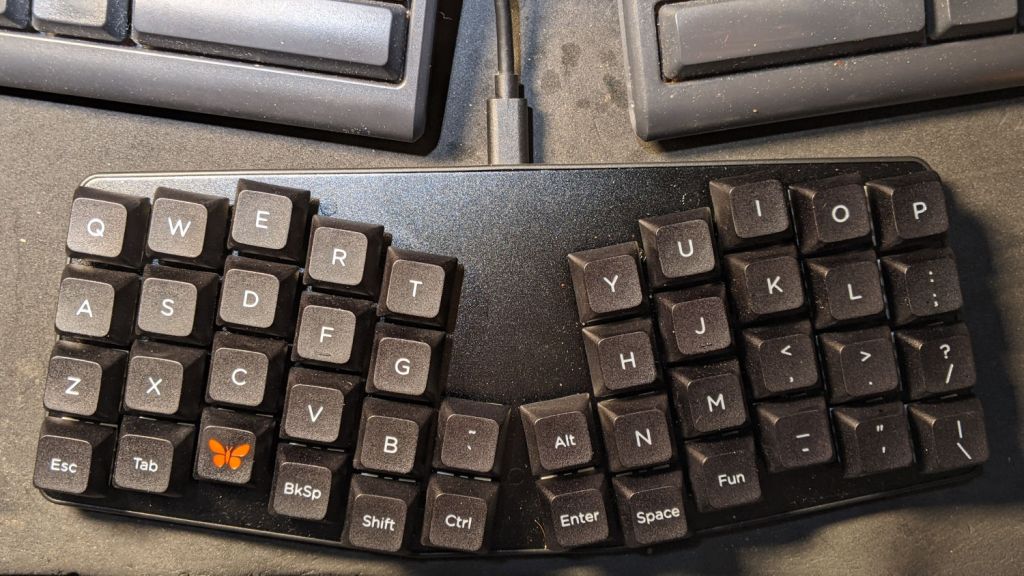

Having a customizable keyboard like the KeyboardIO Atreus means one must customize it. As it turns out, I wanted to use some features of the underlying QMK Kaleidoscope firmware that aren’t exposed by Chrysalis, KeyboardIO’s otherwise competent keymap configuration utility, so what you see below runs on hard mode.

Start by installing QMK, compiling the default Atreus layout, and flashing the keyboard just to confirm all the steps work:

With all that working, add (or create) two lines to the rules.mk file in the keymap directory you’re tweaking:

AUTO_SHIFT_ENABLE = yes # allow automagic shifting

TAP_DANCE_ENABLE = yes # allow multi-tap keysEnabling Auto-Shift lets you generate shifted characters (like Z) by briefly holding down the unshifted key (like z). This requires unlearning an entire lifetime of touch typing practice, but is definitely worthwhile; if a thumb still reaches for the shift key, there’s no harm done. There are, of course, a myriad options, all of which I left unchanged.

Complex passwords suffer, as you must blind-type carefully while tapping each key rapidly.

Enabling Tap Dance lets a key generate one character when tapped and another when double-tapped; you can go crazy with more taps. An enum{} in the keymap.c file generates indexes for the keys and an array holds the action definitions:

enum {

TD_SPC_ENT,

TD_BS_DEL,

};

qk_tap_dance_action_t tap_dance_actions[] = {

[TD_SPC_ENT] = ACTION_TAP_DANCE_DOUBLE(KC_SPC, KC_ENT),

[TD_BS_DEL] = ACTION_TAP_DANCE_DOUBLE(KC_BSPC, KC_DEL),

};Then each key uses a TD() macro in the keymap.c file:

… TD(TD_BS_DEL), … TD(TD_SPC_ENT), …In contrast, layer shifting uses straightforward built-in macros. The Fun key produces a momentary shift to Layer 1 (known as _RS) when held down:

… MO(_RS), …The ESC key in the lower left corner emits the expected Escape key code when tapped and switches to Layer 2 (a.k.a. _LW) when held:

LT(_LW,KC_ESC), …

For reference, the current state of the keymap.c file:

// Modified from the KeyboardIO layout

// Ed Nisley - KE4ZNU

// Enable Auto Shift and Tap Dance in rules.mk

#include QMK_KEYBOARD_H

enum layer_names {

_QW,

_RS,

_LW,

};

enum {

TD_SPC_ENT,

TD_BS_DEL,

};

qk_tap_dance_action_t tap_dance_actions[] = {

[TD_SPC_ENT] = ACTION_TAP_DANCE_DOUBLE(KC_SPC, KC_ENT),

[TD_BS_DEL] = ACTION_TAP_DANCE_DOUBLE(KC_BSPC, KC_DEL),

};

const uint16_t PROGMEM keymaps[][MATRIX_ROWS][MATRIX_COLS] = {

[_QW] = LAYOUT( /* Qwerty */

KC_Q, KC_W, KC_E, KC_R, KC_T, KC_Y, KC_U, KC_I, KC_O, KC_P ,

KC_A, KC_S, KC_D, KC_F, KC_G, KC_H, KC_J, KC_K, KC_L, KC_SCLN ,

KC_Z, KC_X, KC_C, KC_V, KC_B, KC_GRV, KC_LALT, KC_N, KC_M, KC_COMM, KC_DOT, KC_SLSH ,

LT(_LW,KC_ESC), KC_TAB, KC_LGUI, TD(TD_BS_DEL), KC_LSFT, KC_LCTL, KC_ENT , TD(TD_SPC_ENT), MO(_RS), KC_MINS, KC_QUOT, KC_BSLS),

[_RS] = LAYOUT( /* [> RAISE <] */

KC_EXLM, KC_AT, KC_UP, KC_DLR, KC_PERC, KC_PGUP, KC_7, KC_8, KC_9, KC_HOME,

KC_LPRN, KC_LEFT, KC_DOWN, KC_RGHT, KC_RPRN, KC_PGDN, KC_4, KC_5, KC_6, KC_END,

KC_LBRC, KC_RBRC, KC_HASH, KC_LCBR, KC_RCBR, KC_CIRC, KC_AMPR,KC_ASTR, KC_1, KC_2, KC_3, KC_PLUS,

KC_NO , KC_INS, KC_LGUI, KC_DEL , KC_BSPC, KC_LCTL, KC_LALT,KC_SPC, KC_TRNS, KC_DOT, KC_0, KC_EQL ),

[_LW] = LAYOUT( /* [> LOWER <] */

KC_INS, KC_HOME, KC_UP, KC_END, KC_PGUP, KC_UP, KC_F7, KC_F8, KC_F9, KC_F10 ,

KC_DEL, KC_LEFT, KC_DOWN, KC_RGHT, KC_PGDN, KC_DOWN, KC_F4, KC_F5, KC_F6, KC_F11 ,

KC_NO, KC_VOLU, KC_NO, KC_NO, RESET, _______, _______, KC_NO, KC_F1, KC_F2, KC_F3, KC_F12 ,

KC_NO, KC_VOLD, KC_LGUI, KC_LSFT, KC_BSPC, KC_LCTL, KC_LALT, KC_SPC, TO(_QW), KC_PSCR, KC_SLCK, KC_PAUS )

};

