-

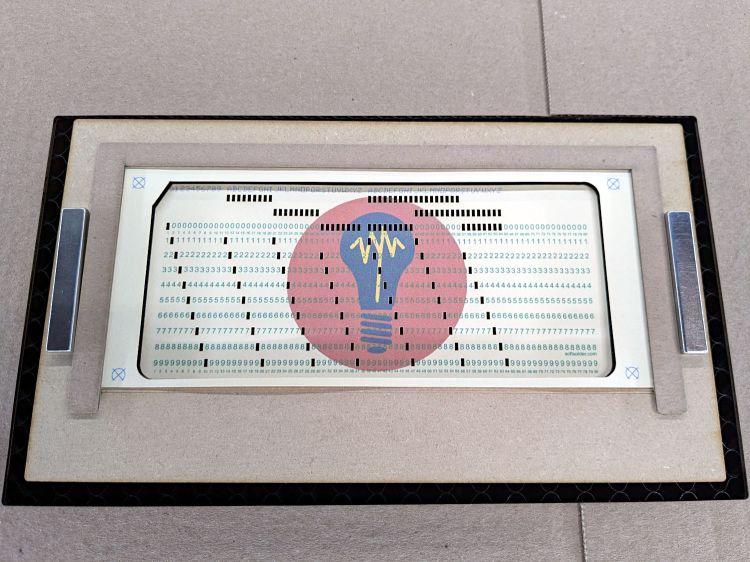

So I know whether the gizmo I’m building or the parts I’m arranging actually fit on the Thing-O-Matic’s build platform.

-

Knowing the risetime, you can calculate the voltage across the inductor

-

It’s a pan-head screw that miraculously fits snugly inside the cut-off shaft section

-

I suppose they’re Matryoshka-sized from one end to the other.

-

The az-el joint axes and the mirror shaft axis now meet at a common point, so the mirror shaft moves as the radius of a sphere.

-

It came rather close to doing the Ouroboros thing

-

The optical 1/rev signal may line up perversely with the start of a microstep

-

Subscribe

Subscribed

Already have a WordPress.com account? Log in now.