I have unfairly maligned the TPU snout, because the PETG snout failed the same way:

Seen with the shock cord in place, it’s obvious that combining moderately high temperature with steady compression sufficed to bend the PETG enough to pop those tabs loose from the vent.

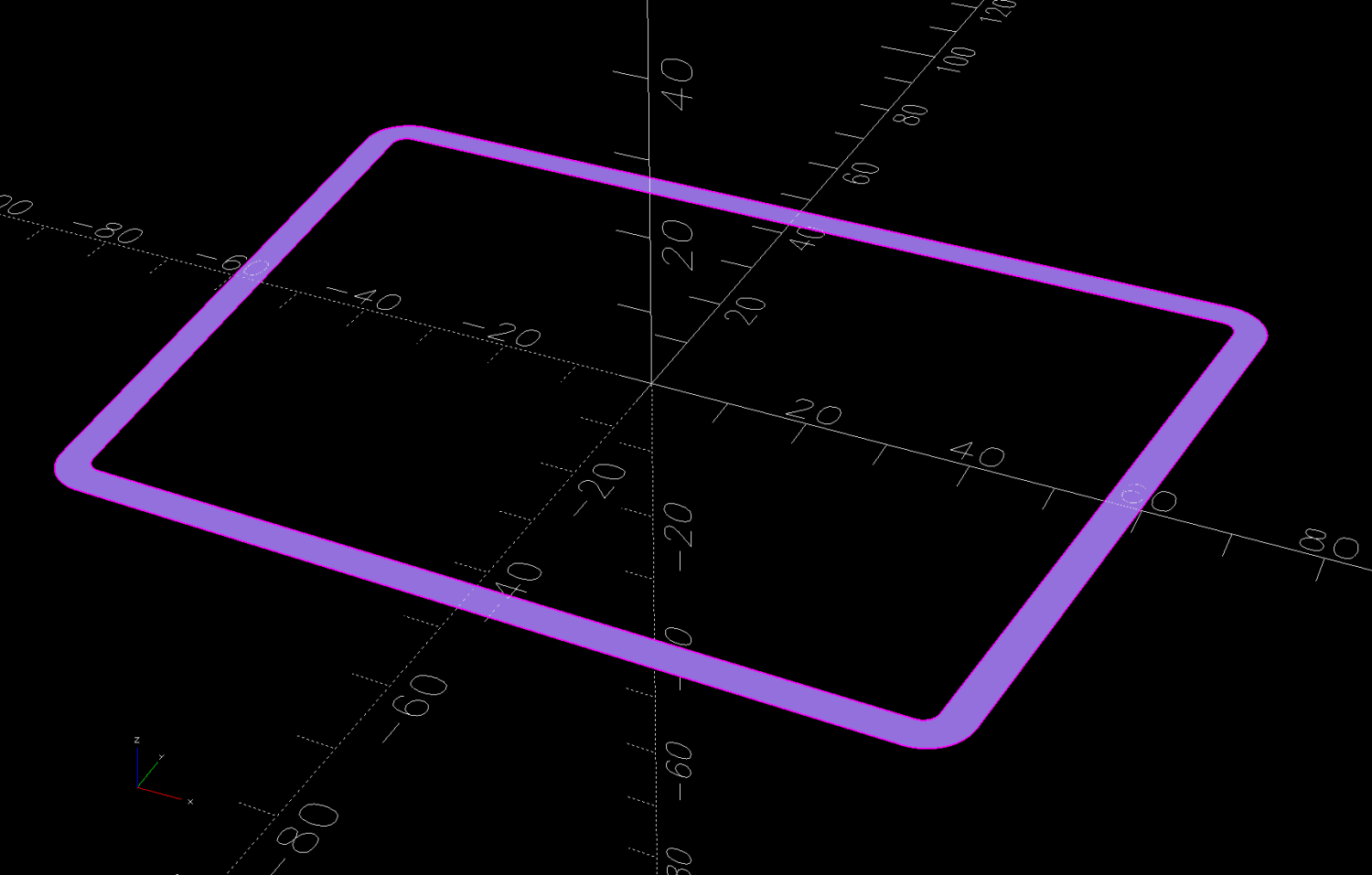

So the OpenSCAD model now produces a stiffening ring to be laser-cut from acrylic:

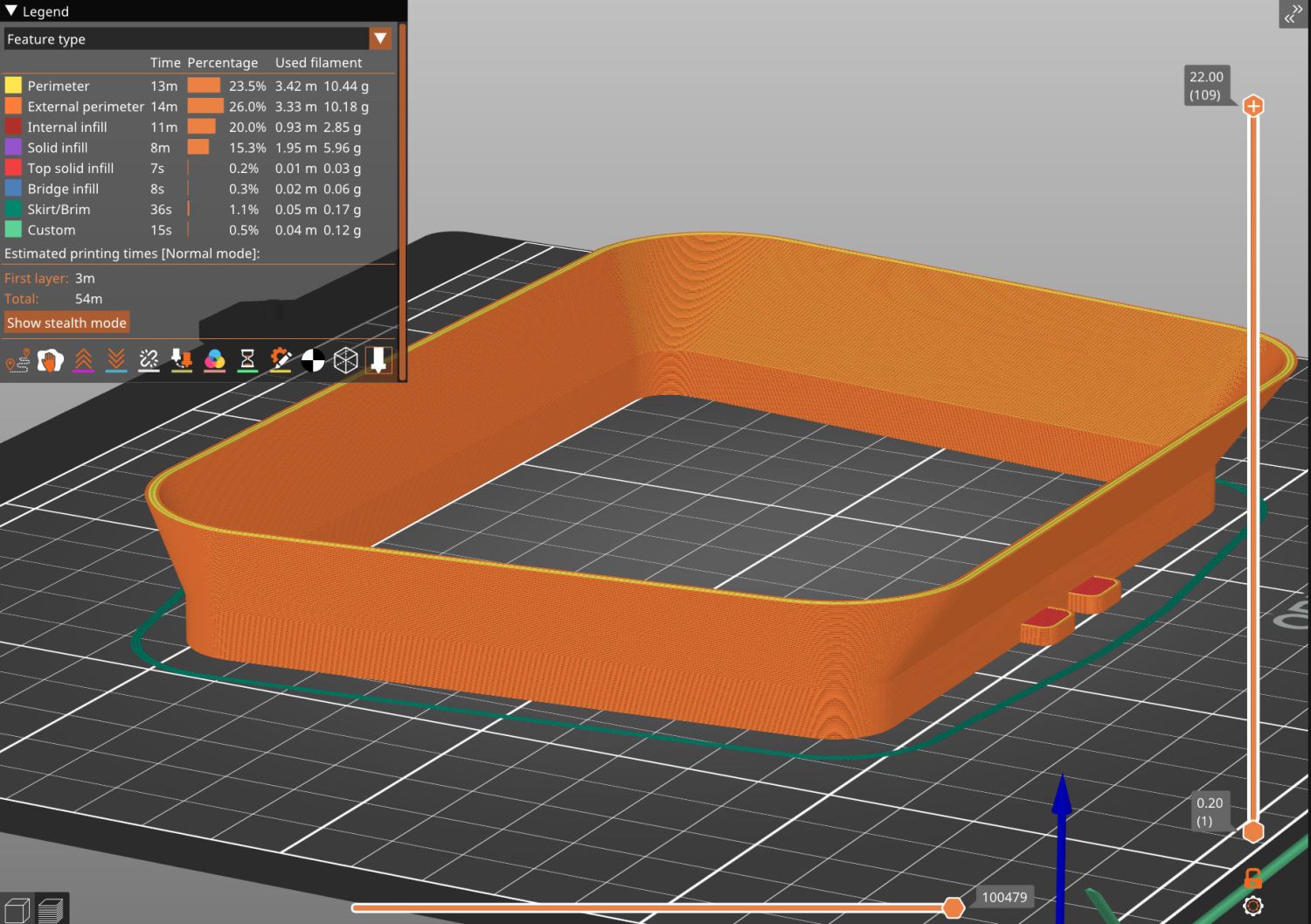

The whole snout builds as a single unit in the obvious orientation:

Because the part of the snout with the tabs is 7 mm tall, I glued a 4 mm acrylic ring to a 3 mm ring, with both of them glued to the snout:

That’s “natural” PETG, which I expected to be somewhat more transparent, but it’s definitely not a dealbreaker.

Mary will sew up another cheesecloth filter and we’ll see what happens to this setup.

As the saying goes, “Experience is what you get when you don’t get what you want.”

Fortunately, living in the future makes it easy to iterate on the design & implementation until experience produces what should have been obvious at the start.

Spam comments get trashed, so don’t bother. Comment moderation may cause a delay.