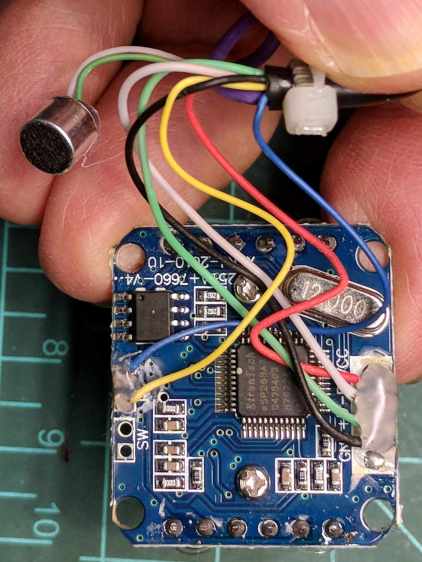

The wiring hairball between the control button pendant and the Protoneer board looks like this:

The as-built schematic, such as it is:

Yes, the SSR negative output goes to the Protoneer + Power Input.

I should drive the SSR from the Motor Enable output (in the external motor control header), rather than +5 V, to let GRBL control the motors, with a manual E-Stop override. The A4988 drivers require -Enable, so:

-Enableto SSR-Controlinput (replaces GND)- +5 V to BRS to SSR

+Controlinput (as before)

The SSR Control input draws 13 mA at 5 V, suggesting I should drive the AC SSR (for the spindle motor) from the DC SSR output, rather than paralleling the two on a single Arduino output pin.

I belatedly recognized the E-Stop BRS as an instantiation of an SCP-001-J Keter-class anomaly; it is now appropriately labeled:

I can attest to its effect on rational thought; a molly-guard may be required.