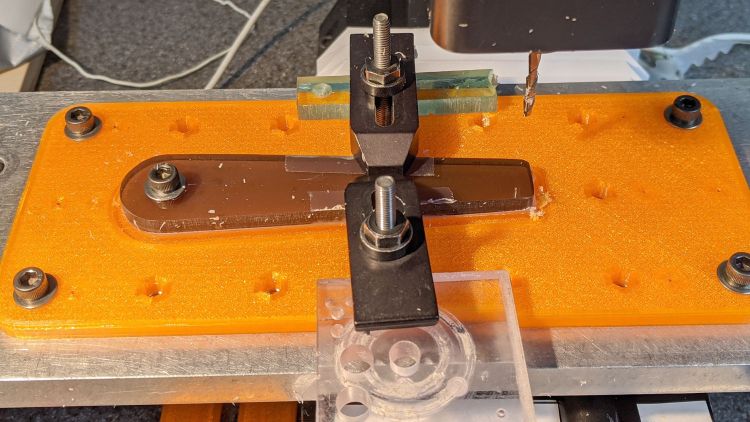

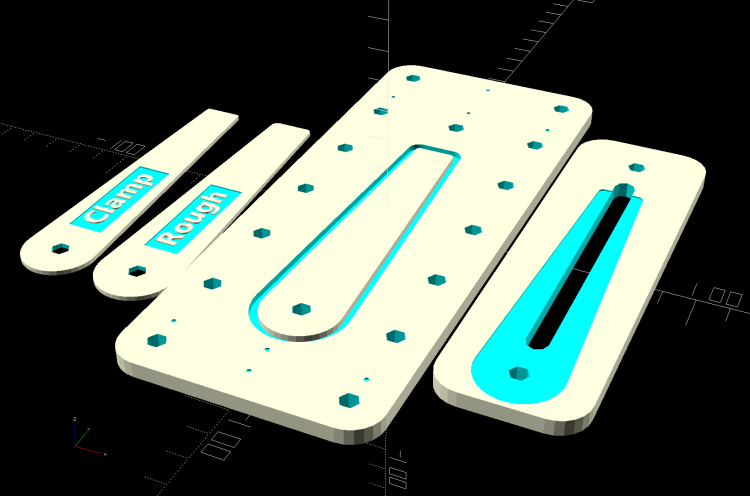

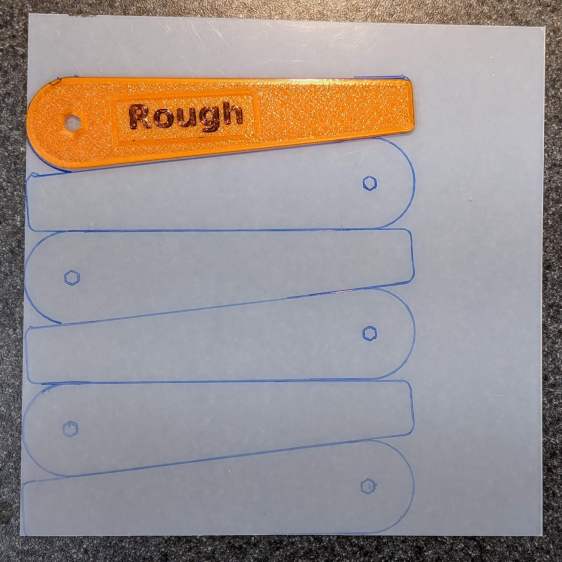

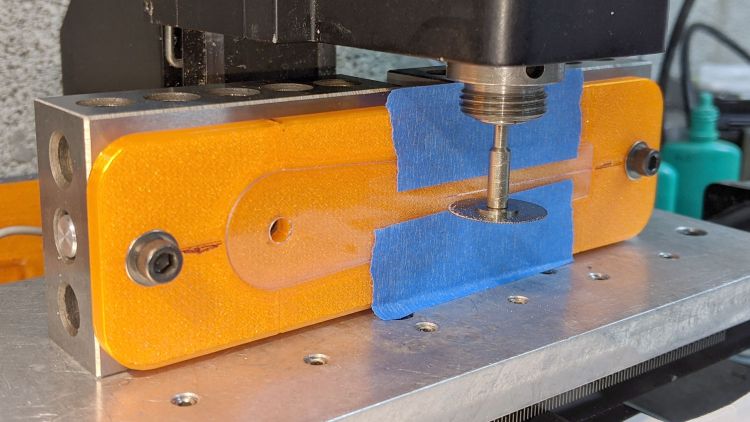

This is a fixture to hold a cursor for an Homage Tektronix Circuit Computer while a tiny circular saw blade cuts a narrow flat-bottomed trench:

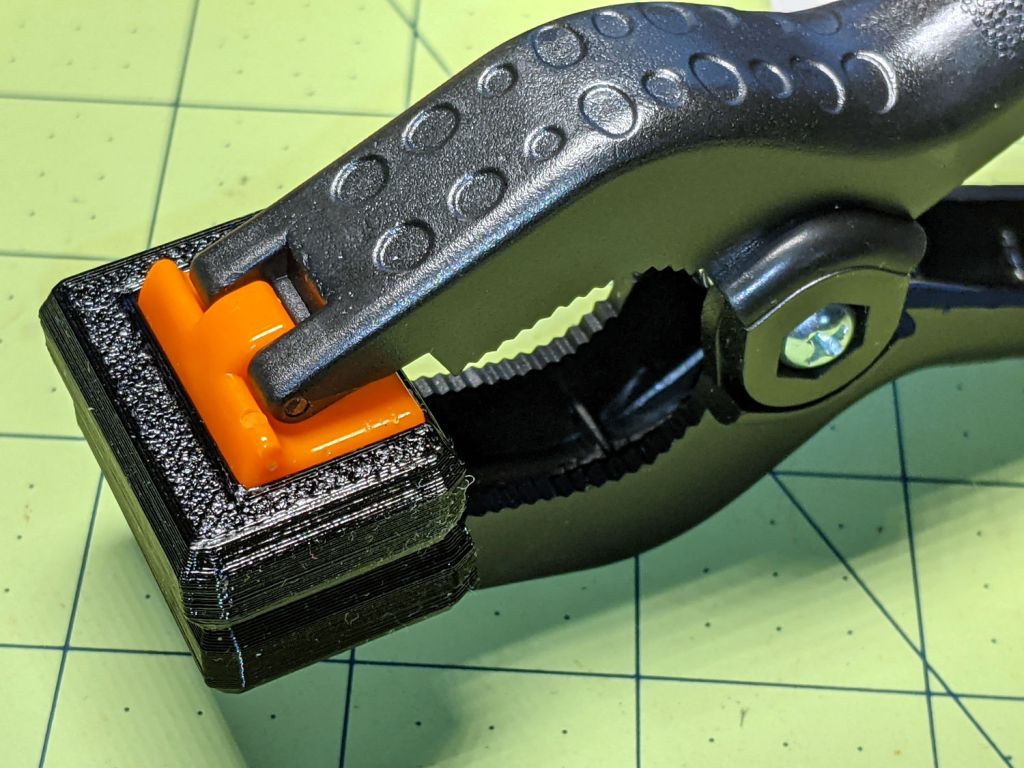

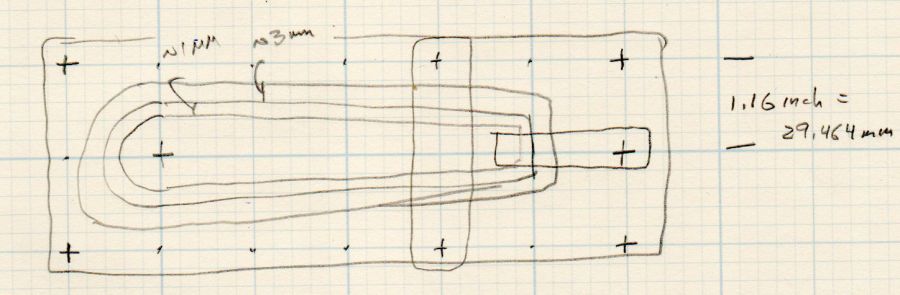

Each of the 123 blocks is held to the Sherline tooling plate with a 10-32 SHCS in a little aluminum pin, with another threaded pin for the screw holding the fixture on the side. The minimal top clearance provided some of the motivation behind making those pins in the first place; there’s no room for the usual threaded stud sticking out of the block with a handful of washers under the nut.

The fixture has locating slots (scribbled with black Sharpie) to touch off the spindle axis and the saw blade at the XZ origin at the pivot hole center. Touching off the saw blade on the cursor surface sets Y=0, although only a few teeth will go ting, so the saw must be spinning.

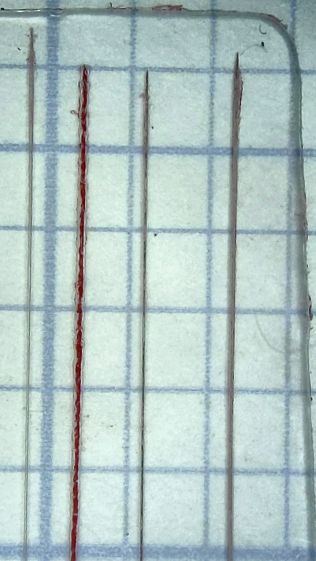

I cut the first slot under manual control to a depth of 0.3 mm on a scrap cursor with a grotty engraved hairline:

It looks better than I expected with some red lacquer crayon scribbled into it:

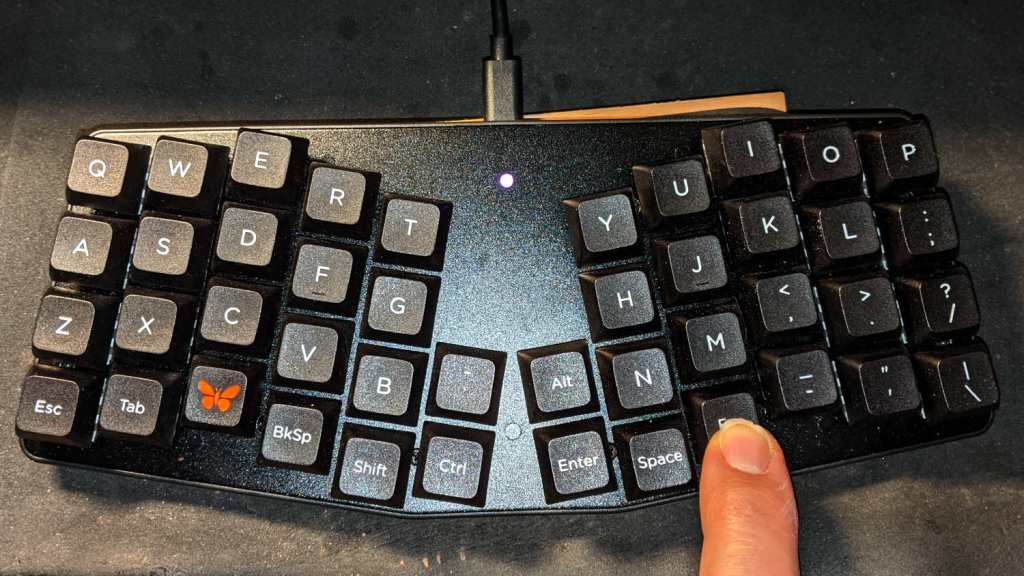

A few variations of speed and depth seem inconclusive, although they look more consistent and much smoother than the diamond-drag engraved line with red fill:

The saw produces a ramp at the entry and exit which I don’t like at all, but the cut is, overall, an improvement on the diamond point.

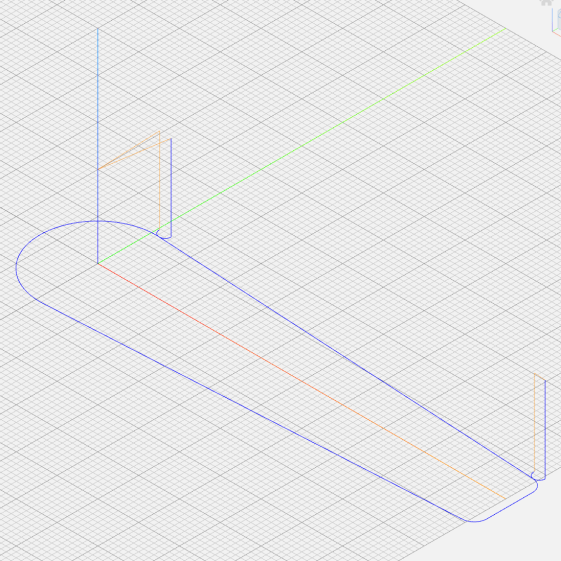

The OpenSCAD source code as a GitHub Gist:

| // Sawing fixtures for Tek Circuit Computer cursor hairline | |

| // Ed Nisley KE4ZNU Jan 2021 | |

| // Rotated 90° and screwed to 123 blocks for sawing | |

| Layout = "Show"; // [Show, Build, Cursor] | |

| Gap = 4.0; | |

| /* [Hidden] */ | |

| ThreadThick = 0.25; | |

| ThreadWidth = 0.40; | |

| HoleWindage = 0.2; | |

| Protrusion = 0.1; // make holes end cleanly | |

| inch = 25.4; | |

| function IntegerMultiple(Size,Unit) = Unit * ceil(Size / Unit); | |

| module PolyCyl(Dia,Height,ForceSides=0) { // based on nophead's polyholes | |

| Sides = (ForceSides != 0) ? ForceSides : (ceil(Dia) + 2); | |

| FixDia = Dia / cos(180/Sides); | |

| cylinder(d=(FixDia + HoleWindage),h=Height,$fn=Sides); | |

| } | |

| //———————- | |

| // Dimensions | |

| CursorHubOD = 1.0*inch; // must match SVG hub OD | |

| CursorThick = 0.71; // including protective layers | |

| HairlineMin = 48.4188; // extent of hairline | |

| HairlineMax = 97.4250; | |

| HairlineDepth = 0.20; | |

| PocketDepth = 0.75*CursorThick; // half above surface for taping | |

| PocketClear = 0.25; // E-Z insertion clearance | |

| TableOC = [1.16*inch,1.16*inch]; // Sherline tooling plate grid | |

| BlockOC = [(9/16)*inch,(9/16)*inch]; // 123 block hole grid | |

| BlockOffset = [(3/8)*inch,(3/8)*inch]; // .. block edge to hole center | |

| ScrewClear = 5.0; // … screw clearance | |

| CursorOffset = [2*BlockOC.x,0,0]; // hub center relative to leftmost screw | |

| FixtureGrid = [5*TableOC.x,0,0]; // size in Table grid units | |

| Screws = [ // relative to leftmost screw | |

| [0,0,0], // on table grid | |

| CursorOffset, // on block grid | |

| [FixtureGrid.x,0,0] // on table grid | |

| ]; | |

| echo(str("Screw centers: ",Screws)); | |

| CornerRad = 10.0; // corner radius | |

| Fixture = [2*CornerRad + FixtureGrid.x,2*CornerRad + CursorHubOD,5.0]; | |

| echo(str("Fixture plate: ",Fixture)); | |

| //———————- | |

| // Import SVG of cursor outline | |

| // Requires our CursorHubOD to match actual cut outline | |

| // Hub center at origin | |

| module CursorSVG(t=CursorThick,ofs=0.0) { | |

| hr = CursorHubOD/2; | |

| translate([-hr,-hr,0]) | |

| linear_extrude(height=t,convexity=3) | |

| offset(r=ofs) | |

| import( | |

| file="/mnt/bulkdata/Project Files/Tektronix Circuit Computer/Firmware/TekCC-Cursor-Mark.svg", | |

| center=false); | |

| } | |

| //———————- | |

| // Show-n-Tell cursor | |

| module Cursor() { | |

| difference() { | |

| CursorSVG(CursorThick,0.0); | |

| translate([0,0,-Protrusion]) | |

| rotate(180/6) | |

| PolyCyl(ScrewClear,CursorThick + 2*Protrusion,6); | |

| } | |

| } | |

| //———————- | |

| // Sawing fixture for cursor hairline | |

| // Plate center at origin | |

| module Fixture() { | |

| difference() { | |

| hull() // basic plate shape | |

| for (i=[-1,1], j=[-1,1]) | |

| translate([i*(Fixture.x/2 – CornerRad),j*(Fixture.y/2 – CornerRad),0]) | |

| cylinder(r=CornerRad,h=Fixture.z,$fn=24); | |

| translate([0,0,Fixture.z – ThreadThick/2 + Protrusion/2]) // will be Z=0 index | |

| cube([2*Fixture.x,ThreadWidth,ThreadThick + Protrusion],center=true); | |

| translate(-FixtureGrid/2) { | |

| translate(CursorOffset + [0,0,Fixture.z – 2*PocketDepth]) | |

| difference() { | |

| CursorSVG(2*PocketDepth + Protrusion,PocketClear); | |

| CursorSVG(PocketDepth + Protrusion,-PocketClear); | |

| } | |

| translate([CursorOffset.x,0,Fixture.z – ThreadThick/2 + Protrusion/2]) // will be front X=0 index | |

| cube([ThreadWidth,2*Fixture.y,ThreadThick + Protrusion],center=true); | |

| translate([CursorOffset.x,Fixture.y/2 – ThreadThick/2 + Protrusion/2,0]) // will be top X=0 index | |

| cube([ThreadWidth,ThreadThick + Protrusion,2*Fixture.z],center=true); | |

| translate([CursorOffset.x + HairlineMin,0,Fixture.z – ThreadThick/2 + Protrusion/2]) // hairline min | |

| cube([ThreadWidth,2*Fixture.y,ThreadThick + Protrusion],center=true); | |

| translate([CursorOffset.x + HairlineMax,0,Fixture.z – ThreadThick/2 + Protrusion/2]) // hairline min | |

| cube([ThreadWidth,2*Fixture.y,ThreadThick + Protrusion],center=true); | |

| /* | |

| # translate(CursorOffset + [0,0,Fixture.z – 2*ThreadThick]) { // alignment pips | |

| for (x=[-20.0,130.0], y=[-30.0,0.0,30.0]) | |

| translate([x,y,0]) | |

| cylinder(d=4*ThreadWidth,h=1,$fn=6); | |

| # for (x=[-30.0,130.0,150.0]) | |

| translate([x,0,0]) | |

| cylinder(d=4*ThreadWidth,h=1,$fn=6); | |

| */ | |

| for (pt=Screws) | |

| translate(pt + [0,0,-Protrusion]) | |

| rotate(180/6) | |

| PolyCyl(ScrewClear,Fixture.z + 2*Protrusion,6); | |

| } | |

| } | |

| } | |

| //———————- | |

| // Build it | |

| if (Layout == "Cursor") { | |

| Cursor(); | |

| } | |

| if (Layout == "Show") { | |

| rotate([0*90,0,0]) { | |

| Fixture(); | |

| color("Green",0.3) | |

| translate(-FixtureGrid/2 + CursorOffset + [0,0,Fixture.z + Gap]) | |

| Cursor(); | |

| } | |

| } | |

| if (Layout == "Build"){ | |

| // rotate(90) | |

| Fixture(); | |

| } | |