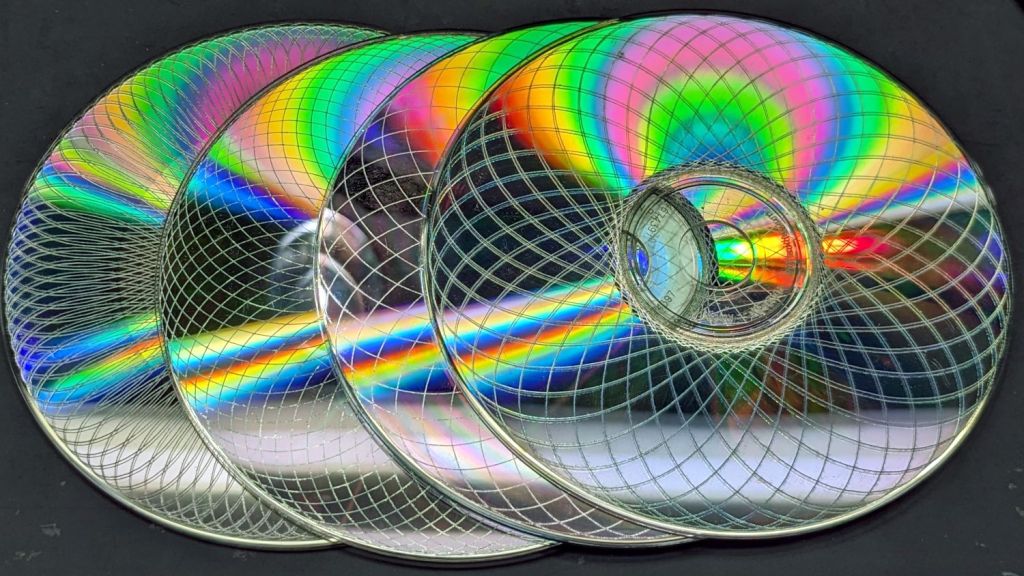

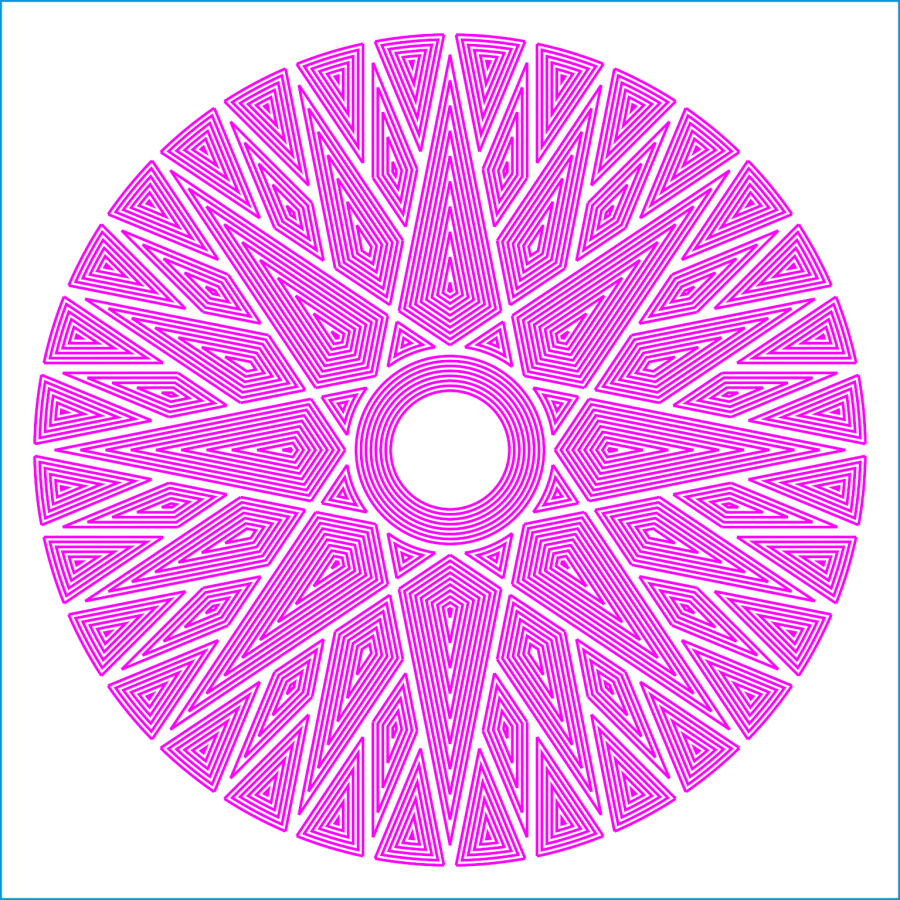

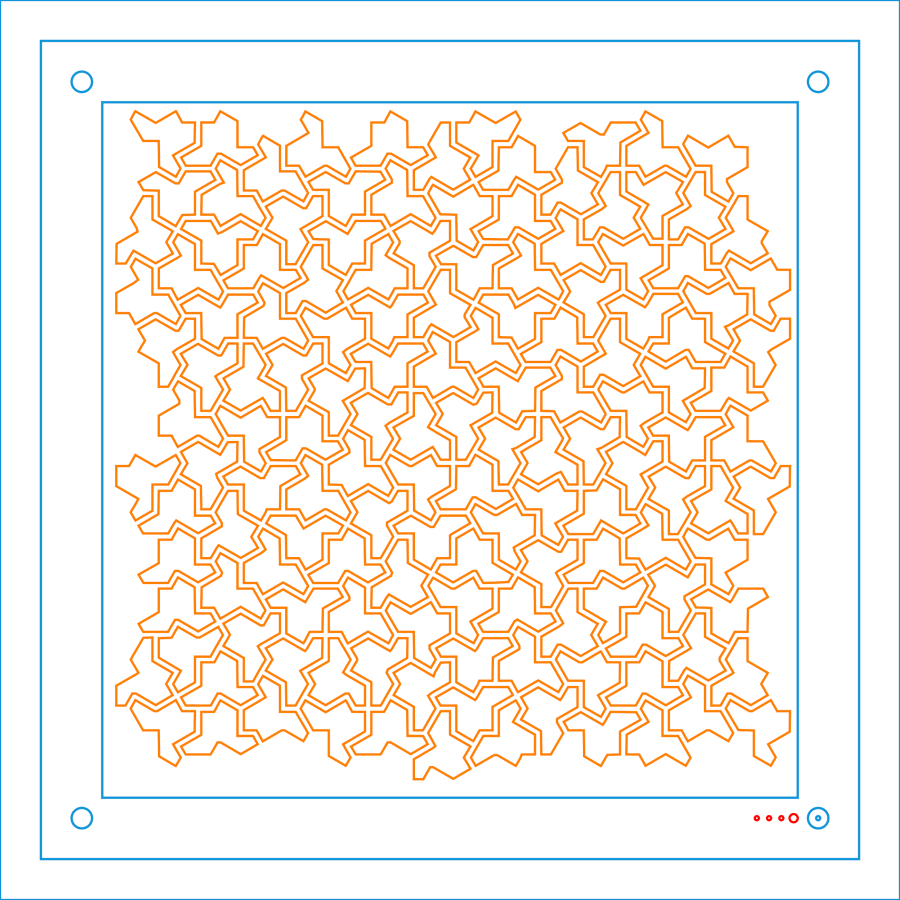

