|

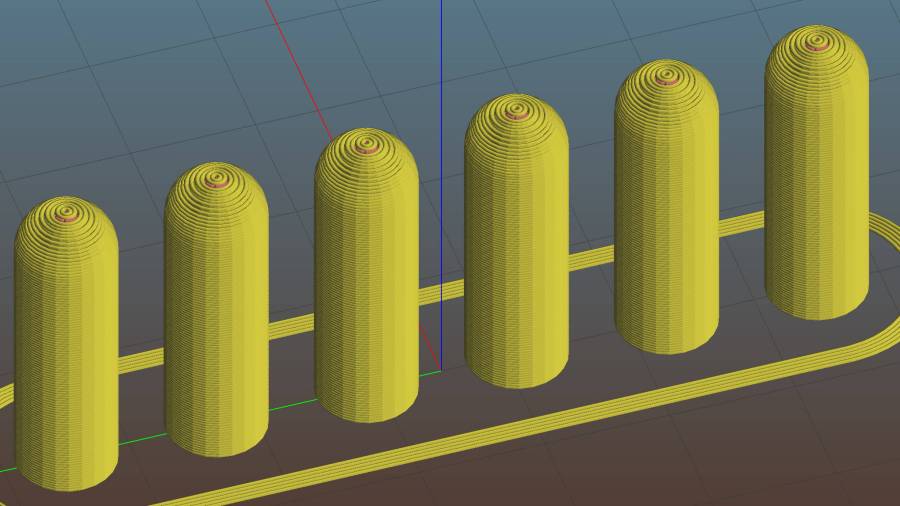

# generated by PrusaSlicer 2.2.0+linux-x64 on 2021-01-01 at 13:33:03 UTC |

|

avoid_crossing_perimeters = 0 |

|

bed_custom_model = |

|

bed_custom_texture = |

|

bed_shape = -100x-125,100x-125,100×125,-100×125 |

|

bed_temperature = 90 |

|

before_layer_gcode = |

|

between_objects_gcode = |

|

bottom_fill_pattern = hilbertcurve |

|

bottom_solid_layers = 3 |

|

bottom_solid_min_thickness = 0 |

|

bridge_acceleration = 0 |

|

bridge_angle = 0 |

|

bridge_fan_speed = 100 |

|

bridge_flow_ratio = 1 |

|

bridge_speed = 50 |

|

brim_width = 0 |

|

clip_multipart_objects = 1 |

|

colorprint_heights = |

|

complete_objects = 0 |

|

cooling = 1 |

|

cooling_tube_length = 5 |

|

cooling_tube_retraction = 91.5 |

|

default_acceleration = 0 |

|

default_filament_profile = "" |

|

default_print_profile = |

|

deretract_speed = 0 |

|

disable_fan_first_layers = 6 |

|

dont_support_bridges = 1 |

|

draft_shield = 0 |

|

duplicate_distance = 6 |

|

elefant_foot_compensation = 0 |

|

end_filament_gcode = "; Filament-specific end gcode \n;END gcode for filament\n" |

|

end_gcode = ;– PrusaSlicer End G-Code for M2 starts –\n; Ed Nisley KE4NZU – 15 November 2013\nG1 Z160 F2000 ; lower bed\nG1 X135 Y100 F30000 ; nozzle to right, bed front\nM104 S0 ; drop extruder temperature\nM140 S0 ; drop bed temperature\nM106 S0 ; bed fan off\nM84 ; disable motors\n;– PrusaSlicer End G-Code ends –\n\n |

|

ensure_vertical_shell_thickness = 1 |

|

external_perimeter_extrusion_width = 0 |

|

external_perimeter_speed = 50% |

|

external_perimeters_first = 0 |

|

extra_loading_move = -2 |

|

extra_perimeters = 1 |

|

extruder_clearance_height = 20 |

|

extruder_clearance_radius = 20 |

|

extruder_colour = "" |

|

extruder_offset = 0x0 |

|

extrusion_axis = E |

|

extrusion_multiplier = 0.95 |

|

extrusion_width = 0.4 |

|

fan_always_on = 0 |

|

fan_below_layer_time = 15 |

|

filament_colour = #29B2B2 |

|

filament_cooling_final_speed = 3.4 |

|

filament_cooling_initial_speed = 2.2 |

|

filament_cooling_moves = 4 |

|

filament_cost = 25 |

|

filament_density = 0.95 |

|

filament_deretract_speed = nil |

|

filament_diameter = 1.72 |

|

filament_load_time = 0 |

|

filament_loading_speed = 28 |

|

filament_loading_speed_start = 3 |

|

filament_max_volumetric_speed = 0 |

|

filament_minimal_purge_on_wipe_tower = 15 |

|

filament_notes = "" |

|

filament_ramming_parameters = "120 100 6.6 6.8 7.2 7.6 7.9 8.2 8.7 9.4 9.9 10.0| 0.05 6.6 0.45 6.8 0.95 7.8 1.45 8.3 1.95 9.7 2.45 10 2.95 7.6 3.45 7.6 3.95 7.6 4.45 7.6 4.95 7.6" |

