|

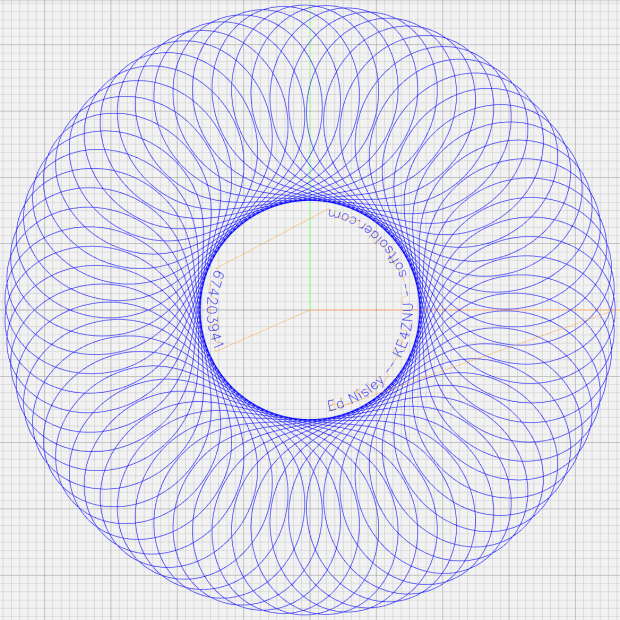

// Spirograph simulator for MPCNC used as plotter |

|

// Ed Nisley KE4ZNU – 2017-12-23 |

|

// Adapted for Guillioche plots with ball point pens – 2018-09-25 |

|

// 2019-06 Text on circular arcs |

|

// 2019-08 Coordinate pruning |

|

// 2019-09 Allow L > 1.0, proper scale to fit disk |

|

|

|

// Spirograph equations: |

|

// https://en.wikipedia.org/wiki/Spirograph |

|

// Loosely based on GCMC cycloids.gcmc demo: |

|

// https://gitlab.com/gcmc/gcmc/tree/master/example/cycloids.gcmc |

|

|

|

//—– |

|

// Library routines |

|

|

|

include("tracepath.inc.gcmc"); |

|

include("engrave.inc.gcmc"); |

|

|

|

//—– |

|

// Define useful constants |

|

|

|

SafeZ = 10.00mm; |

|

TravelZ = 1.00mm; |

|

|

|

AngleStep = 0.1deg; |

|

|

|

Snuggly = 0.2mm; // prune coordinates when closer |

|

|

|

TextFont = FONT_HSANS_1_RS; |

|

TextSize = [1.5mm,1.5mm]; |

|

|

|

//—– |

|

// Command line parameters |

|

|

|

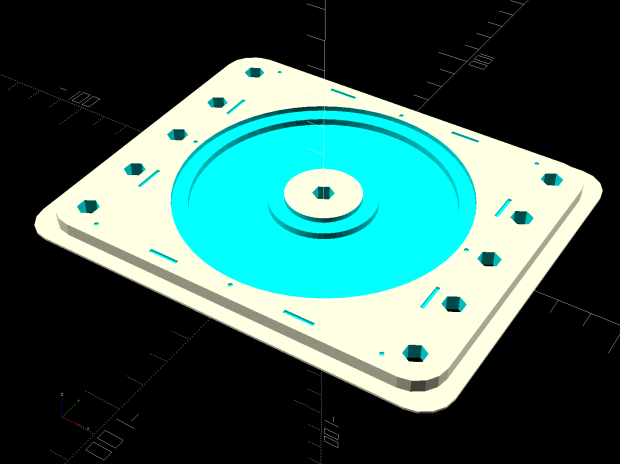

// -D DiskType="string" |

|

|

|

if (!isdefined("DiskType")) { |

|

DiskType = "CD"; |

|

} |

|

|

|

if (DiskType != "CD" && // list all possible types |

|

DiskType != "3.5" && |

|

DiskType != "TrimCD" |

|

) { |

|

error("Unknown disk type: ",DiskType); |

|

} |

|

|

|

comment("Disk type: ",DiskType); // default is "CD" |

|

|

|

Margin = 1.5mm; // clamping margin around disk OD |

|

|

|

DiskDia = (DiskType == "3.5") ? 95.0mm : |

|

(DiskType == "TrimCD") ? 95.0mm : |

|

120.0mm; |

|

OuterDia = DiskDia – 2*Margin; |

|

OuterRad = OuterDia / 2; |

|

comment("Outer Diameter: ",OuterDia); |

|

comment(" Radius: ",OuterRad); |

|

|

|

InnerDia = (DiskType == "3.5") ? 33.0mm : |

|

(DiskType == "TrimCD") ? 38.0mm : |

|

38.0mm; |

|

InnerDia = InnerDia; |

|

InnerRad = InnerDia / 2; |

|

comment("Inner Diameter: ",InnerDia); |

|

comment(" Radius: ",InnerRad); |

|

|

|

MidDia = (InnerDia + OuterDia) / 2; |

|

MidRad = MidDia / 2; |

|

comment("Mid Diameter: ",MidDia); |

|

comment(" Radius: ",MidRad); |

|

|

|

LegendDia = (DiskType == "3.5") ? 31.0mm : |

|

(DiskType == "TrimCD") ? 31.0mm : |

