|

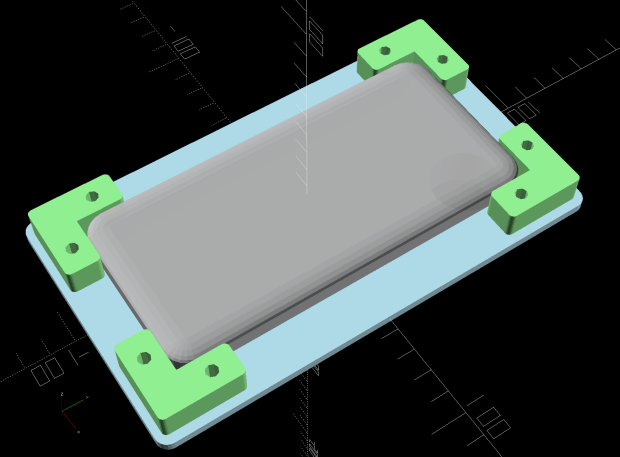

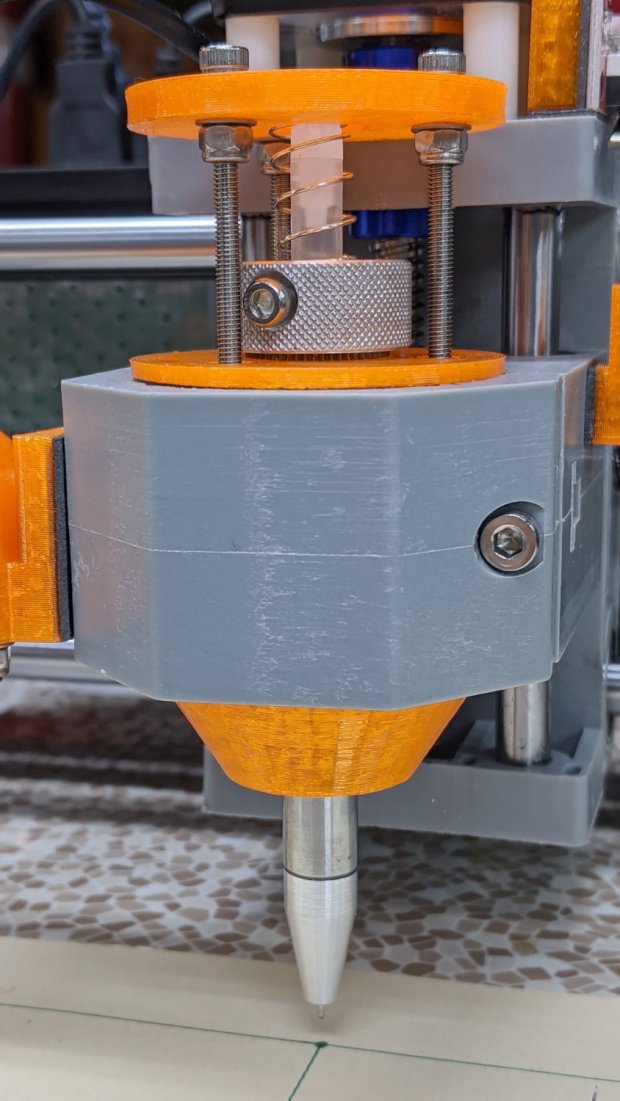

// Google Pixel 3a mount for stereo zoom microscope |

|

// Ed Nisley – KE4ZNU – 2019-12 |

|

|

|

Layout = "Show"; // [Show,BuildAll,BuildBumpers,BuildPlate,DrillGuide,Phone,Plate,Bumper] |

|

|

|

/* [Hidden] */ |

|

|

|

ThreadThick = 0.25; |

|

ThreadWidth = 0.40; |

|

|

|

HoleWindage = 0.2; |

|

|

|

Protrusion = 0.1; // make holes end cleanly |

|

|

|

function IntegerMultiple(Size,Unit) = Unit * ceil(Size / Unit); |

|

|

|

ID = 0; |

|

OD = 1; |

|

LENGTH = 2; |

|

|

|

inch = 25.4; |

|

|

|

//———————- |

|

// Dimensions |

|

|

|

Phone = [74.5,156.0,12.0]; // inside Spigen case |

|

PhoneRadii = [10.0,10.0,3.0]; // corner rounding, likewise |

|

|

|

LensOffset = [-17.0,-18.5,0]; // looking at phone screen, (-) sign = from right/top edge |

