|

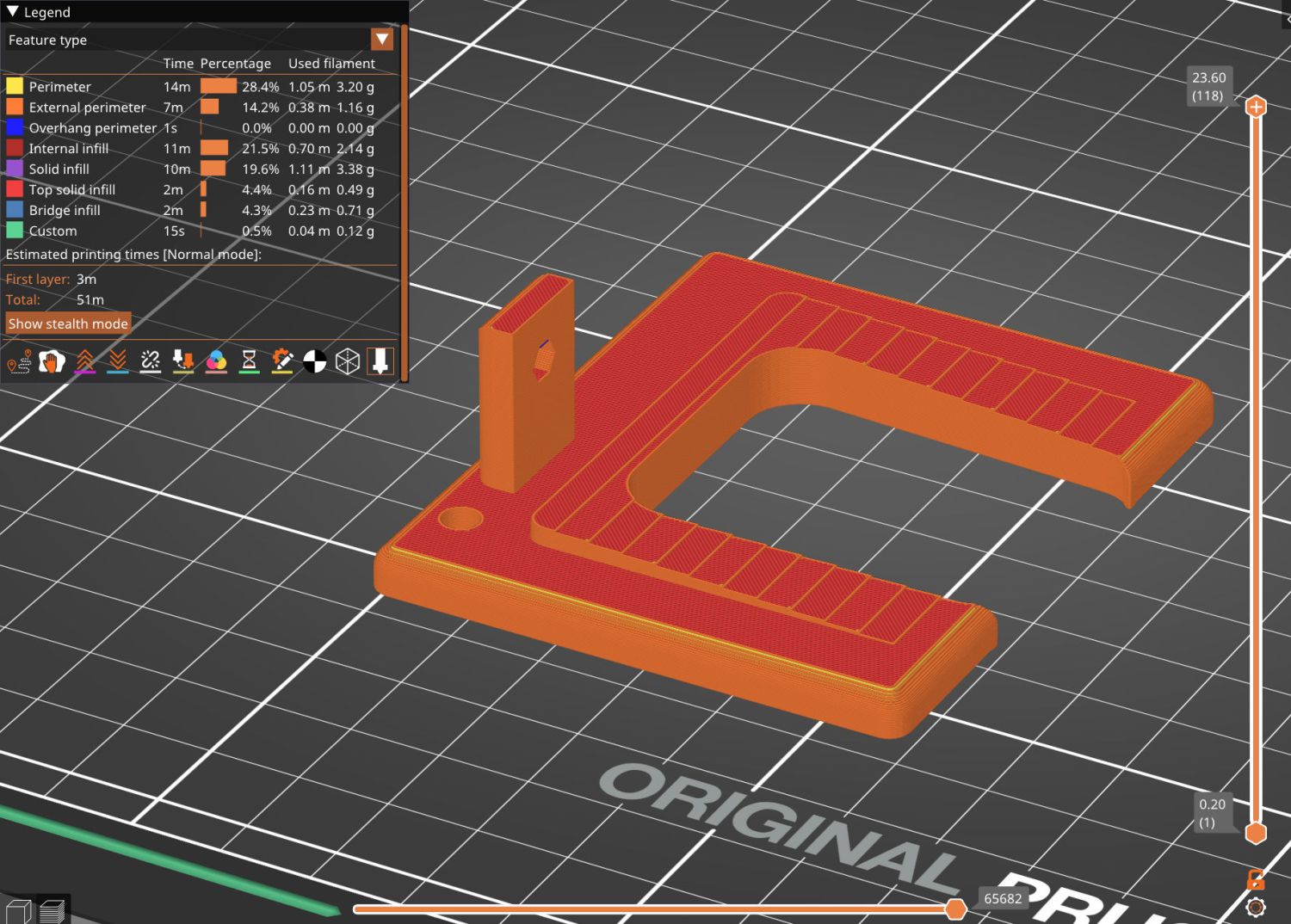

// HQ Sixteen Nose Ring Lights |

|

// Ed Nisley – KE4ZNU |

|

// 2025-05-23 |

|

|

|

include <BOSL2/std.scad> |

|

|

|

Layout = "Show"; // [Show,Build,NosePlan,PowerCap] |

|

|

|

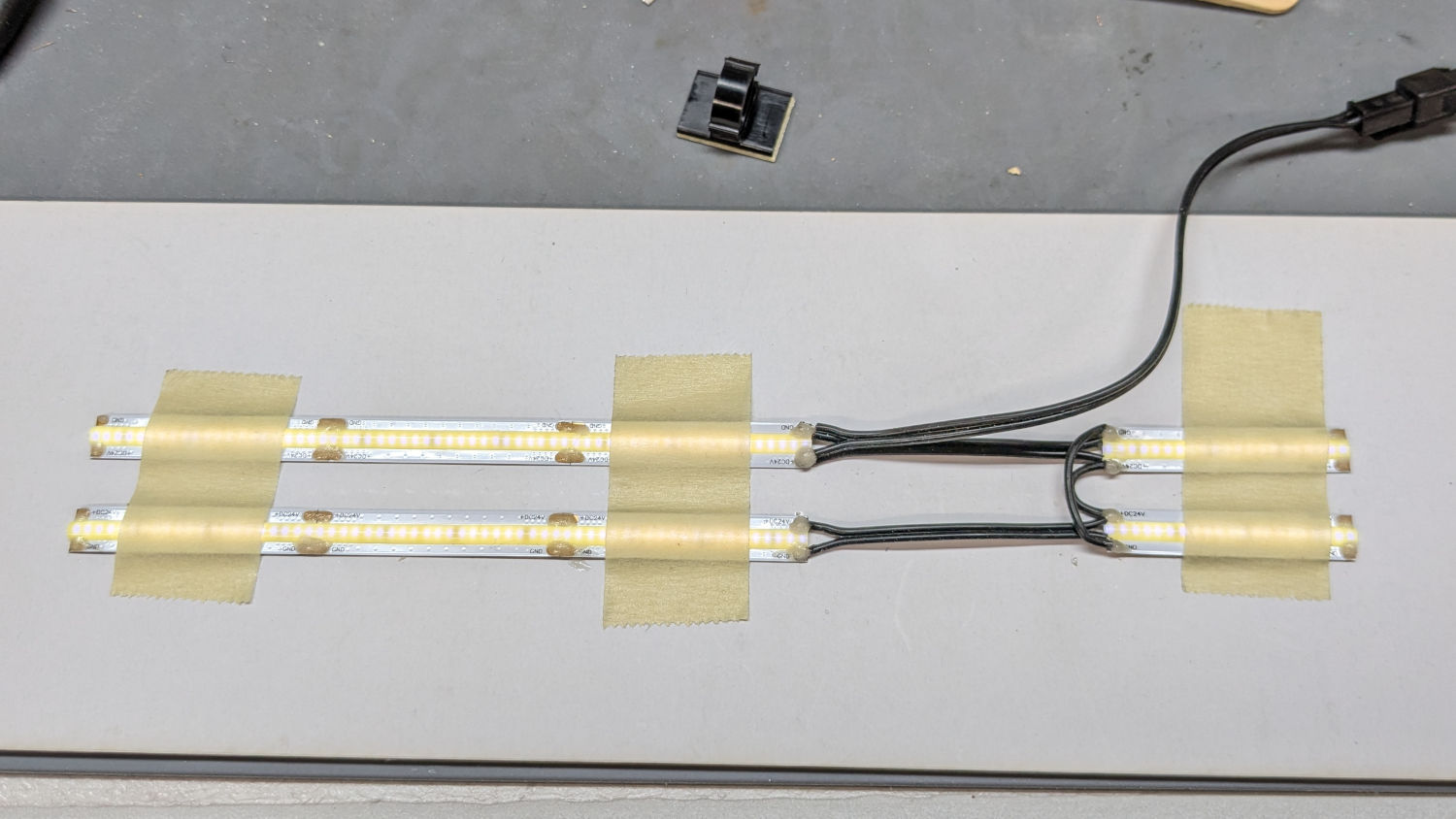

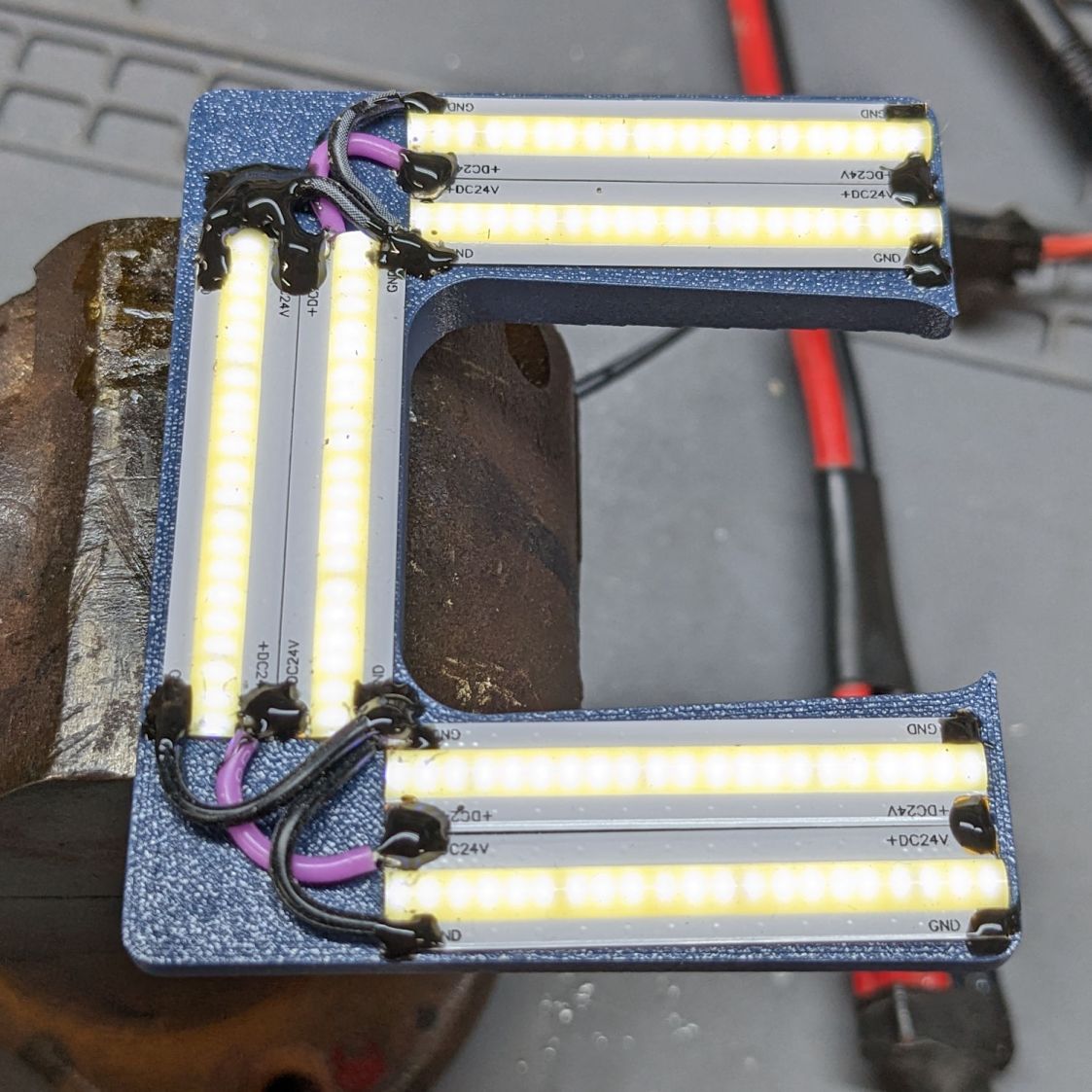

// Number of side-by-side LED strips |

|

Strips = 2; |

|

|

|

/* [Hidden] */ |

|

|

|

HoleWindage = 0.2; |

|

Protrusion = 0.1; |

|

NumSides = 3*3*4; |

|

|

|

$fn=NumSides; |

|

|

|

ID = 0; |

|

OD = 1; |

|

LENGTH = 2; |

|

|

|

Gap = 5.0; |

|

|