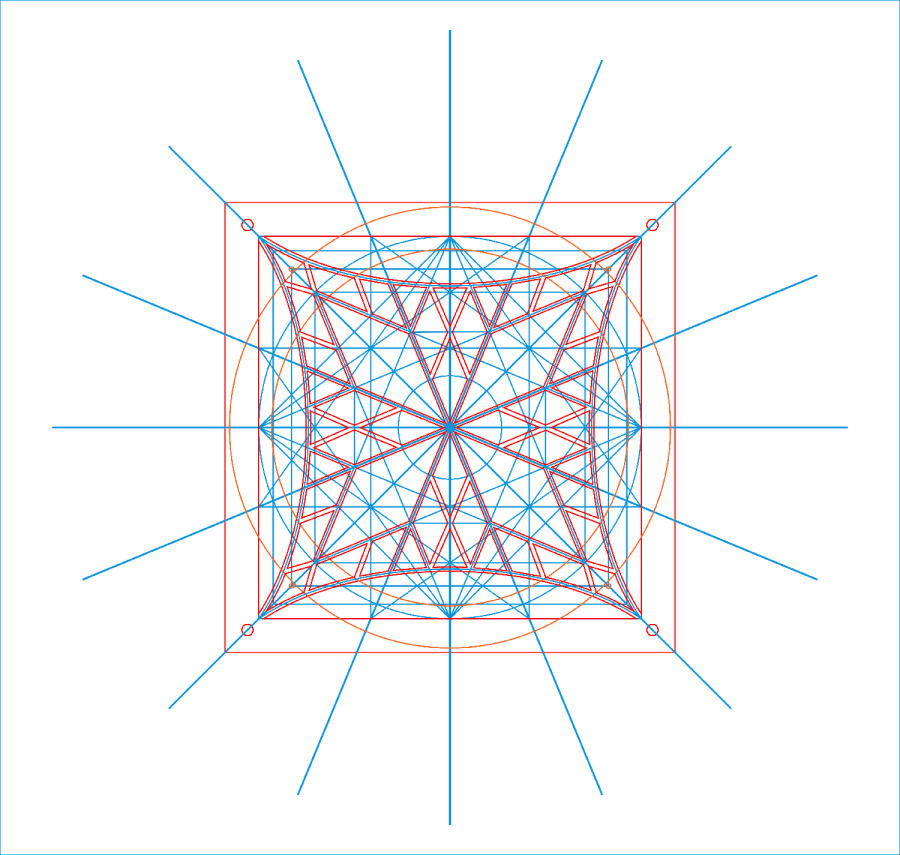

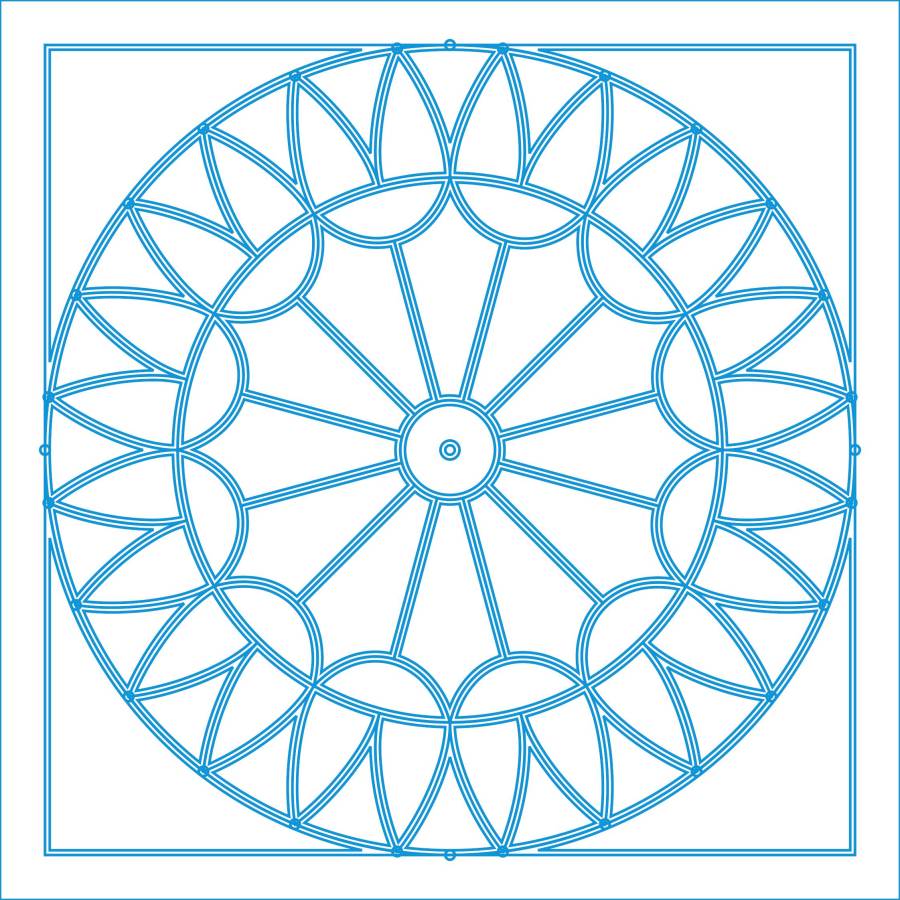