|

filament_retract_before_travel = nil |

|

filament_retract_before_wipe = nil |

|

filament_retract_layer_change = nil |

|

filament_retract_length = nil |

|

filament_retract_lift = nil |

|

filament_retract_lift_above = nil |

|

filament_retract_lift_below = nil |

|

filament_retract_restart_extra = nil |

|

filament_retract_speed = nil |

|

filament_settings_id = "M2 Esun PETG" |

|

filament_soluble = 0 |

|

filament_toolchange_delay = 0 |

|

filament_type = PET |

|

filament_unload_time = 0 |

|

filament_unloading_speed = 90 |

|

filament_unloading_speed_start = 100 |

|

filament_vendor = (Unknown) |

|

filament_wipe = nil |

|

fill_angle = 45 |

|

fill_density = 25% |

|

fill_pattern = 3dhoneycomb |

|

first_layer_acceleration = 0 |

|

first_layer_bed_temperature = 90 |

|

first_layer_extrusion_width = 0 |

|

first_layer_height = 0.25 |

|

first_layer_speed = 15 |

|

first_layer_temperature = 250 |

|

gap_fill_speed = 25 |

|

gcode_comments = 0 |

|

gcode_flavor = marlin |

|

gcode_label_objects = 0 |

|

high_current_on_filament_swap = 0 |

|

host_type = octoprint |

|

infill_acceleration = 0 |

|

infill_every_layers = 1 |

|

infill_extruder = 1 |

|

infill_extrusion_width = 0 |

|

infill_first = 1 |

|

infill_only_where_needed = 0 |

|

infill_overlap = 15% |

|

infill_speed = 60 |

|

interface_shells = 0 |

|

layer_gcode = |

|

layer_height = 0.25 |

|

machine_max_acceleration_e = 10000,5000 |

|

machine_max_acceleration_extruding = 10000,1250 |

|

machine_max_acceleration_retracting = 10000,1250 |

|

machine_max_acceleration_x = 2500,1000 |

|

machine_max_acceleration_y = 2500,1000 |

|

machine_max_acceleration_z = 2500,200 |

|

machine_max_feedrate_e = 10000,5000 |

|

machine_max_feedrate_x = 450,200 |

|

machine_max_feedrate_y = 450,200 |

|

machine_max_feedrate_z = 100,30 |

|

machine_max_jerk_e = 100,50 |

|

machine_max_jerk_x = 25,10 |

|

machine_max_jerk_y = 25,10 |

|

machine_max_jerk_z = 10,5 |

|

machine_min_extruding_rate = 0,0 |

|

machine_min_travel_rate = 0,0 |

|

max_fan_speed = 100 |

|

max_layer_height = 0 |

|

max_print_height = 200 |

|

max_print_speed = 80 |

|

max_volumetric_speed = 0 |

|

min_fan_speed = 100 |

|

min_layer_height = 0.1 |

|

min_print_speed = 10 |

|

min_skirt_length = 25 |

|

notes = |

|

nozzle_diameter = 0.35 |

|

only_retract_when_crossing_perimeters = 1 |

|

ooze_prevention = 0 |

|

output_filename_format = [input_filename_base].gcode |

|

overhangs = 1 |

|

parking_pos_retraction = 92 |

|

perimeter_acceleration = 0 |

|

perimeter_extruder = 1 |

|

perimeter_extrusion_width = 0 |

|

perimeter_speed = 50 |

|

perimeters = 3 |

|

post_process = |

|

print_host = |

|

print_settings_id = M2 Default |

|

printer_model = |

|

printer_notes = |

|

printer_settings_id = M2 Default |

|

printer_technology = FFF |

|

printer_variant = |

|

printer_vendor = |

|

printhost_apikey = |

|

printhost_cafile = |

|

raft_layers = 0 |

|

remaining_times = 0 |

|

resolution = 0.01 |

|

retract_before_travel = 3 |

|

retract_before_wipe = 0% |

|

retract_layer_change = 0 |

|

retract_length = 1 |

|

retract_length_toolchange = 10 |

|

retract_lift = 0 |

|

retract_lift_above = 0 |

|

retract_lift_below = 0 |

|

retract_restart_extra = 0 |

|

retract_restart_extra_toolchange = 0 |

|

retract_speed = 60 |

|

seam_position = nearest |

|

serial_port = |

|

serial_speed = 250000 |

|

silent_mode = 1 |

|

single_extruder_multi_material = 0 |

|

single_extruder_multi_material_priming = 1 |

|

