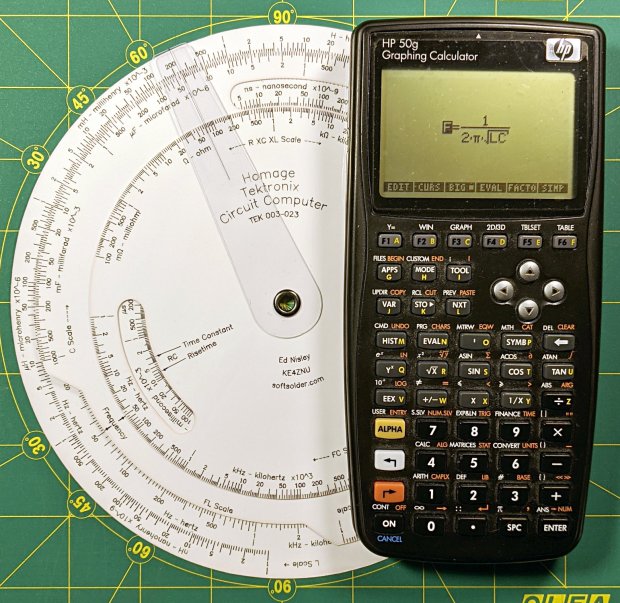

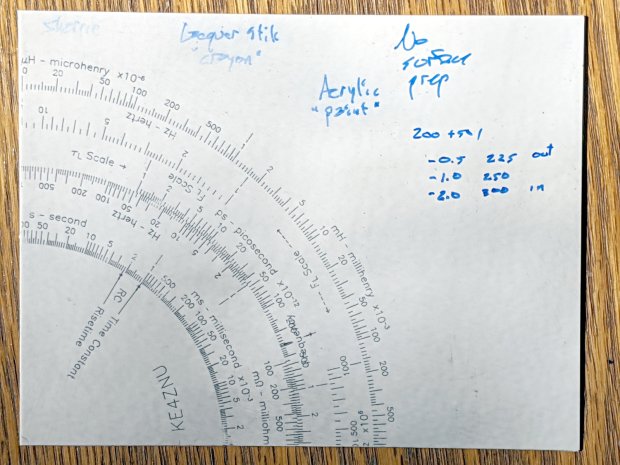

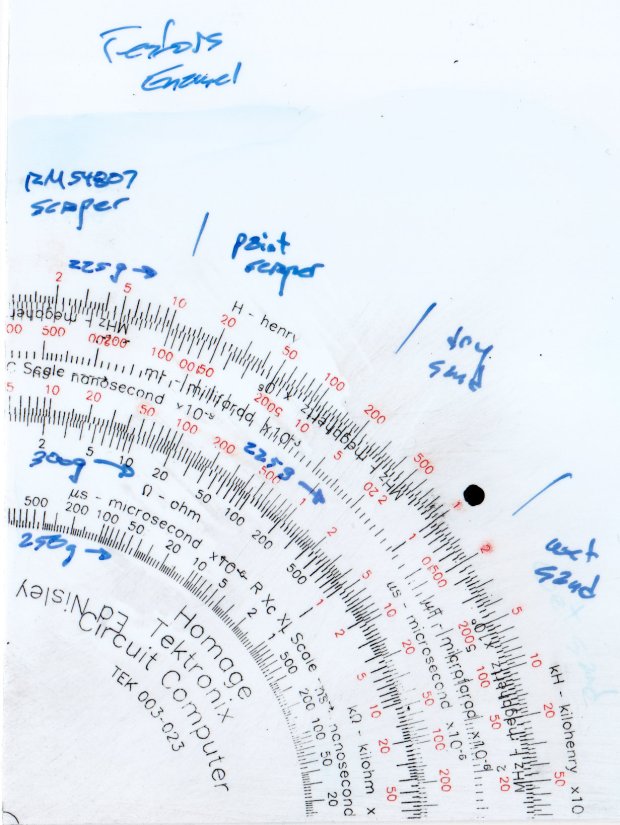

For the first time in a loooong time, I applied Testors Gloss Enamel paint to styrene plastic:

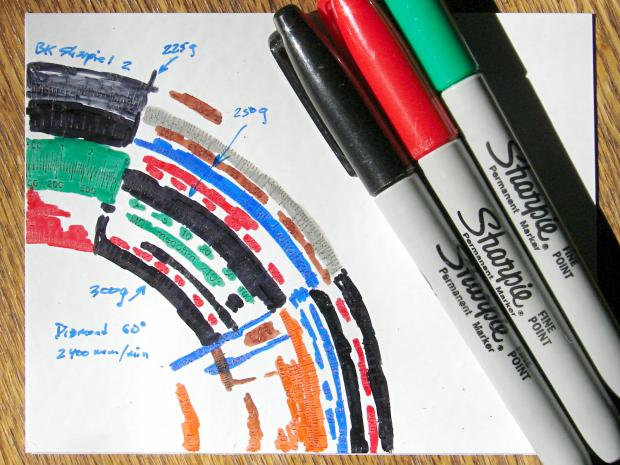

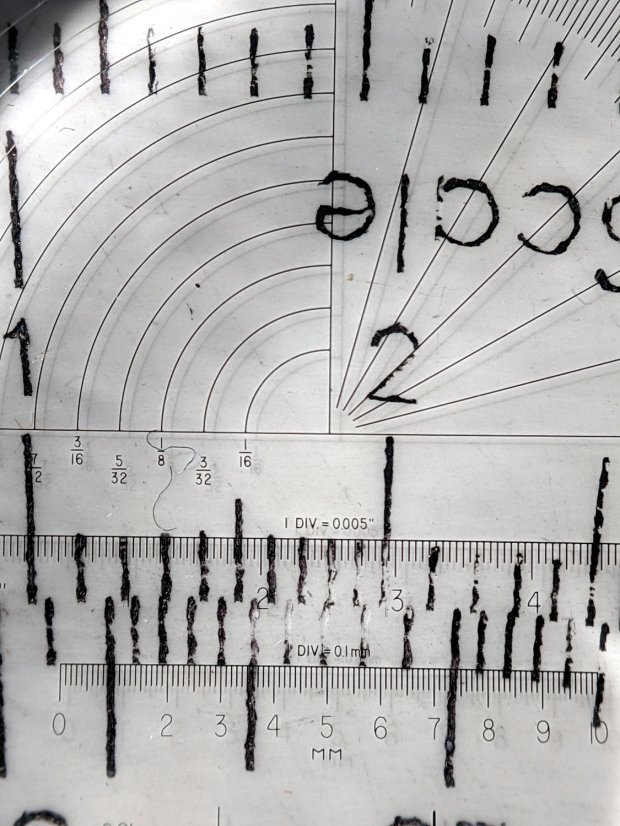

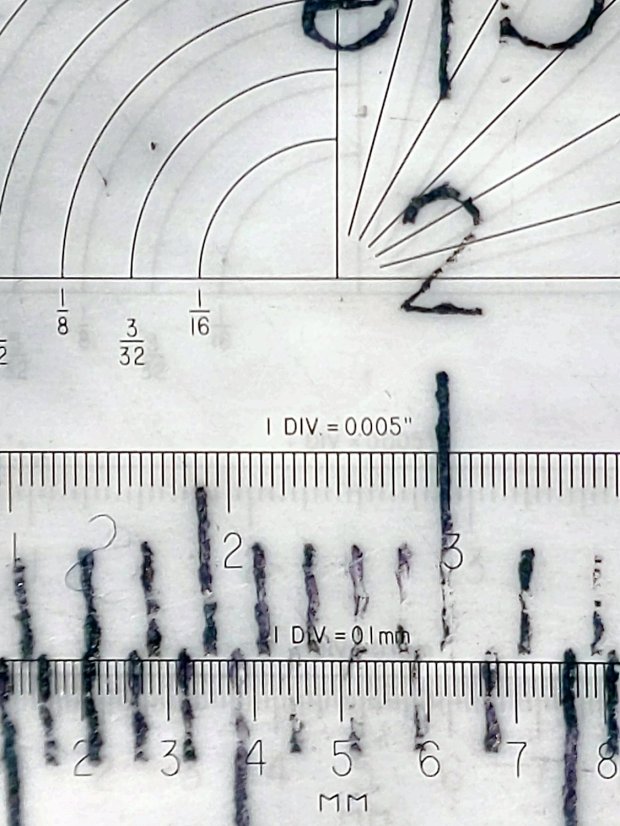

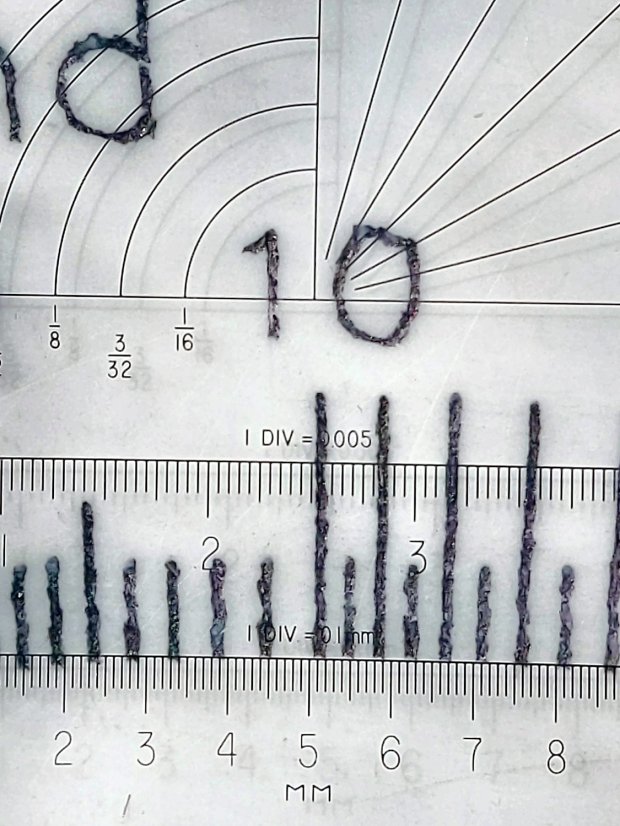

Two coats of black paint produced the larger areas along the inner scales and completely filled those engraved lines:

With exactly the correct paint on exactly the correct material, it cured into a non-removable layer. Being enamel, however, the last coat requires two or three days for a full cure, so this isn’t a short-attention-span project.

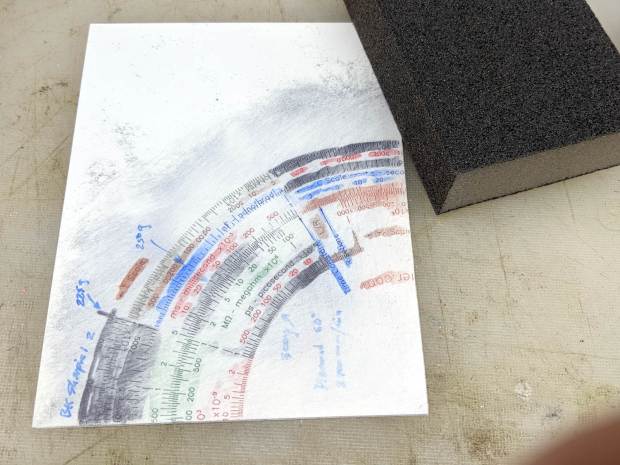

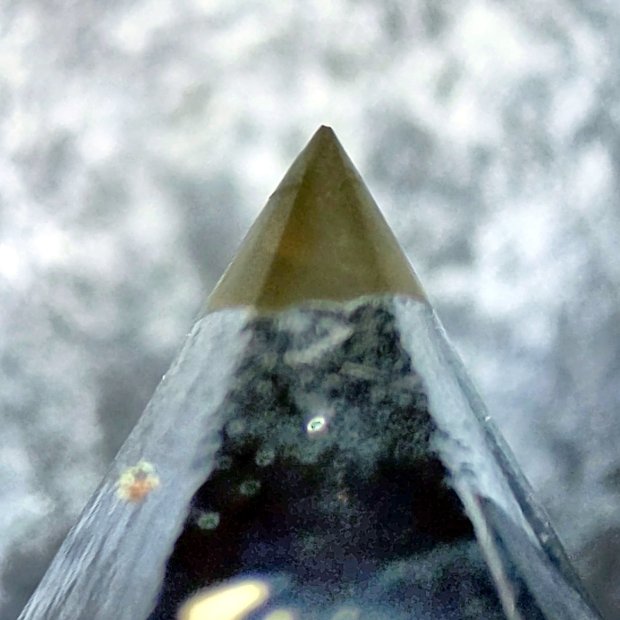

It’s “non-removable” unless you’re willing to abrade the surface:

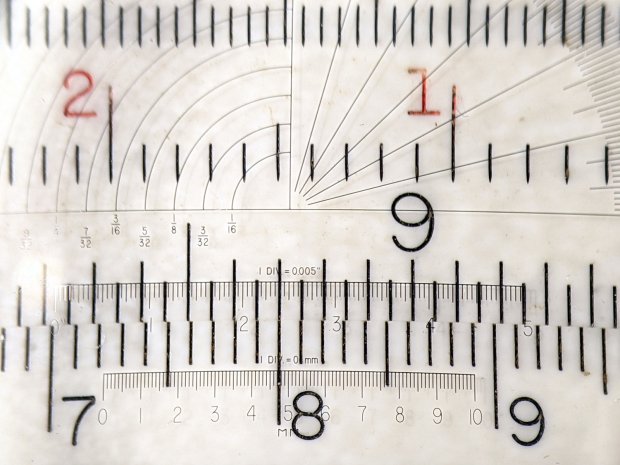

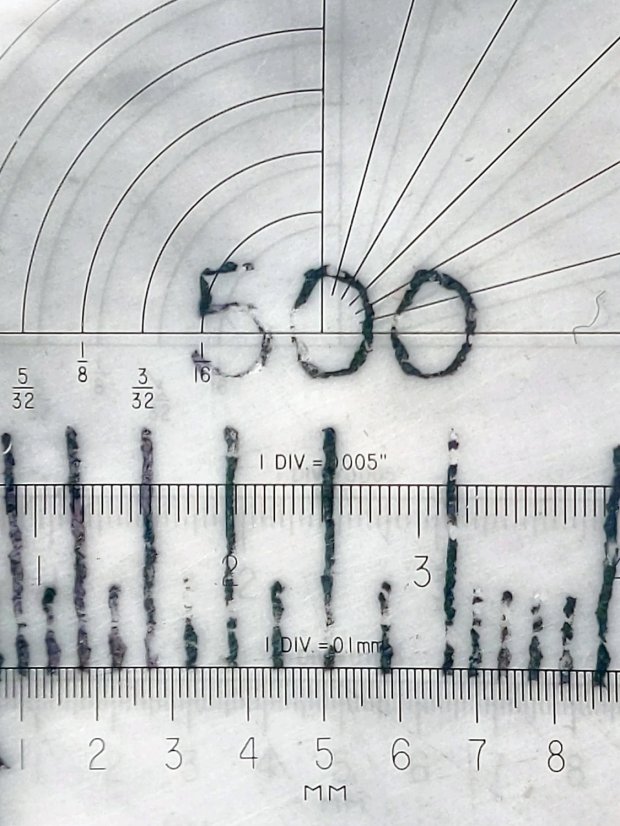

Sanding tends to remove too much plastic, particularly when confronted with raised walls & suchlike along the grooves. The darkest scale down the middle was engraved with 300 g downforce and is deep enough to retain all its paint:

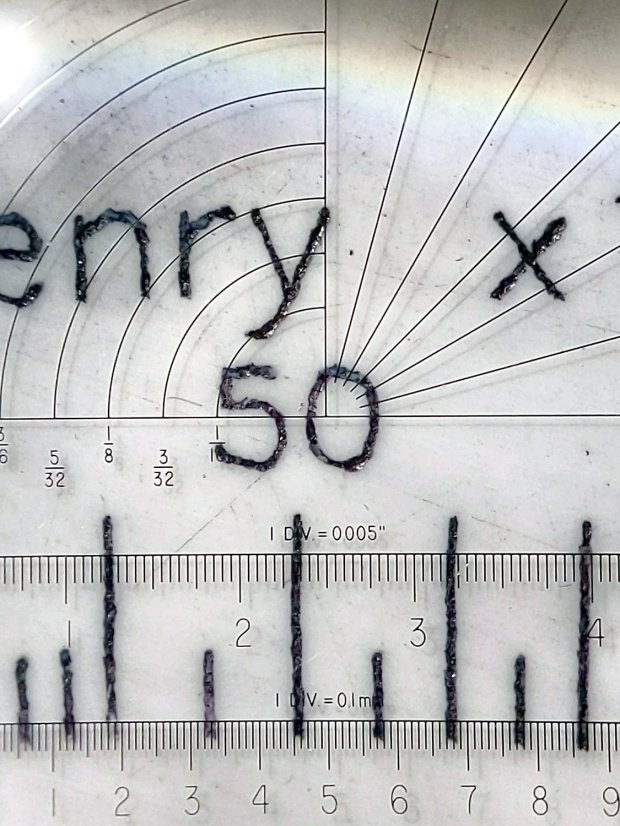

As expected, paint scrapers produce better results:

There’s not much visible difference between the 250 g and 300 g scales.

All the scraped lines are over 0.1 mm wide, with the heavier downforce producing maybe 0.12 mm.

The double-coated lines are flush with the (scraped) surface and visibly matte. The single-coated regions have the usual glossy enamel finish remaining deep in the lines & numbers, with a thin matte outline flush with the surrounding surface. It’s basically impossible to photograph those features, at least for me.

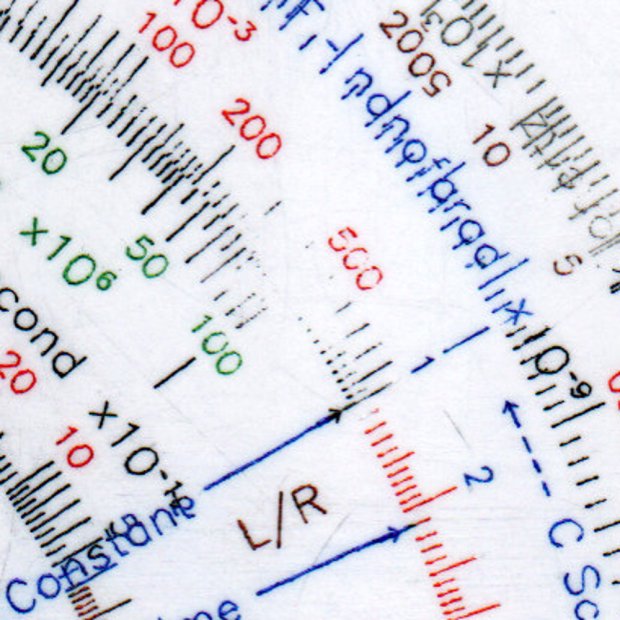

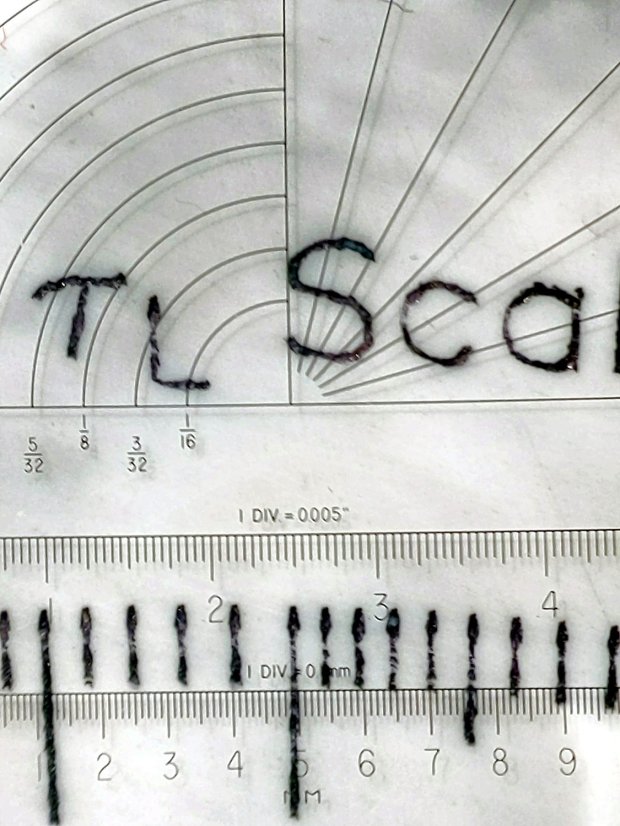

The colors are crisp & vivid: enamel paint is the way to go!

The next testpiece should run downforce variations from 300 through 500 g and speeds from 1000 to 2400 mm/min. Scraping off the raised plastic before painting should deliver a better ahem painting experience without much surface damage; the trick will be clearing all the debris from the engraved lines.