|

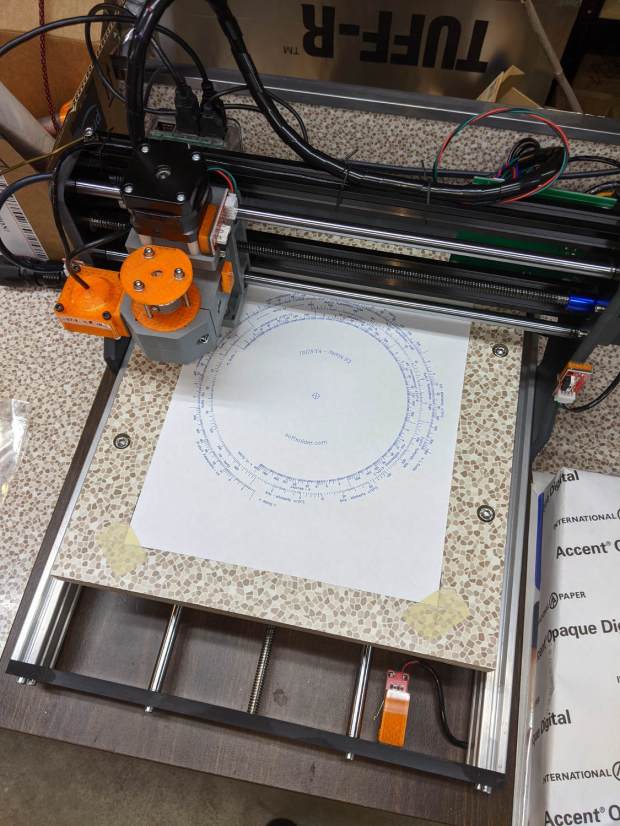

// CNC 3018-Pro Run-Hold Switches |

|

// Ed Nisley – KE4ZNU – 2020-01 |

|

|

|

Layout = "Build"; // [Show,Build,ProjectionX,ProjectionY,ProjectionZ,Block] |

|

|

|

/* [Hidden] */ |

|

|

|

ThreadThick = 0.25; |

|

ThreadWidth = 0.40; |

|

|

|

HoleWindage = 0.2; |

|

|

|

Protrusion = 0.1; // make holes end cleanly |

|

|

|

function IntegerMultiple(Size,Unit) = Unit * ceil(Size / Unit); |

|

|

|

ID = 0; |

|

OD = 1; |

|

LENGTH = 2; |

|

|

|

inch = 25.4; |

|

|

|

//———————- |

|

// Dimensions |

|

|

|

RodScrewOffset = [22,0,-14.5]; // X=left edge, Y=dummy, Z=from top edge |

|

BeamScrewOffset = [50,0,-10]; |

|

LeadScrewOffset = [RodScrewOffset.x,0,-45]; // may be off the bottom; include anyway |

|

LeadScrew = [8.0,10.0,5.0]; // ID=actual, OD=clearance, LENGTH=stick-out |

|

|

|

Screw = [5.0,10.0,6.0]; // M5 SHCS, OD=washer, LENGTH=washer+head |

|

ScrewSides = 8; // hole shape |

|

|

|

WallThick = 3.0; // minimum wall thickness |

|

FlangeThick = 5.0; // flange thickness |

|

|

|

Switch = [15.0 + 2*HoleWindage,15.0 + 2*HoleWindage,12.5]; // switch body |

|

SwitchCap = [17.5,17.5,12.0]; // … pushbutton |

|

SwitchClear = SwitchCap + [2*2.0,2*2.0,Screw[OD]/(2*cos(180/ScrewSides))]; |

|

SwitchContacts = 5.0; // contacts below switch |

|

SwitchBase = SwitchContacts + Switch.z; // bottom to base of switch |

|

|

|

MountOffset = abs(RodScrewOffset.z) + SwitchClear.z; // top of switch mounting plate |

|

|

|

FrameWidth = 60.0; // CNC 3018-Pro upright |

|

FrameRadius = 10.0; // … front corner rounding |

|

|

|

CornerRadius = 5.0; // pretty part rounding |

|

CornerSquare = 10; // dummy for square corner |

|

|

|

MountOAL = [FrameWidth, // covers machine frame |

|

2*FlangeThick + 2*Screw[LENGTH] + SwitchClear.y, // clear screw heads |

|

MountOffset + Switch.z + SwitchContacts |

|

]; |

|

echo(str("MountOAL: ",MountOAL)); |

|

|

|

SwitchOC = [MountOAL.x/2,FlangeThick + 2*Screw[LENGTH] + SwitchClear.y/2,0]; |

|

|

|

CableOD = 5.0; |

|

|

|

NumSides = 2*3*4; |

|

|

|

Gap = 2.0; // between build layout parts |

|

|

|

//———————- |

|

// Useful routines |

|

|

|

module PolyCyl(Dia,Height,ForceSides=0) { // based on nophead's polyholes |

|

|

|

Sides = (ForceSides != 0) ? ForceSides : (ceil(Dia) + 2); |

|

FixDia = Dia / cos(180/Sides); |

|

cylinder(r=(FixDia + HoleWindage)/2, |

|

h=Height, |

|

$fn=Sides); |

|

} |

|

|

|

// Projections for intersections |

|

|

|

module ProjectionX() { |

|

|

|

sr = CornerSquare/2; |

|

|

|

rotate([0,90,0]) rotate([0,0,90]) |

|

linear_extrude(height=FrameWidth,convexity=3) |

|

// mirror([1,0]) // mount on motor side of gantry |

|

union() { |

|

translate([0,-MountOAL.z]) |

|

square([FlangeThick,MountOAL.z]); |

|

hull() { |

|

translate([MountOAL.y – CornerRadius,-MountOffset + SwitchCap.z – CornerRadius]) |

