Being that type of guy, I wanted to salvage a loooong square-head bolt from the utility pole stub formerly holding up the mailboxes, which would require a few gazillion turns of its square head with the Adjustable Elephant Wrench. After verifying I couldn’t just hammer the mumble thing through the pole, I gave a few turns of the Universal Socket on a ratchet:

It’s intended for goobered hex heads up to 1-¼ inch, but the pins slide down around pretty much anything that sticks out and jam against the shell, so it’s handy for those last-ditch extraction events.

After verifying doing this by hand would occupy me until just before the heat death of the universe, I followed Mad Phil’s signal connector adage: “If you can get to BNC, you can get to anything.”

Some rummaging produced this unsteady mechanical ziggurat:

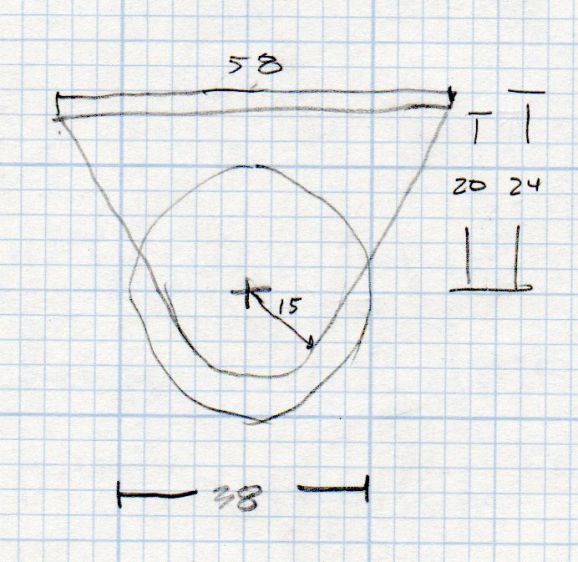

From bottom to top:

- Universal Socket with ½ inch square drive socket

- 1/2 inch square drive to ¾ inch hex

- 19 mm (close enough to ¾ inch) 12-point socket to ⅜ inch square drive socket

- ⅜ inch square drive to ¼ inch square drive socket

- ¼ inch square drive to ¼ inch hex drive

Then stick the teeny end into the hand drill, rig engines for reverse running, and whine away on that bolt, which obligingly backed right out.

After the fact, I found the obviously missing ¼ to ½ inch square drive adapter hiding in the Drawer o’ Sockets:

Which doesn’t make any more sense, but is less likely to fall apart under normal use.

Aaaaand one more adapter makes this possible:

That’s a 50 mm socket turned by ¼ inch hex drive in four easy steps, although I’m reasonably sure it still won’t get the idler bogies off my armored personnel carrier.

The stray adapter steps down from ½ square to ⅜ square, should a need for a breaker bar occur during eyeball surgery.