|

30.0mm; |

|

LegendDia = LegendDia; |

|

LegenRad = LegendDia / 2; |

|

comment("Legend Diameter: ",LegendDia); |

|

comment(" Radius: ",LegenRad); |

|

|

|

// -D PRNG_Seed=integer non-zero random number seed |

|

|

|

if (isdefined("PRNG_Seed")) { // did we get a seed? |

|

if (!PRNG_Seed) { // .. it must not be zero |

|

PRNG_Seed = 347221084; |

|

} |

|

} |

|

else { // no incoming seed, so use a constant |

|

PRNG_Seed = 674203941; |

|

} |

|

comment("PRNG seed: ",PRNG_Seed); |

|

|

|

PRNG_State = PRNG_Seed; // set initial state |

|

|

|

// -D various other useful tidbits |

|

// add unit to speeds and depths: 2000mm / -3.00mm / etc |

|

|

|

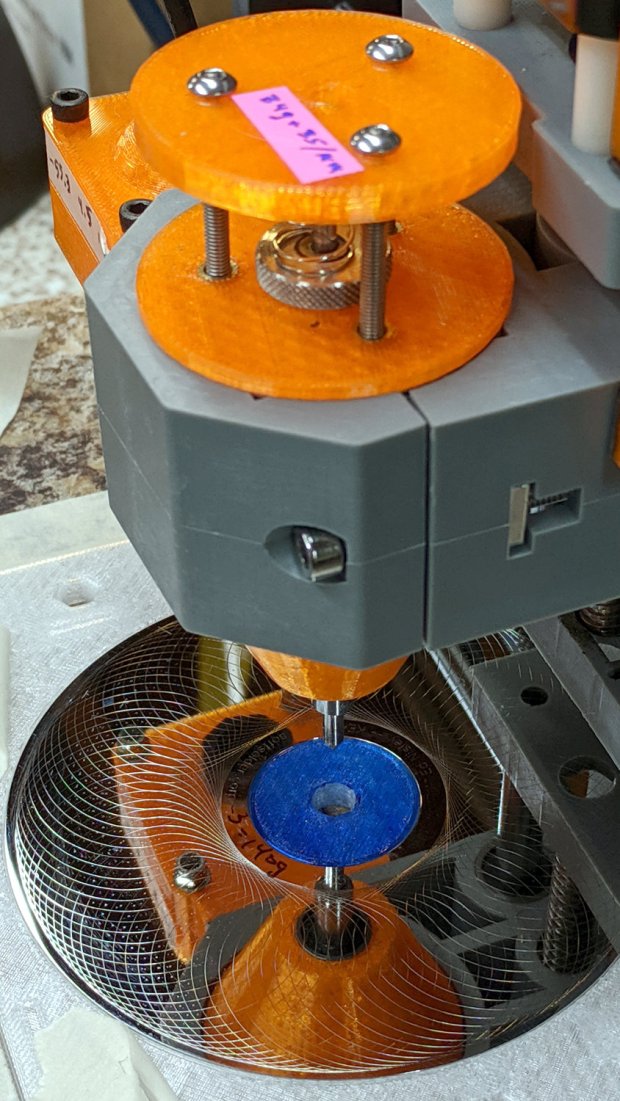

if (!isdefined("PlotSpeed")) { |

|

PlotSpeed = 2400mm; |

|

} |

|

|

|

if (!isdefined("TextSpeed")) { |

|

TextSpeed = 2000mm; |

|

} |

|

|

|

// Force is proportional to depth, but you must know the coefficent! |

|

|

|

if (!isdefined("PlotZ")) { |

|

PlotZ = (DiskType == "3.5") ? -3.00 : -0.25mm; |

|

} |

|

|

|

if (!isdefined("Legend")) { |

|

Legend = "Ed Nisley – KE4ZNU – softsolder.com"; |

|

} |

|

|

|

|

|

|

|

//—– |

|

// Spirograph tooth counts mooched from: |

|

// http://nathanfriend.io/inspirograph/ |

|

// Stators includes both inside and outside counts, because we're not fussy |

|

|

|

// Stator with prime tooth count will always produce that number of lobes |

|

// Prime numbers: |

|

// https://en.wikipedia.org/wiki/Prime_number |

|

// Table of primes: |

|

// https://www.factmonster.com/math/numbers/prime-numbers-facts-examples-table-all-1000 |

|

|

|

// Must be sorted and should not exceed 127 teeth, which will make plenty of lobes |

|

|

|

Stators = [37,41,43,47,53,59,61,67,71,73,79,83,89,97,101,103,107,109,113,127]; |

|

|

|

// Rotor tooth count chosen randomly, these are for the old method |

|

|

|

Rotors = [24, 30, 32, 36, 40, 45, 48, 50, 52, 56, 60, 63, 64, 72, 75, 80, 84]; |

|

//Rotors = [5,7,11,13,17,19,23,31,37,41,47]; |

|

|

|

//—– |

|

// Greatest Common Divisor |

|

// https://en.wikipedia.org/wiki/Greatest_common_divisor#Using_Euclid's_algorithm |

|

// Inputs = integers without units |

|

|

|

// This is unused with prime rotor tooth counts left here for completeness |

|

|

|

function gcd(a,b) { |

|

if (!isnone(a) || isfloat(a) || !isnone(b) || isfloat(b)) { |

|

error("GCD params must be dimensionless integers. a: ",a," b: ",b); |

|

} |

|

|

|

local d = 0; // power-of-two counter |

|

|

|

while (!((a | b) & 1)) { // remove and tally common factors of two |

|

a >>= 1; |

|

b >>= 1; |

|

d++; |

|

} |

|

|

|

while (a != b) { |

|

if (!(a & 1)) {a >>= 1;} // discard non-common factor of 2 |

|

elif (!(b & 1)) {b >>= 1;} // … likewise |

|

elif (a > b) {a = (a – b) >> 1;} // gcd(a,b) also divides a-b |

|

else {b = (b – a) >> 1;} // … likewise |

|

} |

|

|

|

local GCD = a*(1 << d); // form gcd |

|

|

|

// message("GCD: ",GCD); |

|

return GCD; |

|

|

|

} |

|

|

|

//—– |

|

// Max and min functions |

|

|

|

function max(x,y) { |

|

return (x > y) ? x : y; |

|

} |

|

|

|

function min(x,y) { |

|

return (x < y) ? x : y; |

|

} |

|

|

|

//—– |

|

// Pseudo-random number generator |

|

// Based on xorshift: |

|

// https://en.wikipedia.org/wiki/Xorshift |

|

// http://www.jstatsoft.org/v08/i14/paper |

|

// Requires initial state from calling script |

|

// -D "PRNG_Seed=whatever" |

|

// Bash (et. al.) supplies nine reasonably random digits from $(date +%N) |

|

|

|

function XORshift() { |

|

|

|

local x = PRNG_State; // fetch current state |

|

|

|

x ^= x << 13; |

|

x ^= x >> 17; |

|

x ^= x << 5; |

|

|

|

PRNG_State = x; // save state for next invocation |

|

return x; |

|

|

|

} |

|

|

|

//—– |

|

// Bend text around an arc |

|

|

|

function ArcText(TextPath,Center,Radius,BaseAngle,Align) { |

|

|

|

PathLength = TextPath[-1].x; |

|

Circumf = 2*pi()*Radius; |

|

TextAngle = to_deg(360 * PathLength / Circumf); |

|

|

|

AlignAngle = BaseAngle + (Align == "Left" ? 0 : |

|

Align == "Center" ? -TextAngle / 2 : |

