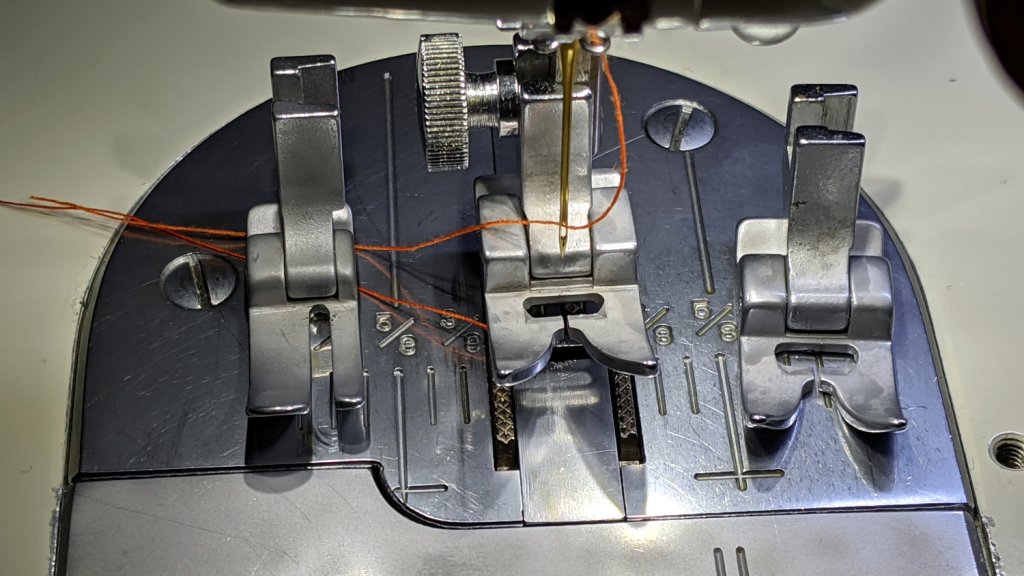

While I was cutting threads for the Floor Lamp poles, I tried measuring my progress over wires:

Those are three lengths of music wire, slightly bent from their storage roll, held in place with a precision clamp metric micrometer. Given the crudity of the setup, the uncalibrated wire diameter, and my lack of thread-fu, the results came out both close and unconvincing.

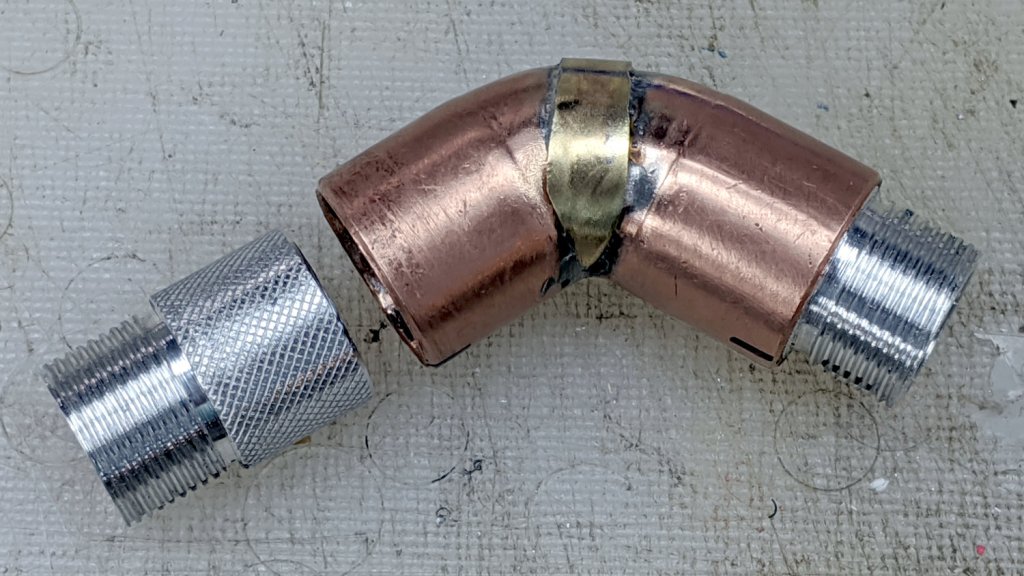

A set of real thread measuring wires being cheap & readily available, I’m prepared for the next time around this block:

The 185 mil “wires” (they’re all allegedly ground rod) will let me cut threads matching things like a Jesus nut; they’re suited for 3 TPI / 8 mm pitch screws. Mostly, wires from the front row will be all I ever need.