|

WallThick = 5.0; // default thickness for things |

|

|

|

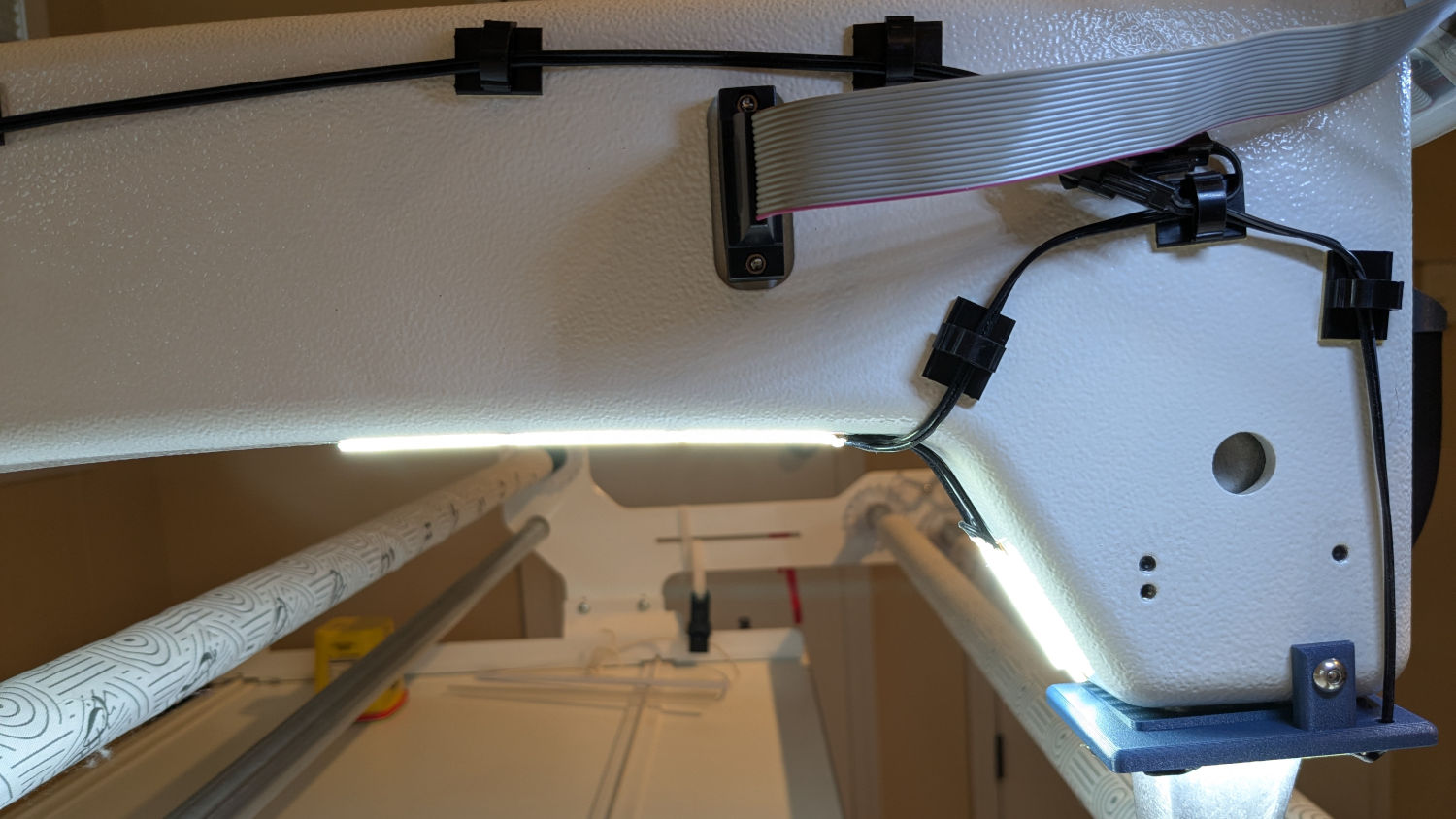

NoseRadius = 6.0; // corner roundoff |

|

|

|

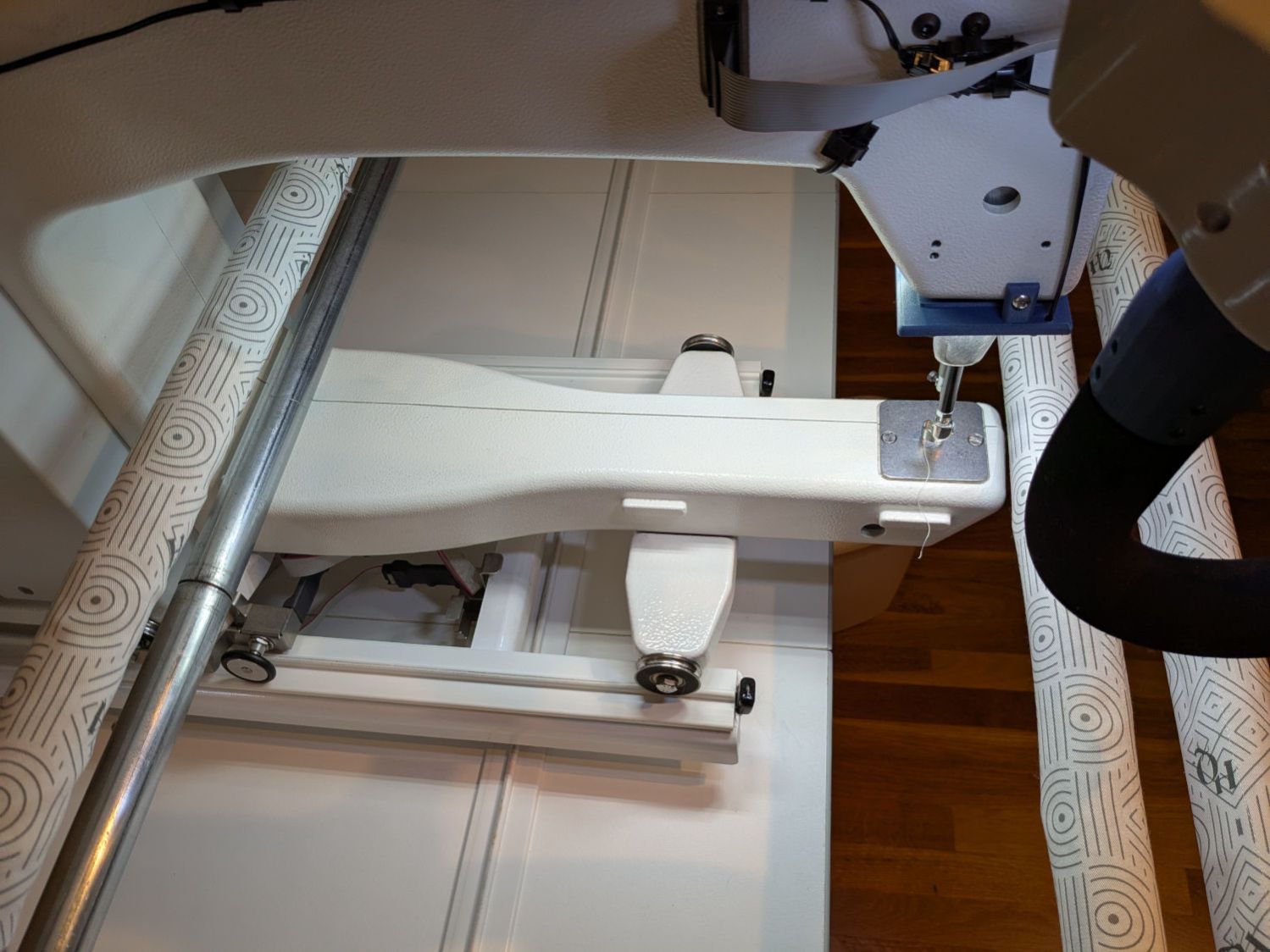

NoseOA = [44.0,36.5]; // overall nose size |

|

NoseAngles = [87,87]; // front & rear inward angles wrt left side |

|

|

|

NoseCenters = [ // centers of circles defining the nose corners |

|

[NoseRadius, NoseOA.y/2 – NoseRadius], |

|

[NoseRadius,-(NoseOA.y/2 – NoseRadius)], |

|

[NoseOA.x – NoseRadius, NoseOA.y/2 – NoseRadius – (NoseOA.x – 2*NoseRadius)*tan(90 – NoseAngles[0])], |

|

[NoseOA.x – NoseRadius,-(NoseOA.y/2 – NoseRadius – (NoseOA.x – 2*NoseRadius)*tan(90 – NoseAngles[1]))], |

|

]; |

|

|

|

LEDMargin = 1.0; |

|

LEDStrip = [41.5 + LEDMargin,8.0 + LEDMargin,1.8 + 0.2]; // 24 V COB LED strip unit + windage |

|

LEDBaseOA = [LEDStrip.x + Strips*LEDStrip.y,NoseOA.y + 2*Strips*LEDStrip.y,WallThick]; // LED mount |

|

|

|

DraftAngle = 3.0; // angle of frame wrt horizontal at right end of nose |

|

DraftWedge = [NoseOA.x,NoseOA.y + 2*LEDStrip.y,NoseOA.x*tan(DraftAngle)]; |

|

|

|

HoleOffset = [-10.0,5.5,DraftWedge.z + 10.0]; // from left front corner of nose |

|

HolePosition = HoleOffset + [0,-NoseOA.y/2,WallThick]; // absolute coordinates from origin |

|

|

|

Screw = [4.0 + HoleWindage,9.0,2.0]; // LENGTH=button head |

|

|

|

Bracket = [WallThick,Screw[OD] + 4.0,HoleOffset.z + Screw[OD/2] + 2.0 + WallThick]; |

