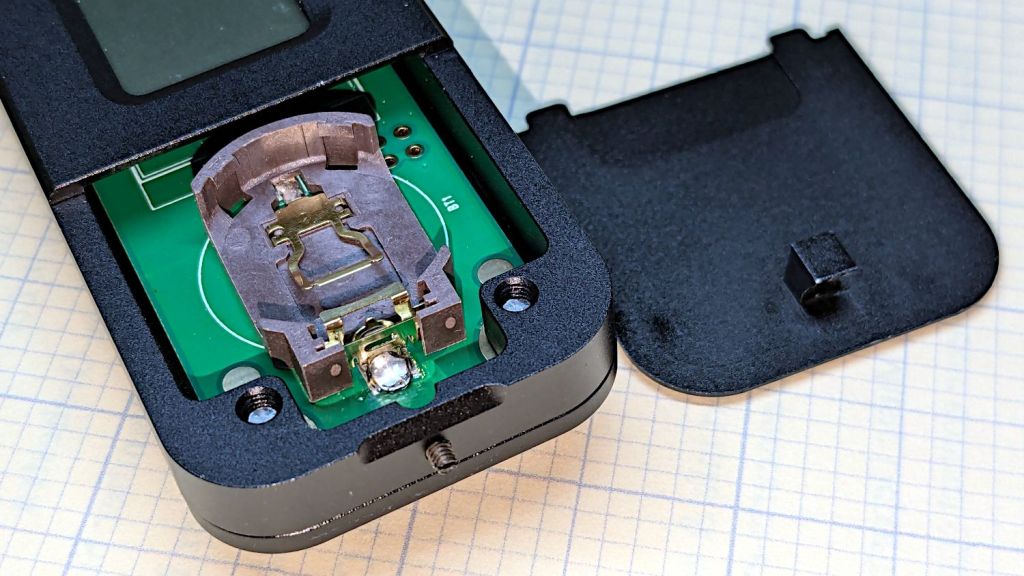

The HLP-200B Laser Power Meter arrives without much in the way of specifications:

The HLP-200B Laser Power Meter Handheld comes fully calibrated at 10.6 μm (CO2). Each laser power meter we calibrate is directly traceable to NIST absolute standards because we use GOLD standards as a reference for each calibration. You will obtain the most accurate result possible

A line in the description says “+/- 3% within the central section”, but that’s not much help. Back in the day, any error percentage referred to the meter’s full-scale value, which would be ±6 W for a 200 W meter.

