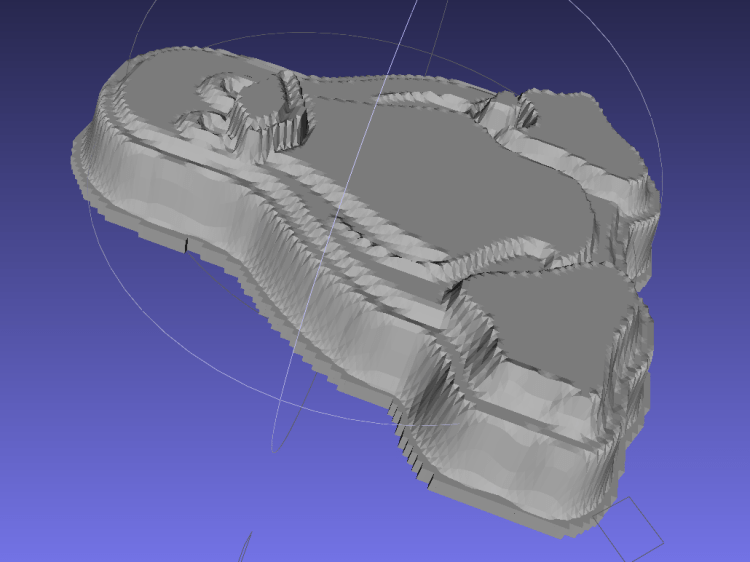

This derives directly from the cookie cutter / press stack, so check that series for more background and explanation. Some height map thoughts and preliminary doodling led up to this.

We start with a tiny grayscale image file that defines the height of each point in the mold:

Feed that file into a Bash script:

./MakeMold.sh Tux.png

And a corresponding STL file pops out:

The MakeMold Bash script orchestrates the whole thing:

#!/bin/bash

DotsPerMM=3.0

MapHeight=5

ImageName="${1%%.*}"

rm ${ImageName}_* ${ImageName}-positive.stl

echo Normalize and prepare grayscale image...

convert $1 -type Grayscale -depth 8 -trim +repage -flip +set comment ${ImageName}_prep.png

echo Create PGM files...

convert ${ImageName}_prep.png -compress none ${ImageName}_map.pgm

convert ${ImageName}_prep.png -white-threshold 1 -compress none ${ImageName}_plate.pgm

echo Create height map data files...

ImageX=`identify -format '%[fx:w]' ${ImageName}_map.pgm`

ImageY=`identify -format '%[fx:h]' ${ImageName}_map.pgm`

echo Width: ${ImageX} x Height: ${ImageY}

cat ${ImageName}_map.pgm | tr -s ' \012' '\012' | tail -n +5 | column -x -c $((8*$ImageX)) > ${ImageName}_map.dat

cat ${ImageName}_plate.pgm | tr -s ' \012' '\012' | tail -n +5 | column -x -c $((8*$ImageX)) > ${ImageName}_plate.dat

echo Create mold positive...

time openscad -D fnPlate=\"${ImageName}_plate.dat\" \

-D fnMap=\"${ImageName}_map.dat\" -D Height=$MapHeight \

-D ImageX=$ImageX -D ImageY=$ImageY -D DotsPerMM=$DotsPerMM \

-o ${ImageName}-positive.stl MoldPositive.scad

The first convert normalizes the grayscale file and produces a PNG file in a standard format.

The next two convert operations translate that PNG file into uncompressed PGM files with the data as ASCII text required by OpenSCAD’s surface() function. It’s not in the proper format, however, so a few lines of Bash-fu rearrange the data into DAT files; the extension is arbitrary.

Then OpenSCAD eats those files along with a bunch of configuration settings and spits out a solid model of the positive mold in STL format.

The MakePositive.scad OpenSCAD source code:

// Mold positive pattern from grayscale height map using Minkowski sum

// Ed Nisley KE4ZNU - February 2014 - adapted from cookie press, added alignment pins

//-----------------

// Mold files

fnMap = "SqWr_map.dat"; // override with -D 'fnMap="whatever.dat"'

fnPlate = "SqWr_plate.dat"; // override with -D 'fnPlate="whatever.dat"'

DotsPerMM = 3.0; // overrride with -D DotsPerMM=number

MapHeight = 5.0; // overrride with -D MapHeight=number

ImageX = 100; // overrride with -D ImageX=whatever

ImageY = 100;

MapScaleXYZ = [1/DotsPerMM,1/DotsPerMM,MapHeight/255];

PlateScaleXYZ = [1/DotsPerMM,1/DotsPerMM,1.0];

echo("Press File: ",fnMap);

echo("Plate File: ",fnPlate);

echo(str("ImageX:",ImageX," ImageY: ", ImageY));

echo(str("Map Height: ",MapHeight));

echo(str("Dots/mm: ",DotsPerMM));

echo(str("Scale Map: ",MapScaleXYZ," Plate: ",PlateScaleXYZ));

//- Extrusion parameters - must match reality!

ThreadThick = 0.25;

ThreadWidth = 2.0 * ThreadThick;

//- Buid parameters

PlateThick = IntegerMultiple(1.0,ThreadThick); // solid plate under press relief

PinOD = 1.75; // locating pin diameter

PinDepth = PlateThick; // ... depth into bottom surface = total length/2

PinOC = 20.0; // spacing within mold item

echo(str("Pin depth: ",PinDepth," spacing: ",PinOC));

//- Useful info

function IntegerMultiple(Size,Unit) = Unit * ceil(Size / Unit);

HoleWindage = 0.2;

Protrusion = 0.1; // make holes & unions work correctly

MaxConvexity = 5; // used for F5 previews in OpenSCAD GUI

ZFuzz = 0.2; // numeric chaff just above height map Z=0 plane

//-----------------

// Import plate height map, slice off a slab to define outline

module Slab(Thick=1.0) {

intersection() {

translate([0,0,Thick/2])

cube([2*ImageX,2*ImageY,Thick],center=true);

scale(PlateScaleXYZ)

difference() {

translate([0,0,-ZFuzz])

surface(fnPlate,center=true,convexity=MaxConvexity);

translate([0,0,-1])

cube([2*ImageX,2*ImageY,2],center=true);

}

}

}

//- Put peg grid on build surface

module ShowPegGrid(Space = 10.0,Size = 1.0) {

Range = floor(50 / Space);

for (x=[-Range:Range])

for (y=[-Range:Range])

translate([x*Space,y*Space,Size/2])

%cube(Size,center=true);

}

//-- convert cylinder to low-count polygon

module PolyCyl(Dia,Height,ForceSides=0) { // based on nophead's polyholes

Sides = (ForceSides != 0) ? ForceSides : (ceil(Dia) + 2);

FixDia = Dia / cos(180/Sides);

cylinder(r=(FixDia + HoleWindage)/2,

h=Height,

$fn=Sides);

}

//-- Locating pin hole with glue recess

// Default length is two pin diameters on each side of the split

module LocatingPin(Dia=PinOD,Len=0.0) {

PinLen = (Len != 0.0) ? Len : (4*Dia);

translate([0,0,-ThreadThick])

PolyCyl((Dia + 2*ThreadWidth),2*ThreadThick,4);

translate([0,0,-2*ThreadThick])

PolyCyl((Dia + 1*ThreadWidth),4*ThreadThick,4);

translate([0,0,-(Len/2 + ThreadThick)])

PolyCyl(Dia,(Len + 2*ThreadThick),4);

}

//- Build it

//ShowPegGrid();

echo("Building mold");

union() {

difference() {

Slab(PlateThick + Protrusion);

for (i=[-1,1])

translate([0,i*PinOC/2,0])

rotate(180/4) LocatingPin(Len=2*PinDepth);

}

translate([0,0,PlateThick]) // cookie press height map

scale(MapScaleXYZ)

difference() {

translate([0,0,-ZFuzz])

surface(fnMap,center=true,convexity=MaxConvexity);

translate([0,0,-1])

cube([2*ImageX,2*ImageY,2],center=true);

}

}

The molds have alignment pin holes in the back:

That match up with the holes in a baseplate:

The plate holds the molds in place, perhaps with tapeless sticky, while you’re slathering silicone goop to make the negative mold:

The plate holds the molds in place, perhaps with tapeless sticky, while you’re slathering silicone goop to make the negative mold:

As you might expect, the OpenSCAD file that generates the plate-with-holes can also embed the positive molds atop the plate, so you could get a solid (well, infilled at 20%) chunk of plastic without attaching the molds. I’d rather do the plate separately from the molds, so you can recycle the plate for many different molds. Your mileage may vary.

The Positive Mold Framework.scad OpenSCAD source code:

// Positive mold framework for chocolate slabs

// Ed Nisley - KE4ZNU - January 2014

Layout = "FramePins"; // FramePins FrameMolds Pin

//- Extrusion parameters must match reality!

// Print with 2 shells and 3 solid layers

ThreadThick = 0.20;

ThreadWidth = 0.40;

Protrusion = 0.1; // make holes end cleanly

HoleWindage = 0.2;

//----------------------

// Dimensions

FileName = "Tux-positive.stl"; // overrride with -D

Molds = [2,3]; // count of molds within framework

MoldOC = [40.0,45.0]; // on-center spacing of molds

MoldSlab = 1.0; // thickness of slab under molds

BaseThick = 5.0;

BaseSize = [(Molds[0]*MoldOC[0] + 0),(Molds[1]*MoldOC[1] + 0),BaseThick];

echo(str("Overall base: ",BaseSize));

PinOD = 1.75; // locating pin diameter

PinLength = 2.0; // ... total length

PinOC = 20.0; // spacing within mold item

//----------------------

// Useful routines

//- Put peg grid on build surface

module ShowPegGrid(Space = 10.0,Size = 1.0) {

RangeX = floor(100 / Space);

RangeY = floor(125 / Space);

for (x=[-RangeX:RangeX])

for (y=[-RangeY:RangeY])

translate([x*Space,y*Space,Size/2])

%cube(Size,center=true);

}

module PolyCyl(Dia,Height,ForceSides=0) { // based on nophead's polyholes

Sides = (ForceSides != 0) ? ForceSides : (ceil(Dia) + 2);

FixDia = Dia / cos(180/Sides);

cylinder(r=(FixDia + HoleWindage)/2,

h=Height,

$fn=Sides);

}

// Locating pin hole with glue recess

// Default length is two pin diameters on each side of the split

module LocatingPin(Dia=PinOD,Len=0.0) {

PinLen = (Len != 0.0) ? Len : (4*Dia);

translate([0,0,-ThreadThick])

PolyCyl((Dia + 2*ThreadWidth),2*ThreadThick,4);

translate([0,0,-2*ThreadThick])

PolyCyl((Dia + 1*ThreadWidth),4*ThreadThick,4);

translate([0,0,-(Len/2 + ThreadThick)])

PolyCyl(Dia,(Len + 2*ThreadThick),4);

}

module LocatingPins(Length) {

for (i=[-1,1])

translate([0,i*PinOC/2,0])

rotate(180/4)

LocatingPin(Len=Length);

}

//-- import a single mold item

module MoldItem() {

import(FileName,convexity=10);

}

//-- Overall frame shape

module Frame() {

// translate([0,0,BaseSize[2]/2]) // platform under molds

// cube(BaseSize,center=true);

difference() {

hull()

for (i=[-1,1], j=[-1,1])

translate([i*BaseSize[0]/2,j*BaseSize[1]/2,0])

sphere(r=BaseThick);

translate([0,0,-BaseThick])

cube(2*BaseSize,center=true);

}

}

//- Build it

ShowPegGrid();

if (Layout == "Pin")

LocatingPin(Len=PinLength);

if (Layout == "Frame")

Frame();

if (Layout == "FramePins")

difference() {

Frame();

translate([-MoldOC[0]*(Molds[0] - 1)/2,-MoldOC[1]*(Molds[1] - 1)/2,0])

for (i=[0:Molds[0]-1],j=[0:Molds[1]-1])

translate([i*MoldOC[0],j*MoldOC[1],BaseSize[2]])

LocatingPins(BaseThick);

}

if (Layout == "FrameMolds") {

Frame();

translate([-MoldOC[0]*(Molds[0] - 1)/2,-MoldOC[1]*(Molds[1] - 1)/2,0])

for (i=[0:Molds[0]-1],j=[0:Molds[1]-1])

translate([i*MoldOC[0],j*MoldOC[1],BaseThick - MoldSlab + Protrusion])

MoldItem();

}

And then it’s time to pour some chocolate… which someone else knows how to do much better than I!