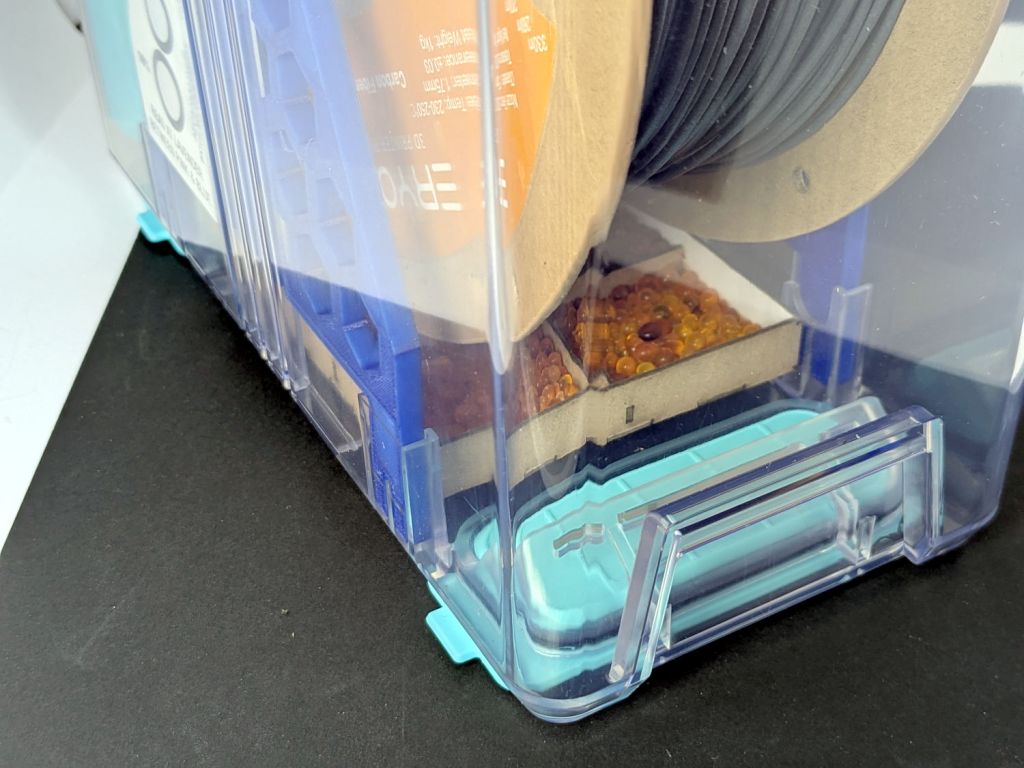

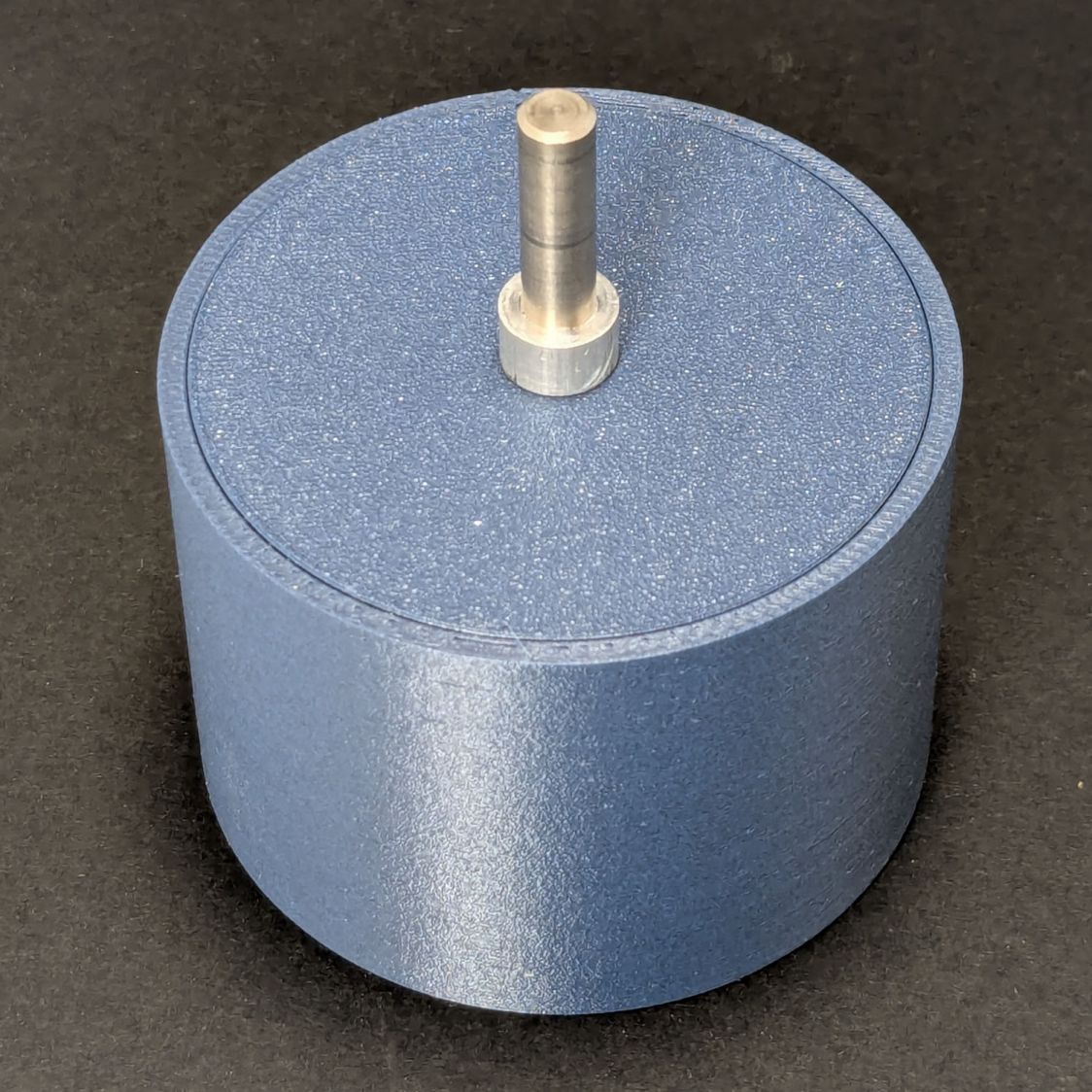

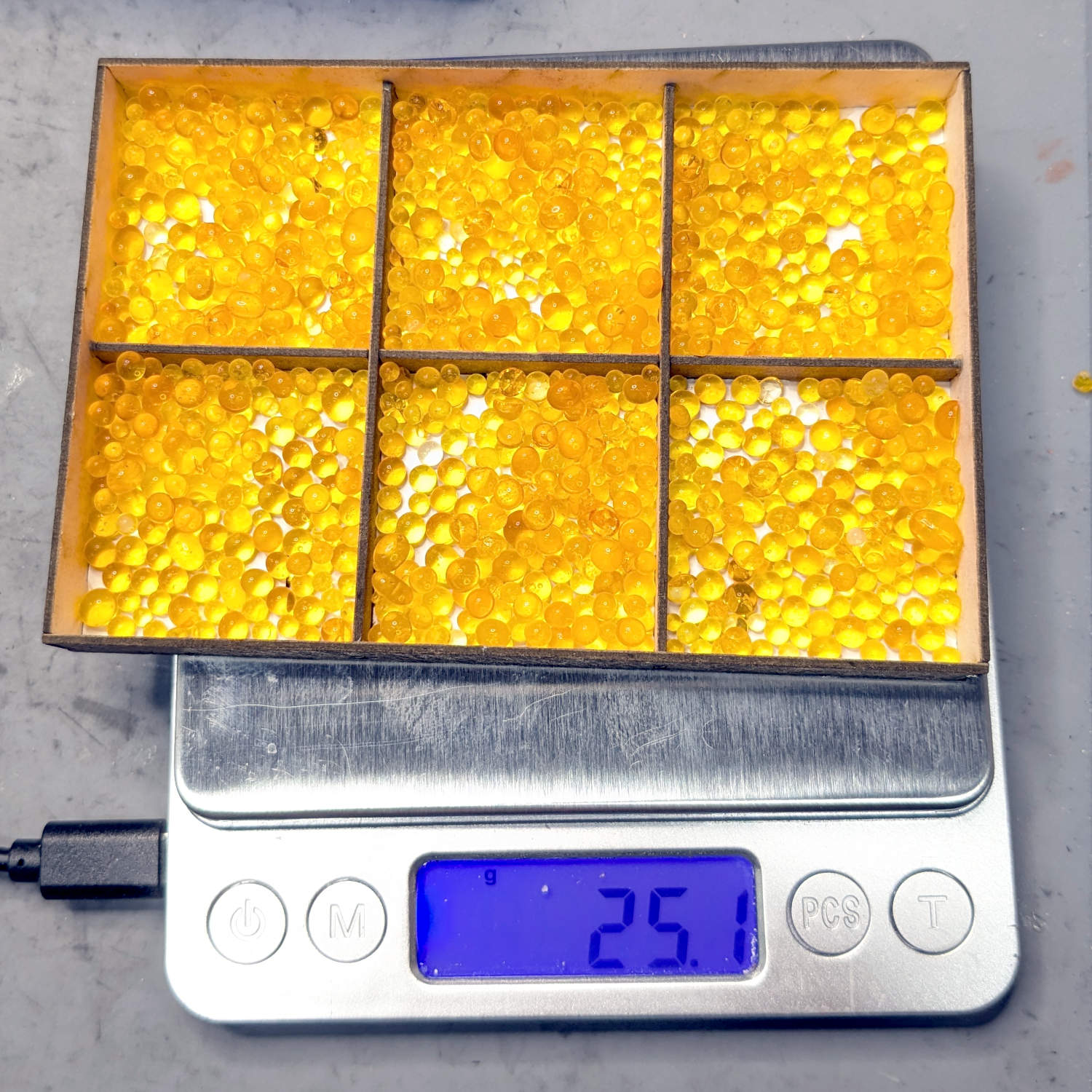

The silica gel beads I’ve been using in the PolyDryer boxes start out a uniform yellow / light brown:

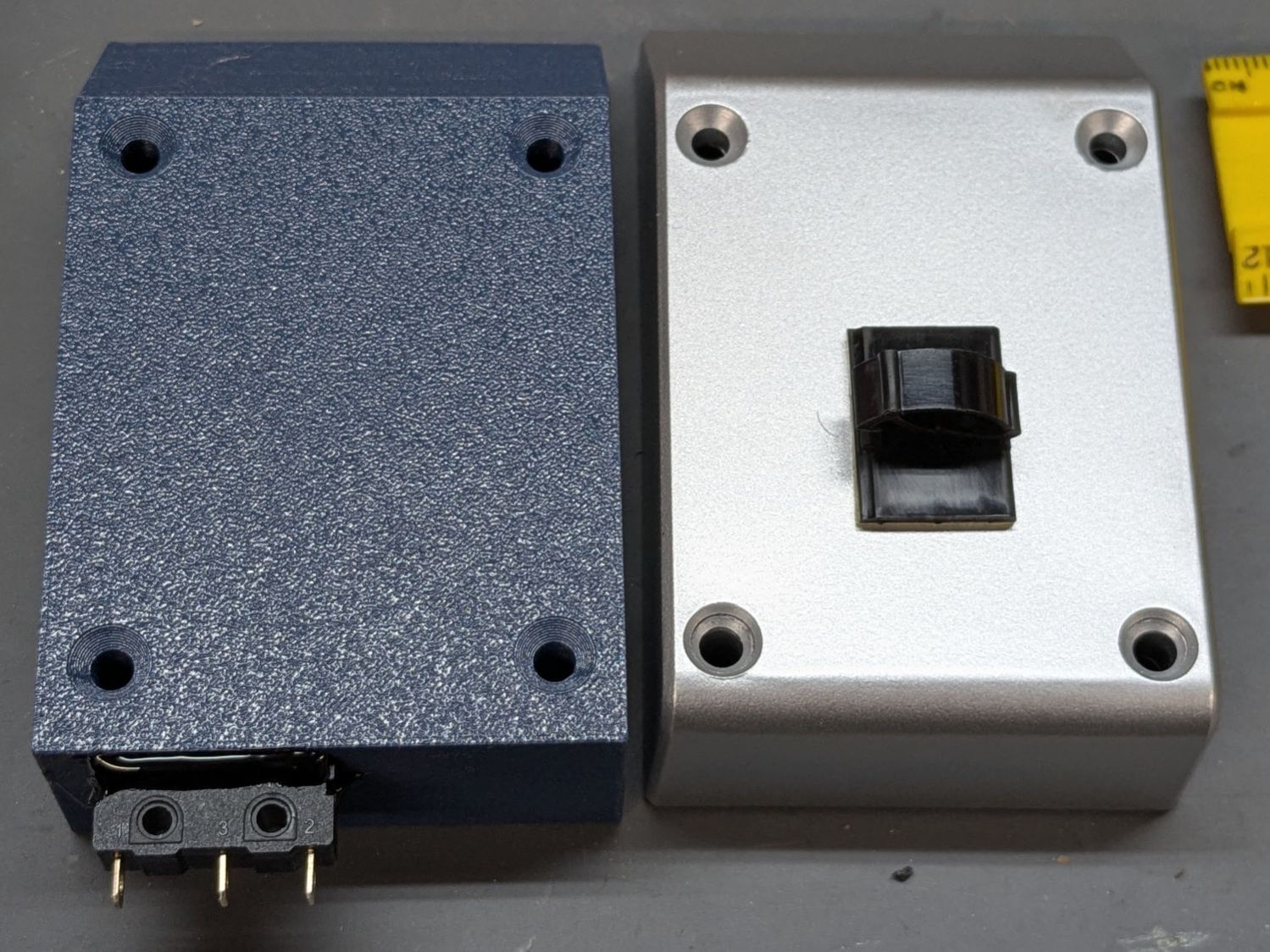

The humidity indicating chemical seems to be methyl violet, described as changing from yellow to green when saturated, which has never happened here. For example, these beads, retrieved from random corners of the workbench, have been sitting in 40-ish %RH basement air for weeks:

The fragment just left of center looks greenish, but the rest are, at best, various shades of brown. This may be due to the (relatively) low humidity in the basement, but putting them under a damp sponge for a few hours didn’t change their color.

