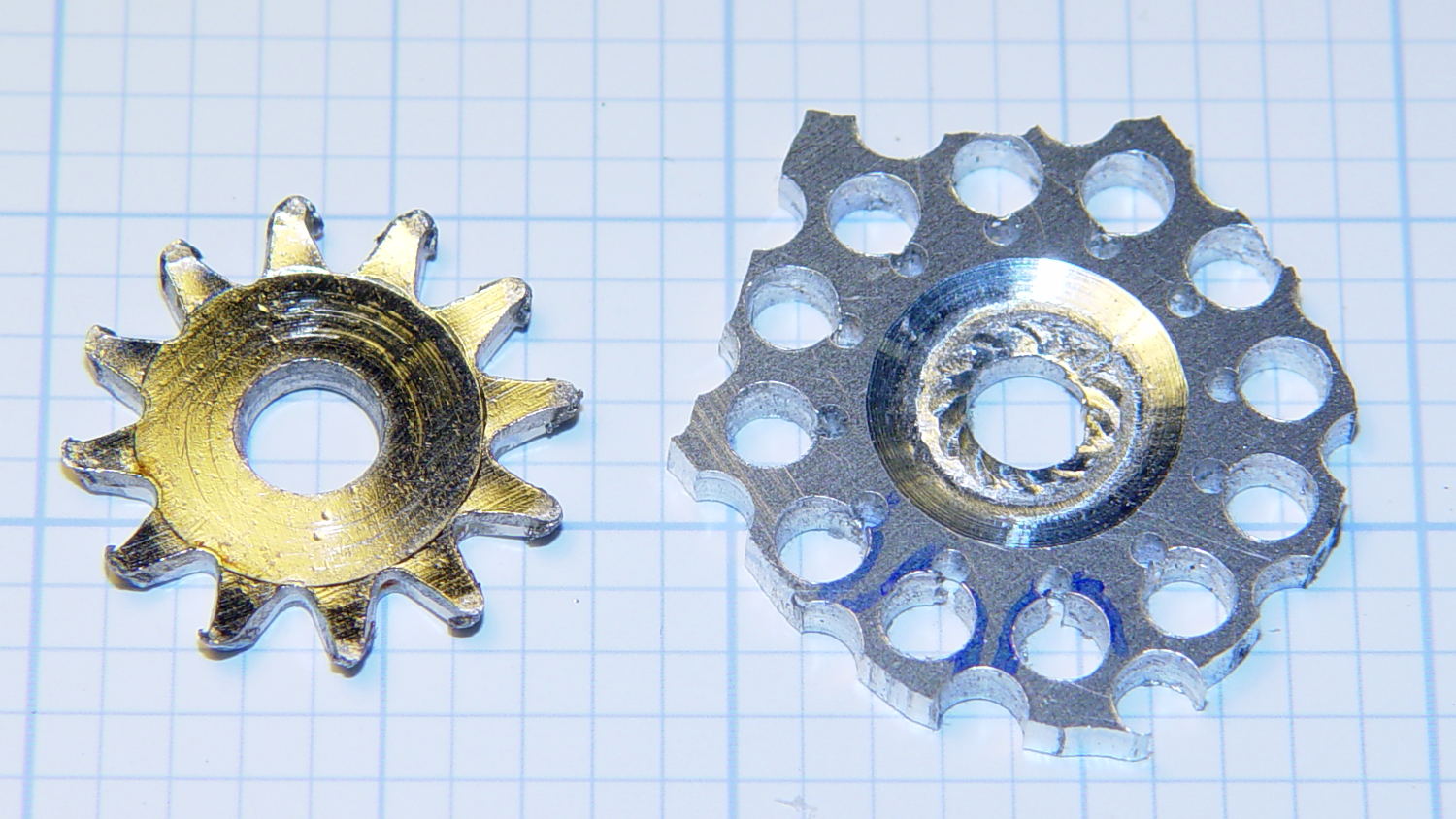

My old Thing-O-Matic has new life as the Frank-O-Squid at Squidwrench Galactic HQ, with all the original Makerbot electronics replaced by an Azteeg X3 controller. Over the last several weeks I’ve coaxed it into doing most of the right things at the proper speeds & feeds, so we can now move on to actually making stuff:

The warping on that little digital caliper thumbwheel holder show that I don’t have the tiny-object slowdown settings quite correct, but it’s getting close.

The Marlin firmware is on GitHub. I intended to set it up so that pulling changes from upstream Marlin would be easy, but totally blundered something along the way. I’ll eventually plug the changes from Configuration.h, Configuration_adv.h, and pins.h into a clean branch and start over, but, for now, we’re slowly diverging from consensus reality.

Although the platform still has the Z-min switch over on the right edge, neither the firmware nor Slic3r pay any attention to it. A stub in the startup G-Code sequence does a head fake toward the switch, but doesn’t actually probe it.

I scrapped the original craptastic Makerbot ATX power supply and replaced it with Makergear’s huge 12 V laptop brick that powered the original M2 platform, so the thermal switches on the extruder no longer do anything useful; it’s running bare, pretty much like all other 3D printers.

The Slic3r configuration exports thusly:

# generated by Slic3r 1.0.0RC1 on Mon Mar 3 07:48:29 2014 avoid_crossing_perimeters = 0 bed_size = 105,120 bed_temperature = 100 bottom_solid_layers = 3 bridge_acceleration = 0 bridge_fan_speed = 100 bridge_flow_ratio = 1 bridge_speed = 40 brim_width = 1.0 complete_objects = 0 cooling = 1 default_acceleration = 0 disable_fan_first_layers = 1000 duplicate = 1 duplicate_distance = 6 duplicate_grid = 1,1 end_gcode = ;---- end.gcode starts ----\n; TOM 286 - Al plates + Geared extruder\n; Ed Nisley - KE4ZNU - January 2014\n; Marlin with tweaks for Azteeg X3 with thermocouple\n;- inhale filament blob\nG91\nG1 E-5 F900\nG90\n;- turn off heaters\nM104 S0 ; extruder head\nM140 S0 ; HBP\n;- move to eject position\nG0 Z115 F1000 ; home Z to get nozzle away from object\n;G92 Z115 ; reset Z\nG1 X0 F6000 ; center X axis\nG1 Y35 ; move Y stage forward\n;---- end.gcode ends ---- external_perimeter_speed = 50% external_perimeters_first = 0 extra_perimeters = 1 extruder_clearance_height = 20 extruder_clearance_radius = 20 extruder_offset = 0x0 extrusion_axis = E extrusion_multiplier = 0.95 extrusion_width = 0.50 fan_always_on = 0 fan_below_layer_time = 1 filament_diameter = 2.95 fill_angle = 45 fill_density = 0.15 fill_pattern = honeycomb first_layer_acceleration = 0 first_layer_bed_temperature = 100 first_layer_extrusion_width = 0.50 first_layer_height = 0.25 first_layer_speed = 10 first_layer_temperature = 210 g0 = 0 gap_fill_speed = 30 gcode_arcs = 0 gcode_comments = 0 gcode_flavor = reprap infill_acceleration = 0 infill_every_layers = 2 infill_extruder = 1 infill_extrusion_width = 0.50 infill_first = 1 infill_only_where_needed = 1 infill_speed = 50 layer_gcode = layer_height = 0.25 max_fan_speed = 100 min_fan_speed = 35 min_print_speed = 10 min_skirt_length = 3 notes = nozzle_diameter = 0.4 only_retract_when_crossing_perimeters = 1 ooze_prevention = 0 output_filename_format = [input_filename_base].gcode overhangs = 1 perimeter_acceleration = 0 perimeter_extruder = 1 perimeter_extrusion_width = 0.50 perimeter_speed = 30 perimeters = 1 post_process = print_center = 0,0 raft_layers = 0 randomize_start = 1 resolution = 0.05 retract_before_travel = 0.0 retract_layer_change = 0 retract_length = 0.75 retract_length_toolchange = 10 retract_lift = 0 retract_restart_extra = 0 retract_restart_extra_toolchange = 0 retract_speed = 30 rotate = 0 scale = 1 skirt_distance = 2 skirt_height = 1 skirts = 1 slowdown_below_layer_time = 30 small_perimeter_speed = 50% solid_fill_pattern = rectilinear solid_infill_below_area = 5 solid_infill_every_layers = 0 solid_infill_extrusion_width = 0.50 solid_infill_speed = 150% spiral_vase = 0 standby_temperature_delta = -5 start_gcode = ;---- start.gcode begins ----\n; TOM 286 - Al plates + Geared extruder + Zmin platform sense\n; Ed Nisley - KE4ZNU - January 2014\n; Marlin with tweaks for Azteeg X3 with thermocouple\n;\n; Set initial conditions\nG21 ; set units to mm\nG90 ; set positioning to absolute\n;----------\n; Begin heating\nM104 S[first_layer_temperature] ; extruder head\nM140 S[first_layer_bed_temperature] ; start bed heating\n;----------\n; Home axes\nG28 X0 Y0 Z0\nG92 X-53.5 Y-58.5 Z114.5\n;----------\n; Initial nozzle wipe to clear snot for Z touchoff\nG1 X0 Y0 Z3.0 F1000 ; pause at center to build confidence\nG4 P1000\nG1 Z10 ; ensure clearance\nG1 X39 Y-58.0 F1000 ; move to front, avoid wiper blade\nG1 X55 ; to wipe station\nG1 Z6.0 ; to wipe level\nM116 ; wait for temperature settling\nG1 Y-45 F500 ; slowly wipe nozzle\n;-----------------------------------------------\n; Z platform height touchoff\n; Make sure the XY position is actually over the switch!\n; Home Z downward to platform switch\n; Compensate for 0.05 mm backlash in G92: make it 0.05 too low\nG1 X56.0 Y8.2 F5000\nG1 Z4.0 F1000 ; get over build platform switch\n;G1 Z0 F50 ; home downward very slowly\n;G92 Z1.45 ; set Z-min switch height\nG1 Z6.0 F1000 ; back off switch to wipe level\n;-----------------------------------------------\n; Prime extruder to stabilize initial pressure\nG1 X55 Y-45 F5000 ; set up for wipe from rear\nG1 Y-58.0 F500 ; wipe to front\nG91 ; use incremental motion for extrusion\nG1 F100 ; set decent rate\nG1 E10 ; extrude enough to get good pressure\nG1 F2000 ; set for fast retract\nG1 E-1.0 ; retract\nG90 ; back to absolute motion\nG1 Y-45 F1000 ; wipe nozzle to rear\n;----------\n; Set up for Skirt start in right front corner\n; Compensate for Z backlash: move upward from zero point\nG1 X40 Y-40 F5000\nG1 Z0.0 F1000 ; kiss platform\nG1 Z0.2 F1000 ; take up Z backlash to less than thread height\n;G92 E1.0 ; preset to avoid huge un-Reversal blob\n;G1 X0 Y0\n;---- start.gcode ends ---- start_perimeters_at_concave_points = 1 start_perimeters_at_non_overhang = 1 support_material = 0 support_material_angle = 0 support_material_enforce_layers = 0 support_material_extruder = 1 support_material_extrusion_width = 0.50 support_material_interface_extruder = 1 support_material_interface_layers = 3 support_material_interface_spacing = 0 support_material_pattern = honeycomb support_material_spacing = 2.5 support_material_speed = 60 support_material_threshold = 0 temperature = 210 thin_walls = 1 threads = 2 toolchange_gcode = top_infill_extrusion_width = 0.50 top_solid_infill_speed = 50% top_solid_layers = 3 travel_speed = 150 use_firmware_retraction = 0 use_relative_e_distances = 0 vibration_limit = 0 wipe = 0 z_offset = 0

All of that should become three TOM286 - Default sub-profiles.