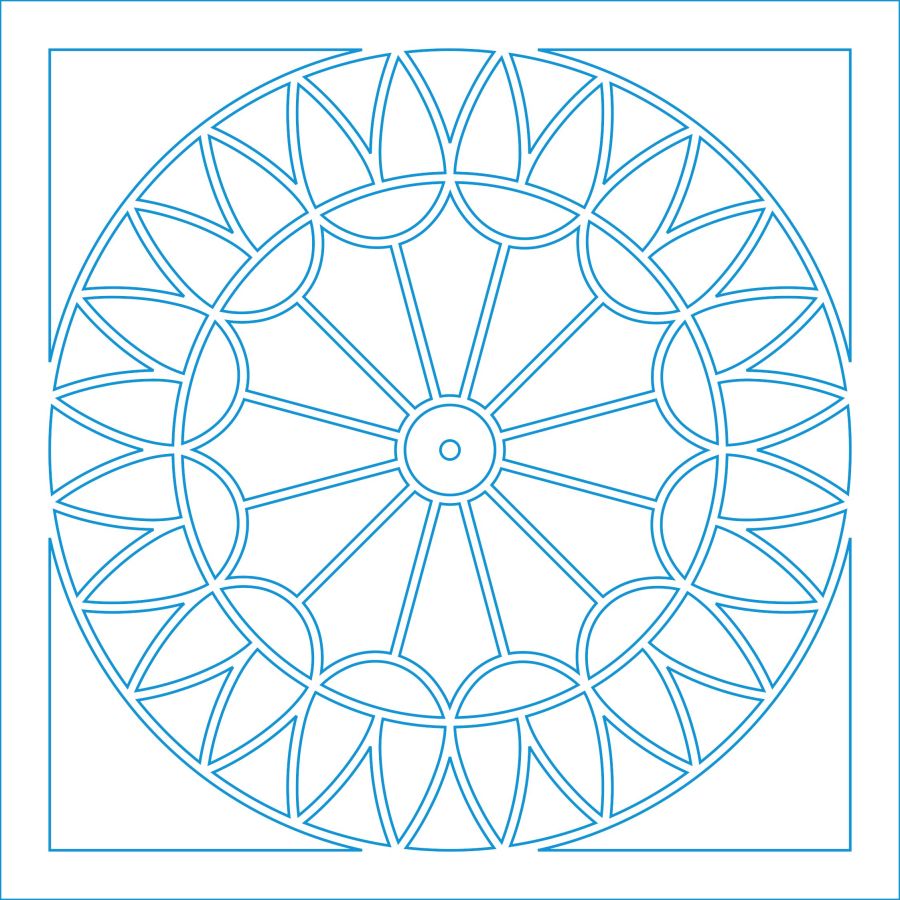

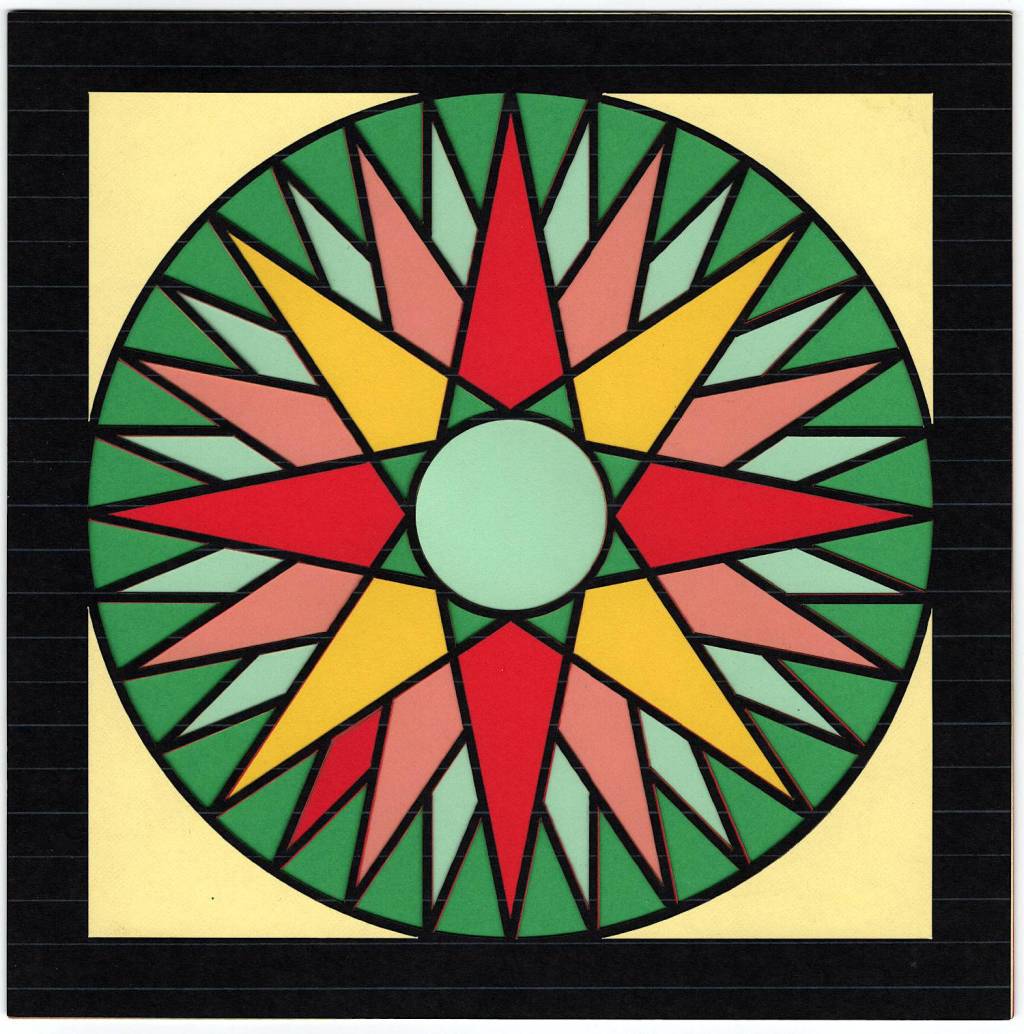

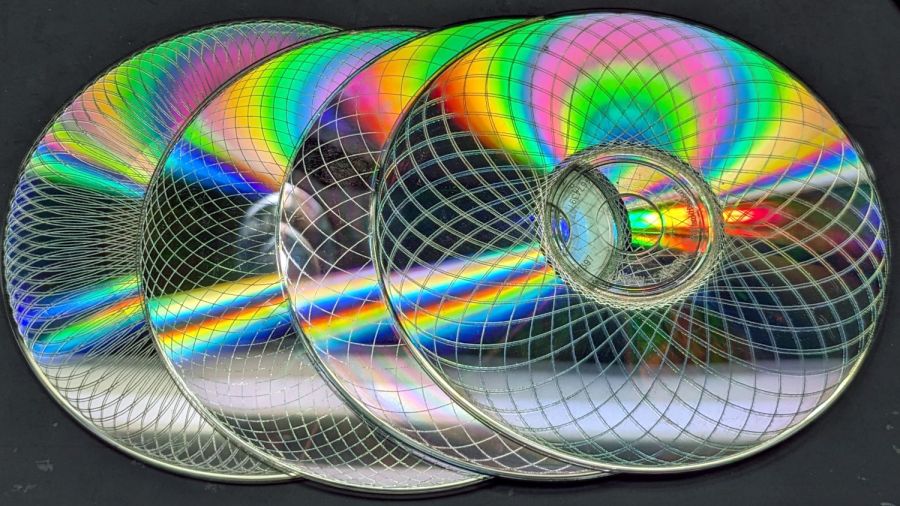

Tweaking the GCMC Guilloche generator to define colors for the SVG layers produces a pattern ready for LightBurn:

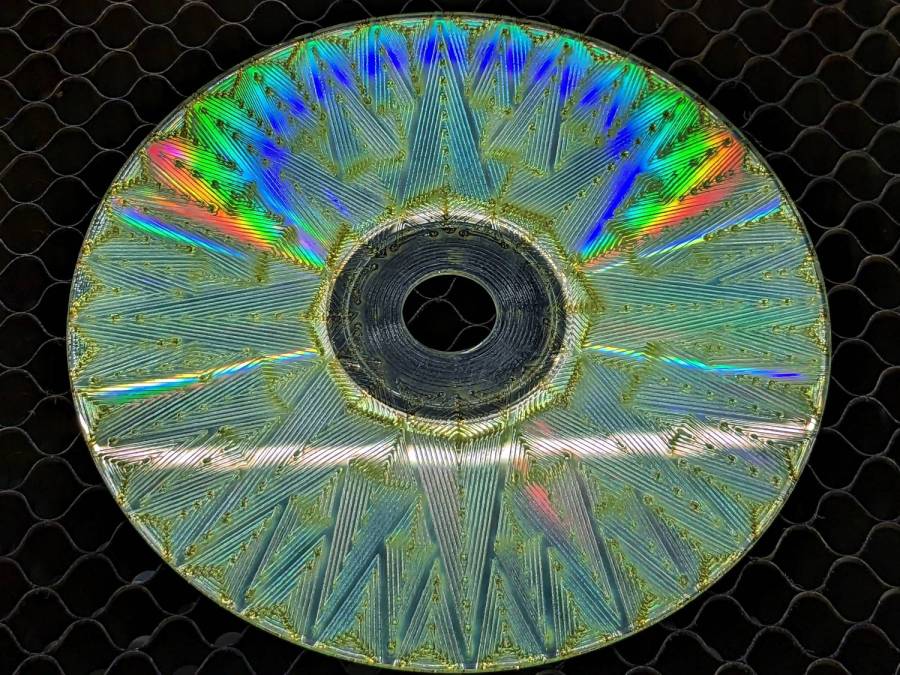

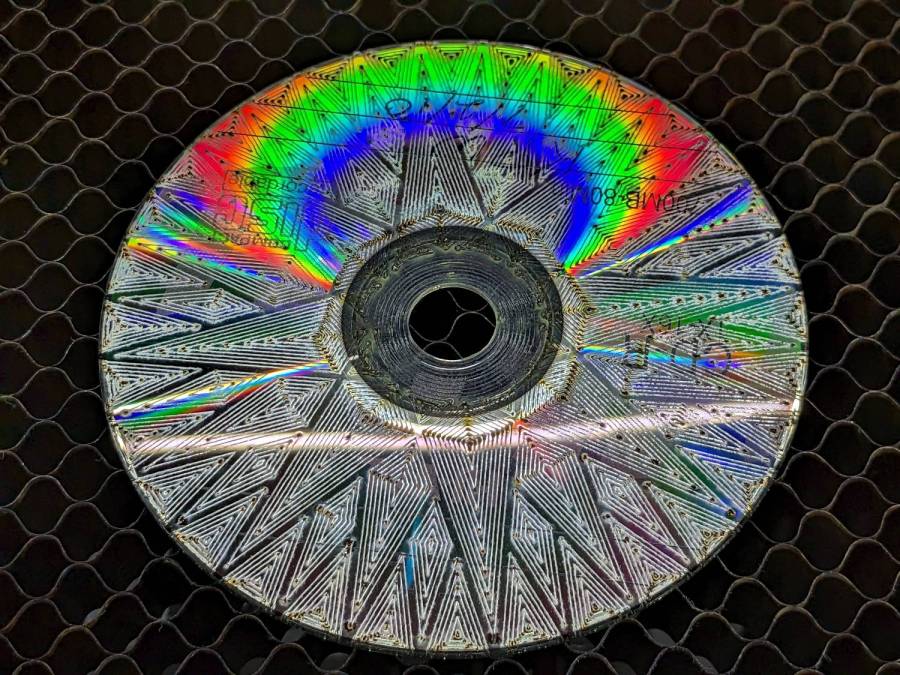

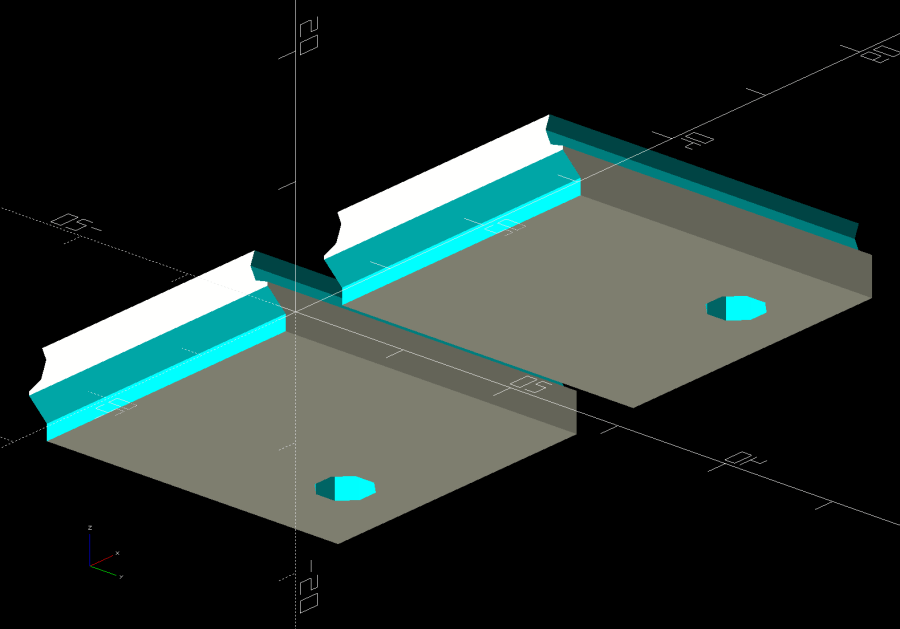

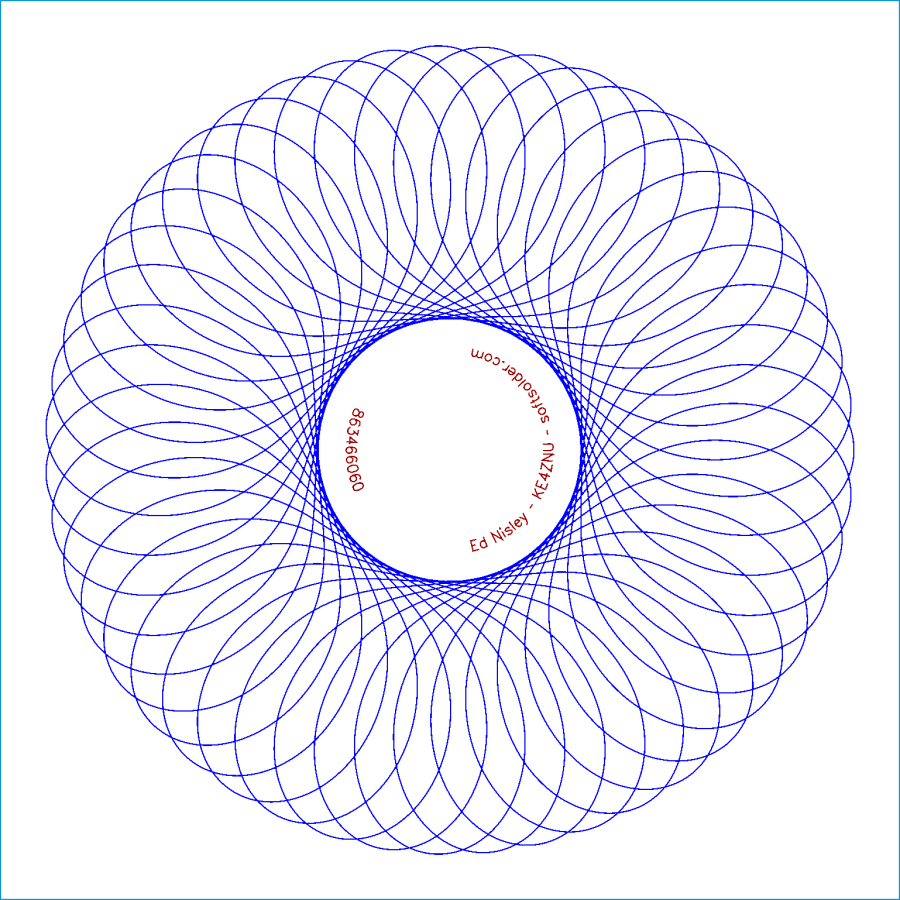

The blue layer runs at 300 mm/s at 10% PWM to carve trenches all over the CD / DVD surface, which should render it unreadable:

The laser runs much faster than a drag knife or a diamond engraving tool!

