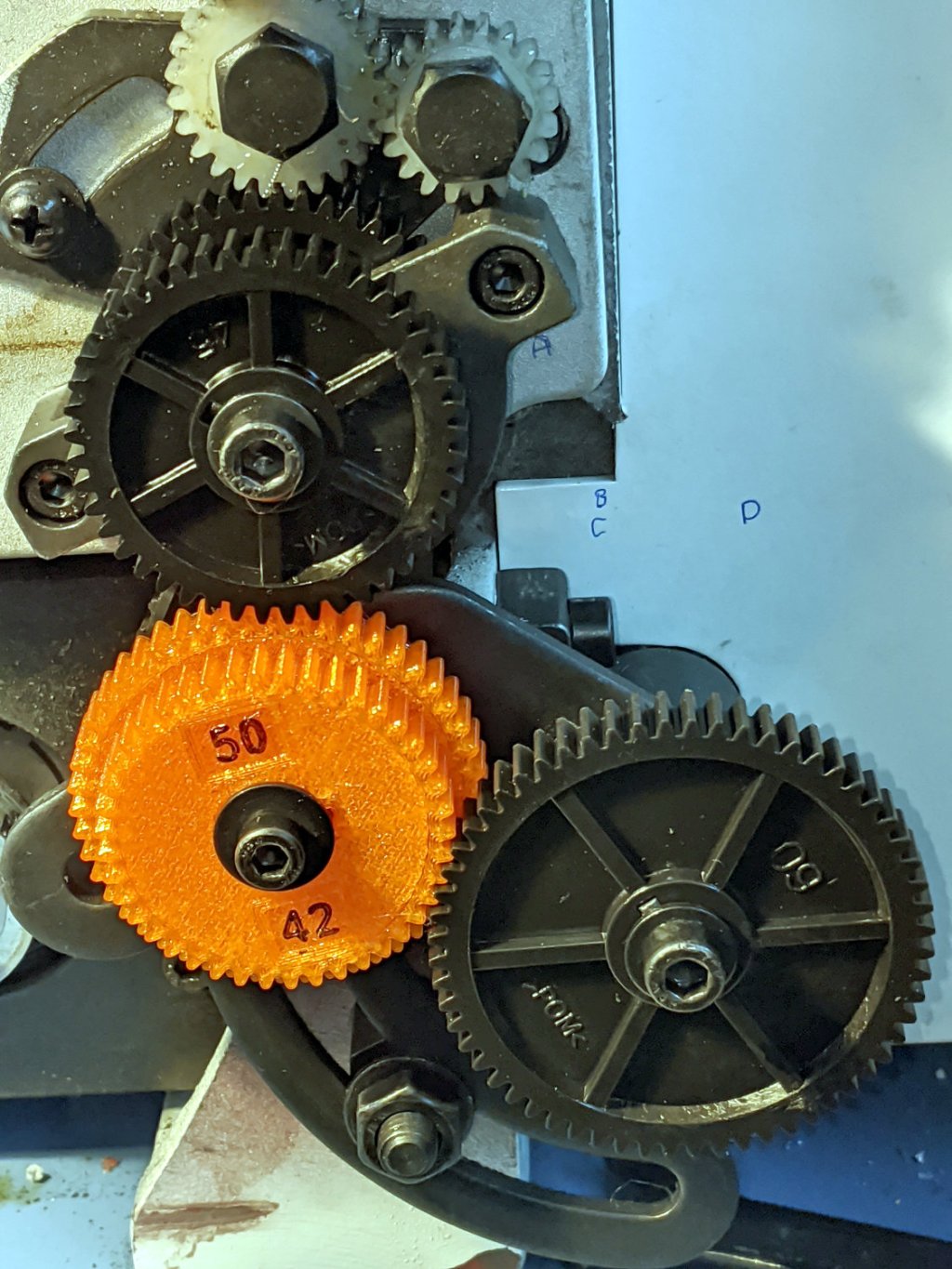

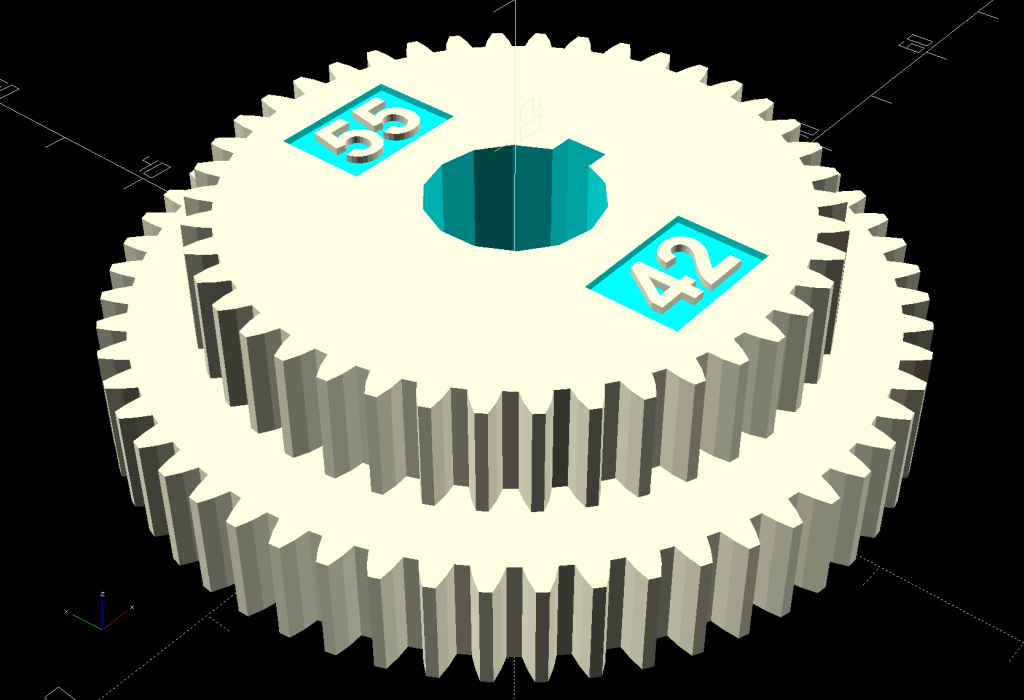

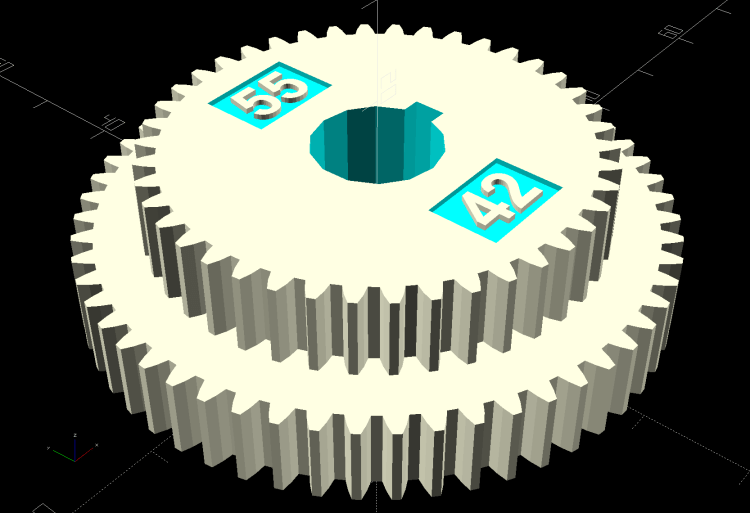

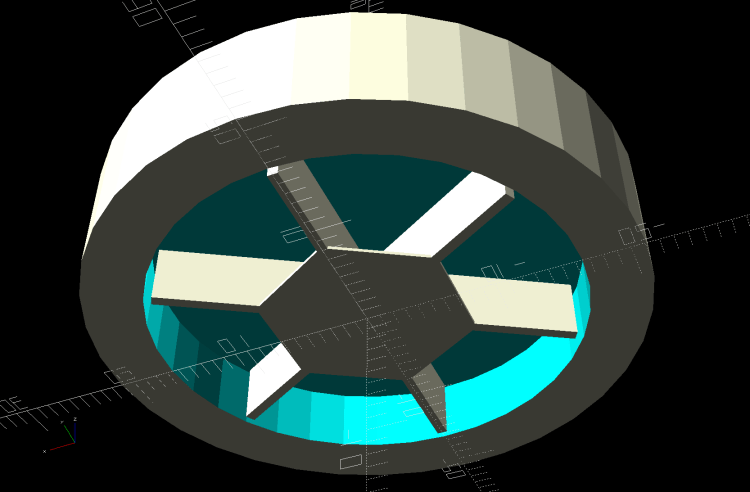

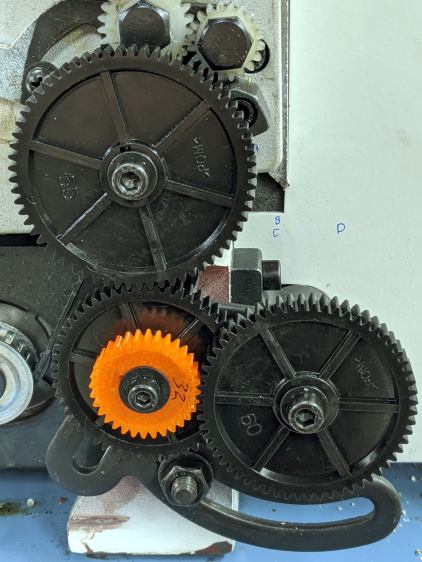

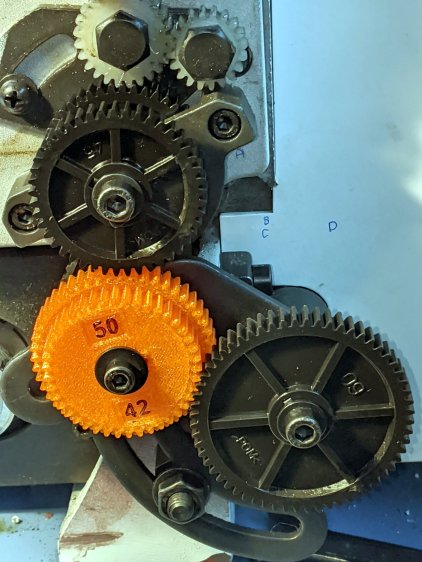

Running my assortment of custom 3D printed change gears through the LittleMachineShop calculator and copying the results into a spreadsheet for E-Z formatting produces a useful table:

The same table in text-ish format, minus the colored highlights marking the custom gears:

| Pitch | A | B | C | D | Actual | Error | In 10 pitches | |

| 0.10 | ||||||||

| 20 | 80 | 20 | 80 | 0.099 | 0.786% | 0.008 | ||

| 20 | 79 | 20 | 80 | 0.100 | 0.468% | 0.005 | ||

| 20 | 80 | 20 | 79 | 0.100 | 0.468% | 0.005 | ||

| 0.20 | ||||||||

| 20 | 79 | 40 | 80 | 0.201 | 0.473% | 0.009 | ||

| 20 | 80 | 40 | 79 | 0.201 | 0.473% | 0.009 | ||

| 40 | 79 | 20 | 80 | 0.201 | 0.473% | 0.009 | ||

| 40 | 80 | 20 | 79 | 0.201 | 0.473% | 0.009 | ||

| 0.25 | ||||||||

| 20 | 55 | 35 | 81 | 0.249 | 0.225% | 0.006 | ||

| 20 | 81 | 35 | 55 | 0.249 | 0.225% | 0.006 | ||

| 35 | 55 | 20 | 81 | 0.249 | 0.225% | 0.006 | ||

| 0.30 | ||||||||

| 20 | 57 | 35 | 65 | 0.300 | 0.023% | 0.001 | ||

| 20 | 65 | 35 | 57 | 0.300 | 0.023% | 0.001 | ||

| 0.40 | ||||||||

| 20 | 55 | 45 | 65 | 0.400 | 0.088% | 0.004 | ||

| 20 | 65 | 45 | 55 | 0.400 | 0.088% | 0.004 | ||

| 0.50 | ||||||||

| 21 | 50 | 45 | 60 | 0.500 | 0.012% | 0.001 | ||

| 21 | 60 | 45 | 50 | 0.500 | 0.012% | 0.001 | ||

| 21 | 80 | 60 | 50 | 0.500 | 0.012% | 0.001 | ||

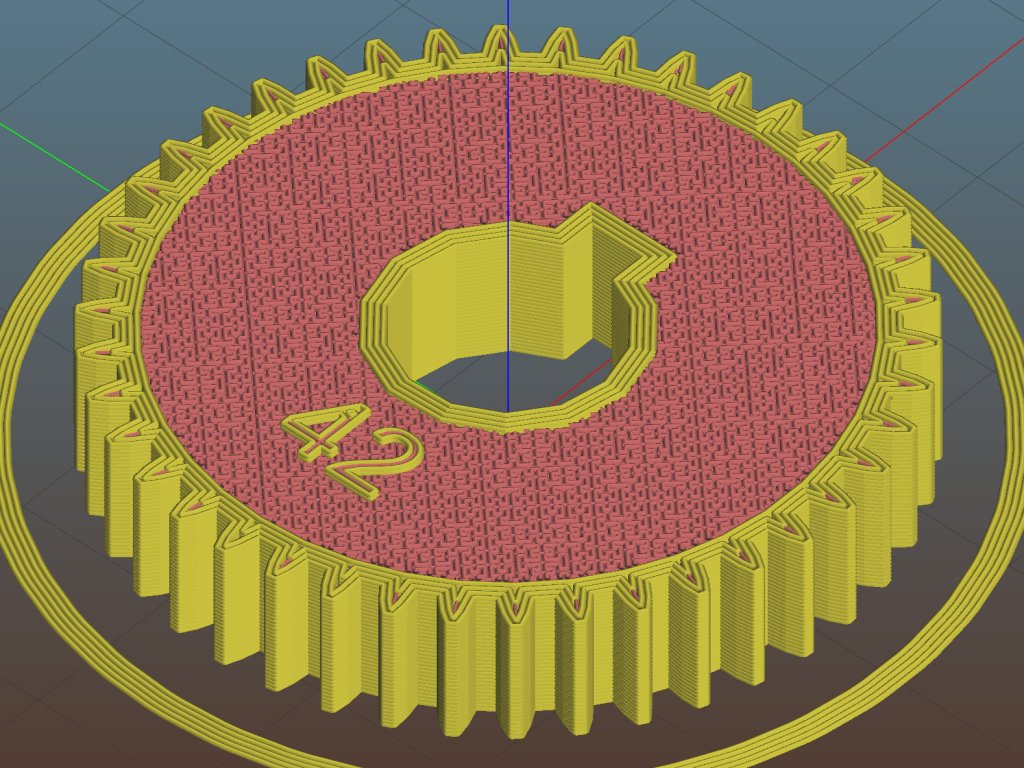

| 42 | 35 | 21 | 80 | 0.500 | 0.012% | 0.001 | ||

| 60 | 50 | 21 | 80 | 0.500 | 0.012% | 0.001 | ||

| 0.60 | ||||||||

| 35 | 57 | 40 | 65 | 0.600 | 0.022% | 0.001 | ||

| 35 | 65 | 40 | 57 | 0.600 | 0.022% | 0.001 | ||

| 40 | 57 | 35 | 65 | 0.600 | 0.022% | 0.001 | ||

| 40 | 65 | 35 | 57 | 0.600 | 0.022% | 0.001 | ||

| 0.70 | ||||||||

| 35 | 55 | 45 | 65 | 0.699 | 0.087% | 0.006 | ||

| 35 | 65 | 45 | 55 | 0.699 | 0.087% | 0.006 | ||

| 45 | 55 | 35 | 65 | 0.699 | 0.087% | 0.006 | ||

| 45 | 65 | 35 | 55 | 0.699 | 0.087% | 0.006 | ||

| 50 | 77 | 55 | 81 | 0.700 | 0.006% | 0.000 | ||

