One of my Wyze V2 cameras either arrived with dead IR hardware or failed early on in its tenure here, but it simply didn’t work in night-vision mode: the IR LEDs didn’t turn on and the IR-cut filter didn’t move. Neither the Official Wyze App nor the Xiaomi-Dafang Hacks firmware had any effect, so I expected a (possibly simple) hardware problem.

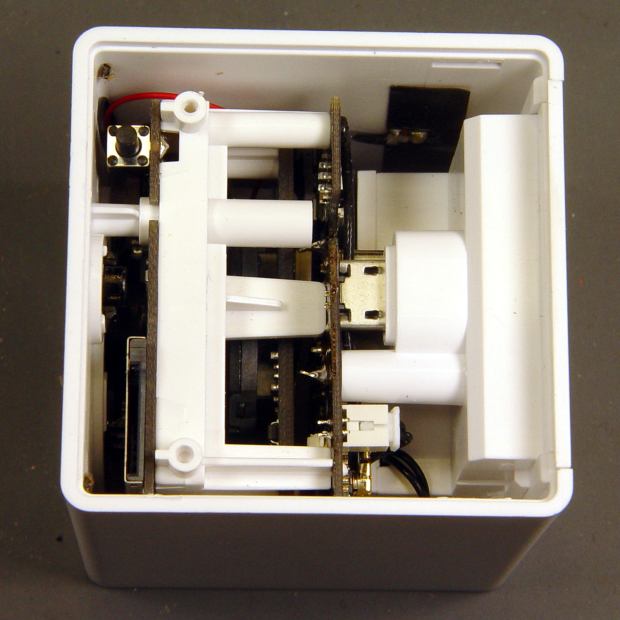

The first hint of trouble was finding the case had only one of the two screws securing its bottom lid, with the missing screw having never been installed. Removing the single screw and prying a bit popped the lid, revealing the innards:

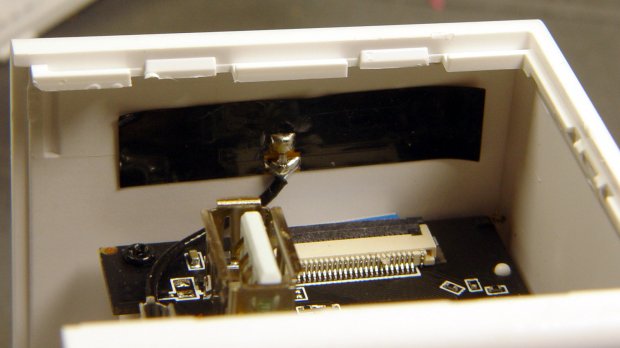

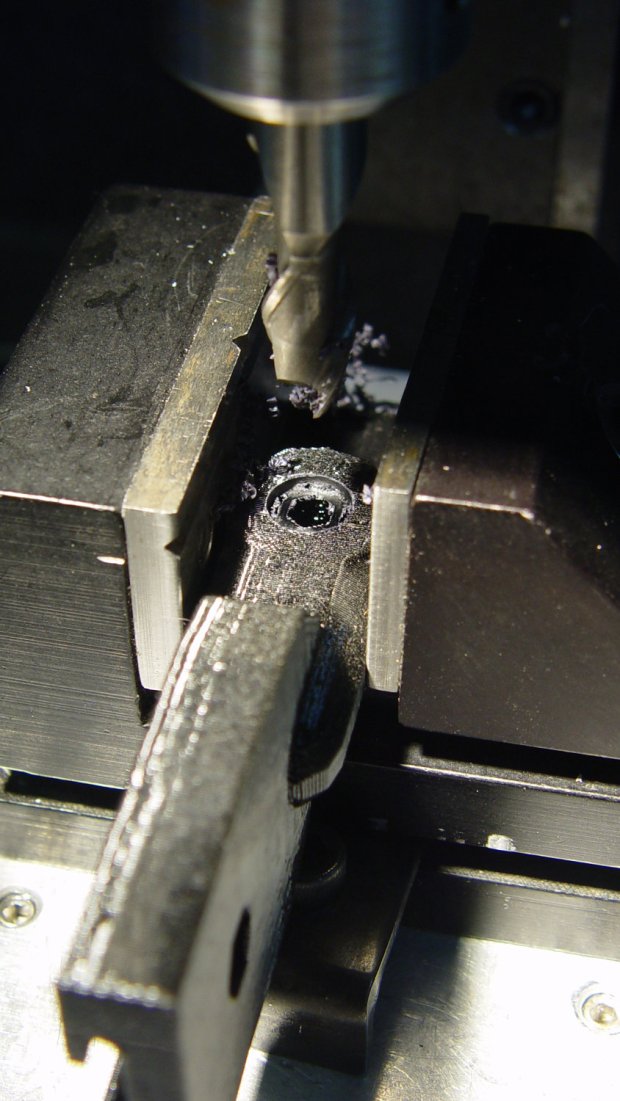

The rear panel (on the right) comes off after abusing the snaps holding it to the main case:

That’s best done with a small, designated Prydriver, rather than a screwdriver to which you have a deep emotional attachment.

