on nophead's polyholes | |

| Sides = (ForceSides != 0) ? ForceSides : (ceil(Dia) + 2); | |

| FixDia = Dia / cos(180/Sides); | |

| cylinder(r=(FixDia + HoleWindage)/2,h=Height,$fn=Sides); | |

| } | |

| //- Ball around flashlight | |

| // Must print two! | |

| module BodyBall() { | |

| difference() { | |

| intersection() { | |

| sphere(d=BallOD,$fn=2*NumSides); // basic ball | |

| cube([BallLength,2*BallOD,2*BallOD],center=true); // max of flashlight grip length | |

| } | |

| translate([-LightBodies[FlashIndex][F_GRIPOD],0,0]) | |

| rotate([0,90,0]) rotate(180/NumSides) | |

| PolyCyl(LightBodies[FlashIndex][F_GRIPOD],2*BallOD,NumSides); // flashlight body | |

| for (j=[-1,1]) | |

| translate([0,j*BallScrewOC/2,0]) // commmon screw offset | |

| translate([0,0,-BallOD]) | |

| PolyCyl(BallInsert[ID],2*BallOD,6); // punch screw shaft through everything | |

| translate([0,BallScrewOC/2,-Protrusion]) | |

| PolyCyl(BallInsert[OD],(BallInsert[LENGTH] + 3*ThreadThick + Protrusion),6); // threaded insert | |

| translate([0,-BallScrewOC/2,BallThick]) | |

| PolyCyl(BallScrew[OD],BallOD,6); // screw head clearance | |

| translate([0,0,-BallOD/2]) // remove bottom half | |

| cube(BallOD,center=true); | |

| translate([0,0,BallOD – BallThick/2]) // slice off top = bottom for E-Z build | |

| cube(BallOD,center=true); | |

| } | |

| if (Support) { | |

| NumRibs = 24; | |

| RibHeight = (BallOD – LightBodies[FlashIndex][F_GRIPOD]/cos(180/NumSides) – BallThick) / 2; | |

| ChordC = 2*sqrt(BallThick*BallOD/2 – pow(BallThick/2,2)); | |

| intersection() { | |

| cube([BallLength,2*BallOD,2*BallOD],center=true); // max of flashlight grip length | |

| translate([0,0,BallOD/2 – BallThick/2]) | |

| for (i=[0:NumRibs – 1]) | |

| rotate(i*360/NumRibs + 180/NumRibs) // avoid screw holes | |

| translate([ChordC/2 + BallOD/8,0,-RibHeight/2]) | |

| cube([BallOD/4,2*ThreadWidth,RibHeight],center=true); | |

| } | |

| } | |

| } | |

| //- Fairing Bracket | |

| // Magic numbers taken from the actual fairing mount | |

| // Centered on screw hole | |

| /* [Hidden] */ | |

| inch = 25.4; | |

| BracketHoleOD = 0.25 * inch; // 1/4-20 bolt holes | |

| BracketHoleOC = 1.0 * inch; // fairing hole spacing | |

| // usually 1 inch, but 15/16 on one fairing | |

| Bracket = [48.0,16.3,3.6 – 0.6]; // fairing bracket end plate overall size | |

| BracketHoleOffset = (3/8) * inch; // end to hole center | |

| BracketM = 3.0; // endcap arc height | |

| BracketR = (pow(BracketM,2) + pow(Bracket[1],2)/4) / (2*BracketM); // … radius | |

| module Bracket() { | |

| linear_extrude(height=Bracket[2],convexity=2) | |

| difference() { | |

| translate([(Bracket[0]/2 – BracketHoleOffset),0,0]) | |

| offset(delta=ThreadWidth) | |

| intersection() { | |

| square([Bracket[0],Bracket[1]],center=true); | |

| union() { | |

| for (i=[-1,0,1]) // middle circle fills gap | |

| translate([i*(Bracket[0]/2 – BracketR),0]) | |

| circle(r=BracketR); | |

| } | |

| } | |

| circle(d=BracketHoleOD/cos(180/8),$fn=8); // dead center at the origin | |

| } | |

| } | |

| //- General plate shape | |

| // Centered on the hole for the fairing bracket | |

| Plate = [100.0,30.0,6*ThreadThick + Bracket[2]]; | |

| PlateRad = Plate[1]/4; | |

| echo(str("Base plate thick: ",Plate[2])); | |

| module PlateBlank() { | |

| difference() { | |

| translate([BracketHoleOC,0,0]) | |

| intersection() { | |

| translate([0,0,Plate[2]/2]) // select upper half of spheres | |

| cube(Plate,center=true); | |

| hull() | |

| for (i=[-1,1], j=[-1,1]) | |

| translate([i*(Plate[0]/2 – PlateRad),j*(Plate[1]/2 – PlateRad),0]) | |

| resize([2*PlateRad,2*PlateRad,2*Plate[2]]) | |

| sphere(r=PlateRad); // nice rounded corners! | |

| } | |

| translate([2*BracketHoleOC,0,-Protrusion]) // screw holes | |

| PolyCyl(BracketHoleOD,2*Plate[2],8); | |

| translate([0,0,-Protrusion]) | |

| PolyCyl(BracketHoleOD,2*Plate[2],8); | |

| } | |

| } | |

| //- Inner plate | |

| module InnerPlate() { | |

| difference() { | |

| PlateBlank(); | |

| translate([0,0,Plate[2] – Bracket[2] + Protrusion]) // punch out fairing bracket | |