| 50 | 81 | 55 | 77 | 0.700 | 0.006% | 0.000 | ||

| 55 | 77 | 50 | 81 | 0.700 | 0.006% | 0.000 | ||

| 0.75 | ||||||||

| 42 | 50 | 45 | 80 | 0.750 | 0.012% | 0.001 | ||

| 42 | 80 | 45 | 50 | 0.750 | 0.012% | 0.001 | ||

| 45 | 50 | 42 | 80 | 0.750 | 0.012% | 0.001 | ||

| 45 | 80 | 42 | 50 | 0.750 | 0.012% | 0.001 | ||

| 0.80 | ||||||||

| 40 | 55 | 45 | 65 | 0.799 | 0.088% | 0.007 | ||

| 40 | 65 | 45 | 55 | 0.799 | 0.088% | 0.007 | ||

| 45 | 55 | 40 | 65 | 0.799 | 0.088% | 0.007 | ||

| 45 | 65 | 40 | 55 | 0.799 | 0.088% | 0.007 | ||

| 20 | 55 | 79 | 57 | 0.800 | 0.010% | 0.001 | ||

| 20 | 57 | 79 | 55 | 0.800 | 0.010% | 0.001 | ||

| 1.00 | ||||||||

| 21 | 50 | 60 | 40 | 1.000 | 0.012% | 0.001 | ||

| 42 | 50 | 45 | 60 | 1.000 | 0.012% | 0.001 | ||

| 42 | 60 | 45 | 50 | 1.000 | 0.012% | 0.001 | ||

| 42 | 80 | 60 | 50 | 1.000 | 0.012% | 0.001 | ||

| 45 | 50 | 42 | 60 | 1.000 | 0.012% | 0.001 | ||

| 45 | 60 | 42 | 50 | 1.000 | 0.012% | 0.001 | ||

| 60 | 50 | 42 | 80 | 1.000 | 0.012% | 0.001 | ||

| 1.25 | ||||||||

| 21 | 50 | 60 | 32 | 1.250 | 0.013% | 0.002 | ||

| 35 | 40 | 45 | 50 | 1.250 | 0.013% | 0.002 | ||

| 42 | 40 | 45 | 60 | 1.250 | 0.013% | 0.002 | ||

| 42 | 80 | 60 | 40 | 1.250 | 0.013% | 0.002 | ||

| 45 | 40 | 42 | 60 | 1.250 | 0.013% | 0.002 | ||

| 60 | 20 | 21 | 80 | 1.250 | 0.013% | 0.002 | ||

| 60 | 40 | 42 | 80 | 1.250 | 0.013% | 0.002 | ||

| 1.50 | ||||||||

| 42 | 40 | 45 | 50 | 1.500 | 0.013% | 0.002 | ||

| 45 | 40 | 42 | 50 | 1.500 | 0.013% | 0.002 | ||

| 1.75 | ||||||||

| 65 | 42 | 57 | 80 | 1.751 | 0.029% | 0.005 | ||

| 2.00 | ||||||||

| 42 | 40 | 60 | 50 | 2.000 | 0.012% | 0.003 | ||

| 42 | 50 | 60 | 40 | 2.000 | 0.012% | 0.003 | ||