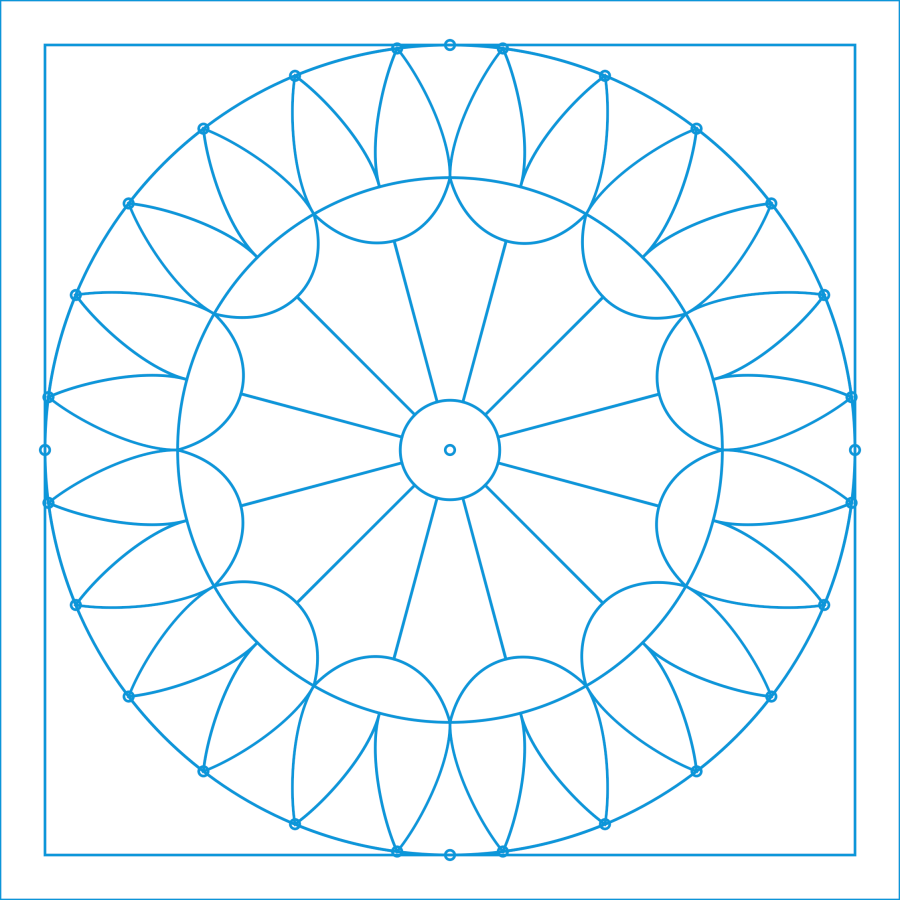

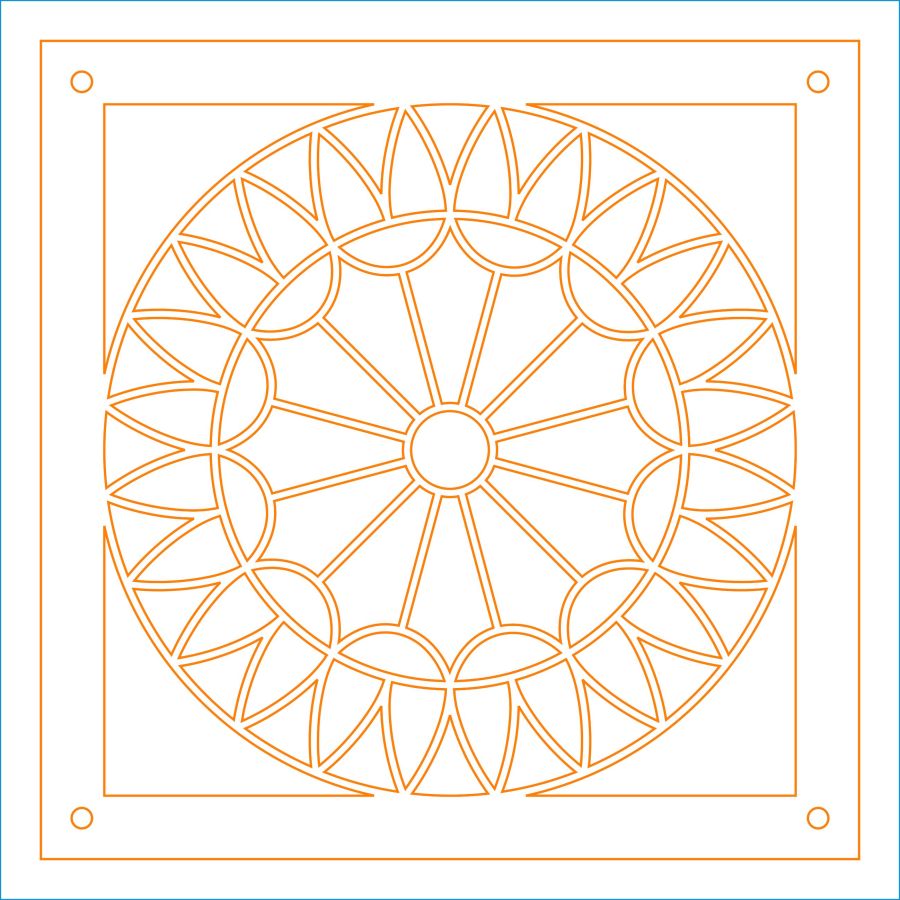

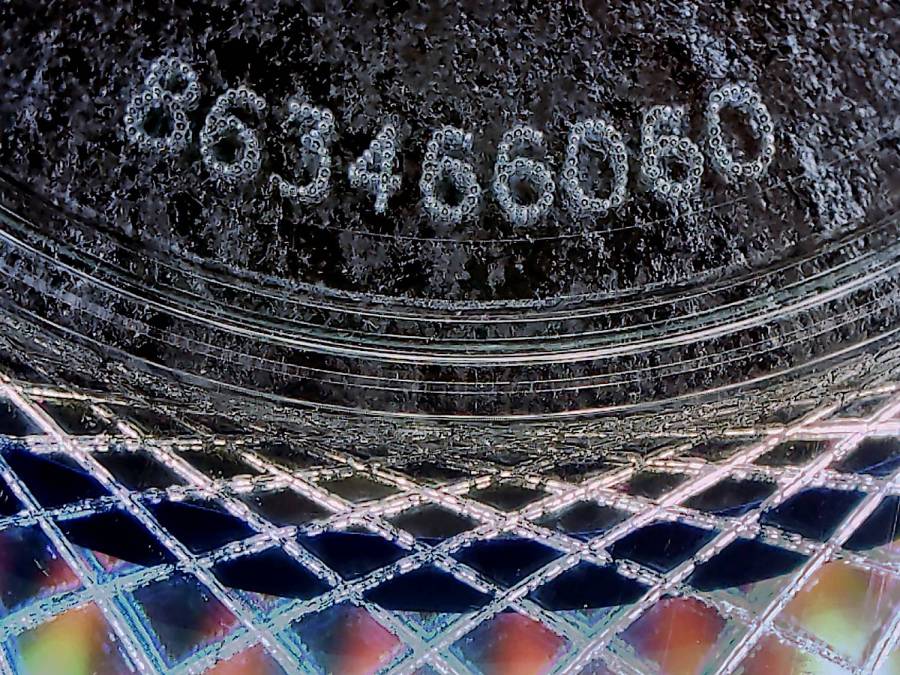

The reddish layer uses Dot mode to draw the legend around the hub:

The characters are 1.5 mm top-to-bottom, with dots just under 0.2 mm diameter on 0.2 mm centers.

Stipulated: there’s no real point to annotating a CD that you’re wrecking, but the code was already there, so why not?

