Having just emptied a propane tank while making bacon, I couldn’t find any of the wrench adapters I made to remove the QD adapter from the tank’s POL fitting. With memory of the broken garden valve wrench still fresh, I tweaked the solid model to include a trio of 1 mm music wire reinforcements:

Holes that small require clearing with a 1 mm drill, after which ramming the wires in place poses no problem:

Except for the one that got away:

The music wire came from a coil and each snippet required gentle straightening; perhaps that one wasn’t sufficiently bar-straight.

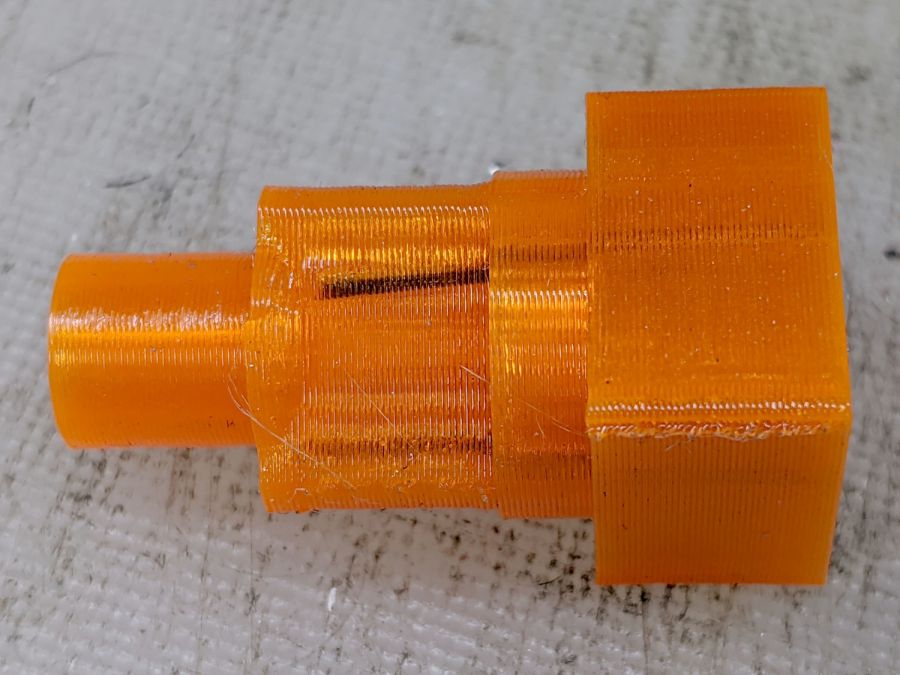

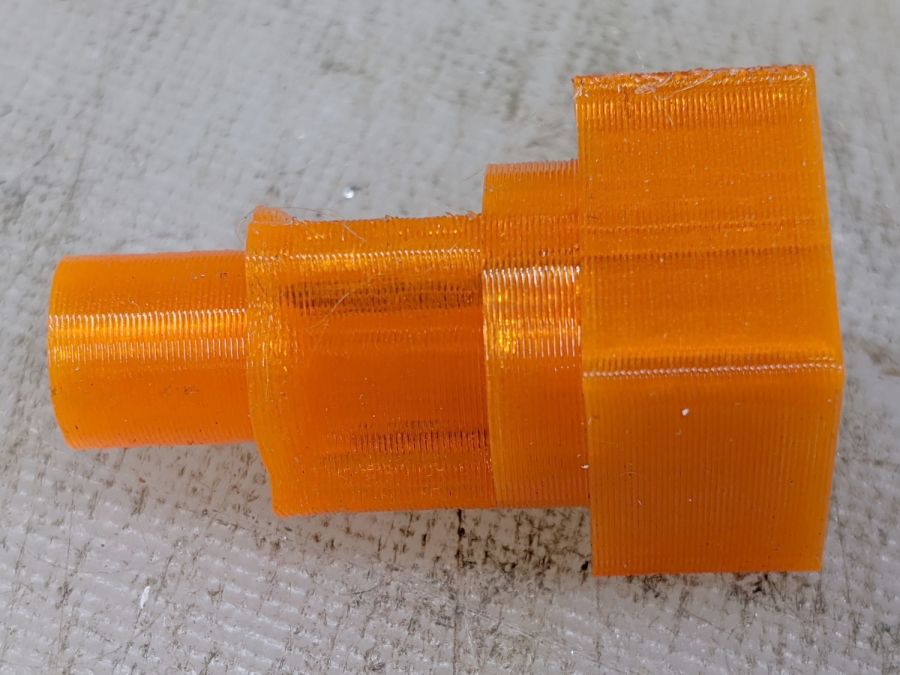

Anyhow, I printed two tools for that very reason:

They’re now where I can’t miss ’em the next time I need them, although that’s not where the previous ones reside.

The OpenSCAD source code as a GitHub Gist:

| // Propane tank QD connector adapter tool | |

| // Ed Nisley KE4ZNU November 2012 | |

| // 2018-04-08 toss MCAD includes overboard | |

| // 2020-07-27 add reinforcing rods | |

| //- Extrusion parameters must match reality! | |

| // Print with about half a dozen perimeter threads and 50% infill | |

| ThreadThick = 0.25; | |

| ThreadWidth = 2.0 * ThreadThick; | |

| HoleWindage = 0.2; | |

| function IntegerMultiple(Size,Unit) = Unit * ceil(Size / Unit); | |

| Protrusion = 0.1; // make holes end cleanly | |

| inch = 25.4; | |

| //———————- | |

| // Dimensions | |

| WrenchSize = (5/8) * inch; // across the flats | |

| WrenchThick = 10; | |

| NoseDia = 8.6; | |

| NoseLength = 9.0; | |

| LockDia = 12.5; | |

| LockRingLength = 1.0; | |

| LockTaperLength = 1.5; | |

| TriDia = 15.1; | |