| 60 | 40 | 42 | 50 | 2.000 | 0.012% | 0.003 | ||

| 2.50 | ||||||||

| 42 | 32 | 60 | 50 | 2.500 | 0.012% | 0.003 | ||

| 42 | 40 | 60 | 40 | 2.500 | 0.012% | 0.003 | ||

| 42 | 50 | 60 | 32 | 2.500 | 0.012% | 0.003 | ||

| 60 | 20 | 42 | 80 | 2.500 | 0.012% | 0.003 | ||

| 60 | 32 | 42 | 50 | 2.500 | 0.012% | 0.003 | ||

| 3.00 | ||||||||

| 65 | 50 | 80 | 55 | 3.002 | 0.061% | 0.018 | ||

| 65 | 55 | 80 | 50 | 3.002 | 0.061% | 0.018 | ||

| 80 | 50 | 65 | 55 | 3.002 | 0.061% | 0.018 | ||

| 3.50 | ||||||||

| 57 | 40 | 65 | 42 | 3.501 | 0.029% | 0.010 | ||

| 57 | 42 | 65 | 40 | 3.501 | 0.029% | 0.010 | ||

| 65 | 21 | 57 | 80 | 3.501 | 0.029% | 0.010 | ||

| 65 | 40 | 57 | 42 | 3.501 | 0.029% | 0.010 | ||

| 65 | 42 | 57 | 40 | 3.501 | 0.029% | 0.010 | ||

| 4.00 | ||||||||

| 60 | 20 | 42 | 50 | 4.000 | 0.012% | 0.005 | ||

| 5.00 | ||||||||

| 55 | 21 | 60 | 50 | 4.989 | 0.215% | 0.107 | ||

| 55 | 35 | 80 | 40 | 4.989 | 0.215% | 0.107 | ||

| 55 | 40 | 80 | 35 | 4.989 | 0.215% | 0.107 | ||

| 60 | 21 | 55 | 50 | 4.989 | 0.215% | 0.107 | ||

| 80 | 35 | 55 | 40 | 4.989 | 0.215% | 0.107 | ||

| 80 | 40 | 55 | 35 | 4.989 | 0.215% | 0.107 | ||

| 35 | 45 | 81 | 20 | 5.001 | 0.012% | 0.006 | ||

| 45 | 55 | 77 | 20 | 5.001 | 0.012% | 0.006 | ||

| 77 | 20 | 45 | 55 | 5.001 | 0.012% | 0.006 |

The basic formulas:

TPI = 16 / ((A/B) x (C/D)) Pitch = 25.4 / TPI = 1.5875 x ((A/B) x (C/D))

So, for example, a 45-50-42-60 train will produce a 1 mm thread pitch with 120 ppm error adding up to a mere 1 micron in 10 pitches:

Overall, the errors are so low as to not matter, even without using the custom gears, but it’s the principle of the thing …