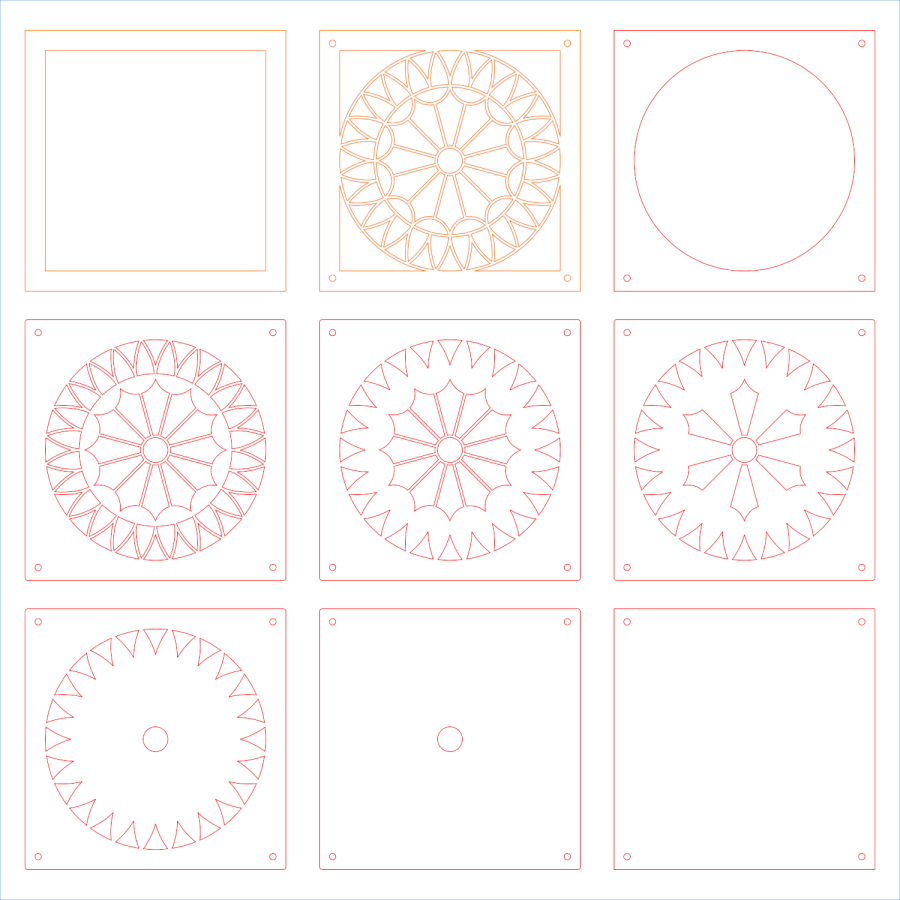

So the overall workflow involves generating an SVG image, importing it into LightBurn with those layers set up with the appropriate cut parameters, using the Three-Point Circle Center Finder tool to align the pattern with the CD, then Fire The Laser. Alignment stops on the laser platform eliminate the need to realign every pattern, so it boils down to running the generator script enough times, importing a batch of patterns, then snapping each one into place and cutting it.

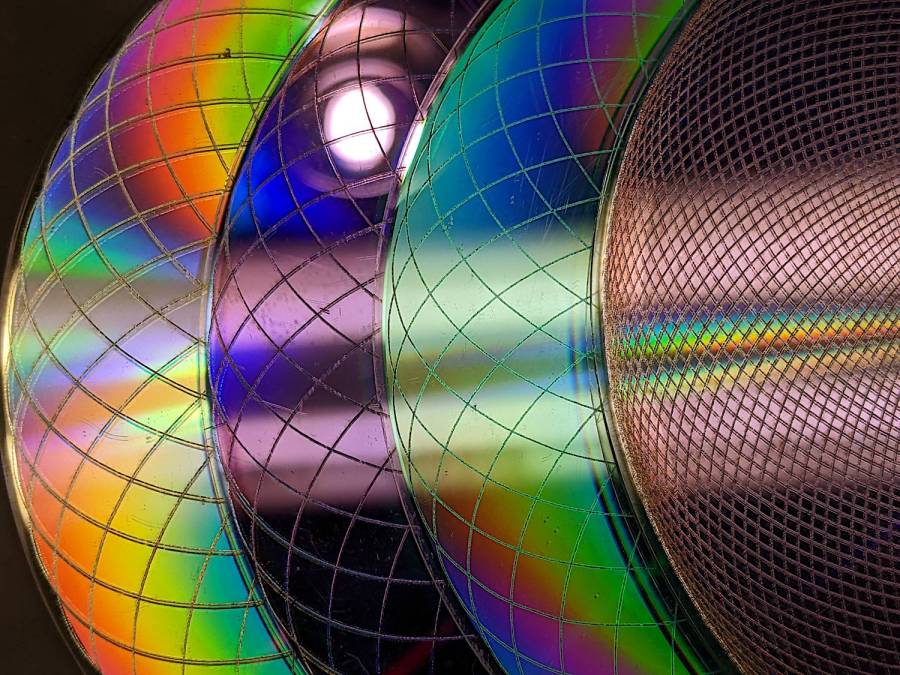

They’re kinda pretty, in the usual techie way:

I have a lot of scrap discs, some ideas of optimizing the process, and a general notion what to do with the prettier results.

The GCMC source code and Bash driver script as a GitHub Gist: