|

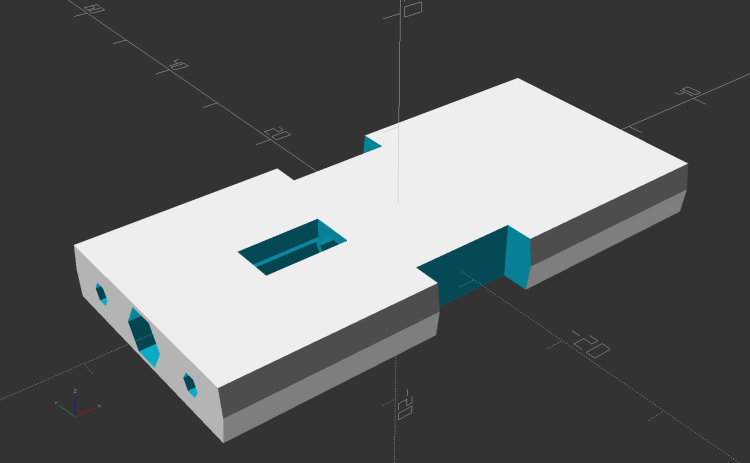

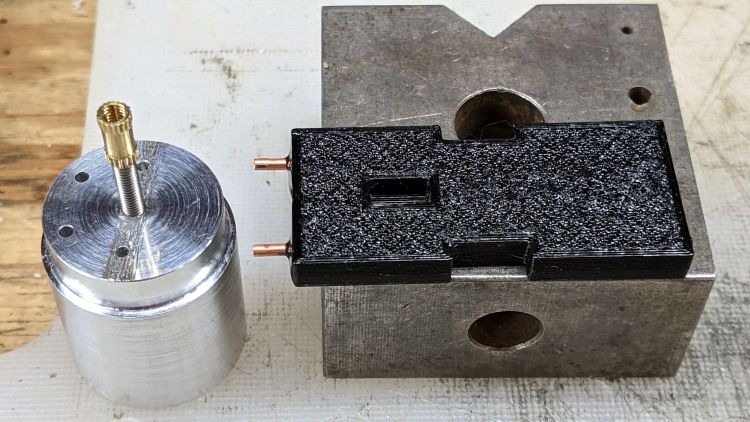

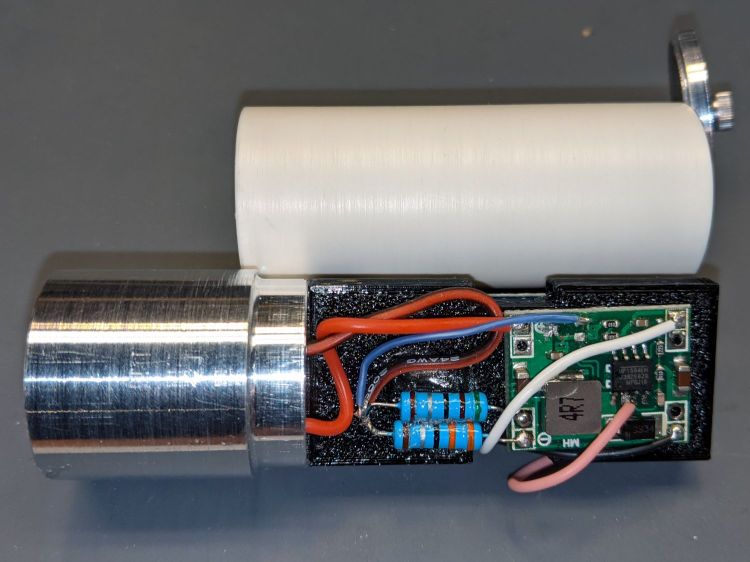

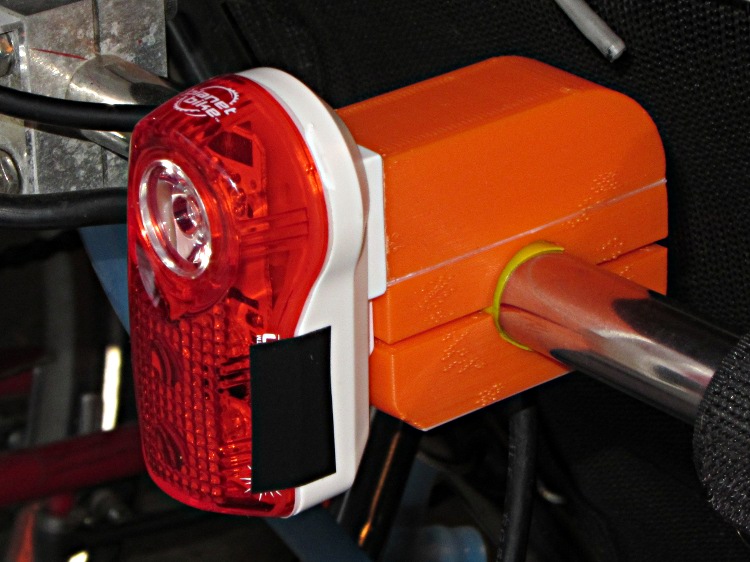

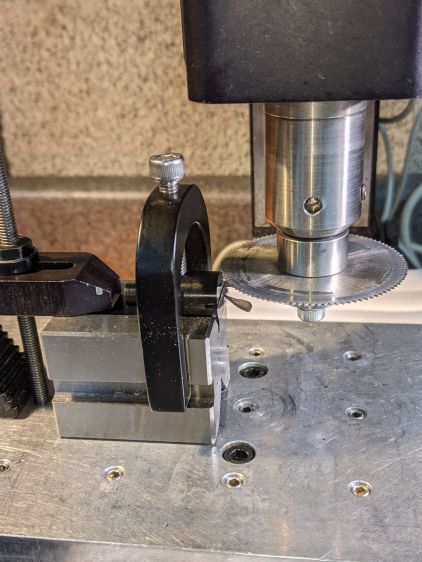

// Rear running light clamp for Tour Easy seat strut |

|

// Ed Nisley – KE4ZNU – 2021-09 |

|

|

|

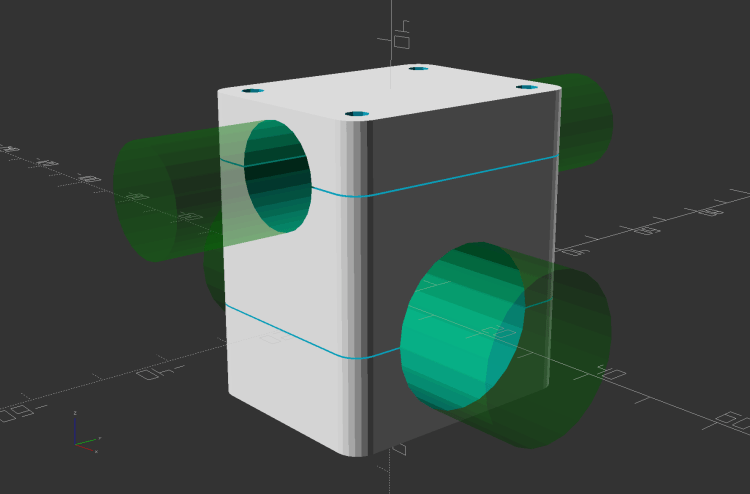

Layout = "Show"; // [Show,Build,Block] |

|

|

|

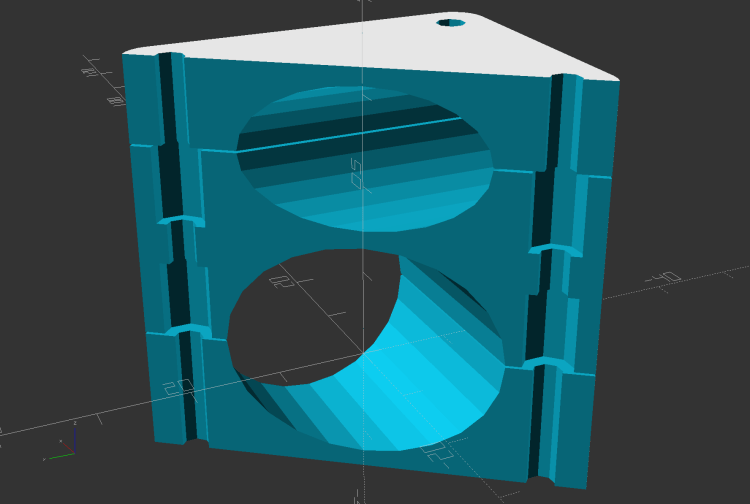