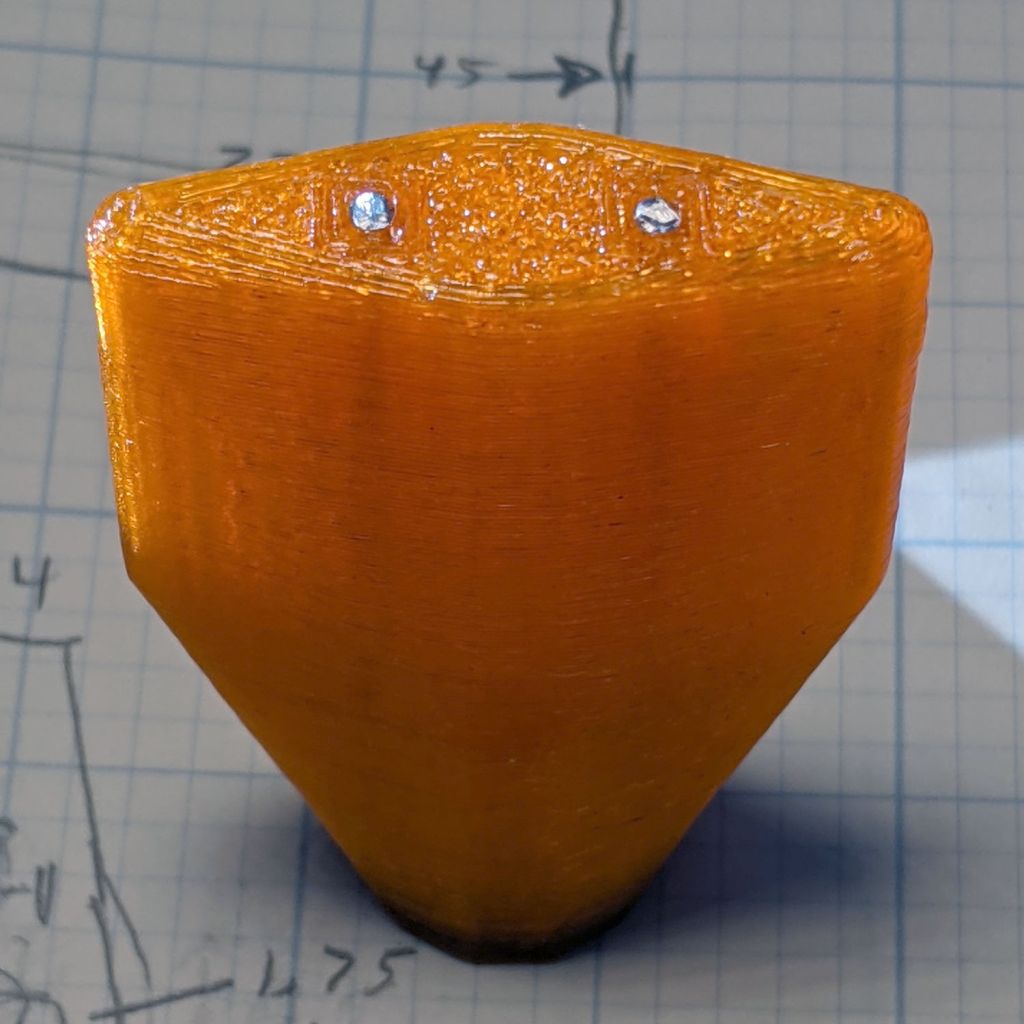

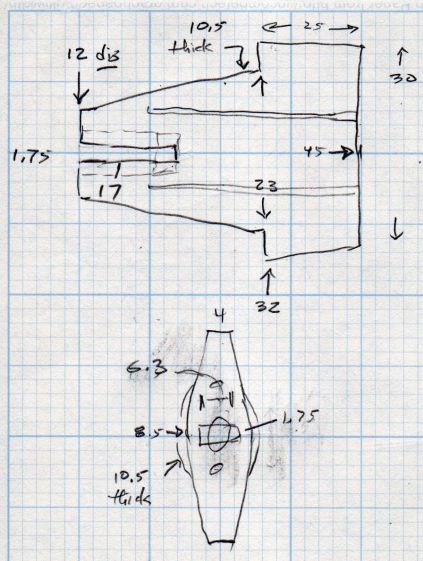

With all that set up, It Just Works and I can contemplate grafting a status LED into the thing.