| Bracket(); | |

| } | |

| } | |

| //- Clamp around flashlight ball | |

| module BallClamp() { | |

| BossLength = ClampScrew[LENGTH] – ClampScrewNut[LENGTH] – 2*ClampScrewWasher[LENGTH] – 4*ThreadThick; | |

| difference() { | |

| union() { | |

| intersection() { | |

| sphere(d=ClampOD,$fn=NumSides); // exterior ball blamp | |

| cube([ClampLength,2*ClampOD,2*ClampOD],center=true); // aiming allowance | |

| } | |

| for (i=[0]) | |

| hull() { | |

| for (j=[-1,1]) | |

| translate([i*(ClampLength/2 – ClampScrew[OD]),j*ClampScrewOC/2,-BossLength/2]) | |

| rotate(180/8) | |

| cylinder(d=(ClampScrewWasher[OD] + 2*ThreadWidth),h=BossLength,$fn=8); | |

| } | |

| } | |

| sphere(d=(BallOD + 1*ThreadThick),$fn=NumSides); // interior ball | |

| for (i=[0] , j=[-1,1]) { | |

| translate([i*(ClampLength/2 – ClampScrew[OD]),j*ClampScrewOC/2,-ClampOD]) // screw clearance | |

| rotate(180/8) | |

| PolyCyl(ClampScrew[ID],2*ClampOD,8); | |

| } | |

| } | |

| color("Yellow") | |

| if (Support) { // ad-hoc supports for top half | |

| NumRibs = 6; | |

| RibLength = 0.5 * BallOD; | |

| RibWidth = 1.9*ThreadWidth; | |

| SupportOC = ClampLength / NumRibs; | |

| cube([ClampLength,RibLength,4*ThreadThick],center=true); // base plate for adhesion | |

| intersection() { | |

| sphere(d=BallOD – 0*ThreadWidth); // cut at inner sphere OD | |

| cube([ClampLength + 2*ThreadWidth,RibLength,BallOD],center=true); | |

| union() { // ribs for E-Z build | |

| for (j=[-1,0,1]) | |

| translate([0,j*SupportOC,0]) | |

| cube([ClampLength,RibWidth,1.0*BallOD],center=true); | |

| for (i=[0:NumRibs]) // allow +1 to fill the far end | |

| translate([i*SupportOC – ClampLength/2,0,0]) | |

| rotate([0,90,0]) | |

| cylinder(d=BallOD – 2*ThreadThick, | |

| h=RibWidth,$fn=NumSides,center=true); | |

| } | |

| } | |

| } | |

| } | |

| //- Mount between fairing plate and flashlight ball | |

| module Mount() { | |

| translate([-BracketHoleOC,0,0]) | |

| PlateBlank(); | |

| translate([Shift,0,ClampOD/2]) | |

| rotate([-Roll,ToeIn,Tilt]) | |

| intersection() { | |

| translate([0,0,-ClampOD/2]) | |

| cube([2*ClampOD,2*ClampOD,ClampOD],center=true); | |

| BallClamp(); | |

| } | |

| if (MountSupport) { // anchor outer corners during worst overhang | |

| RibWidth = 1.9*ThreadWidth; | |

| SupportOC = 0.1 * ClampLength; | |

| difference() { | |

| rotate([0,0,Tilt]) | |

| translate([Shift + 0.3,0,0]) | |

| for (i=[-4.5,-2.5,0,2.0,4.5]) | |

| translate([i*SupportOC – 0.0,0,(ClampThick + Plate[2])/2]) | |

| cube([RibWidth,0.8*ClampOD,(ClampThick + Plate[2])],center=true); | |

| # translate([Shift,0,ClampOD/2]) | |

| rotate([-Roll,ToeIn,Tilt]) | |

| sphere(d=ClampOD – 2*ThreadWidth,$fn=NumSides); | |

| } | |

| } | |

| } | |

| //- Build things | |

| if (Component == "Ball") | |

| if (Layout == "Show") | |

| BodyBall(); | |

| else if (Layout == "Build") { | |

| translate([0,+1*(BallOD/2 + BallThick/2),0]) | |

| translate([0,0,BallOD/2 – BallThick/2]) | |

| rotate([180,0,0]) | |

| BodyBall(); | |

| translate([0,-1*(BallOD/2 + BallThick/2),0]) | |

| translate([0,0,BallOD/2 – BallThick/2]) | |

| rotate([180,0,0]) | |

| BodyBall(); | |

| } | |

| if (Component == "BallClamp") | |

| if (Layout == "Show") | |

| BallClamp(); | |

| else if (Layout == "Build") { | |

| Both = false; | |

| difference() { | |

| union() { | |

| translate([Both ? ClampLength : 0,0,0]) | |

| BallClamp(); | |

| if (Both) | |

| translate([-ClampLength,0,0]) | |

| rotate([180,0,0]) | |

| BallClamp(); | |

| } | |

| translate([0,0,-ClampOD/2]) | |

| cube([2*ClampOD,2*ClampOD,ClampOD],center=true); | |

| } | |

| } | |

| if (Component == "Mount") | |

| Mount(); | |

| if (Component == "Plates") { | |

| translate([0,0.7*Plate[1],0]) | |

| InnerPlate(); | |

| translate([0,-0.7*Plate[1],0]) | |

| PlateBlank(); | |

| } | |

| if (Component == "Bracket") | |

| Bracket(); |