Section = true; |

|

|

|

/* [Hidden] */ |

|

|

|

ThreadThick = 0.25; |

|

ThreadWidth = 0.40; |

|

|

|

HoleWindage = 0.2; |

|

|

|

Protrusion = 0.1; // make holes end cleanly |

|

|

|

function IntegerMultiple(Size,Unit) = Unit * ceil(Size / Unit); |

|

|

|

ID = 0; |

|

OD = 1; |

|

LENGTH = 2; |

|

|

|

inch = 25.4; |

|

|

|

//———————- |

|

// Dimensions |

|

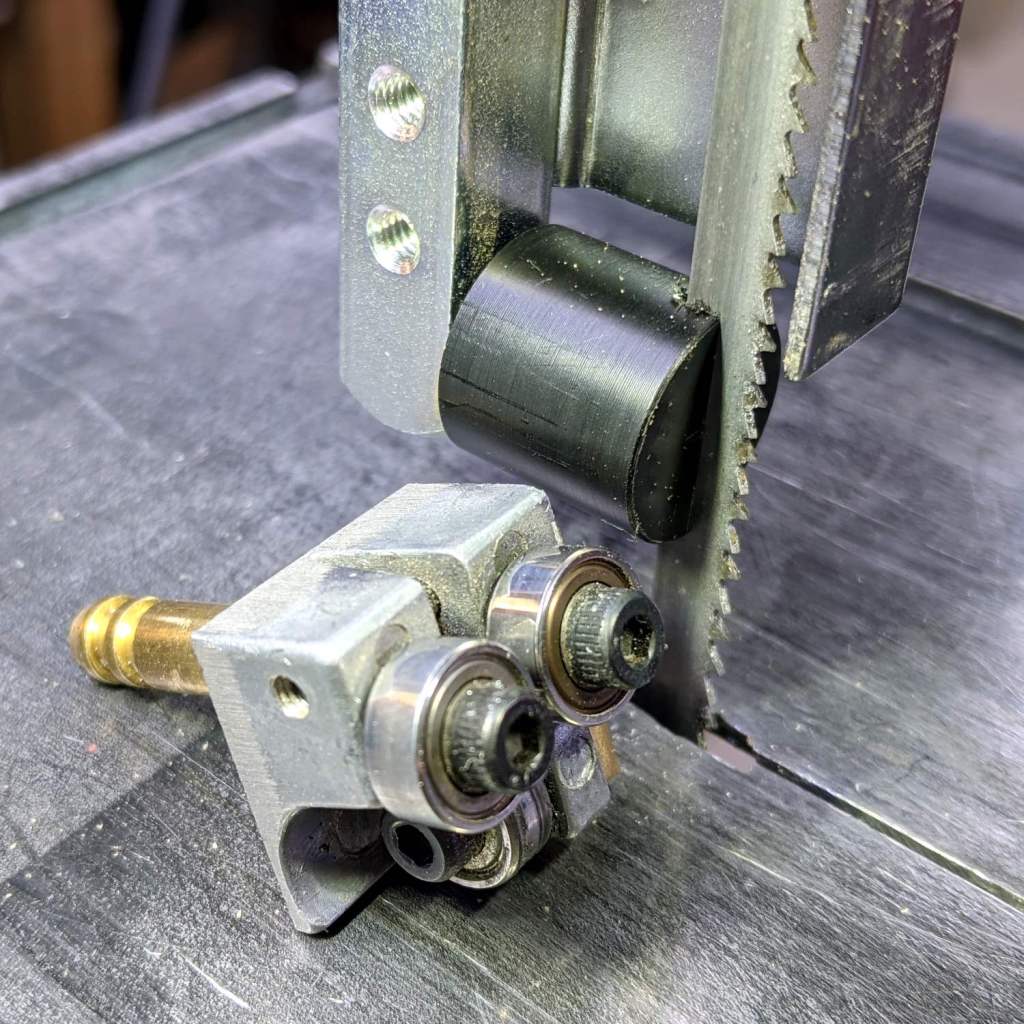