|

circle(r=CornerRadius,$fn=NumSides); |

|

translate([sr,-MountOffset + SwitchCap.z – sr]) |

|

square(CornerSquare,center=true); |

|

translate([sr,-MountOAL.z + sr]) |

|

square(CornerSquare,center=true); |

|

translate([MountOAL.y – sr,-MountOAL.z + sr]) |

|

square(CornerSquare,center=true); |

|

} |

|

} |

|

} |

|

|

|

module ProjectionY() { |

|

|

|

sr = CornerSquare/2; |

|

|

|

rotate([90,0,0]) |

|

translate([0,0,-FrameWidth]) |

|

difference() { |

|

linear_extrude(height=2*FrameWidth,convexity=3) |

|

hull() { |

|

translate([FrameRadius,-FrameRadius]) |

|

circle(r=FrameRadius,$fn=NumSides); |

|

translate([FrameWidth – sr,-sr]) |

|

square(CornerSquare,center=true); |

|

translate([sr,-MountOAL.z + sr]) |

|

square(CornerSquare,center=true); |

|

translate([MountOAL.x – sr,-MountOAL.z + sr]) |

|

square(CornerSquare,center=true); |

|

} |

|

translate([RodScrewOffset.x,RodScrewOffset.z,-Protrusion]) |

|

rotate(180/ScrewSides) PolyCyl(Screw[ID],2*(FrameWidth + Protrusion),ScrewSides); |

|

for (j=[-FlangeThick,FrameWidth + FlangeThick]) |

|

translate([RodScrewOffset.x,RodScrewOffset.z,j]) |

|

rotate(180/ScrewSides) PolyCyl(Screw[OD],FrameWidth,ScrewSides); |

|

|

|

translate([BeamScrewOffset.x,BeamScrewOffset.z,-Protrusion]) |

|

rotate(180/ScrewSides) PolyCyl(Screw[ID],2*(FrameWidth + Protrusion),ScrewSides); |

|

for (j=[-FlangeThick,FrameWidth + FlangeThick]) |

|

translate([BeamScrewOffset.x,BeamScrewOffset.z,j]) |

|

rotate(180/ScrewSides) PolyCyl(Screw[OD],FrameWidth,ScrewSides); |

|

|

|

translate([LeadScrewOffset.x,LeadScrewOffset.z,FrameWidth – LeadScrew[LENGTH]]) |

|

rotate(180/ScrewSides) PolyCyl(LeadScrew[OD],2*LeadScrew[LENGTH],ScrewSides); |

|

} |

|

} |

|

|

|

|

|

module ProjectionZ() { |

|

translate([0,0,-MountOAL.z]) |

|

// mirror([0,1]) // mount on motor side of gantry |

|

difference() { |

|

linear_extrude(height=MountOAL.z,convexity=3) |

|

difference() { |

|

square([MountOAL.x,MountOAL.y]); |

|

translate([SwitchOC.x/2,SwitchOC.y]) |

|

square([Switch.x,Switch.y],center=true); |

|

translate([3*SwitchOC.x/2,SwitchOC.y]) |

|

square([Switch.x,Switch.y],center=true); |

|

} |

|

for (i=[-1,1]) |

|

translate([i*SwitchOC.x/2 + MountOAL.x/2,SwitchOC.y,SwitchBase + MountOAL.z/2]) |

|

cube([SwitchClear.x,SwitchClear.y,MountOAL.z],center=true); |

|

|

|

translate([-Protrusion,SwitchOC.y – 2*CableOD – Switch.y/2,-Protrusion]) |

|

cube([MountOAL.x + 2*Protrusion,CableOD,CableOD + Protrusion],center=false); |

|

|

|

for (i=[-1,1]) |

|

translate([i*SwitchOC.x/2 + MountOAL.x/2,SwitchOC.y – SwitchCap.y/2,CableOD/2 – Protrusion]) |

|

cube([CableOD,SwitchClear.y/2,CableOD + Protrusion],center=true); |

|

|

|

translate([SwitchOC.x/2,SwitchOC.y – CableOD/2,-Protrusion]) |

|

cube([SwitchOC.x,CableOD,CableOD + Protrusion],center=false); |

|

|

|

} |

|

} |

|

|

|

module Block() { |

|

intersection() { |

|

ProjectionX(); |

|

ProjectionY(); |

|

ProjectionZ(); |

|

} |

|

} |

|

|

|

|

|

//- Build things |

|

|

|

if (Layout == "ProjectionX") |

|

ProjectionX(); |

|

|

|

if (Layout == "ProjectionY") |

|

ProjectionY(); |

|

|

|

if (Layout == "ProjectionZ") |

|

ProjectionZ(); |

|

|

|

if (Layout == "Block") |

|

Block(); |

|

|

|

if (Layout == "Show") { |

|

translate([-MountOAL.x/2,-MountOAL.y/2,MountOAL.z]) { |

|

Block(); |

|

translate([MountOAL.x/2 + SwitchOC.x/2,SwitchOC.y,SwitchCap.z/2 – MountOAL.z + SwitchBase + 0*Switch.z]) |

|

color("Yellow",0.75) |

|

cube(SwitchCap,center=true); |

|

translate([MountOAL.x/2 – SwitchOC.x/2,SwitchOC.y,SwitchCap.z/2 – MountOAL.z + SwitchBase + 0*Switch.z]) |

|

color("Green",0.75) |

|

cube(SwitchCap,center=true); |

|

} |

|

} |

|

|

|

if (Layout == "Build") |

|

translate([-MountOAL.x/2,-MountOAL.y/2,MountOAL.z]) |

|

Block(); |

|

|