skirt_distance = 3 |

|

skirt_height = 1 |

|

skirts = 3 |

|

slice_closing_radius = 0.049 |

|

slowdown_below_layer_time = 5 |

|

small_perimeter_speed = 25% |

|

solid_infill_below_area = 70 |

|

solid_infill_every_layers = 0 |

|

solid_infill_extruder = 1 |

|

solid_infill_extrusion_width = 0 |

|

solid_infill_speed = 75% |

|

spiral_vase = 0 |

|

standby_temperature_delta = -5 |

|

start_filament_gcode = "; Filament gcode\n" |

|

start_gcode = ;– PrusaSlicer Start G-Code for M2 starts –\n; Ed Nisley KE4NZU\n; Makergear V4 hot end\n; Origin at platform center, set by MANUAL_X_HOME_POS compiled constants\n; Z-min switch at platform, must move nozzle to X=135 to clear\nG90 ; absolute coordinates\nG21 ; millimeters\nM83 ; relative extrusion distance\nM104 S[first_layer_temperature] ; start extruder heating\nM140 S[first_layer_bed_temperature] ; start bed heating\nM17 ; enable steppers\nG4 P500 ; … wait for power up\nG92 Z0 ; set Z to zero, wherever it might be now\nG0 Z10 F1000 ; move platform downward to clear nozzle; may crash at bottom\nG28 Y ; home Y to clear plate, offset from compiled constant\nG28 X ; home X, offset from M206 X, offset from compiled constant\nG0 X135 Y0 F15000 ; move off platform to right side, center Y\nG28 Z ; home Z to platform switch, offset from M206 Z measured\nG0 Z2.0 F1000 ; get air under switch\nG0 Y-126 F10000 ; set up for priming, zig around corner\nG0 X0 ; center X\nG0 Y-124.5 ; just over platform edge\nG0 Z0 F500 ; exactly at platform\nM190 S[first_layer_bed_temperature] ; wait for bed to finish heating\nM109 S[first_layer_temperature] ; set extruder temperature and wait\nG1 E20 F300 ; prime to get pressure, generate blob on edge\nG0 Y-123 F5000 ; shear off blob\nG0 X15 F15000 ; jerk away from blob, move over surface\nG4 P500 ; pause to attach\nG1 X45 F500 ; slowly smear snot to clear nozzle\nG1 Z1.0 F2000 ; clear bed for travel\n;– PrusaSlicer Start G-Code ends –\n |

|

support_material = 0 |

|

support_material_angle = 0 |

|

support_material_auto = 1 |

|

support_material_buildplate_only = 0 |

|

support_material_contact_distance = 0.2 |

|

support_material_enforce_layers = 0 |

|

support_material_extruder = 1 |

|

support_material_extrusion_width = 0.31 |

|

support_material_interface_contact_loops = 0 |

|

support_material_interface_extruder = 1 |

|

support_material_interface_layers = 3 |

|

support_material_interface_spacing = 0 |

|

support_material_interface_speed = 100% |

|

support_material_pattern = rectilinear |

|

support_material_spacing = 2.5 |

|

support_material_speed = 60 |

|

support_material_synchronize_layers = 0 |

|

support_material_threshold = 0 |

|

support_material_with_sheath = 1 |

|

support_material_xy_spacing = 50% |

|

temperature = 250 |

|

thin_walls = 1 |

|

threads = 4 |

|

thumbnails = |

|

toolchange_gcode = |

|

top_fill_pattern = hilbertcurve |

|

top_infill_extrusion_width = 0 |

|

top_solid_infill_speed = 50% |

|

top_solid_layers = 3 |

|

top_solid_min_thickness = 0 |

|

travel_speed = 300 |

|

use_firmware_retraction = 0 |

|

use_relative_e_distances = 0 |

|

use_volumetric_e = 0 |

|

variable_layer_height = 1 |

|

wipe = 0 |

|

wipe_into_infill = 0 |

|

wipe_into_objects = 0 |

|

wipe_tower = 0 |

|

wipe_tower_bridging = 10 |

|

wipe_tower_no_sparse_layers = 0 |

|

wipe_tower_rotation_angle = 0 |

|

wipe_tower_width = 60 |

|

wipe_tower_x = 180 |

|

wipe_tower_y = 140 |

|

wiping_volumes_extruders = 70,70 |

|

wiping_volumes_matrix = 0 |

|

xy_size_compensation = 0 |

|

z_offset = 0 |