| TriWide = 12.2; // from OD across center to triangle side | |

| TriOffset = TriWide – TriDia/2; // from center to triangle side | |

| TriLength = 9.8; | |

| NeckDia = TriDia; | |

| NeckLength = 4.0; | |

| RebarOD = 1.0; // music wire pin 1 mm = 39 mil | |

| RebarLength = WrenchThick + NeckLength + TriLength; | |

| //———————- | |

| // Useful routines | |

| module PolyCyl(Dia,Height,ForceSides=0) { // based on nophead's polyholes | |

| Sides = (ForceSides != 0) ? ForceSides : (ceil(Dia) + 2); | |

| FixDia = Dia / cos(180/Sides); | |

| cylinder(r=(FixDia + HoleWindage)/2, | |

| h=Height, | |

| $fn=Sides); | |

| } | |

| //——————- | |

| // Build it… | |

| $fn = 4*6; | |

| union() { | |

| translate([0,0,(WrenchThick + NeckLength + TriLength – LockTaperLength – LockRingLength + Protrusion)]) | |

| cylinder(r1=NoseDia/2,r2=LockDia/2,h=LockTaperLength); | |

| translate([0,0,(WrenchThick + NeckLength + TriLength – LockRingLength)]) | |

| cylinder(r=LockDia/2,h=LockRingLength); | |

| difference() { | |

| union() { | |

| translate([0,0,WrenchThick/2]) | |

| cube([WrenchSize,WrenchSize,WrenchThick],center=true); | |

| cylinder(r=TriDia/2,h=(WrenchThick + NeckLength +TriLength)); | |

| cylinder(r=NoseDia/2,h=(WrenchThick + NeckLength + TriLength + NoseLength)); | |

| } | |

| for (a=[-1:1]) { | |

| rotate(a*120) | |

| translate([(TriOffset + WrenchSize/2),0,(WrenchThick + NeckLength + TriLength/2 + Protrusion/2)]) | |

| cube([WrenchSize,WrenchSize,(TriLength + Protrusion)],center=true); | |

| } | |

| for (a=[-1:1]) { | |

| rotate(a*120 + 60) | |

| translate([NoseDia/2,0,-Protrusion]) | |

| PolyCyl(RebarOD,RebarLength,6); | |

| } | |

| } | |

| } |