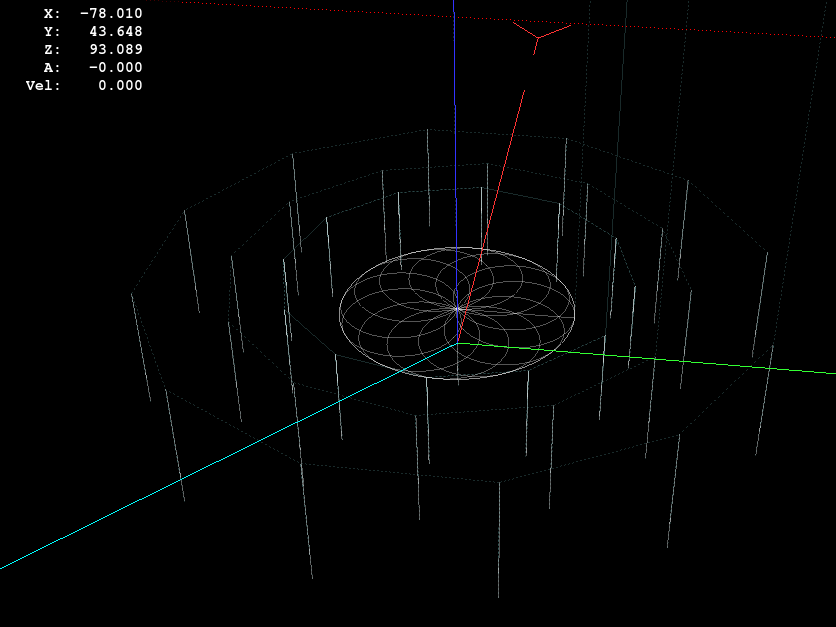

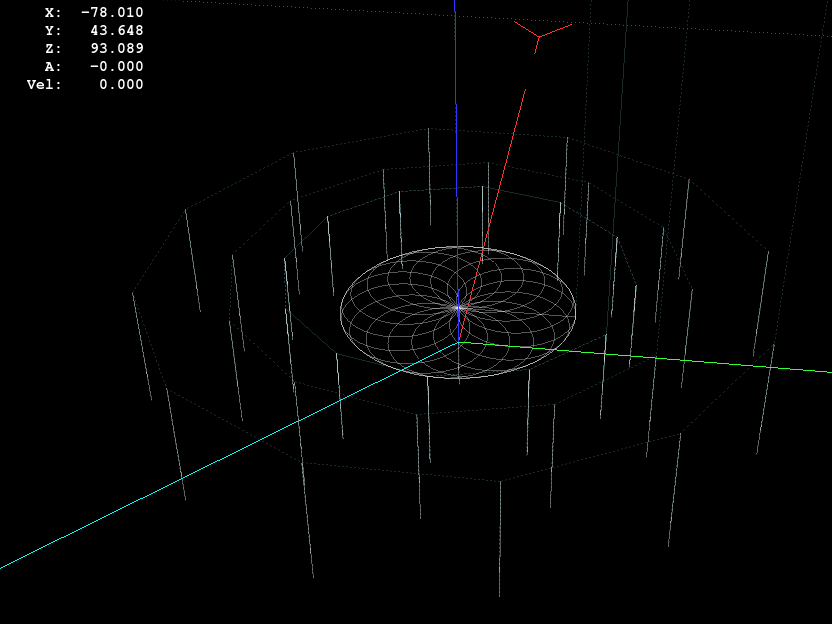

The Pronterface configuration looks like this:

set port /dev/ttyUSB0 set monitor True set last_bed_temperature 100.0 set last_temperature 210.0 set baudrate 115200 set temperature_abs 210 set xy_feedrate 5000 set z_feedrate 1000 set build_dimensions 110.00x120.00x117.00+0.00+0.00+0.00+0.00+0.00+0.00 set extruders 1 set slic3rintegration True set tempgauges True set preview_extrusion_width 0.4 set e_feedrate 100 set last_extrusion 3 set last_file_path /home/ed/Documents/Thing-O-Matic/Calibration/Thread Thickness set recentfiles ["/home/ed/Documents/Thing-O-Matic/Calibration/Thread Thickness/Caliper Thumbwheel Holder.gcode", "/home/ed/Documents/Thing-O-Matic/Calibration/Thread Thickness/Thinwall Open Box.gcode", "/home/ed/Documents/Thing-O-Matic/Calibration/Thread Thickness/Platform Level.gcode", "/home/ed/Documents/Thing-O-Matic/Calibration/Circle Diameter Calibration/Small Circle Cal - M2 0.2 mm.gcode", "/home/ed/Documents/Thing-O-Matic/Calibration/Circle Diameter Calibration/Small Circle Cal - TOM.gcode"]

As you can see, it’s all running from a directory on my old laptop. The next step involves migrating everything to a dedicated PC next to the printer, so nobody else need worry about this stuff…