The corresponding part of the main body shows less abuse:

The black patch is the WiFi antenna, which you must unplug from the top board before going much further.

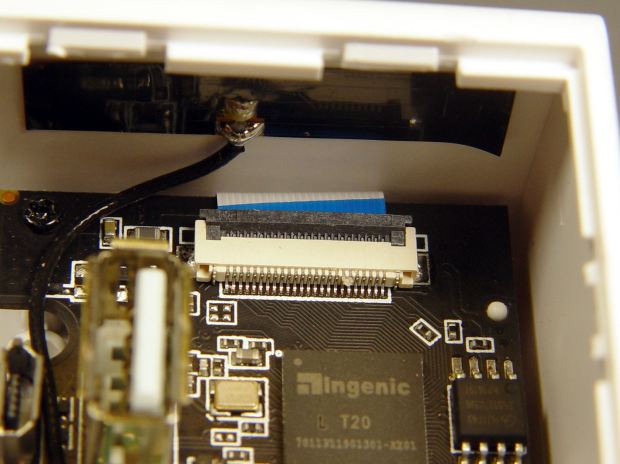

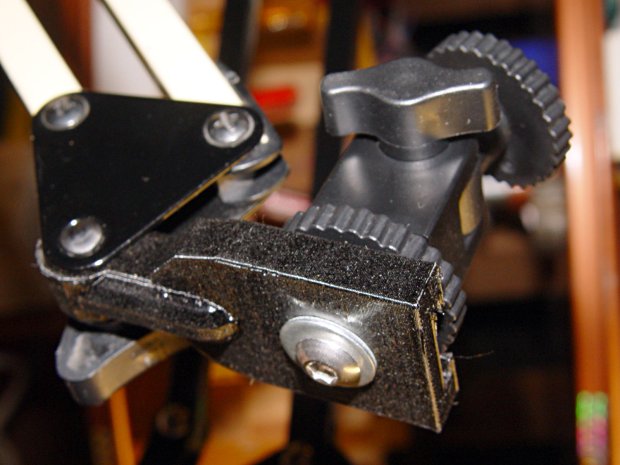

The small blue wedge below the antenna gave me hope I’d found the root of the IR problem:

Everybody has trouble with those delicate ribbon cable socket clamps!

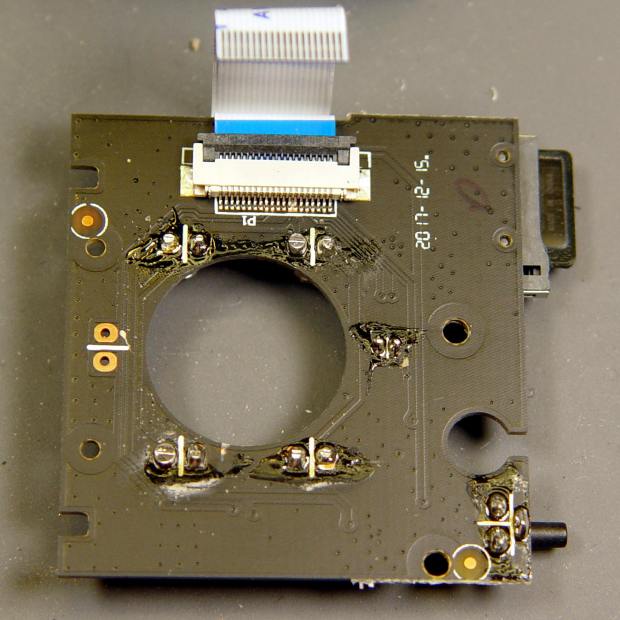

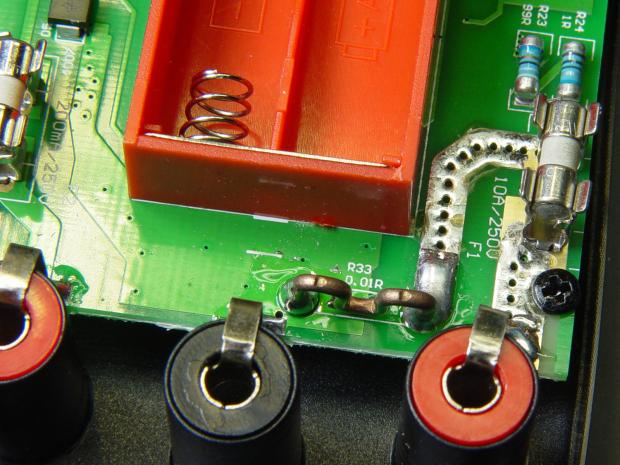

While I had the case open, I extracted everything and looked it over:

The IR LED soldering left a bit to be desired, so I touched up those joints and washed off most of the flux.

Alas, the IR hardware still didn’t work with everything stuffed back in the case. There are worse things than having a small daylight-only IP camera, though.

So it goes …