// Light case along X axis, seat strut along Y, Z=0 at strut centerline |

|

|

|

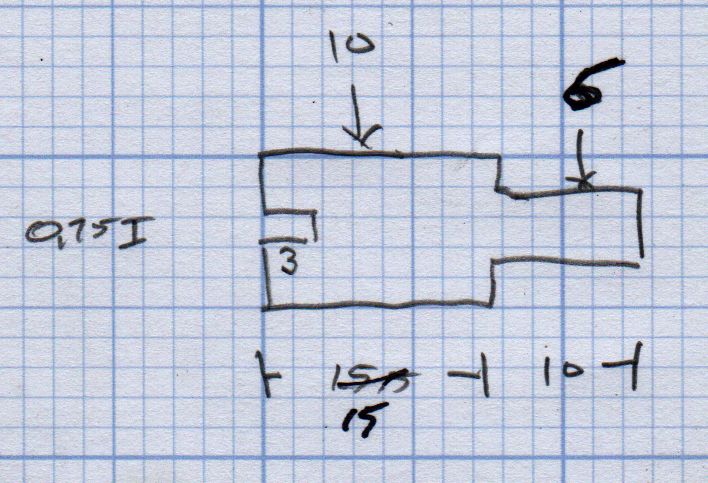

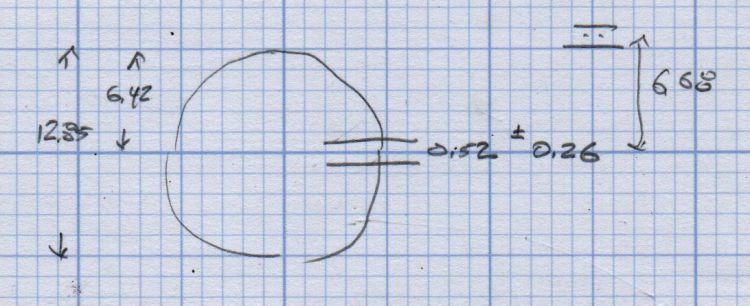

LightOD = 25.4 + HoleWindage; |

|

|

|

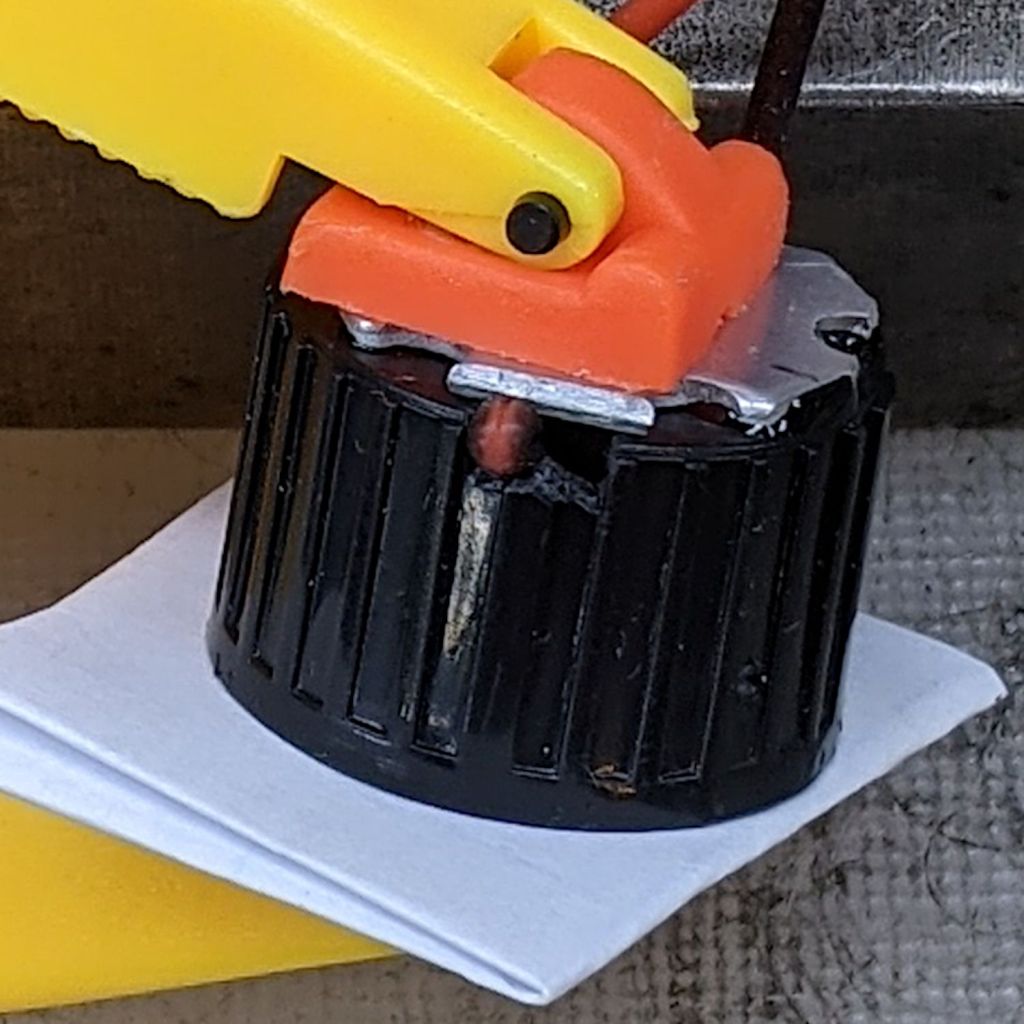

StrutOD = 5/8 * inch + HoleWindage; |

|

|

|

PlateThick = 1/16 * inch; |

|

|

|

WallThick = 2.0; |

|

|

|

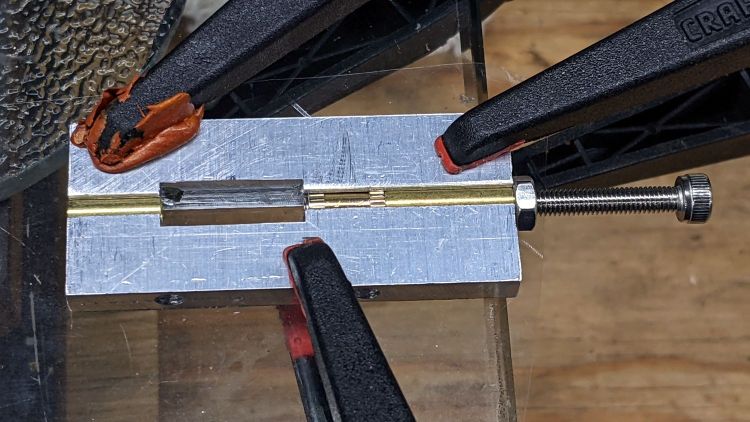

Kerf = ThreadThick; |

|

|

|

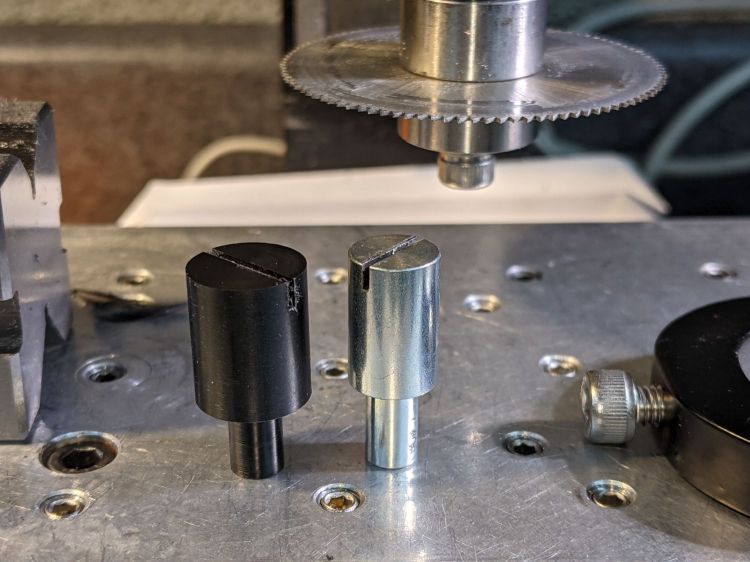

Screw = [3.0,6.8,4.0]; // M3 OD=washer, length=nut + washers |

|

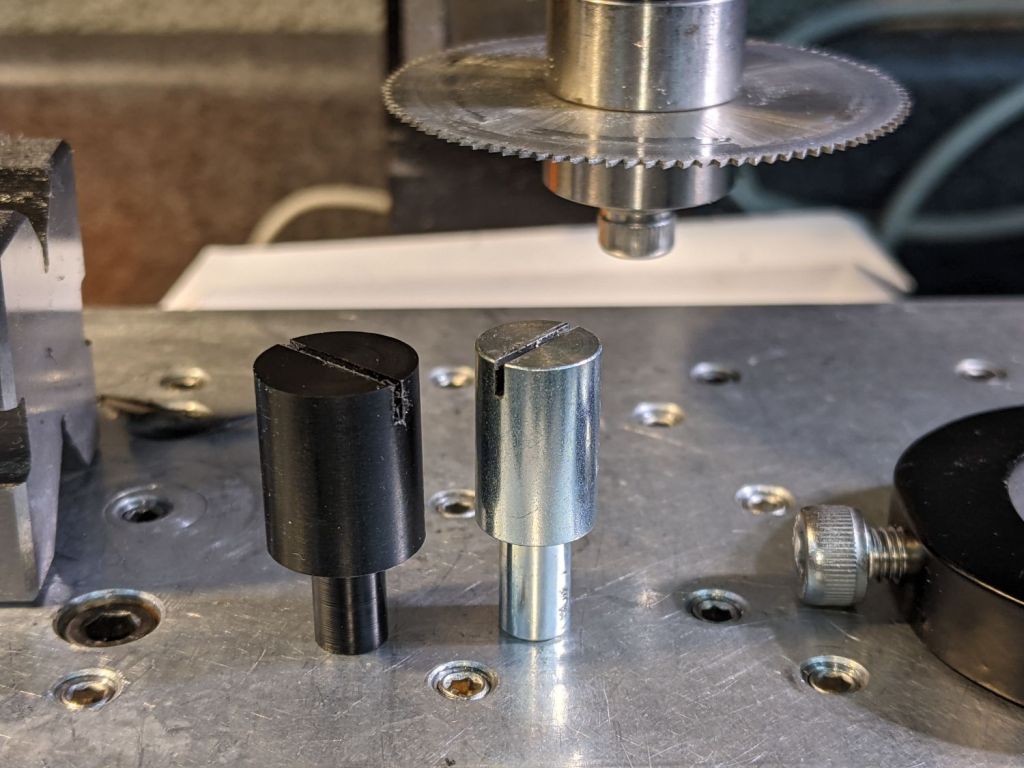

Insert = [3.0,5.4,8.0 + 1.0]; // splined brass insert |

|

|

|

RoundRadius = IntegerMultiple(Screw[OD]/2,0.5); // corner rounding |

|

|

|

ScrewOC = [IntegerMultiple(StrutOD + 2*WallThick + Screw[ID],1.0), |

|

IntegerMultiple(LightOD + 2*WallThick + Screw[ID],1.0)]; |