|

Align == "Right" ? -TextAngle : |

|

0); |

|

|

|

ArcPath = {}; |

|

|

|

foreach(TextPath; pt) { |

|

if (!isundef(pt.x) && !isundef(pt.y) && isundef(pt.z)) { // XY motion, no Z |

|

r = Radius – pt.y; |

|

a = 360deg * (pt.x / Circumf) + AlignAngle; |

|

ArcPath += {[r*cos(a) + Center.x, r*sin(a) + Center.y,-]}; |

|

} |

|

elif (isundef(pt.x) && isundef(pt.y) && !isundef(pt.z)) { // no XY, Z up/down |

|

ArcPath += {pt}; |

|

} |

|

else { |

|

error("Point is not pure XY or pure Z: " + to_string(pt)); |

|

} |

|

} |

|

|

|

return ArcPath; |

|

|

|

} |

|

|

|

|

|

|

|

//—– |

|

// Set up gearing |

|

|

|

s = (XORshift() & 0xffff) % count(Stators); |

|

StatorTeeth = Stators[s]; |

|

comment("Stator ",s,": ",StatorTeeth); |

|

|

|

// When Stator has prime teeth, any Rotor will have GCD = 1 |

|

|

|

if (1) { |

|

RotorTeeth = Stators[-1]; |

|

n = 0; |

|

while (RotorTeeth >= floor(0.95 * StatorTeeth) || RotorTeeth < 5) { |

|

RotorTeeth = (XORshift() & 0x007f); // this is why Stator can't have more than 127 teeth |

|

n++; |

|

} |

|

comment("Rotor: ",RotorTeeth," in ",n," iterations"); |

|

} |

|

else { |

|

r = (XORshift() & 0xffff) % count(Rotors); |

|

RotorTeeth = Rotors[r]; |

|

comment("Rotor ",r,": ",RotorTeeth); |

|

} |

|

|

|

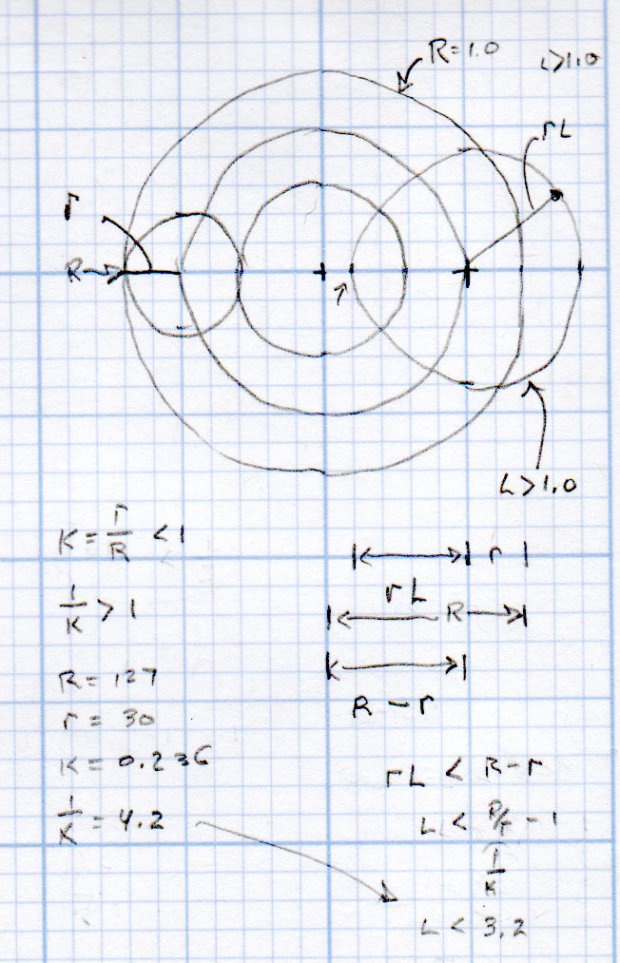

K = to_float(RotorTeeth) / to_float(StatorTeeth); // find normalized rotor dia |

|

comment("Dia ratio K: ",K," 1/K: ",1.0/K); |

|

|

|

GCD = gcd(StatorTeeth,RotorTeeth); // reduce teeth to ratio of least integers |

|

comment("GCD: ",GCD); |

|

|

|

Lobes = StatorTeeth / GCD; // compute useful values |

|

comment("Lobes: ", Lobes); |

|

|

|

Turns = RotorTeeth / GCD; |

|

comment("Turns: ", Turns); |

|

|

|

// Find normalized pen offset to never cross Stator center |

|

|

|

if (1) { |

|

n = 0; |

|

do { |

|

L = (to_float((XORshift() & 0x1f) + 1) / 32.0) * (1.0/K – 1.0); // allow L > 1.0 |

