A rear spoke snapped on Mary’s Tour Easy while we were at the far end of a ride. Unlike most broken spokes, the flanged end that I couldn’t maneuver the stub out of the hub and deploy the FiberFix, so we rode home slowly while avoiding as much rough pavement as feasible.

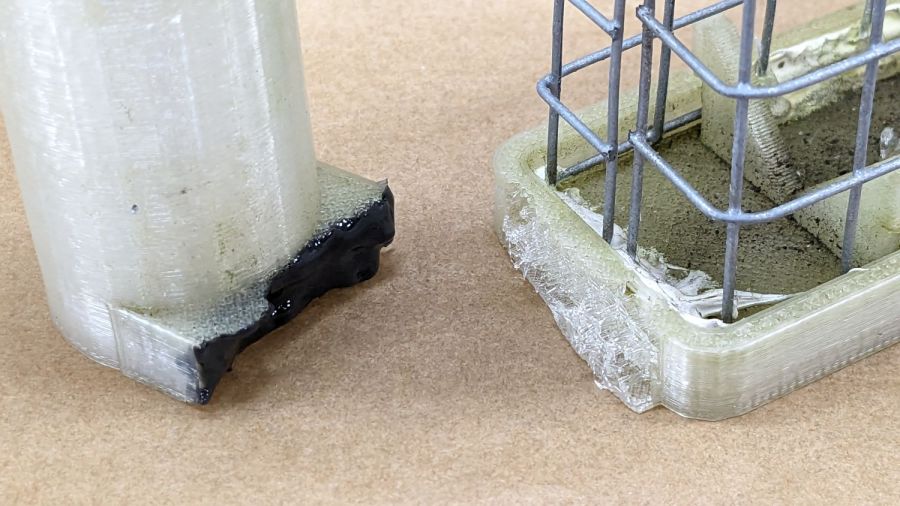

Once in the shop, pulling the sprocket and extracting the stub posed no problem:

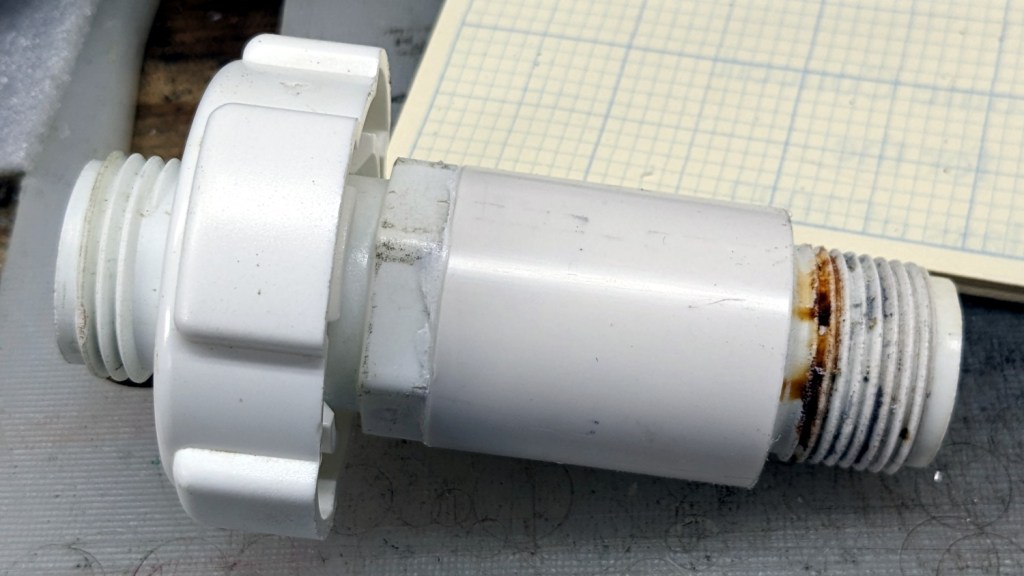

Install the new spoke, crank to 23 on the Park Spoke Tension Meter to match the rest of the wheel, check the truing, and it’s all good.

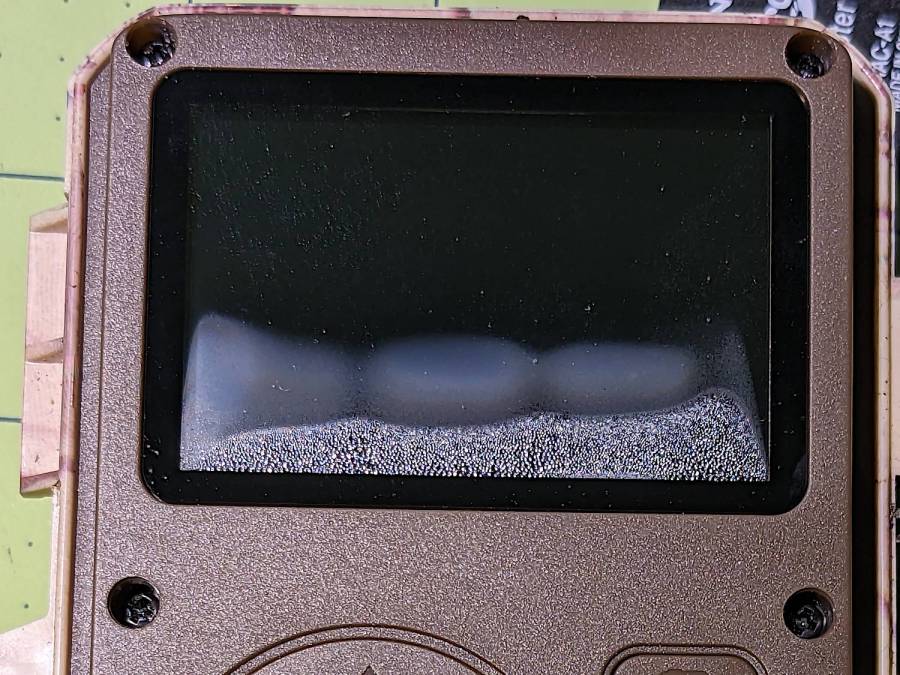

At some point in the last two decades of riding, it seem the chain fell off the high side and gouged the spokes around the hub:

If another spoke snaps in the near future, I’ll replace the lot of them, but until then, well, there’s riding to be done …