|

|

|

echo(str("Screw OC: ",ScrewOC)); |

|

|

|

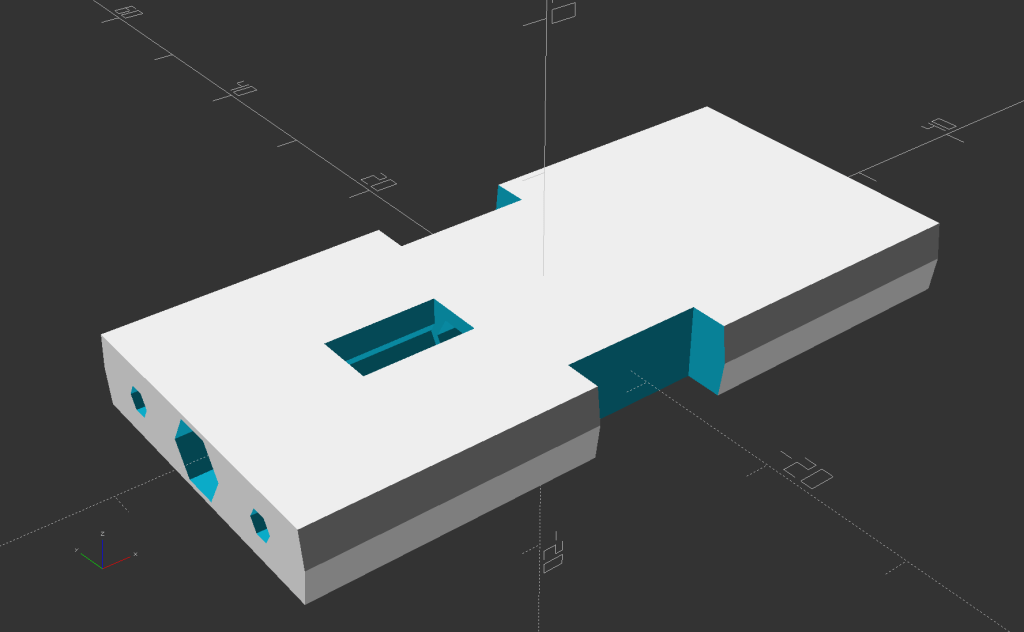

BlockSize = [ScrewOC.x + Insert[OD] + 2*WallThick, |

|

ScrewOC.y + Insert[OD] + 2*WallThick, |

|

LightOD + StrutOD + 3*WallThick]; |

|

|

|

echo(str("Block: ",BlockSize)); |

|

|

|

BaseOffset = -(WallThick + LightOD/2); // block bottom to centerline |

|

StrutOffset = LightOD/2 + WallThick + StrutOD/2; // light centerline to strut centerline |

|

|

|

echo(str("Strut screw min: ",IntegerMultiple(PlateThick + WallThick + StrutOD/2 + Insert[LENGTH]/2,1.0))); |

|

echo(str("Light screw min: ",IntegerMultiple(PlateThick + WallThick + LightOD/2 + Insert[LENGTH]/2,1.0))); |

|

|

|

NumSides = 2*3*4; |

|

|

|

//———————- |

|

// Useful routines |

|

|

|

module PolyCyl(Dia,Height,ForceSides=0) { // based on nophead's polyholes |

|

|

|

Sides = (ForceSides != 0) ? ForceSides : (ceil(Dia) + 2); |

|

FixDia = Dia / cos(180/Sides); |

|

cylinder(r=(FixDia + HoleWindage)/2, |

|

h=Height, |

|

$fn=Sides); |

|

} |

|

|

|

// Block with light along X axis |

|

|

|

module Block() { |

|

|

|

difference() { |

|

hull() |

|

for (i=[-1,1], j=[-1,1]) |

|

translate([i*(BlockSize.x/2 – RoundRadius),j*(BlockSize.y/2 – RoundRadius),BaseOffset]) |