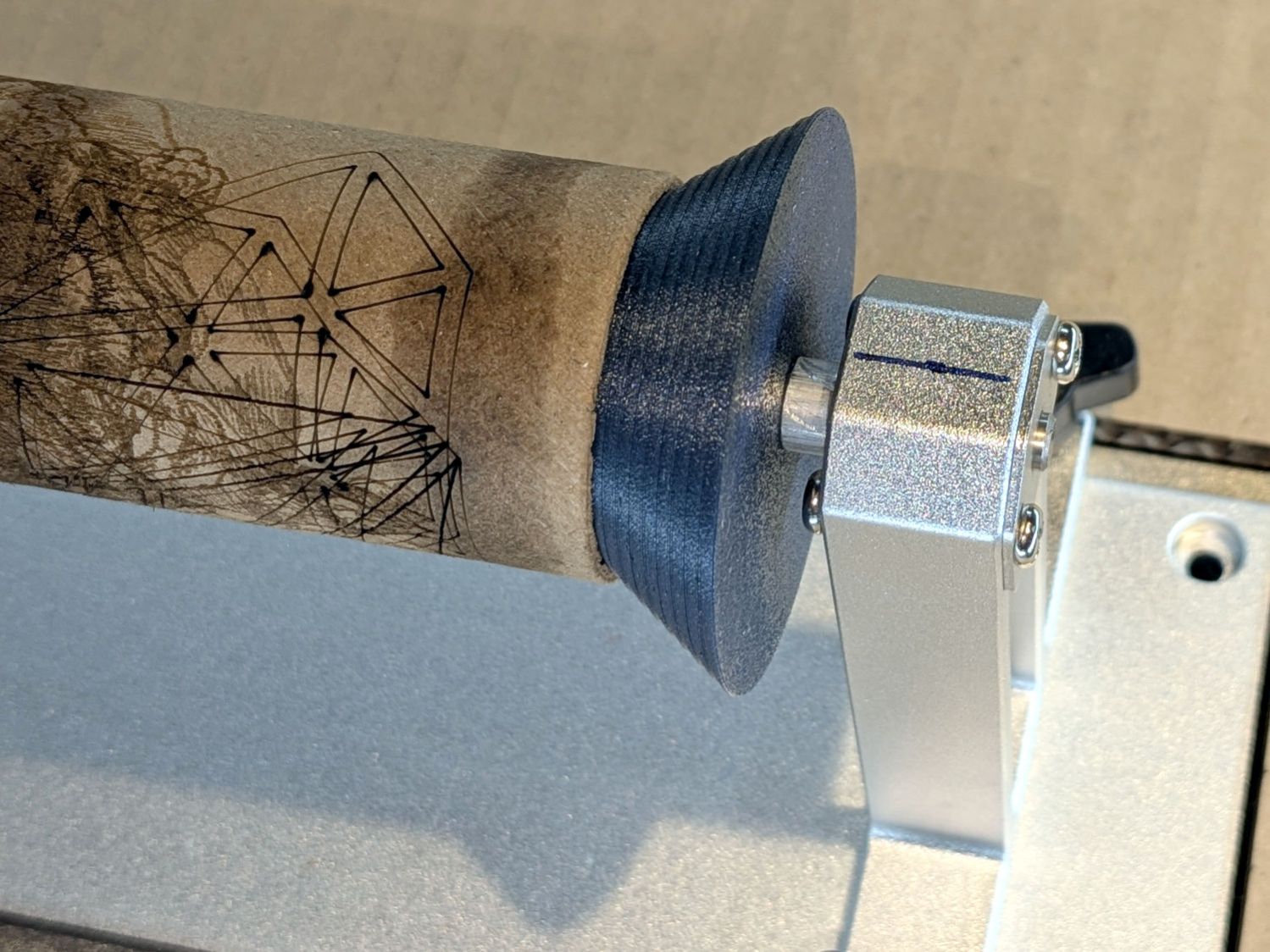

The most recent regeneration session started with an open cast-iron pan on an induction cooktop:

The variety of browns comes from various amounts of adsorbed water in the PolyDryer boxes, but AFAICT there really isn’t much correlation between the humidity level and the amount of adsorbed water.

The drying process went like this:

- 650 g at start

- 50% power for 2 hr → 200 °F

- Covered the pan & turned it off overnight

- 623 g at start

- 50% power for 2 hr → 220 °F

- 612 g

- 50% power for 1 hr → 236 °F

- 610 g

- 30% power for 30 min → 205 °F

- 35% power for 30 min → 200 °F

- 609 g

So about four hours at 50% power would get all but the laser few grams of water out of the silica gel.

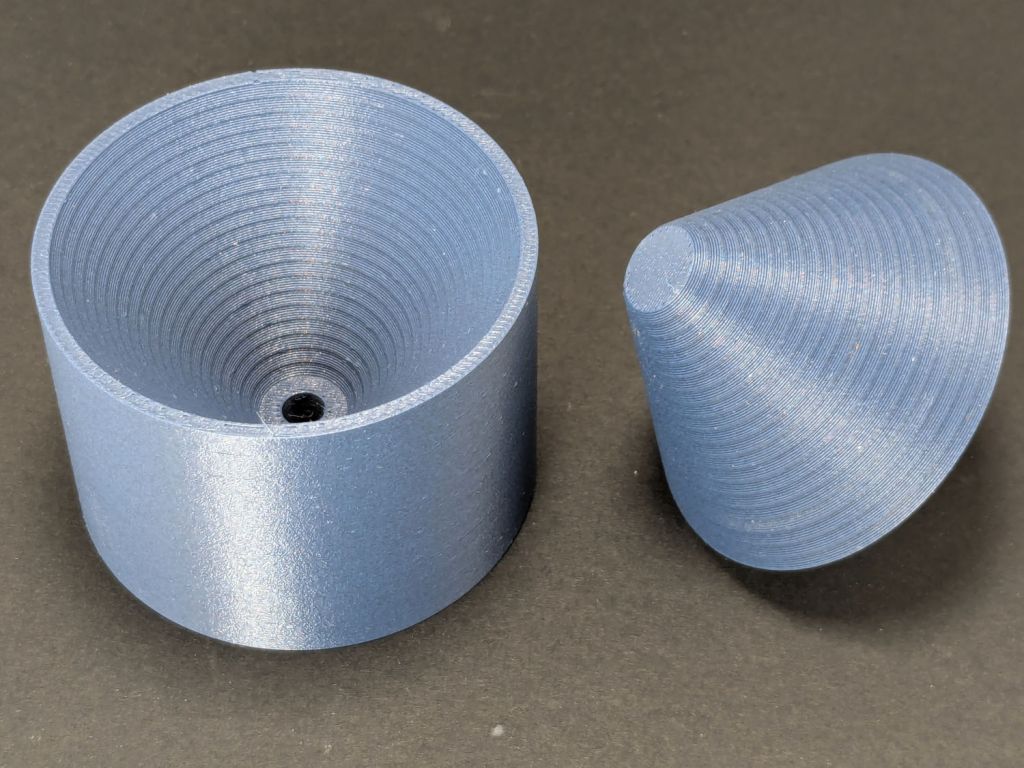

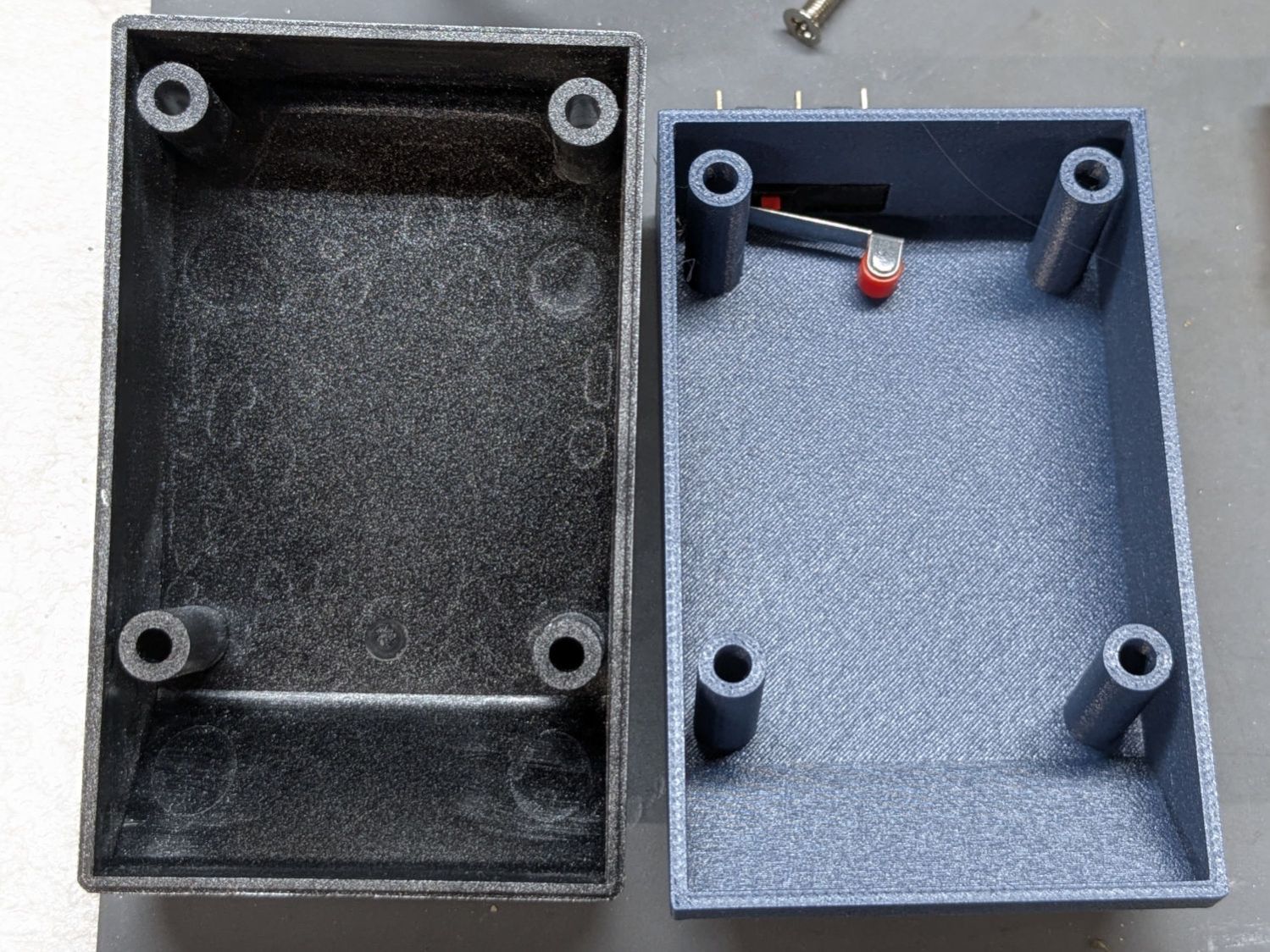

After all that, the beads looked about the same in a white bowl for cooling:

Each regeneration cycle leaves more dark brown beads in the mix, which may be due to poor temperature control, and they do not return to their original yellow / pale brown shade.

Apparently cooking silica gel beads over 120 °C = 250 °F (various sources give various temperatures) can damage their structure or the methyl violet indicator; for sure some of those beads have been abused.

Unsurprisingly, the bead temperature rises as they dry out. Although the induction cooktop has a temperature control, we’ve found the setting doesn’t match the pan temperature and the overall control is poor. I could set the gas oven to 200 °F, but I’m certain it doesn’t control the temperature all that closely, either.

The original jug held 2 pounds = 907 g of beads. Add the 609 g from this session to the 350 g of allegedly dry beads in seven of the PolyDryer boxes: my regeneration hand is weak.