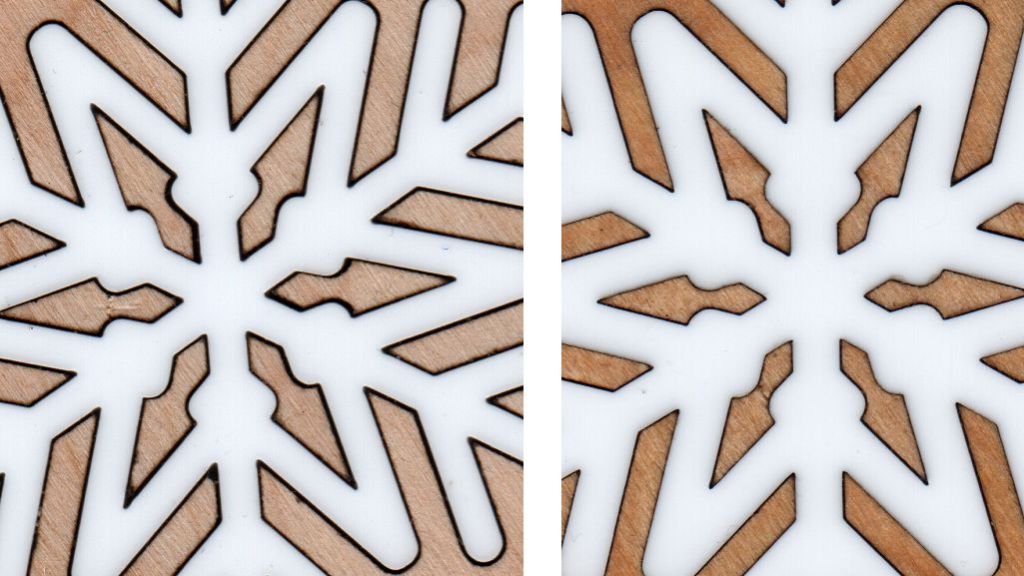

After the first two snowflake coasters, it finally penetrated my thick skill that putting a 1 mm hole in the flake cut from the center of the plywood would convert it into a decorative window hanging:

Admittedly, I may be using the word “decorative” in a manner you had not previously encountered, but work with me on this.

Cutting a similar flake from transparent acrylic looks better:

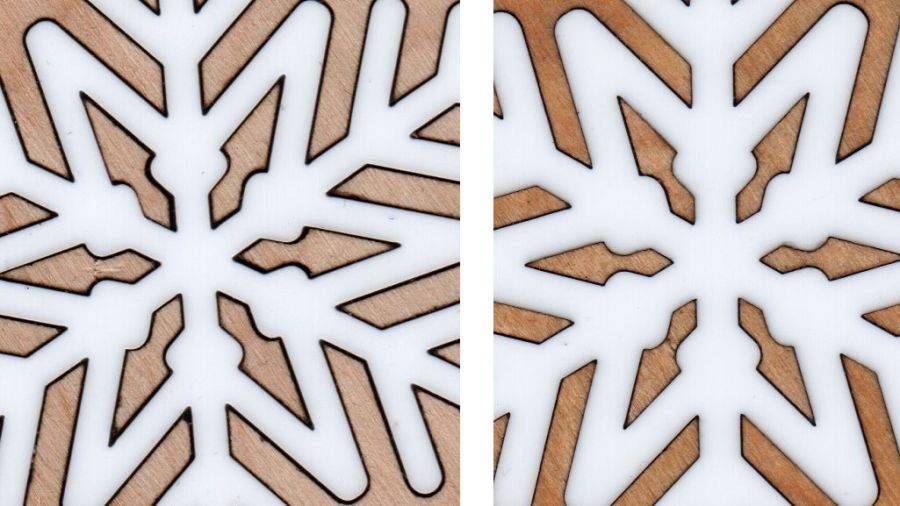

Transparent acrylic turned out to be, well, too transparent, so I set up a LightBurn layout to “engrave” a light frosting on the flake before cutting it out:

That worked for all subsequent flakes, but I had to do something about the first few flakes. After realizing that the time to engrave an object depends only on its width, I set up a rectangle with the proper parameters, snugged two forlorn flakes next to each other, and fired the laser:

I thought using cardboard was a Good Idea™ for a stable backing, but lightly vaporizing the top layer produced an unbelievable amount of filth:

I had to scrub those poor flakes with dish detergent and a toothbrush to get them even close to their former pristine state; the blue one may never recover.

Anyhow, frosted flakes look good if you don’t look closely:

The grid pattern comes from the window screen in direct sunlight; the vertical bars are DIY BirdSavers.

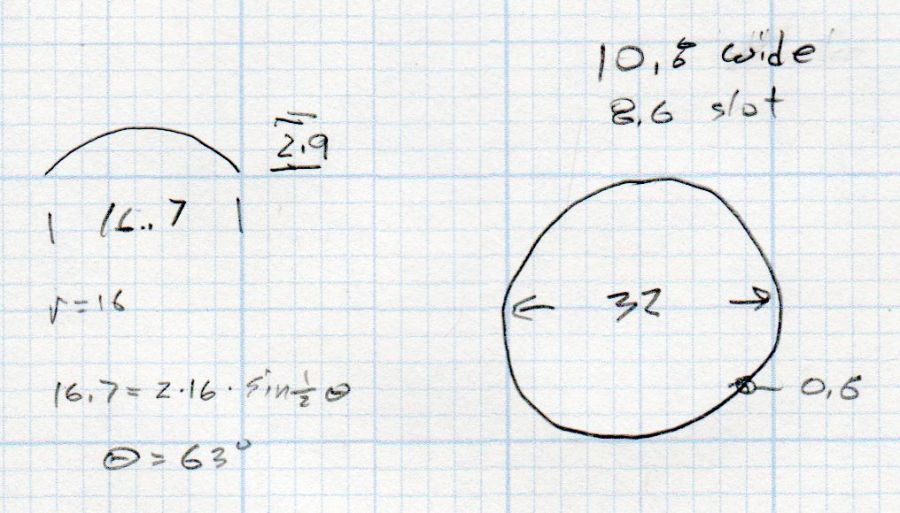

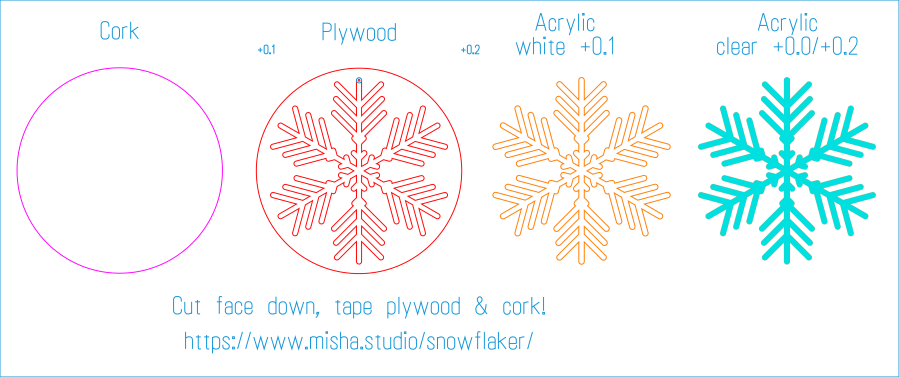

The LightBurn layout produces 120 mm coasters to fit my 20 ounce mugs:

You get two hanging flakes: one plain plywood and one frosted acrylic!

The LightBurn SVG layout as a GitHub Gist: