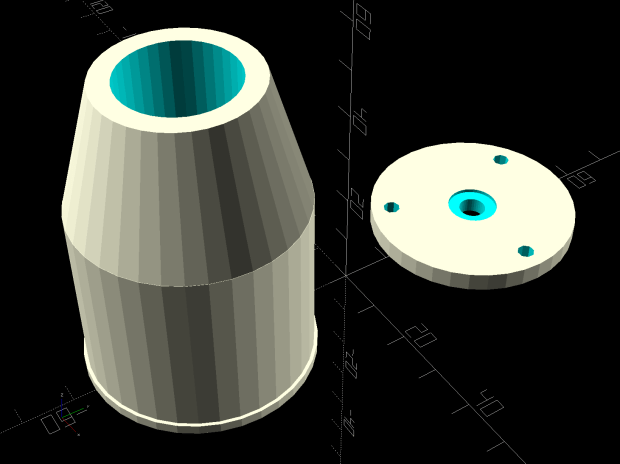

Along the same lines as the MPCNC pen holder, I now have one for the 3018:

The body happened to be slightly longer than two LM12UU linear bearings stacked end-to-end, which I didn’t realize must be a constraint until I was pressing them into place:

In the unlikely event I need another one, the code will sprout a max() function in the appropriate spot.

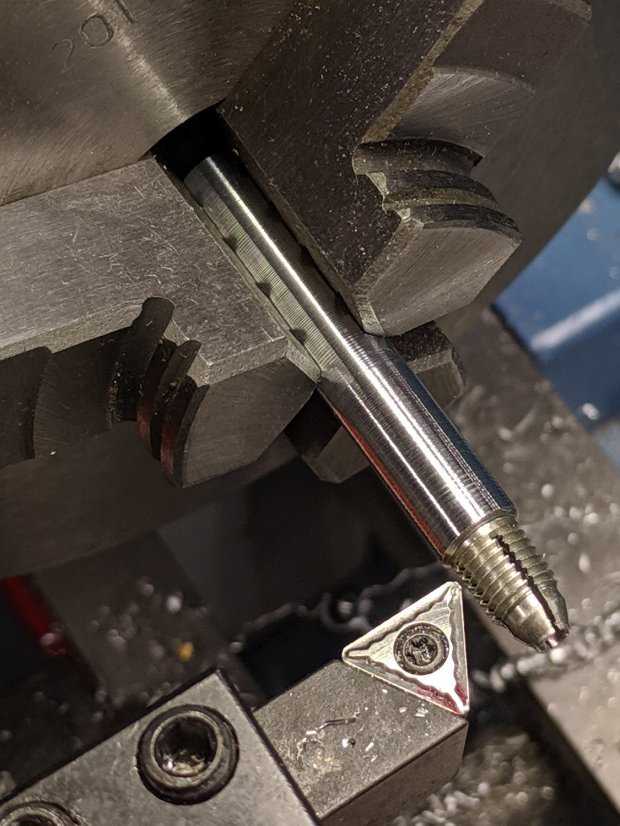

Drilling the aluminum rod for the knurled ring produced a really nice chip:

Yeah, a good drill will produce two chips, but I’ll take what I can get.

There’s not much left of the original holder after turning it down to 8 mm so it fits inside the 12 mm rod:

Confronted by so much shiny aluminum, I realized I didn’t need an 8 mm hole through the rod, so I cut off the collet shaft and drilled out the back end to clear the flanges on the ink tubes:

I figured things would eventually go badly if I trimmed enough ink-filled crimps:

The OpenSCAD source code as a GitHub Gist:

| // Collet Pen Holder in LM12UU linear bearings for CNC3018 | |

| // Ed Nisley KE4ZNU – 2019-10-30 | |

| Layout = "Build"; // [Build, Show, Base, Mount, Plate] | |

| /* [Hidden] */ | |

| ThreadThick = 0.25; // [0.20, 0.25] | |

| ThreadWidth = 0.40; // [0.40, 0.40] | |

| /* [Hidden] */ | |

| Protrusion = 0.1; // [0.01, 0.1] | |

| HoleWindage = 0.2; | |

| inch = 25.4; | |

| function IntegerMultiple(Size,Unit) = Unit * ceil(Size / Unit); | |

| ID = 0; | |

| OD = 1; | |

| LENGTH = 2; | |

| //- Adjust hole diameter to make the size come out right | |

| module PolyCyl(Dia,Height,ForceSides=0) { // based on nophead's polyholes | |

| Sides = (ForceSides != 0) ? ForceSides : (ceil(Dia) + 2); | |

| FixDia = Dia / cos(180/Sides); | |

| cylinder(r=(FixDia + HoleWindage)/2,h=Height,$fn=Sides); | |

| } | |

| //- Dimensions | |

| PenOD = 3.5; // pen cartridge diameter | |

| Bearing = [12.0,21.0,30.0]; // linear bearing body | |

| SpringSeat = [0.56,10.0,3*ThreadThick]; // wire = ID, coil = OD, seat depth = length | |

| WallThick = 4.0; // minimum thickness / width | |

| Screw = [3.0,6.75,25.0]; // holding it all together, OD = washer | |

| Insert = [3.0,5.5,8.2]; // brass insert | |

| //Insert = [4.0,6.0,10.0]; | |

| Clamp = [43.2,44.5,34.0]; // tool clamp ring, OD = clearance around top | |

| LipHeight = IntegerMultiple(2.0,ThreadThick); // above clamp for retaining | |

| BottomExtension = 25.0; // below clamp to reach workpiece | |

| MountOAL = LipHeight + Clamp[LENGTH] + BottomExtension; // total mount length | |

| echo(str("Mount OAL: ",MountOAL)); | |

| Plate = [1.5*PenOD,Clamp[ID] – 0*2*WallThick,WallThick]; // spring reaction plate | |

| NumScrews = 3; | |

| ScrewBCD = Bearing[OD] + Insert[OD] + 2*WallThick; | |

| echo(str("Retainer max OD: ",ScrewBCD – Screw[OD])); | |

| NumSides = 9*4; // cylinder facets (multiple of 3 for lathe trimming) | |

| // Basic mount shape | |

| module CNC3018Base() { | |

| translate([0,0,MountOAL – LipHeight]) | |

| cylinder(d=Clamp[OD],h=LipHeight,$fn=NumSides); | |

| translate([0,0,MountOAL – LipHeight – Clamp[LENGTH] – Protrusion]) | |

| cylinder(d=Clamp[ID],h=(Clamp[LENGTH] + 2*Protrusion),$fn=NumSides); | |

| cylinder(d1=Bearing[OD] + 2*WallThick,d2=Clamp[ID],h=BottomExtension + Protrusion,$fn=NumSides); | |

| } | |

| // Mount with holes & c | |

| module Mount() { | |

| difference() { | |

| CNC3018Base(); | |

| translate([0,0,-Protrusion]) // bearing | |

| PolyCyl(Bearing[OD],2*MountOAL,NumSides); | |

| for (i=[0:NumScrews – 1]) // clamp screws | |

| rotate(i*360/NumScrews) | |

| translate([ScrewBCD/2,0,MountOAL – Clamp[LENGTH]]) | |

| rotate(180/8) | |

| PolyCyl(Insert[OD],Clamp[LENGTH] + Protrusion,8); | |

| } | |

| } | |

| module SpringPlate() { | |

| difference() { | |

| cylinder(d=Plate[OD],h=Plate[LENGTH],$fn=NumSides); | |

| translate([0,0,-Protrusion]) | |

| PolyCyl(Plate[ID],2*MountOAL,NumSides); | |

| translate([0,0,Plate.z – SpringSeat[LENGTH]]) // spring retaining recess | |

| PolyCyl(SpringSeat[OD],SpringSeat[LENGTH] + Protrusion,NumSides); | |

| for (i=[0:NumScrews – 1]) // clamp screws | |

| rotate(i*360/NumScrews) | |

| translate([ScrewBCD/2,0,-Protrusion]) | |

| rotate(180/8) | |

| PolyCyl(Screw[ID],2*MountOAL,8); | |

| } | |

| } | |

| //—– | |

| // Build it | |

| if (Layout == "Base") | |

| CNC3018Base(); | |

| if (Layout == "Mount") | |

| Mount(); | |

| if (Layout == "Plate") | |

| SpringPlate(); | |

| if (Layout == "Show") { | |

| Mount(); | |

| translate([0,0,1.25*MountOAL]) | |

| rotate([180,0,0]) | |

| SpringPlate(); | |

| } | |

| if (Layout == "Build") { | |

| translate([0,-0.75*Clamp[OD],MountOAL]) | |

| rotate([180,0,0]) | |

| Mount(); | |

| translate([0,0.75*Plate[OD],0]) | |

| SpringPlate(); | |

| } |

Comments

6 responses to “CNC 3018-Pro: Collet Pen Holder”

[…] length ($131=338) and puts the G54 coordinate at the new middle, with the Z-axis origin kissing the ball-point pen on the new […]

[…] superscripts, but the characters already live at the small end of what’s do-able with a ballpoint pen cartridge. Engraving will surely work better, but stylin’ exponents are definitely in the nature of […]

[…] Shared bon Soft Solder: […]

[…] Cheap Chinese 1.0 mm pen cartridge […]

[…] Fine Pilot V5 pens have a 0.5 mm ball, in contrast to the 1.0 mm ball in the cheap pens I’ve been using, so they should produce much finer […]

[…] For reference, the cheap pens use a collet holder: […]