|

|

|

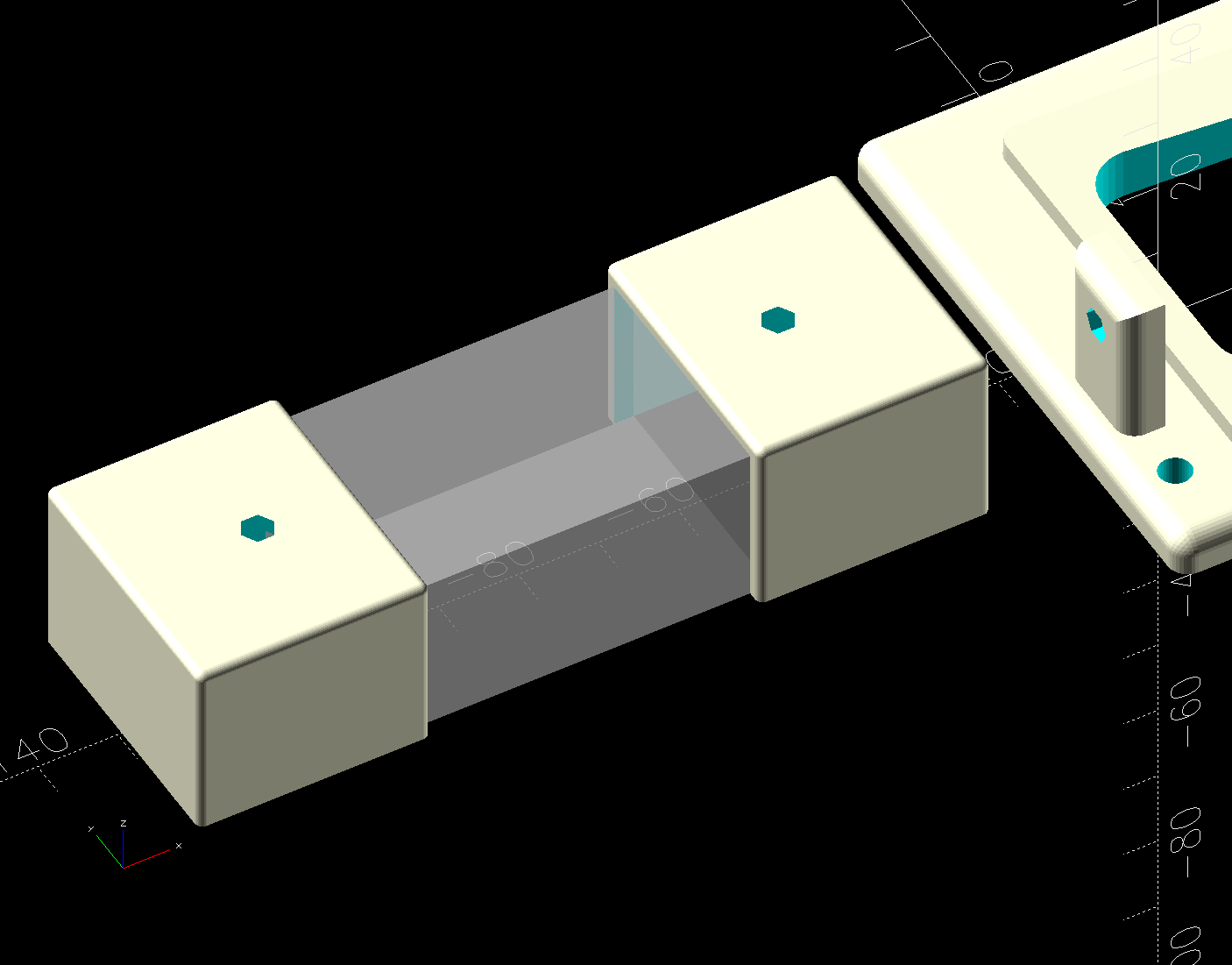

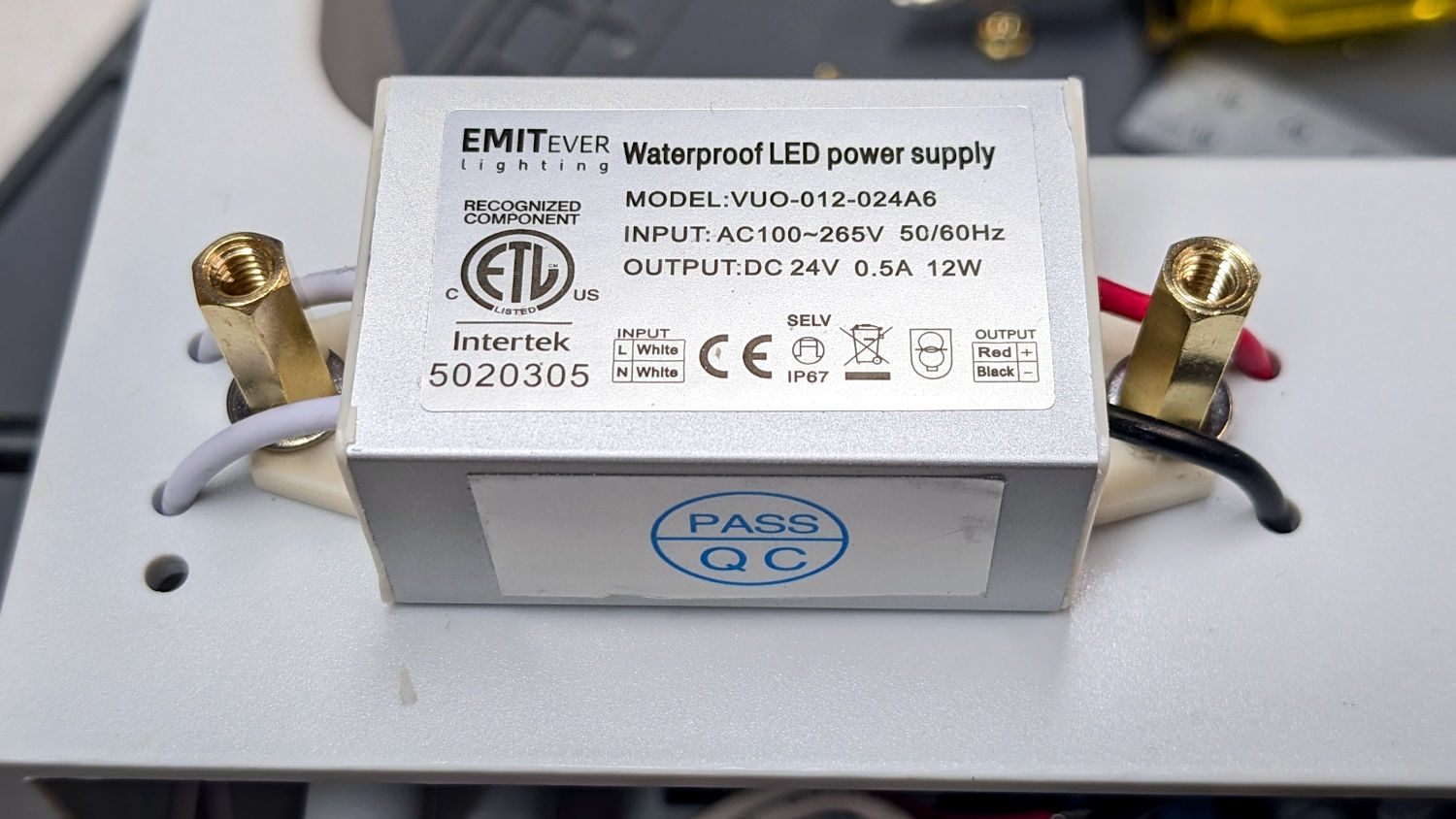

Supply = [46.0,30.0,21.0]; // 24 VDC power supply |

|

SupplyScrewOffset = 5.0; // … M4 screw hole from end of supply case |

|

|

|

CapWall = 3.0; |

|

CapRadius = CapWall – 1.0; |

|

CapInset = 1.0; |

|

CapOA = [20.0,Supply.y + 2*CapWall,Supply.z + CapWall]; // x & y to cover existing holes |

|

|

|

//———- |

|

// Define Shapes |

|

|

|

//—– 2D outline of nose piece just under frame casting |

|

|

|

module NosePlan() { |

|

hull() |

|

for (p = NoseCenters) |

|

translate(p) circle(r=NoseRadius); |

|

} |

|

|

|

//—– LED mounting plate |

|

|

|

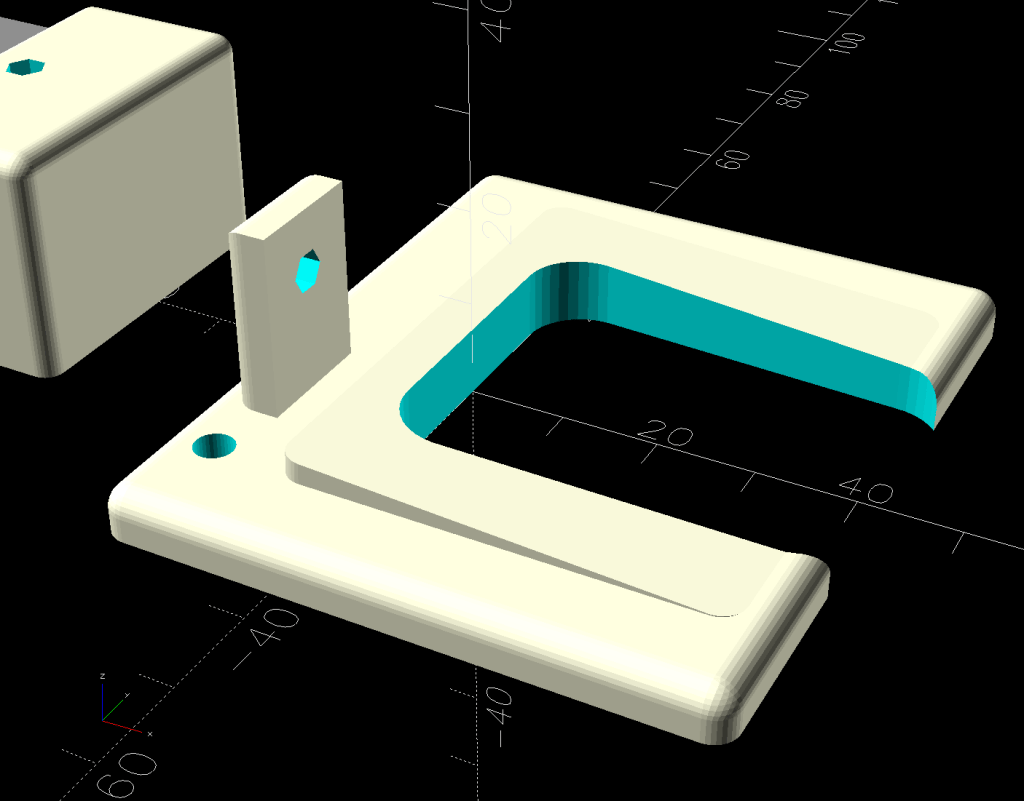

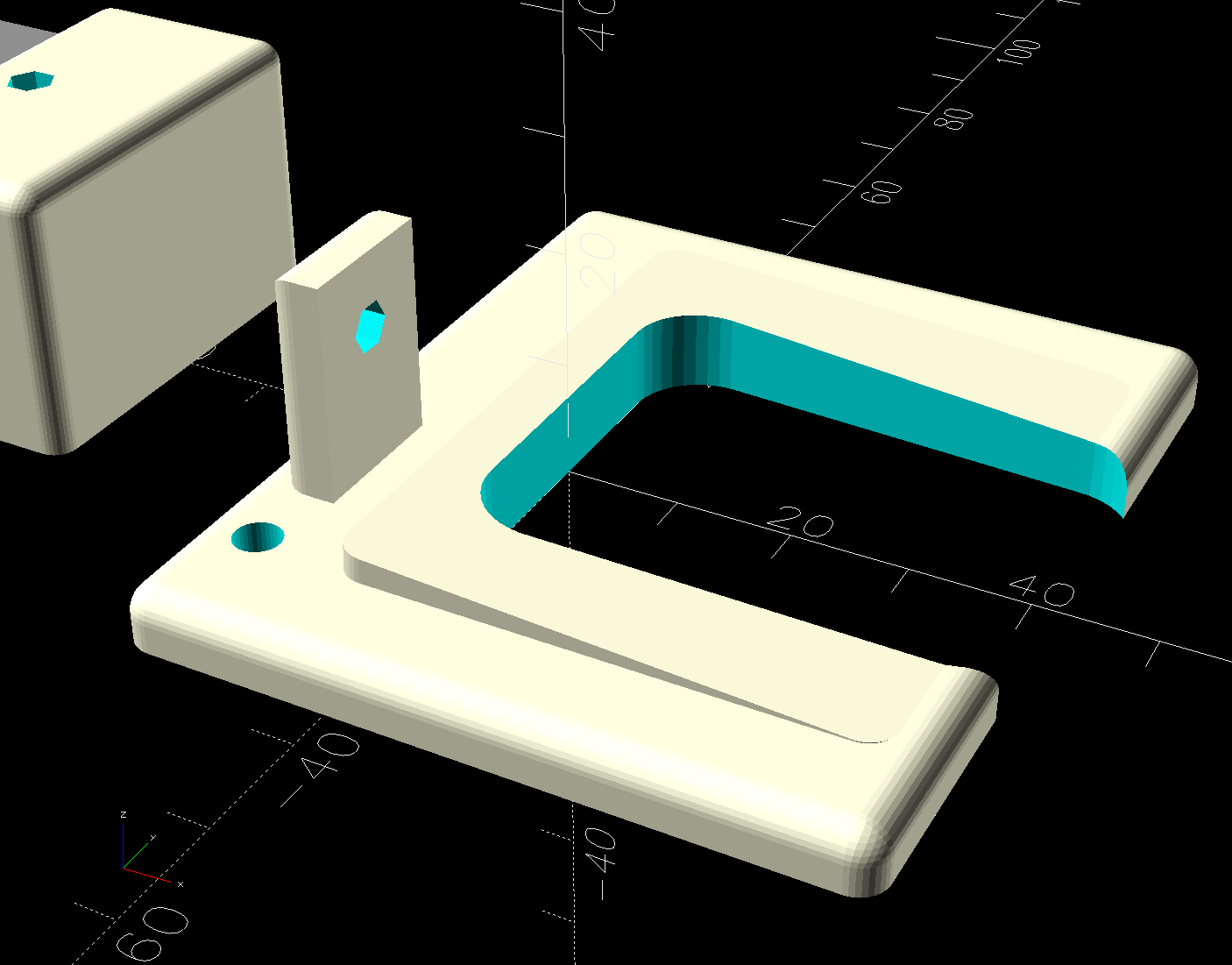

module Mount() { |

|

|

|

union() { |

|

difference() { |

|

union() { |

|

right(LEDBaseOA.x/2 – Strips*LEDStrip.y) |

|

cuboid(LEDBaseOA,rounding=WallThick/2,except=BOTTOM,anchor=BOTTOM); |

|

up(LEDBaseOA.z) left(-HoleOffset.x/2) |

|

yrot(DraftAngle) |

|

cuboid(DraftWedge,rounding=WallThick/2,edges="Z",anchor=LEFT+BOTTOM); |

|

} |

|

down(Protrusion) |

|

linear_extrude(LEDBaseOA.z + DraftWedge.z + Protrusion) |

|

NosePlan(); |

|

if (Strips > 1) |

|

translate([HolePosition.x – Bracket.x/2,HolePosition.y – Bracket.y,-Protrusion]) |

|

cyl(LEDBaseOA.z + 2*Protrusion,d=4.0,anchor=BOTTOM); |

|

} |

|

difference() { |

|

union() { |

|

translate([HolePosition.x,HolePosition.y,(Bracket.x/2)*sin(DraftAngle)]) |

|

left(Bracket.x) |

|

cuboid(Bracket,rounding=WallThick/2,edges=LEFT,anchor=BOTTOM+LEFT); |

|

translate([HolePosition.x – Bracket.x/2,HolePosition.y,0]) // rounding filler |

|

cuboid([LEDStrip.y,Bracket.y,WallThick],anchor=BOTTOM+LEFT); |

|

} |

|

translate(HolePosition) |

|

xrot(180/6) xcyl(l=NoseOA.x,d=Screw[ID],$fn=6); |

|

} |

|

} |

|

} |

|

|

|

//—– Endcap for power supply |

|

|

|

module EndCap() { |

|

|

|

difference() { |

|

cuboid(CapOA,rounding=CapRadius,except=BOTTOM,anchor=LEFT+BOTTOM); |

|

right(CapOA.x – CapWall) down(Protrusion) |

|

cuboid(Supply + [0,0,Protrusion],anchor=RIGHT+BOTTOM); |

|

right(CapInset + SupplyScrewOffset) |

|

zcyl(l=2*CapOA.z,d=Screw[ID],$fn=6,anchor=BOTTOM); |

|

} |

|

|

|

} |

|

|

|

|

|

//———- |

|

// Build things |

|

|

|

if (Layout == "NosePlan") { |

|

NosePlan(); |

|

} |

|

|

|

if (Layout == "PowerCap") { |

|

EndCap(); |

|

} |

|

|

|

if (Layout == "Show") { |

|

Mount(); |

|

|

|

ctr = 80; |

|

ofs = Supply.x/2 – CapInset; |

|

left(ctr – ofs) |

|

EndCap(); |

|

left(ctr + ofs) |

|

xflip() |

|

EndCap(); |

|

color("Silver",0.6) |

|

left (ctr) |

|

cuboid(Supply,anchor=BOTTOM); |

|

} |

|

|

|

if (Layout == "Build") { |

|

Mount(); |

|

back((LEDBaseOA.y + CapOA.y)/2 + Gap) right(Gap) up(CapOA.z) zflip() |

|

EndCap(); |

|

back((LEDBaseOA.y + CapOA.y)/2 + Gap) left(Gap) zrot(180) up(CapOA.z) zflip() |

|

EndCap(); |

|

} |