|

// comment(" test L: ",L); |

|

n++; |

|

} while (L >= (1.0/K – 1.0) || L < 0.01); |

|

} |

|

else { |

|

n = 0; |

|

do { |

|

L = to_float((XORshift() & 0x1f) + 1) / 32.0; // force L < 1.0 |

|

n++; |

|

} while (L >= (1.0/K – 1.0) || L < 0.01); |

|

} |

|

|

|

comment("Offset L: ", L," in ",n," iterations"); |

|

|

|

//—– |

|

// Crank out a list of points in normalized coordinates |

|

|

|

Path = {}; |

|

|

|

for (a = 0.0deg ; a <= Turns*360deg ; a += AngleStep) { |

|

x = (1 – K)*cos(a) + L*K*cos(a*(1 – K)/K); |

|

y = (1 – K)*sin(a) – L*K*sin(a*(1 – K)/K); |

|

Path += {[x,y]}; |

|

} |

|

|

|

//—– |

|

// Calculate normalized limits for band traced by pen in rotor at offset L |

|

// L was chosen to produce a band around the rotor center point |

|

|

|

RotorMin = 1.0 – 2*K; |

|

comment("Rotor Min: ",RotorMin); |

|

|

|

BandCtr = 1.0 – K; // band center radius |

|

BandMin = BandCtr – L*K; // … min radius |

|

BandMax = BandCtr + L*K; // … max radius |

|

|

|

BandAmpl = BandMax – BandCtr; |

|

|

|

comment("Band Min: ",BandMin," Ctr: ",BandCtr," Max: ",BandMax); |

|

|

|

//—– |

|

// Scale normalized band to fill physical limits centered at mid-disk radius |

|

|

|

FillPath = {}; |

|

|

|

foreach (Path; pt) { |

|

|

|

a = atan_xy(pt); // recover angle to point |

|

r = length(pt); // … radius to point |

|

|

|

br = (r – BandCtr) / BandAmpl; // remove center bias, rescale to 1.0 amplitude |

|

dr = br * (OuterRad – MidRad); // rescale to fill disk |

|

pr = dr + MidRad; // set at disk centerline |

|

|

|

x = pr * cos(a); // find new XY coords |

|

y = pr * sin(a); |

|

|

|

FillPath += {[x,y]}; |

|

} |

|

|

|

comment("Path has ",count(FillPath)," points"); |

|

|

|

//—– |

|

// Prune too-snuggly physical coordinates |

|

|

|

PointList = {FillPath[0]}; // must include first point |

|

|

|

lp = FillPath[0]; |

|

n = 0; |

|

|

|

foreach (FillPath; pt) { |

|

if (length(pt – lp) <= Snuggly) { // discard too-snuggly point |

|

n++; |

|

} |

|

else { |

|

PointList += {pt}; // otherwise, add it to output |

|

lp = pt; |

|

} |

|

} |

|

|

|

PointList += {FillPath[-1]}; // ensure closure at last point |

|

|

|

comment("Pruned ",n," points, ",count(PointList)," remaining"); |

|

|

|

//—– |

|

// Convert coordinate list to G-Code |

|

|

|

comment("Pattern begins"); |

|

|

|

feedrate(PlotSpeed); |

|

|

|

goto([-,-,SafeZ]); |

|

goto([0,0,-]); |

|

goto([-,-,TravelZ]); |

|

|

|

tracepath(PointList, PlotZ); |

|

|

|

//—– |

|

// Draw the legend |

|

|

|

comment("Legend begins"); |

|

|

|

if (Legend) { |

|

tp = scale(typeset(Legend,TextFont),TextSize); |

|

tpa = ArcText(tp,[0mm,0mm],LegenRad,0deg,"Center"); |

|

feedrate(TextSpeed); |

|

engrave(tpa,TravelZ,PlotZ); |

|

} |

|

|

|

tp = scale(typeset(to_string(PRNG_Seed),TextFont),TextSize); |

|

tpa = ArcText(tp,[0mm,0mm],LegenRad,180deg,"Center"); |

|

feedrate(TextSpeed); |

|

engrave(tpa,TravelZ,PlotZ); |

|

|

|

goto([-,-,SafeZ]); // done, so get out of the way |

|

goto([0,0,-]); |

|

|

|

comment("Disk ends"); |