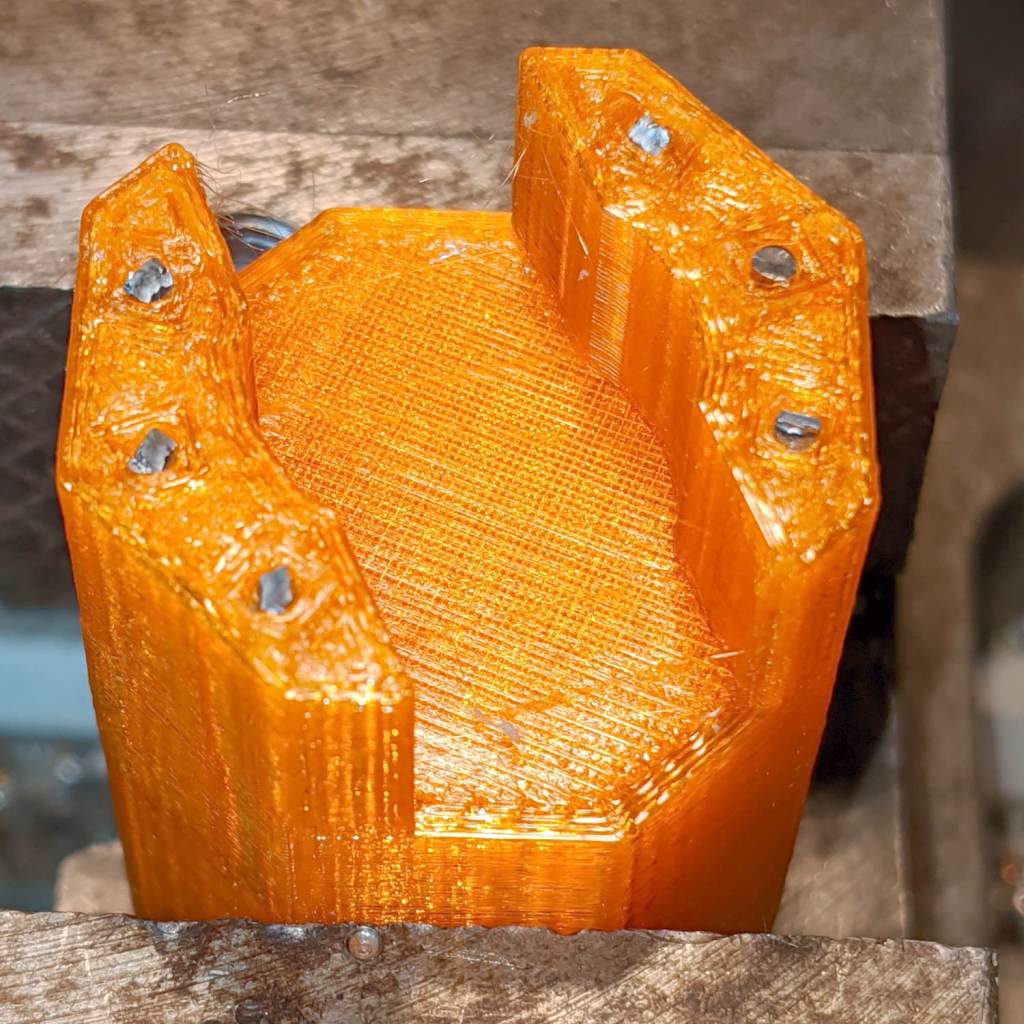

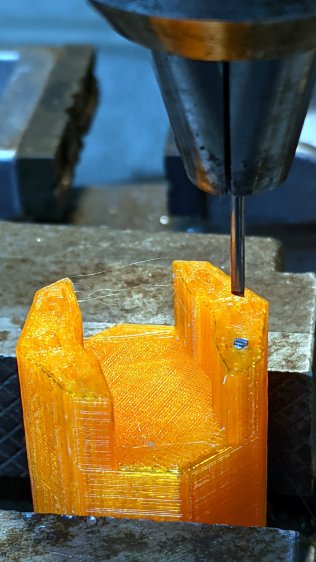

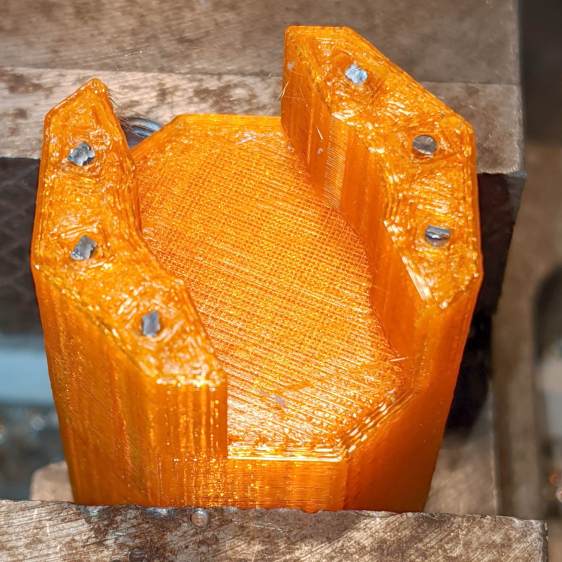

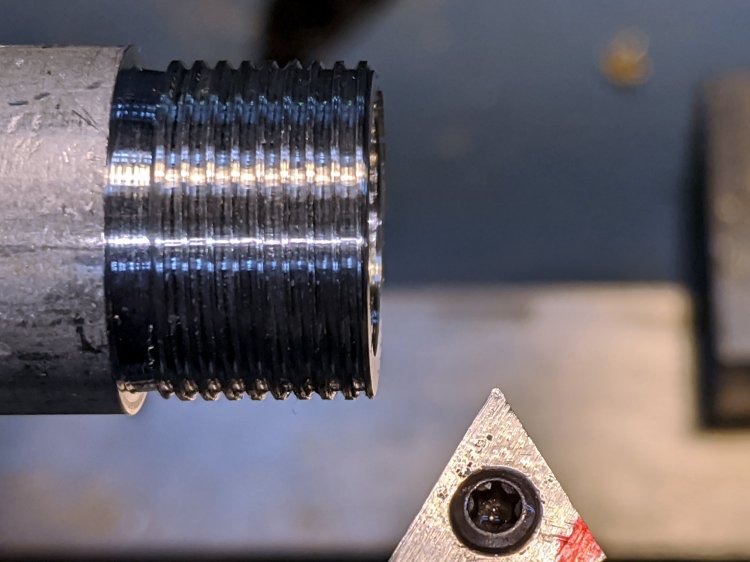

Which look like this in action:

The black doodad (the set includes half a dozen for all the wire sizes) fits over the micrometer anvil and holds two wires betwixt anvil and screw, leaving me to manipulate the screw, the third wire, and the micrometer with my remaining hands. Hence the vise holding the micrometer, which is known to be Very Bad Practice.

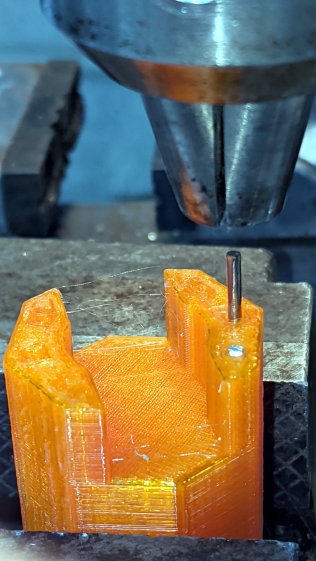

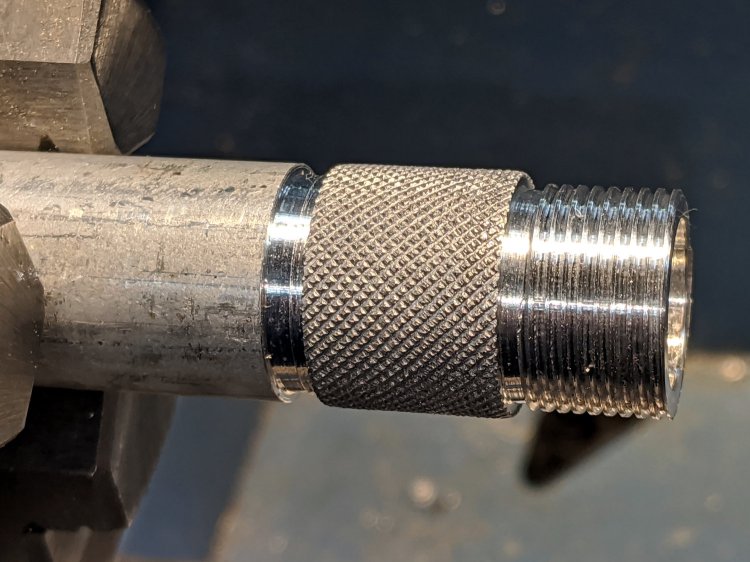

From the side:

All of the smaller wires measure 0.5 mil too thin, which is likely due to my lack of calibrated measurement equipment:

The few thread pitch diameters I measured also came out slightly too small, again likely due to calibration and screw tolerances.

The LittleMachineShop description of measuring threads over wires seems entirely adequate.

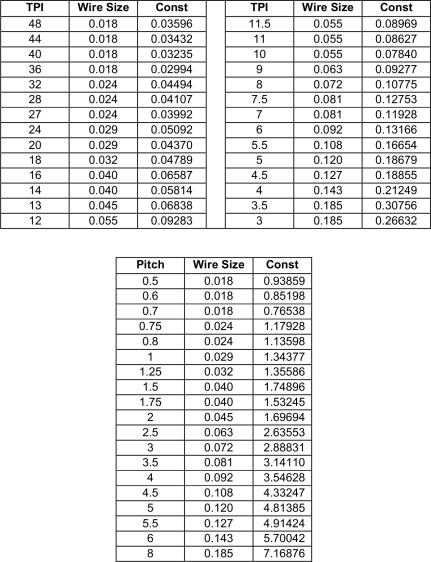

To forestall link rot, a slightly rearranged version of their tables of wire constants:

The lower table has metric thread pitches with the wire sizes in inches.

You measure the distance over the recommended wire (in inches or millimeters, as appropriate), subtract the constant, and get the pitch diameter in the same units. Conversely, add the constant to the desired pitch diameter to get the target over-wire distance, carefully cut the thread until it measures a bit less than that, back up sixty seconds, and cut it spot on.

Verily, it is written: there is no UnDo key (⎌) in machine shop work.