Every tub & shower looks like this after a decade or so:

Go look carefully at your bathroom if you don’t believe me.

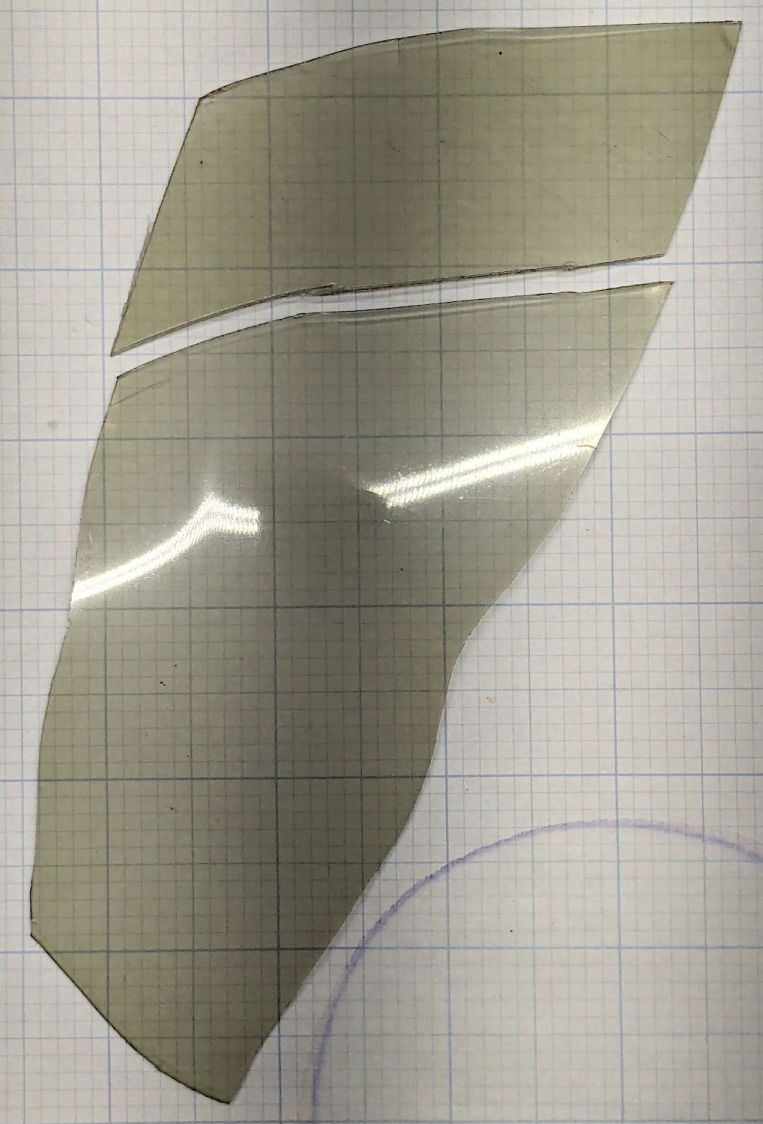

Tubs have a raised lip around their perimeter, but our downstairs bathroom had a caulk crack that routed water running down the wall under the tile, over the lip, and onto the subfloor beside the tub. This had been going on unnoticed for years, but we apparently take showers differently enough to put a puddle of water on the basement floor.

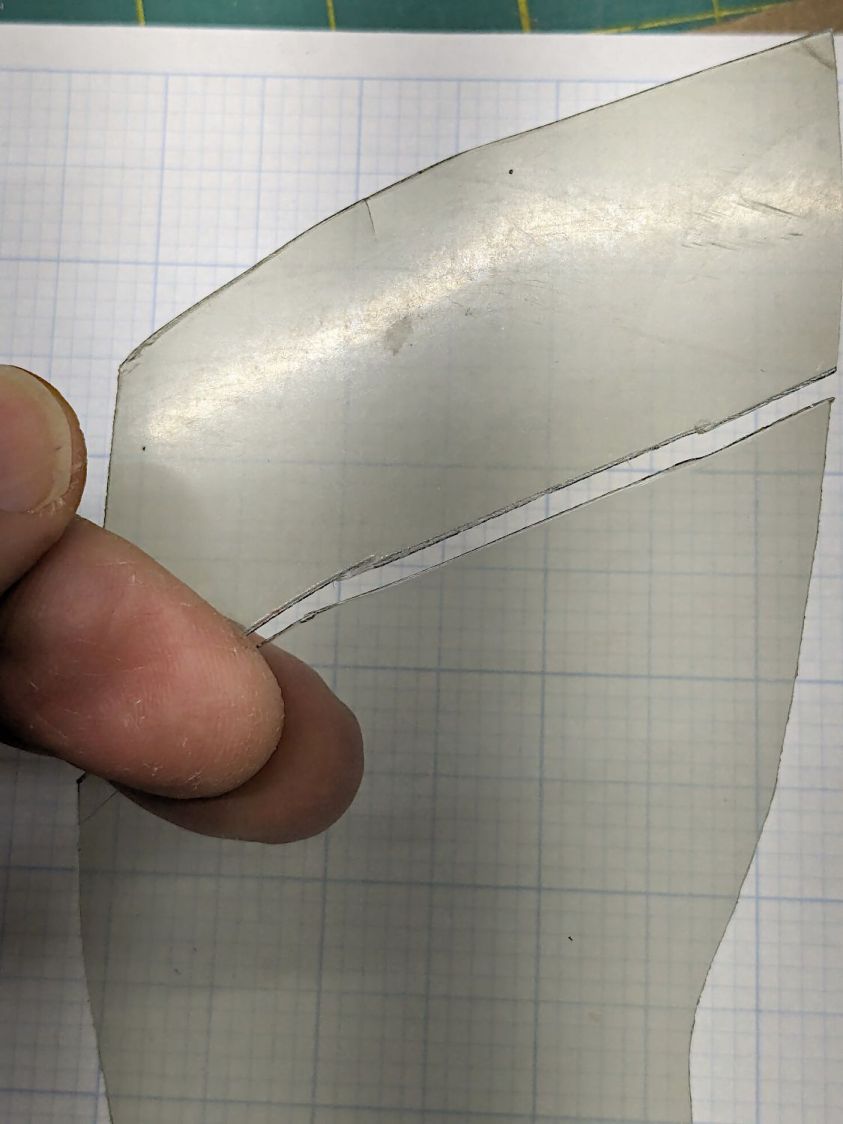

Some exploratory surgery revealed a patch of rotted subfloor (which is why we know it was an ongoing problem), but no structural damage. A few hours of tedious razor knife and hook work extracted the old caulk, after which squirting new caulk took almost no time at all:

I screwed a small fan across the subfloor opening to pull air across the wet area:

A few days dried things out nicely, so I can proceed with a project involving the adjacent shower stall, about which more later.

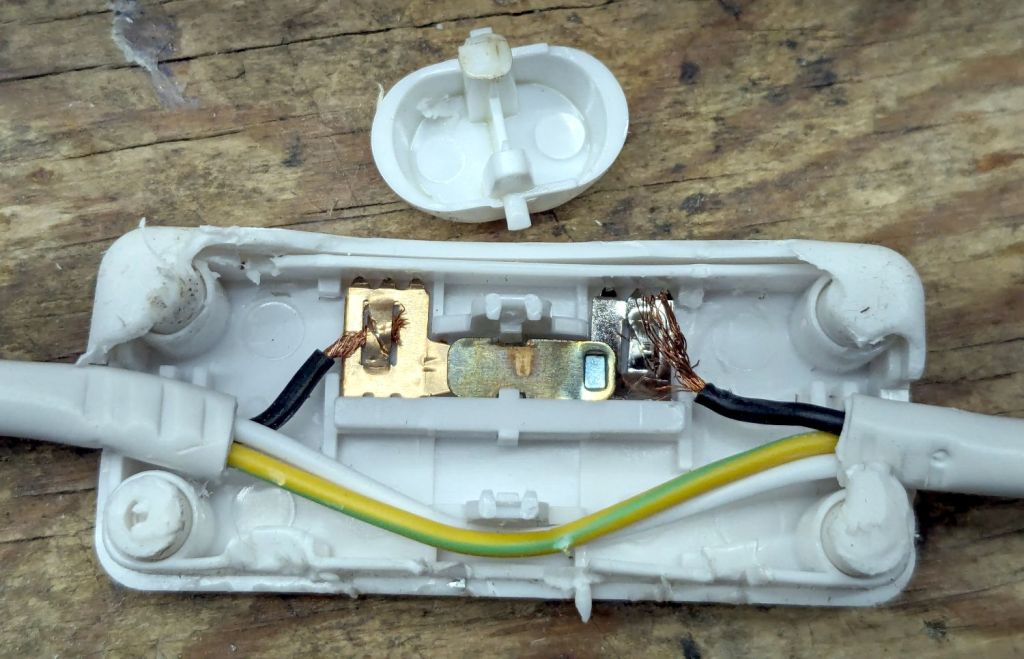

They don’t install drain pipes like that any more! Judging from the many scorch marks on the joists, the plumber had considerable difficulty keeping enough heat on the fittings for good solder joints.