|

cylinder(r=RoundRadius,h=BlockSize.z,$fn=NumSides); |

|

|

|

for (i=[-1,1], j=[-1,1]) |

|

translate([i*ScrewOC.x/2,j*ScrewOC.y/2,BaseOffset – Protrusion]) |

|

rotate(180/8) |

|

PolyCyl(Screw[ID],BlockSize.z + 2*Protrusion,8); |

|

|

|

for (i=[-1,1], j=[-1,1]) |

|

translate([i*ScrewOC.x/2,j*ScrewOC.y/2,0]) { |

|

translate([0,0,-Protrusion]) |

|

rotate(180/8) |

|

PolyCyl(Insert[OD],Insert[LENGTH] + 1*Protrusion,8); |

|

translate([0,0,(StrutOffset – Insert[LENGTH] – Kerf/2 + Protrusion)]) |

|

rotate(180/8) |

|

PolyCyl(Insert[OD],Insert[LENGTH] + 1*Protrusion,8); |

|

} |

|

|

|

translate([-BlockSize.x,0,0]) |

|

rotate([0,90,0]) |

|

cylinder(d=LightOD,h=2*BlockSize.x,$fn=NumSides); |

|

|

|

translate([0,BlockSize.y,StrutOffset]) |

|

rotate([90,0,0]) |

|

cylinder(d=StrutOD,h=2*BlockSize.y,$fn=NumSides); |

|

|

|

translate([0,0,StrutOffset]) |

|

cube([2*BlockSize.x,2*BlockSize.y,Kerf],center=true); |

|

|

|

cube([2*BlockSize.x,2*BlockSize.y,Kerf],center=true); |

|

|

|

} |

|

|

|

} |

|

|

|

|

|

//- Build it |

|

|

|

if (Layout == "Block") |

|

if (Section) |

|

difference() { |

|

Block(); |

|

rotate(atan(ScrewOC.y/ScrewOC.x)) |

|

translate([0,BlockSize.y,0]) |

|

cube(2*BlockSize,center=true); |

|

} |

|

else |

|

Block(); |

|

|

|

if (Layout == "Show") { |

|

Block(); |

|

|

|

color("Green",0.25) |

|

translate([-BlockSize.x,0,0]) |

|

rotate([0,90,0]) |

|

cylinder(d=LightOD,h=2*BlockSize.x,$fn=NumSides); |

|

|

|

color("Green",0.25) |

|

translate([0,BlockSize.y,StrutOffset]) |

|

rotate([90,0,0]) |

|

cylinder(d=StrutOD,h=2*BlockSize.y,$fn=NumSides); |

|

} |

|

|

|

if (Layout == "Build") { |

|

translate([-1.2*BlockSize.x,0,-BaseOffset]) |

|

difference() { |

|

Block(); |

|

translate([0,0,BlockSize.z]) |

|

cube(2*BlockSize,center=true); |

|

} |

|

|

|

translate([1.2*BlockSize.x,0,StrutOD/2 + WallThick]) |

|

difference() { |

|

rotate([180,0,0]) |

|

translate([0,0,-StrutOffset]) |

|

Block(); |

|

translate([0,0,BlockSize.z]) |

|

cube(2*BlockSize,center=true); |

|

} |

|

|

|

translate([0,0,StrutOffset – Kerf/2]) |

|

rotate([180,0,0]) |

|

intersection() { |

|

Block(); |

|

translate([0,0,StrutOffset/2]) |

|

cube([2*BlockSize.x,2*BlockSize.y,StrutOffset],center=true); |

|

} |

|

} |