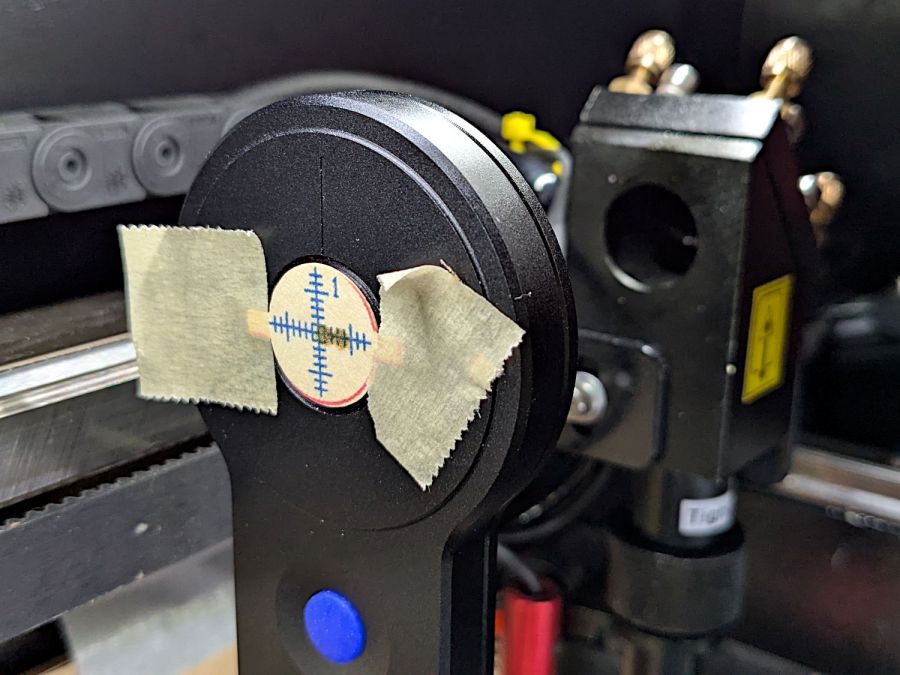

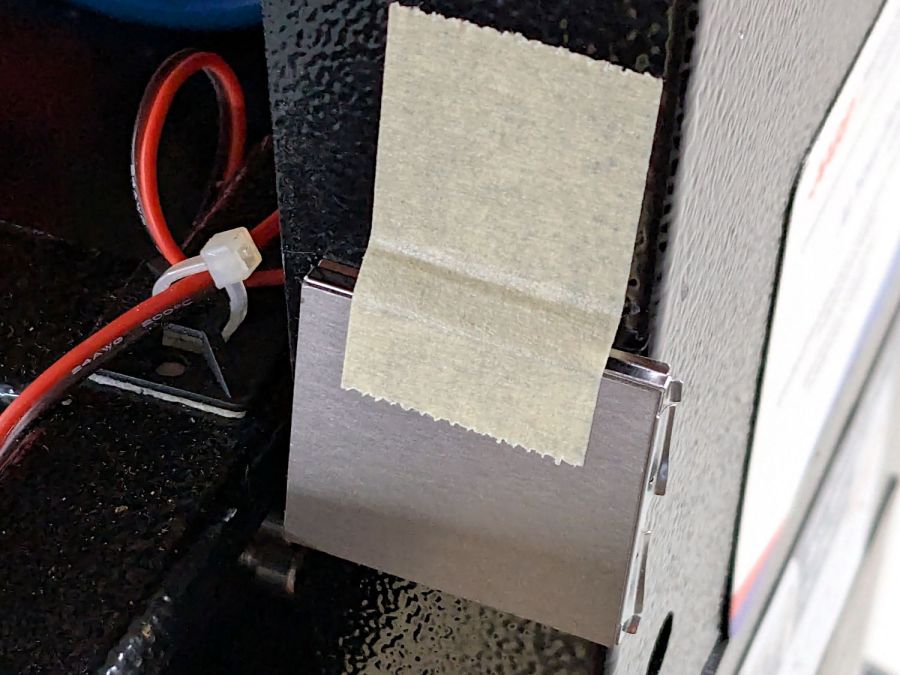

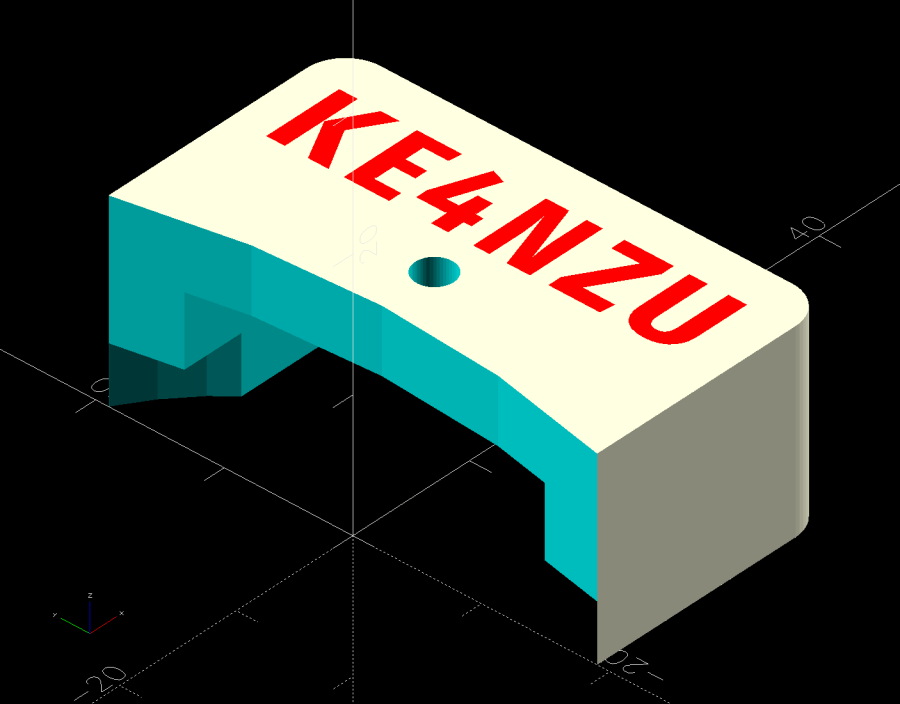

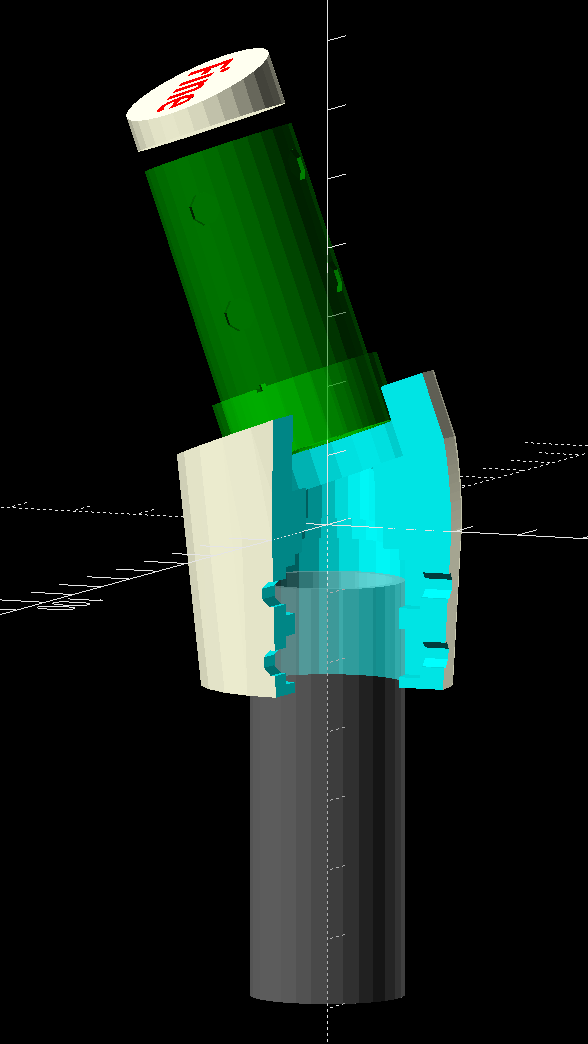

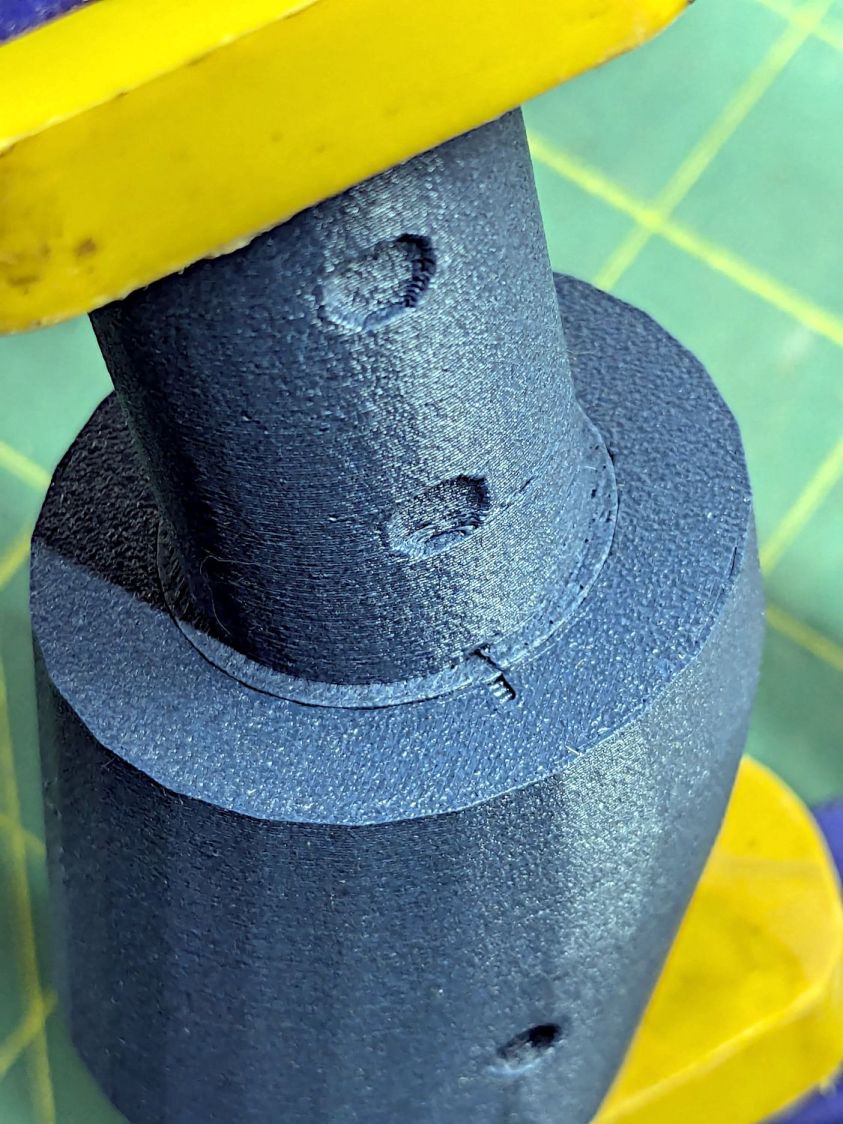

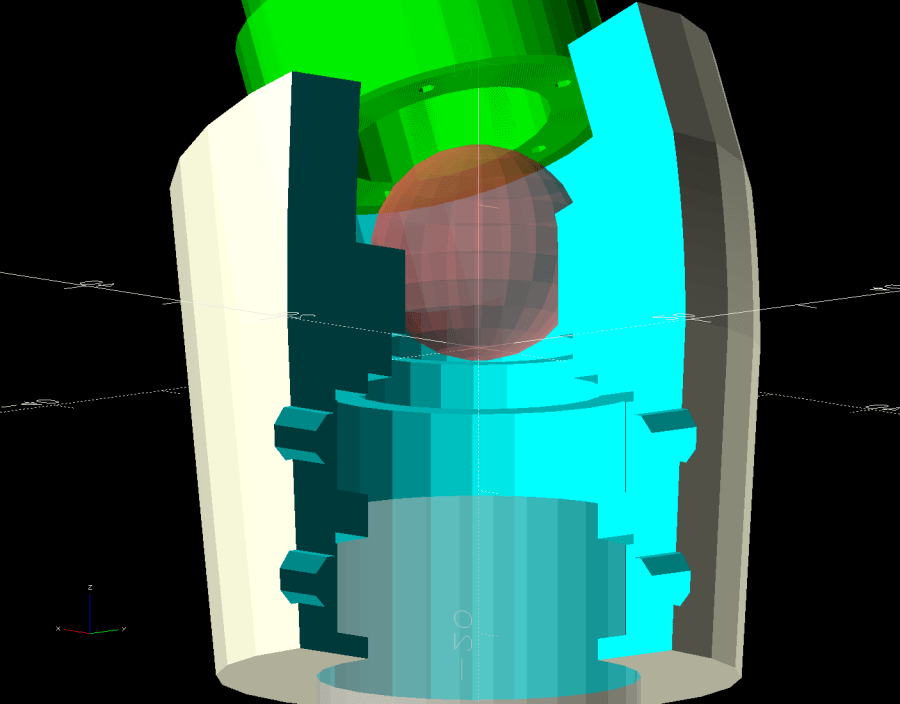

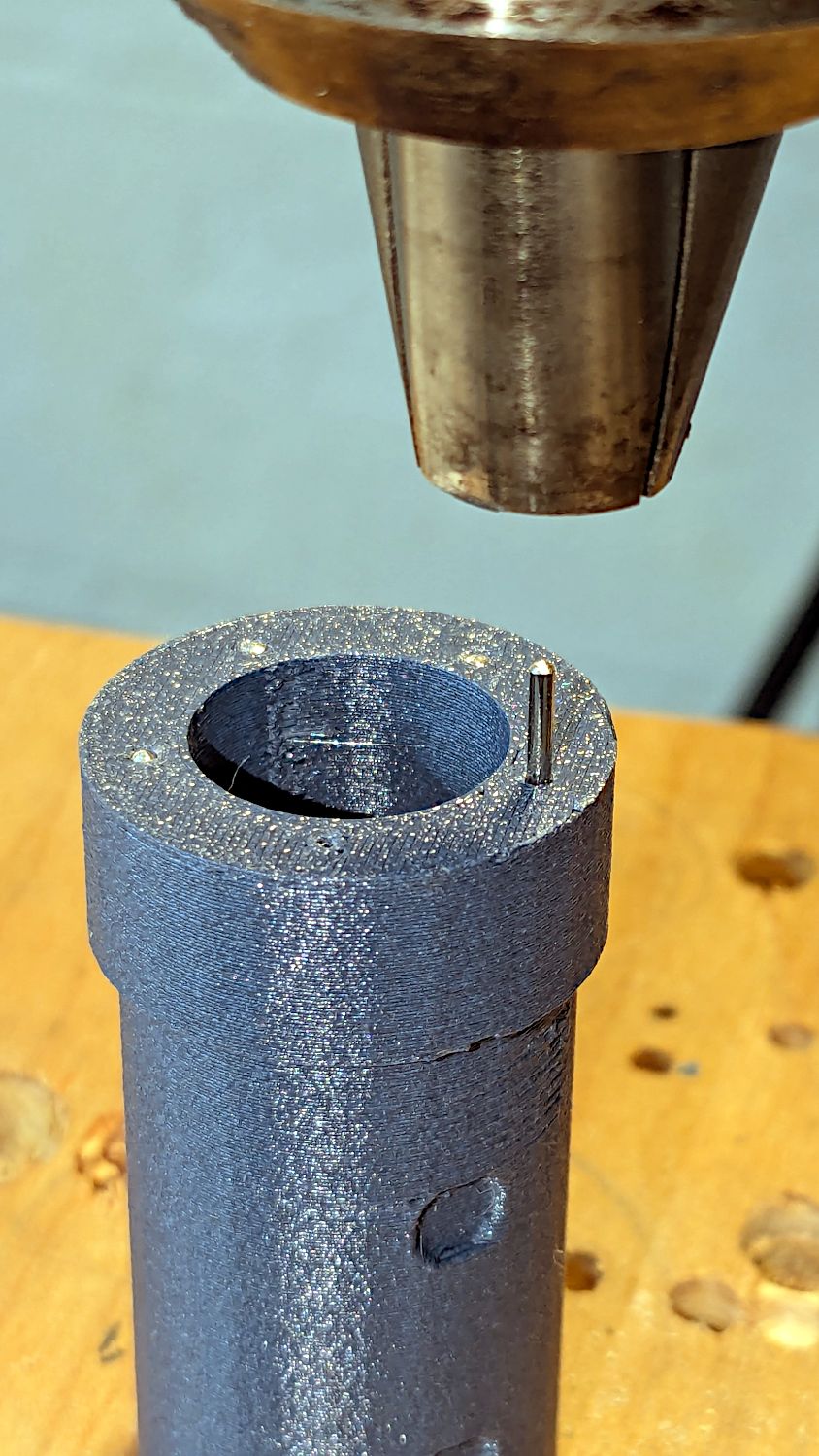

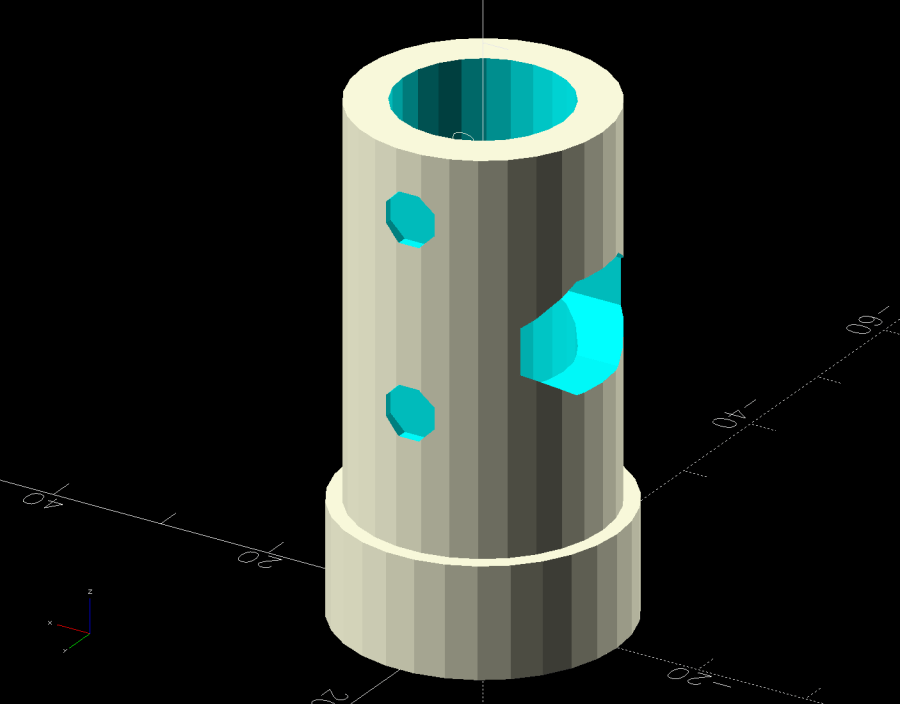

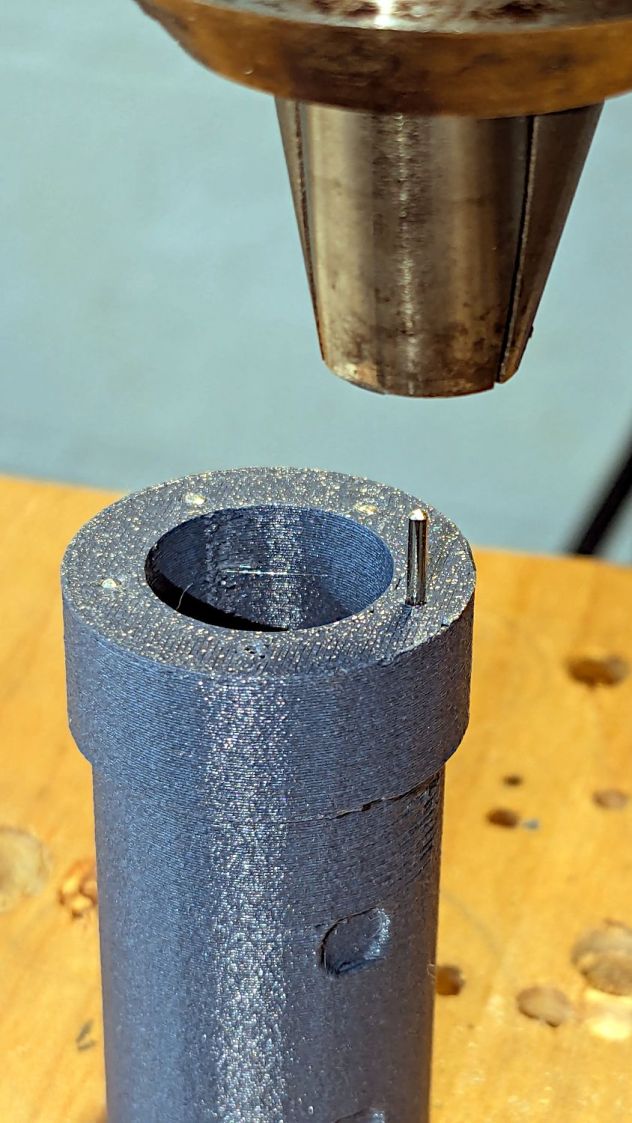

So I plunked the meter in the middle of the laser platform:

Then took five measurements at each of ten power levels:

| PWM % | 10 | 20 | 30 | 40 | 50 | 60 | 70 | 80 | 90 | 99 |

| °C | 17.2 | 17.9 | 18.4 | 19.0 | 19.4 | 20.3 | 20.0 | 20.0 | 20.5 | 19.4 |

| Tube Current | 3 | 4 | 7 | 10 | 14 | 16 | 18 | 20 | 22 | 24 |

| W | 7.1 | 21.0 | 42.0 | 51.8 | 59.1 | 63.0 | 67.8 | 69.6 | 74.7 | 64.0 |

| 6.0 | 19.8 | 37.2 | 48.9 | 52.7 | 56.0 | 65.1 | 69.6 | 72.4 | 71.8 | |

| 6.4 | 21.1 | 39.3 | 45.6 | 56.5 | 53.2 | 61.1 | 60.7 | 74.6 | 75.2 | |

| 5.6 | 17.8 | 37.1 | 40.4 | 55.3 | 53.2 | 55.1 | 64.2 | 74.9 | 73.5 | |

| 6.0 | 17.7 | 36.9 | 45.1 | 54.5 | 53.1 | 62.2 | 69.9 | 72.2 | 70.9 | |

| Avg Power | 6.2 | 19.5 | 38.5 | 46.4 | 55.6 | 55.7 | 62.3 | 66.8 | 73.8 | 71.1 |

| std dev | 0.57 | 1.66 | 2.19 | 4.29 | 2.39 | 4.26 | 4.78 | 4.16 | 1.34 | 4.29 |

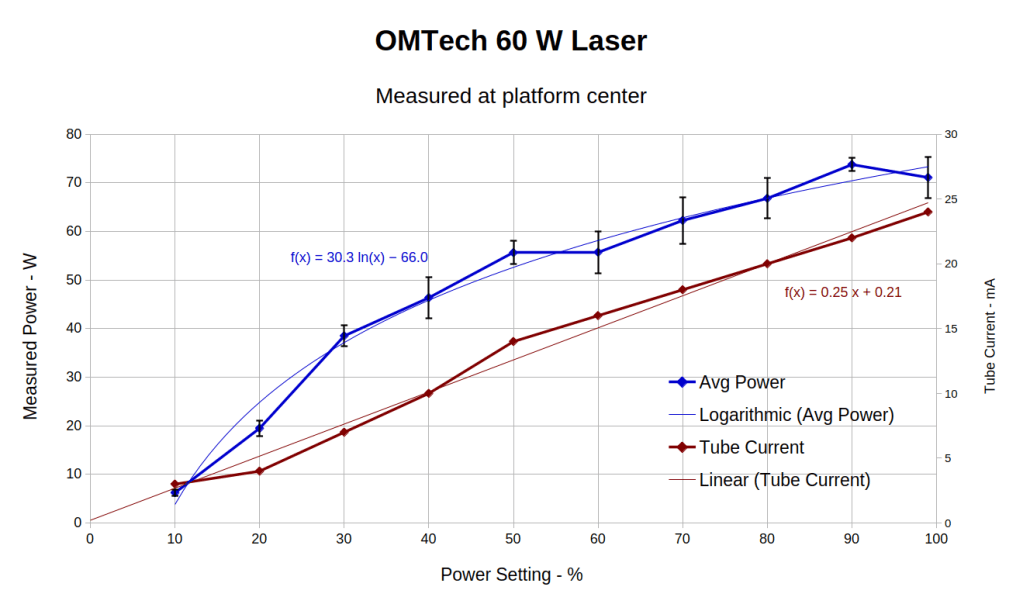

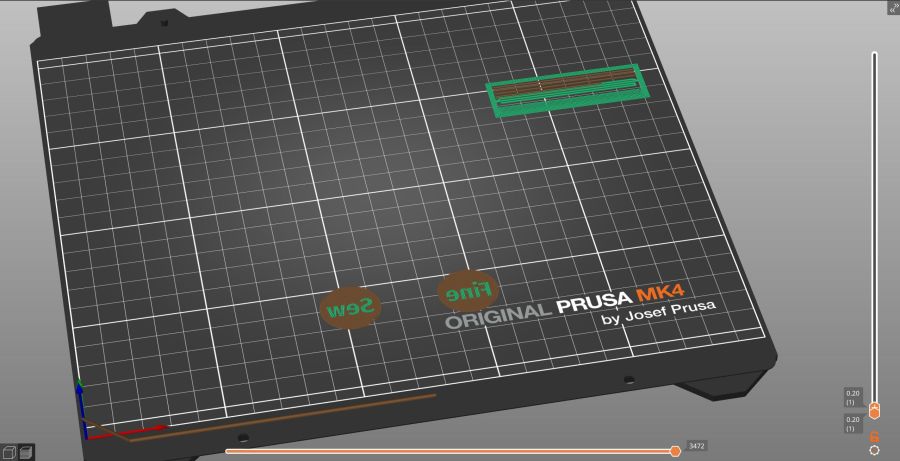

That’s easier to digest from a graph:

The absurdity of computing the sample standard deviation from five measurements taken at each power level does not escape me, but this just surveys the situation.

Earlier measurements of the tube current vs. PWM setting, using an RMS value computed by the oscilloscope’s firmware, produced a plot resembling the brown points (read the mA scale on the right) at the high end and differing greatly on the low end. These values come from the power supply’s digital meter, but the straight-line fit doesn’t look absurdly forced and the zero intercept seems plausible. I *assume* it’s actually measuring the tube current, rather than displaying a value computed from the PWM input, but I don’t know for sure.

The rather sketchy paperwork accompanying the laser had one handwritten “21 mA” seemingly corresponding to 60 W output, which looks approximately correct. The instruction manual has a table of power vs. current suggesting that 65-ish W corresponds to 18 mA, with 100 W at 23 mA; it’s unclear whether that is for the 60 W tube in the machine or applies to the entire range of available tubes. The manual recommends not using more than 95% PWM, with which I heartily agree.

Because my meter stand holds the target in the same position relative to the beam during successive measurements much better than I could by hand, I think the pulse-to-pulse variation comes from meter and tube repeatability.

Earlier measurements with a grossly abused Gentec ED-200 joulemeter suggested the laser has some pulse-to-pulse timing variation, down in the millisecond range, but produced roughly the right power for middle-of-the-range PWM settings. This meter integrates the beam power over about ten seconds, so I think variations will be due to (possible) tube power changes and meter repeatability, rather than timing errors.

Obviously, you must not depend on any single-shot measurement to fall within maybe 10% or several watts of the right answer.

With all that in mind and assuming the meter is delivering approximately the right numbers on average, the power supply overcooks the tube at any PWM setting above 50%. I’ve noticed some beam instability / defocusing over 80% while cutting recalcitrant materials, which is surely due to the tube not lasing properly. I generally avoid doing that.

The log fit to the measured power looks better than I expected, although I’m unprepared to compute natural logs in my head.

Hey, it’s my idea of a good Christmas present …