|

|

|

PrintReader = [0,Phone.y/2 – 44.0,0]; // fingerprint reader from center |

|

PrintReaderDia = [20.0,30.0,0]; // … hole for access |

|

|

|

Eyepiece = [11.5,28.0 + 0.50,27.0]; // ID = lens, OD includes clearance |

|

|

|

Insert = [3.0,4.5,4.0]; // M3 threaded brass insert |

|

Screw = [3.0,7.0,3.5]; // OD = washer, LENGTH = washer + head height |

|

|

|

WallThick = 3.0; // minimum wall thickness |

|

|

|

Bumper = [2*Screw[OD],20.0,Phone.z]; // bumper edge piece |

|

BumperOAL = Bumper.y + Bumper.x; // outside length for corner piece |

|

|

|

BumperRadius = 2.0; |

|

|

|

MinMargin = 1.2*Bumper.x; // at least this much extra plate for bumpers |

|

echo(str("MinMargin: ",MinMargin)); |

|

|

|

Plate = [IntegerMultiple(Phone.x + 2*MinMargin,5.0), |

|

IntegerMultiple(Phone.y + 2*MinMargin,5.0), |

|

false ? 3*ThreadThick : max(Insert[LENGTH] + 2*ThreadThick,WallThick)]; |

|

PlateRadius = 5.0; |

|

echo(str("Plate: ",Plate," radius: ",PlateRadius)); |

|

|

|

EmbossDepth = 2*ThreadThick + Protrusion; |

|

DebossHeight = EmbossDepth; |

|

|

|

ScrewOffset = Bumper.x/2; |

|

ScrewAdjust = 1.5*Screw[ID]; |

|

|

|

NumSides = 2*3*4; |

|

|

|

Gap = 2.0; // between build layout parts |

|

|

|

//———————- |

|

// Useful routines |

|

|

|

module PolyCyl(Dia,Height,ForceSides=0) { // based on nophead's polyholes |

|

|

|

Sides = (ForceSides != 0) ? ForceSides : (ceil(Dia) + 2); |

|

FixDia = Dia / cos(180/Sides); |

|

cylinder(r=(FixDia + HoleWindage)/2, |

|

h=Height, |

|

$fn=Sides); |

|

} |

|

|

|

// Basic shapes |

|

|

|

// Overall phone outline |

|

|

|

module Phone() { |

|

|

|

hull() |

|

for (i=[-1,1], j=[-1,1], k=[-1,1]) |

|

translate([i*(Phone.x/2 – PhoneRadii.x),j*(Phone.y/2 – PhoneRadii.y),k*(Phone.z/2 – PhoneRadii.z)]) |

|

resize(2*PhoneRadii) |

|

sphere(r=1,$fn=NumSides); |

|

} |

|

|

|

module Plate() { |

|

|

|

union() { |

|

difference() { |

|

union() { |

|

hull() |

|

for (i=[-1,1], j=[-1,1]) |

|

translate([i*(Plate.x/2 – PlateRadius),j*(Plate.y/2 – PlateRadius),0]) |

|

cylinder(r=PlateRadius,h=Plate.z,center=true,$fn=NumSides); |

|

translate([Phone.x/2,Phone.y/2,-Eyepiece[LENGTH]/3 + Plate.z/2] + LensOffset) |

|

cylinder(d=Eyepiece[OD] + 2*WallThick,h=Eyepiece[LENGTH]/3, |

|

center=false,$fn=NumSides); |

|

translate([Phone.x/2,Phone.y/2,-2*Eyepiece[LENGTH]/3 + Plate.z/2 + Protrusion] + LensOffset) |

|

cylinder(d1=Eyepiece[OD] + 10*ThreadThick, |

|

d2=Eyepiece[OD] + 2*WallThick, |

|

h=Eyepiece[LENGTH]/3, |

|

center=false,$fn=NumSides); |

|

} |

|

translate([Phone.x/2,Phone.y/2,-2*Eyepiece[LENGTH] + Plate.z/2 + Protrusion] + LensOffset) |

|

PolyCyl(Eyepiece[OD],2*Eyepiece[LENGTH],NumSides); |

|

translate(PrintReader + [0,0,-Plate.z/2 – Protrusion]) |

|

cylinder(d1=PrintReaderDia[OD],d2=PrintReaderDia[ID],h=Plate.z + 2*Protrusion,$fn=NumSides); |

|

for (i=[-1,1], j=[-1,1]) |

|

translate([i*(Phone.x/2 + Bumper.x/2),j*(Phone.y/2 – Bumper.y/2),-Plate.z]) |

|

PolyCyl(Insert[OD],2*Plate.z,8); |

|

for (i=[-1,1], j=[-1,1]) |

|

translate([i*(Phone.x/2 – Bumper.y/2),j*(Phone.y/2 + Bumper.x/2),-Plate.z]) |

|

PolyCyl(Insert[OD],2*Plate.z,8); |

|

|

|

translate([0,-12,Plate.z/2]) // recess for legend |

|

cube([55,40,EmbossDepth],center=true); |

|

} |

|

|

|

translate([0,0,Plate.z/2 – EmbossDepth]) |

|

linear_extrude(height=DebossHeight,convexity=20) |

|

text(text="Pixel 3a",size=6,spacing=1.20, |

|

font="Arial:style:Bold",halign="center",valign="center"); |

|

translate([0,-15,Plate.z/2 – EmbossDepth]) |

|

linear_extrude(height=DebossHeight,convexity=20) |

|

text(text="Ed Nisley",size=6,spacing=1.20, |

|

font="Arial:style:Bold",halign="center",valign="center"); |

|

translate([0,-25,Plate.z/2 – EmbossDepth]) |

|

linear_extrude(height=DebossHeight,convexity=20) |

|

text(text="softsolder.com",size=4,spacing=1.20, |

|

font="Arial:style:Bold",halign="center",valign="center"); |

|

|

|

|

|

} |

|

} |

|

|

|

module BumperPiece() { |

|

difference() { |

|

translate([0,-BumperOAL/2 + Bumper.x,0]) |

|

hull() |

|

for (i=[-1,1], j=[-1,1]) |

|

translate([i*(Bumper.x/2 – BumperRadius),j*(BumperOAL/2 – BumperRadius),0]) |

|

cylinder(r=BumperRadius,h=Bumper.z,center=true,$fn=NumSides); |

|

translate([0,-Bumper.y/2,-Bumper.z]) |

|

PolyCyl(ScrewAdjust,2*Bumper.z,8); |

|

} |

|

} |

|

|

|

// Side bumpers, XY origin at inner corner |

|

|

|

module BumperCorner() { |

|

|

|

union() { |

|

translate([Bumper.x/2,0,0]) |

|

BumperPiece(); |

|

translate([0,Bumper.x/2,0]) |

|

rotate(-90) |

|

BumperPiece(); |

|

} |

|

} |

|

|

|

|

|

//- Build things |

|

|

|

if (Layout == "Phone") |

|

Phone(); |

|

|

|

if (Layout == "Plate") |

|

Plate(); |

|

|

|

if (Layout == "Bumper") |

|

BumperCorner(); |

|

|

|

if (Layout == "Show") { |

|

color("LightBlue") Plate(); |

|

for (i=[-1,1], j=[-1,1]) { |

|

a = |

|

i > 0 && j > 0 ? 0 : |

|

i < 0 && j > 0 ? 90 : |

|

i > 0 && j < 0 ? -90 : |

|

180 |

|

; |

|

translate([i*Phone.x/2,j*Phone.y/2,Plate.z/2 + Bumper.z/2]) |

|

rotate(a) |

|

color("LightGreen") BumperCorner(); |

|

translate([0,0,Phone.z/2 + Plate.z/2 + Protrusion]) |

|

color("DarkGray",0.5) Phone(); |

|

} |

|

} |

|

|

|

if (Layout == "BuildAll") { |

|

translate([0,0,Plate.z/2]) |

|

rotate([0,180,0]) |

|

Plate(); |

|

for (i=[-1,1], j=[-1,1]) { |

|

a = |

|

i > 0 && j > 0 ? 0 : |

|

i < 0 && j > 0 ? 90 : |

|

i > 0 && j < 0 ? -90 : |

|

180 |

|

; |

|

translate([i*(Plate.x/2 + Gap),j*(Plate.y/2 + Gap),Bumper.z/2]) |

|

rotate(a) |

|

BumperCorner(); |

|

} |

|

} |

|

|

|

|

|

if (Layout == "BuildPlate") { |

|

translate([0,0,Plate.z/2]) |

|

rotate([0,180,0]) |

|

Plate(); |

|

} |

|

|

|

|

|

if (Layout == "BuildBumpers") { |

|

for (i=[-1,1], j=[-1,1]) { |

|

a = |

|

i > 0 && j > 0 ? 180 : |

|

i < 0 && j > 0 ? -90 : |

|

i > 0 && j < 0 ? 90 : |

|

0 |

|

; |

|

translate([i*(Bumper.x + Gap),j*(Bumper.x + Gap),Bumper.z/2]) |

|

rotate(a) |

|

BumperCorner(); |

|

} |

|

} |

|

|

|

|

|

if (Layout == "DrillGuide") { |

|

projection(cut=true) |

|

Plate(); |

|

|

|

} |